DEMA 665 Series User manual

www.demaeng.com

1-800-325-3362

I-1091 Page 1 of 8

Rev. C-40014 08/08/14

Overview

The Extreme 4 makes users more efficient, filling bottles and buckets with ease and quickness. Some of

the great design features include:

A single dial for 8 different dilution points

Multi-point locking system for Extreme security

Integrated ASSE approved backflow prevention

Large sight window to identify product and level

Branding panels to meet the ‘look n’ feel’ need

One-handed bottle and optional remote bucket

fill

Warnings

All installations must conform to

local plumbing codes and use

approved backflow prevention

devices. A pressure indicating tee is

to be installed with existing faucets

according to local plumbing codes in the state of

Wisconsin and any other state that requires the use

of a pressure indicating tee

ALWAYS WEAR PROTECTIVE

CLOTHING AND EYEWEAR

WHEN WORKING WITH

CHEMICAL PRODUCTS

Instruction Sheet Contents Operational Requirements

Category Page Water Supply Requirements

Package Contents / Required Tools 1Minimum Maximum

Operational Requirements 1 Water Pressure 20 psi (1.38 bar) 125 psi (8.62 bar)**

Overall Dimensions 2 Water Temperature - 150ºF (65.5ºC)

Installation / Preparation 2-3

Operation 4 ** Recommended water pressure is between 20 psi (1.38 bar)

and 70 psi. (5.52 bar). If pressure exceeds 70 psi, it is

recommended that a water pressure regulator is used.

Metering Tip Charts 5

Troubleshooting 6

Parts List 7

Warranty Information 8

Box Contains

Metering tip

kit Mounting

hardware, template

& key set

665 series

dispenser Instruction sheet

4 SafeLink cap assemblies OR

Bulk tubing, 4 ceramic weights

and foot valves

Suggested Tools

Hammer Phillips

screwdriver

Drill w/ 3/16”

& 9/32” bits Tape measure

Pencil Level

665 Series Dispenser

www.demaeng.com

1-800-325-3362

I-1091 Page 2 of 8

Rev. C-40014 08/08/14

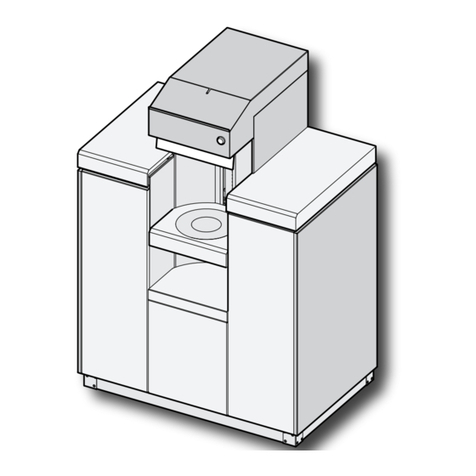

Overall Dimensions

Installation & Preparation

1. Identify desired location of dispenser. Remove cardboard mounting template from packaging, place

against wall and mark hole locations using the template as a guide.

[For accuracy, use level with template to ensure the dispenser is level on the wall]

2. Install all four supplied anchors into marked hole locations from step 1. Using supplied screws, install

top two screws and hang dispenser from them. Install bottom two screws through dispenser holes

into the anchors.

3. Tighten screws against dispenser to assure a secure fit.

4. Install Drip Tray by sliding into place against

tab in back of drip tray holder.

[Optional: Drill 3/16” hole into drip tray barb and

attach ¼” ID hose (not supplied) for draining

chemical from drip tray (Figure 1)

Figure 1

www.demaeng.com

1-800-325-3362

I-1091 Page 3 of 8

Rev. C-40014 08/08/14

Installation & Preparation Cont’d

Steps 5 through 7 explain how to install metering tips. Metering tips will be installed at the two check

valves located in each compartment. Check valves to bucket fill have a plastic ring, and check valves

for bottle fill do not.

5. To install metering tips, locate the correct

check valve in each compartment. Identify

desired metering tip based on color and dilution

rate on the tip chart for bottle and bucket filling

(Figure 2)

Figure 2

6. Screw metering tip clockwise into exposed

threaded check valve barb

Note: A blank tip can be used to prevent a

product from dispensing at bottle or bucket fill

7. For SafeLink cap and tubing: secure the tubing

over the exposed check valve barb (Figure 3)

For Open container: Measure bulk tubing

needed and cut to length. Install ceramic

weight and foot valve at base of tubing.

Secure top of tubing over the exposed check

valve barb

Note: Softening the tube with hot water will

allow the tube to fit over the barb with ease

Figure 3

8. Position chemical container into each

compartment in desired position and connect

SafeLink cap or install tubing w foot valve and

ceramic weight into open container (Figure 4)

9. Close and lock the cabinet doors

Figure 4

10. Connect the supplied water hose to your water

source and activate the dispenser by selecting

a position on the dial and using either the

bucket or bottle fill activation point (Figure 5)

Figure 5

www.demaeng.com

1-800-325-3362

I-1091 Page 4 of 8

Rev. C-40014 08/08/14

Operation

Chemical Selector Dial (Figure 6)

1. Turn the chemical selector dial to the desired

chemical position, indicated by the directional

arrow

2. Dispense chemical by either activating the

bottle fill lever or bucket fill button (or remote fill

trigger)

3. For rinse water, point the dial straight down at

the water symbol- This is not potable water, do

not drink

Figure 6

Dispenser Activation Points – Bottle Fill (Figure 7)

1. Slide the bottle tube inside the spray bottle and

raise the bottle to engage the u-shaped lever of

the bottle fill assembly

2. To stop filling, lower the bottle and the lever will

disengage

3. Be careful when removing the spray bottle so

as to not splash residual chemical

Figure 7

Dispenser Activation Points – Push Button Bucket Fill (if equipped) (Figure 8)

1. To start the flow of diluted chemical, press

button on unit above selector dial

2. For continuous flow, twist button clockwise

3. To disengage, release button or twist button

counterclockwise

Figure 8

Dispenser Activation Points – Remote Fill (if equipped) (Figure 9)

1. To start the flow of diluted chemical, press

trigger on handle of fill gun

2. For continuous flow, while trigger is pressed,

slide the red lever to one side and release

trigger

3. To disengage, simply press the trigger again

and the red lever will move out of position

Figure 9

www.demaeng.com

1-800-325-3362

I-1091 Page 5 of 8

Rev. C-40014 08/08/14

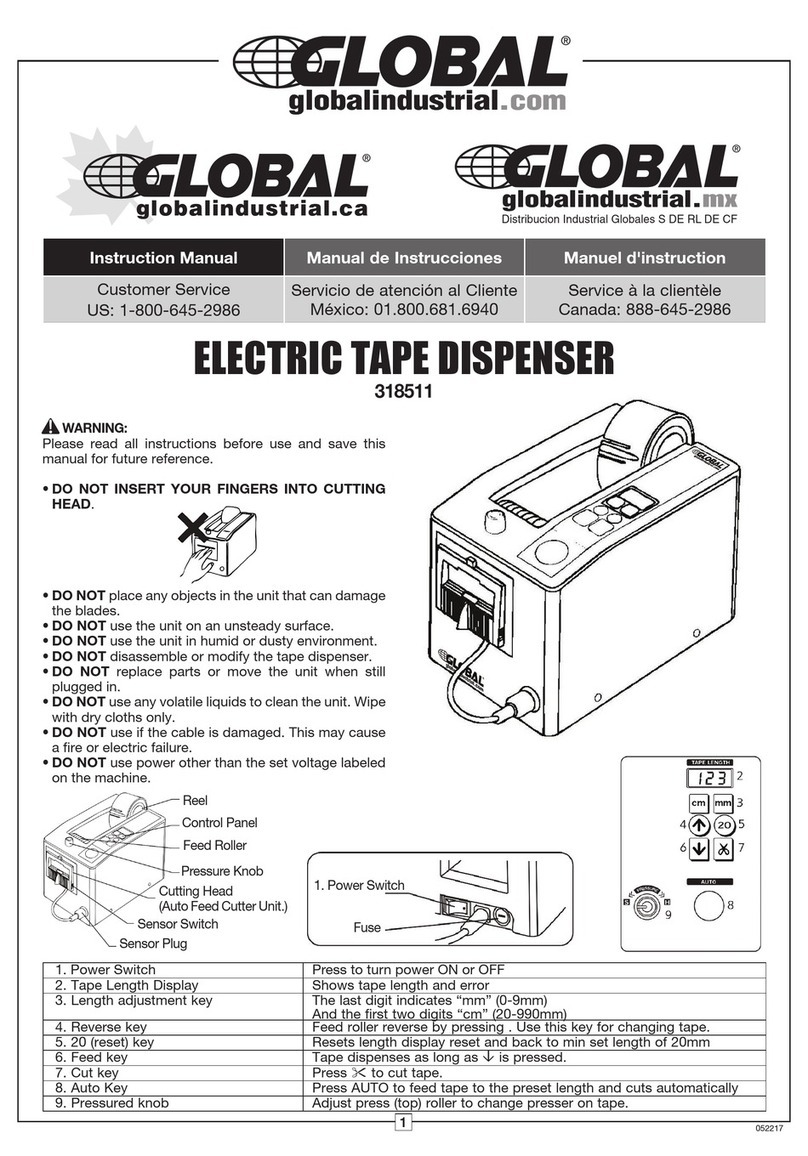

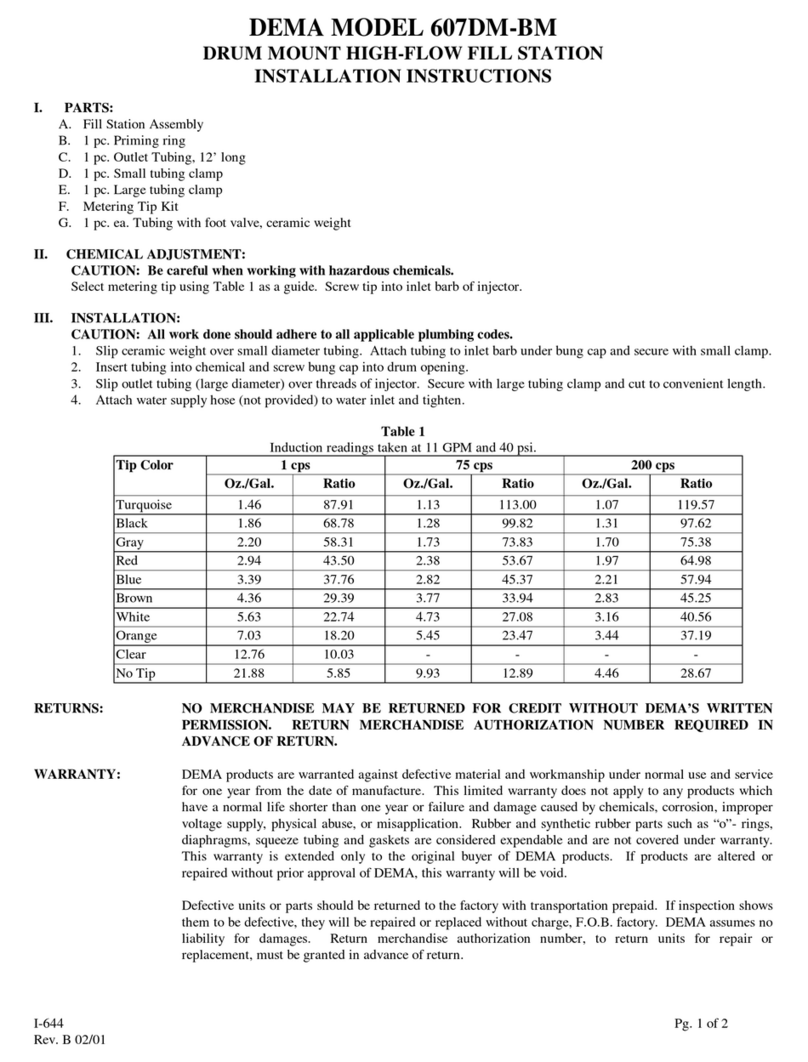

Metering Tip Charts

Table 1: Extreme 4 Metering Tips (Provided)

Metering Tip Color

1 GPM Flow Rate Proportioner 4 GPM Flow Rate Proportioner

Oz./gal ml/L Ratio : 1 Oz./gal ml/L Ratio : 1

Tan 1.25 9.80 102 0.30 2.34 427

Orange 1.70 13.33 75 0.40 3.13 320

Turquoise 2.15 16.67 60 0.50 3.91 256

Royal Blue 2.37 18.52 54 0.56 4.39 228

Charcoal Gray 2.67 20.83 48 0.64 5.00 200

Pink 3.00 23.26 43 0.75 5.88 170

Light Blue 3.90 30.30 33 1.00 7.81 128

Brown 4.55 35.71 28 1.12 8.77 114

Red 5.80 45.45 22 1.50 11.76 85

White 7.00 55.56 18 1.75 13.70 73

Green 7.90 62.50 16 2.00 15.63 64

Blue 9.80 76.92 13 2.50 19.61 51

Yellow 14.80 111.11 9 3.75 39.41 34

Gray 31.60 250.00 4 11.50 90.91 11

No Tip 35.00 277.78 3.6 16.25 125.00 8

INDUCTION RATES BASED ON WATER THIN PRODUCTS (1 cps)

INDUCTION RATES VARY PRODUCT TO PRODUCT. FIELD TESTS ARE RECOMMENDED.

Table 2: Ultra Lean Metering Tips (Not Provided)

Metering Tip Color

1 GPM Flow Rate Proportioner 4 GPM Flow Rate Proportioner

Oz./gal ml/L Ratio : 1 Oz./gal ml/L Ratio : 1

Copper 0.56 4.38 230 0.16 1.25 806

Pumpkin 0.73 5.70 175 0.20 1.56 625

Burgundy 0.90 7.03 143 0.26 2.03 490

Lime 1.28 10.00 100 0.34 2.66 376

INDUCTION RATES BASED ON WATER THIN PRODUCTS (1 cps)

INDUCTION RATES VARY PRODUCT TO PRODUCT. FIELD TESTS ARE RECOMMENDED.

www.demaeng.com

1-800-325-3362

I-1091 Page 6 of 8

Rev. C-40014 08/08/14

Troubleshooting

Symptom Probable Cause Remedy

Proportioner

fails to draw

chemical

properly.

1. Insufficient water supply pressure.

2. Safelink cap has chemical build-up

(if installed).

3. The outlet tubing might be pinched

closed.

4. Chemical metering tip is clogged.

5. Mineral deposits are built up in the

in the proportioner.

1. 20 PSI is the minimum allowable

pressure.

2. Soak in hot water to clean.

3. Straighten out the tubing to remove the

restriction.

4. Remove metering tip from check valve

and replace with new one.

5. Soak proportioner in delimer or off the

shelf product such as CLR to clean

mineral deposits.

“Air Gap”

Proportioner is

dripping or

spraying a mist

(fan pattern) of

water.

1. Mineral deposits are located on Air

Gap nozzle. 1. Soak nozzle and inlet screen in delimer or

off the shelf product such as CLR to clean

and remove mineral deposits.

Water valve is

not shutting off

completely.

1. “Sliding lever” return spring may be

missing on Remote Fill gun.

2. “Sliding lever” is not returning all

the way down due to interference

between the sliding lever and either

the chemical supply and/or outlet

tubing.

3. Bucket fill outlet hose is catching

the bottom edge of the sliding lever

during normal usage.

4. Bottle Fill valve will not shutoff.

1. Remove cover and visually check for

sliding lever return spring. Replace if

missing.

2. Remove cover and visually check for any

tubes rubbing the sliding lever. Routing of

chemical supply and outlet tubing must not

restrict the movement of the sliding lever.

Reroute tubing.

3. Don’t pull the bucket fill outlet hose too

tight from either side otherwise sliding

lever may not return properly.

4. Make sure bottle fill hose is not pressed

against the lever.

Water valve is

leaking. 1. Barbed nut is too loose.

1. Shut water supply off first. Hand-tighten

the barbed nut. Do not over tighten w/tool.

Threaded

connections

are leaking

water.

1. The connection between the

dispenser and water supply line is

too loose or rubber washer is

missing.

2. Backflow prevention devices

and/or proportioners are too loose.

1. Shut water supply off first. Carefully

tighten the female hose coupling on the

dispenser to the inlet water supply line.

Do not over tighten.

2. Tighten loose connection(s) with tools if

necessary. Do not over tighten if using

tools.

Selector valve

is not selecting

the correct

chemical

1. The transmission assembly is

malfunctioning. 1. Make sure the transmission is engaged

with the selector valves. If problem

persists, replace transmission assembly.

Water is

leaking in

between the

two water

valves

1. Plastic fitting connecting the water

valves has lost its seal. 1. Remove the plastic fitting and apply

silicone grease to both O-rings and

reattach to the valves.

www.demaeng.com

1-800-325-3362

I-1091 Page 7 of 8

Rev. C-40014 08/08/14

Parts list

No. Part No. Description Parts Not Shown

1 14-3-3 Cover plate (Button operated) Part No. Description

1 14-3-2

Cover plate (Remote gun

operated) 66-21K Keyset

2 14-2-3 Door – Left side 100-15K-EX4 Metering Tip Kit

3 14-2-4 Door – Right side 10-57-2 Drip Tray

4 10-47 Hinge Pin 100-16V-15 Tubing & Foot Valve Assembly

5 66-339-1 Knob 61-107-2 Ceramic Weight

6 83-53-15 Transmission Assembly 98-40-4 Screw & Anchor Kit

7 63-53-12 Selector Assembly 100-12-38 7/32” Tubing, 15”

8 61-99-4 1 GPM Action Gap Proportioner

8 61-32-AGP 1 GPM Air Gap Proportioner

8 163CHA-NB 2.5 GPM Action Gap Proportioner

8 61-45-4 2.5 GPM Air Gap Proportioner

8 61-22-4 4 GPM Action Gap Proportioner

8 61-126AG-4 4 GPM Air Gap Proportioner

9 16-30 Action Gap Assembly

10 14-5-2 Push Button Valve Assembly

10 14-6-2 Remote Gun Valve Assembly

11 14-6-1 Bottle Fill Valve Assembly

12 98-58-1 Lever Assembly

13 44-3-6FCOS

6’ Black Hose Assembly with

Strainer

14 14-16-1 Check Valve (Threaded)

15 100-12-18 7/32” Tubing, 2”

16 66-500-1 Wye Adapter

17 100-12-19 7/32” Tubing, 5”

18 C38CR4W.00 SafeLink Cap Assembly

19 66-242-1 Bottle Fill Tube – Action Gap

19 66-242-2 Bottle Fill Tube – Air Gap

20 89-30-GAP Bucket Fill Tube – Action Gap

20 85-15-29-6 Bucket Fill Tube – Air Gap

21 98-50-3 Remote Gun Assembly

www.demaeng.com

1-800-325-3362

I-1091 Page 8 of 8

Rev. C-40014 08/08/14

Warranty

Merchandise Returns

No merchandise will be returned for credit without DEMA’s written permission. Please contact

your dealer for warranty issues.

Product Warranty

DEMA’s products are warranted against defective material and workmanship under normal use

and service for one year from the date of manufacture. This limited warranty does not apply to

any products that have a normal life shorter than one year or failure and damage caused by

chemicals, corrosion, physical abuse, or misapplication. Rubber and synthetic rubber parts such

as “O”-rings, diaphragms, PVC tubing, and gaskets are considered expendable and are not

covered under warranty. This warranty is extended only to the original buyer of DEMA products.

If products are altered or repaired without prior approval of DEMA, this warranty is void.

Defective units or parts should be returned to the factory with transportation prepaid. If inspection

shows them to be defective, they will be repaired or replaced without charge, F.O.B. factory.

DEMA assumes no liability for damages. Return merchandise authorization number must be

granted in advance of returned units for repair or replacement (See “Merchandise Returns”

above).

This manual suits for next models

1

Table of contents

Other DEMA Dispenser manuals

DEMA

DEMA Nitro User manual

DEMA

DEMA 607DM-BM User manual

DEMA

DEMA TITAN II Assembly instructions

DEMA

DEMA 302-2 User manual

DEMA

DEMA 301B-SY User manual

DEMA

DEMA 6300 User manual

DEMA

DEMA 693T FOAM STATION II User manual

DEMA

DEMA Extreme 4 User manual

DEMA

DEMA 302-1 User manual

DEMA

DEMA Titan EP Installation guide