1General informations........................................................................................................................ 5

1.1 Introduction to control theory..................................................................................................... 5

1.2 Control of the position-force curve............................................................................................ 5

1.3 Absolute and relative odds........................................................................................................ 5

2Installation Press-Right .................................................................................................................... 7

3How to start ...................................................................................................................................... 8

3.1 Press-Right user interface......................................................................................................... 8

3.2 First approach ........................................................................................................................... 8

3.3 Set the view............................................................................................................................... 9

3.4 The main menu ......................................................................................................................... 9

4Jobs10

4.1 Create a new job..................................................................................................................... 10

4.2 Change the job name.............................................................................................................. 10

4.3 Selecting a job......................................................................................................................... 10

4.4 Selection of a job by barcode.................................................................................................. 10

4.5 Selecting a job via tool recognition.......................................................................................... 10

4.6 Selection of a job via fieldbus.................................................................................................. 11

4.7 Modify job identification codes ................................................................................................ 11

4.8 Copy a job ............................................................................................................................... 11

4.9 Delete a job ............................................................................................................................. 11

4.10 Edit a job ................................................................................................................................. 11

4.11 Job counters............................................................................................................................ 12

4.12 The graph................................................................................................................................ 12

4.13 Phase management................................................................................................................ 12

5Parameters..................................................................................................................................... 14

5.1 Stop values.............................................................................................................................. 14

5.2 Control limits............................................................................................................................ 16

5.3 Checkpoints............................................................................................................................. 17

6Job options ..................................................................................................................................... 18

6.1 Counters.................................................................................................................................. 18

7The tolerance range ....................................................................................................................... 20

7.1 Create the tolerance range ..................................................................................................... 20

7.2 Modify the tolerance range...................................................................................................... 20

7.3 Remove the tolerance range................................................................................................... 21

8Rejected pieces.............................................................................................................................. 22

8.1 The causes of rejected............................................................................................................ 22

8.2 Rejected management............................................................................................................ 23

8.3 Additional sensors................................................................................................................... 23

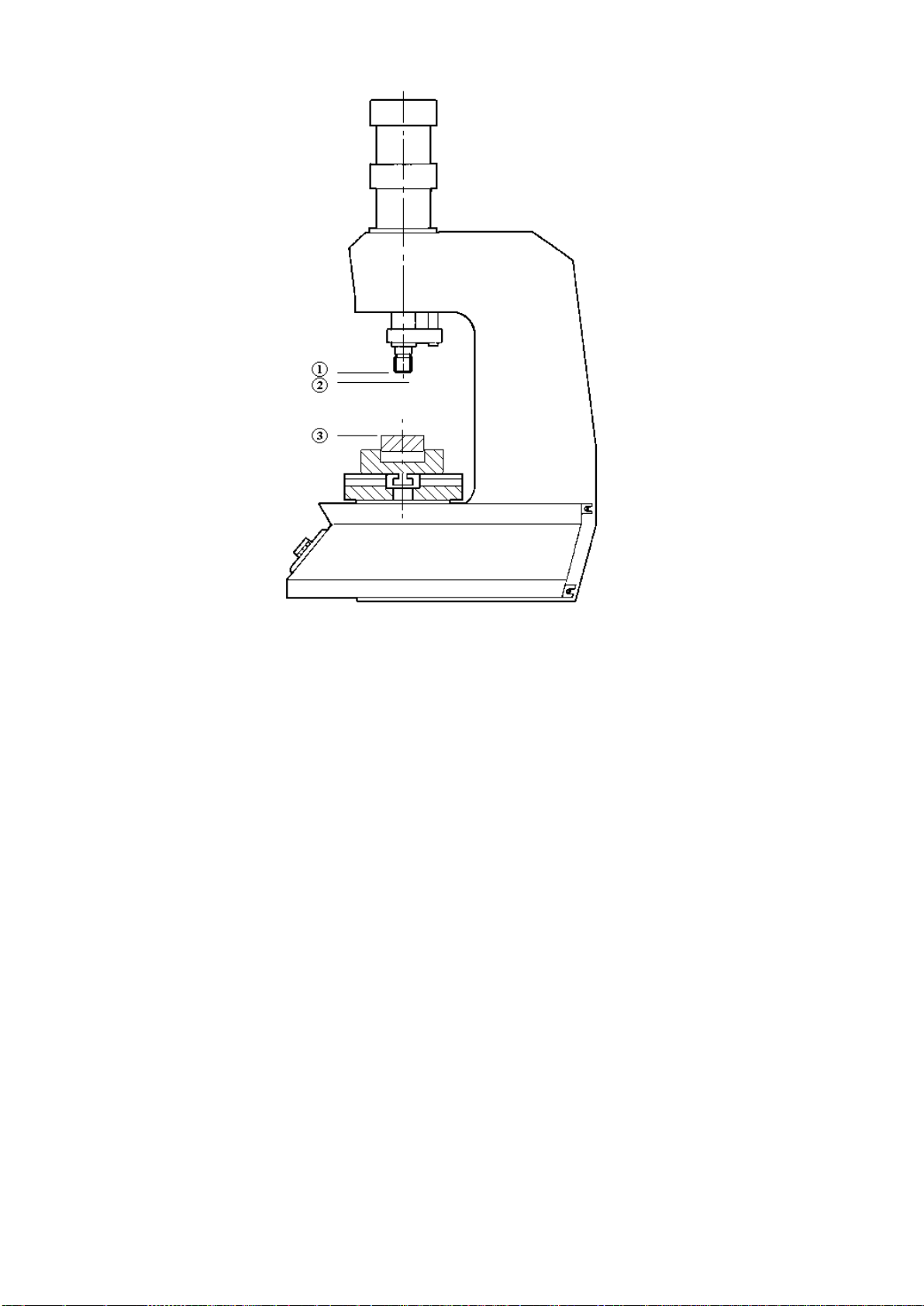

8.4 Force transducers ................................................................................................................... 23

8.5 Accessories............................................................................................................................. 23

8.6 Repetition................................................................................................................................ 23

8.7 Verification............................................................................................................................... 23

8.8 Codes of the job...................................................................................................................... 24

9Measured values............................................................................................................................ 25

9.1 The measured value page ...................................................................................................... 25

9.2 Analysis cursor........................................................................................................................ 25

10 The tools menu............................................................................................................................... 26

10.1 Display options........................................................................................................................ 26

11 Instrument configuration................................................................................................................. 27

11.1 General options....................................................................................................................... 27

11.2 Job selection ........................................................................................................................... 28

12 Diagnosis........................................................................................................................................ 29

12.1 Firmware version..................................................................................................................... 29

13 Special configurations .................................................................................................................... 30

13.1 Additional force transducer ..................................................................................................... 30

13.2 Self-test................................................................................................................................... 30

13.3 Management of supplementary controls................................................................................. 31