3.2.3 Overview of the screen.............................................................................. 45

3.3 Detailed page descriptions...................................................................................... 49

3.3.1 Page 1.1 – Main.........................................................................................49

3.3.2 Page 1.2 – Overview..................................................................................50

3.3.3 Page 1.3 – Reactor....................................................................................53

3.3.4 Page 1.4 – Filter.........................................................................................55

3.3.5 Page 1.5 – CIP...........................................................................................56

3.3.6 Page 1.6 – Cabinet.................................................................................... 57

3.3.7 Page 2.1 – Alarm list..................................................................................59

3.3.8 Page 2.2 – History..................................................................................... 61

3.3.9 Page 2.3 – Audit trail..................................................................................62

3.3.10 Page 3.1 – Trend....................................................................................... 63

3.3.11 Page 4.1 – System 1..................................................................................65

3.3.12 Page 4.2 – System 2..................................................................................66

3.3.13 Page 4.3 – Timers......................................................................................68

3.3.14 Page 4.4 – Remote 1.................................................................................69

3.3.15 Page 4.5 – Remote 2.................................................................................69

3.3.16 Page 4.6 – LPS..........................................................................................71

3.3.17 Page 5.1–5.6 – Parameter pages..............................................................72

3.4 Operating instructions..............................................................................................73

3.4.1 Log in......................................................................................................... 73

3.4.2 Perform ballast...........................................................................................74

3.4.3 Perform deballast.......................................................................................75

3.4.4 Perform tank stripping................................................................................76

3.4.5 Heel (internal transfer)............................................................................... 77

3.4.6 Backflush filter manually............................................................................ 78

3.4.7 CIP clean UV reactor after ballast / deballast ........................................... 79

3.4.8 Attend to alarms.........................................................................................79

3.4.9 Shut down and deactivate system............................................................. 80

3.4.10 Operate components manually..................................................................81

3.4.11 Operate UV lamps manually......................................................................82

3.4.12 Set ship specific component ID..................................................................83

3.4.13 Export control system event log files......................................................... 84

3.4.14 Backup control system settings................................................................. 85

3.4.15 Restore control system settings.................................................................86

3.4.16 Set control panel IP address......................................................................87

3.4.17 Set remote control panel communication...................................................88

3.4.18 Set remote interface communication......................................................... 89

3.4.19 Test remote interface communication........................................................ 89

3.4.20 Update control system softwares...............................................................91

3.4.21 Calibrate the control panel’s touch screen sensibility................................ 92

3.4.22 Fine tune flow and pressure control ..........................................................92

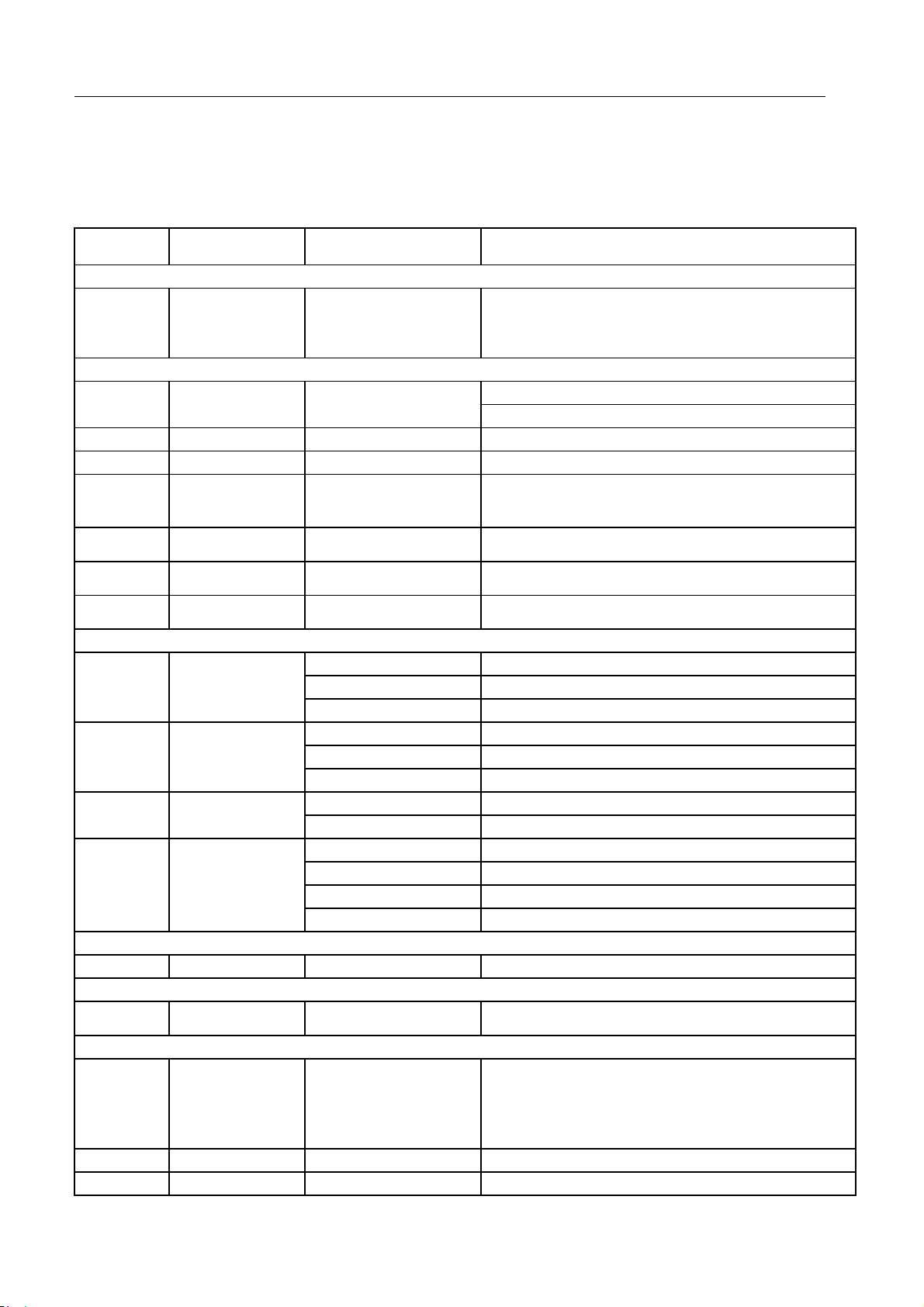

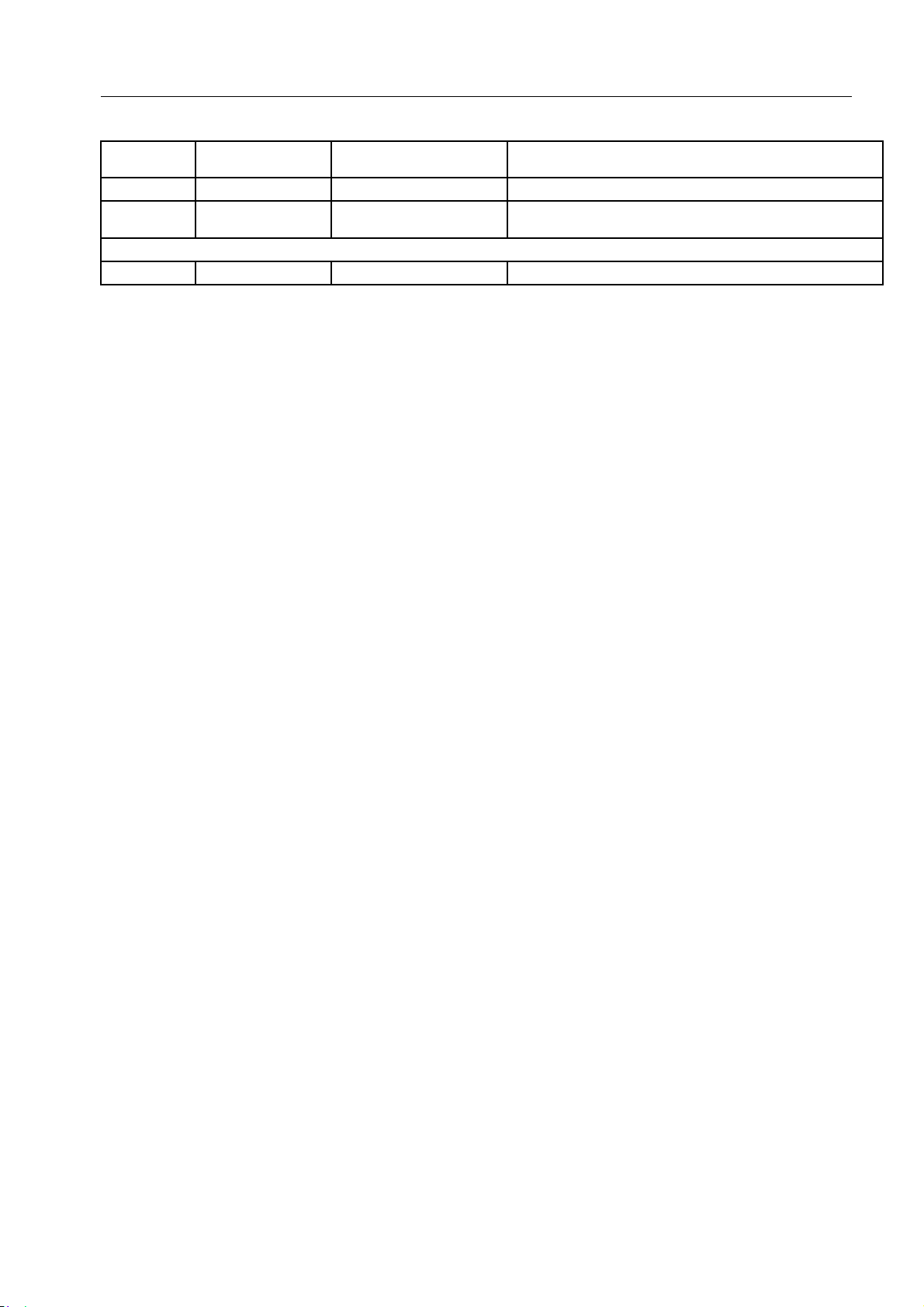

3.5 List of logged information........................................................................................ 96

3.5.1 Event log....................................................................................................96