10 | ALFRESCOPLUS™

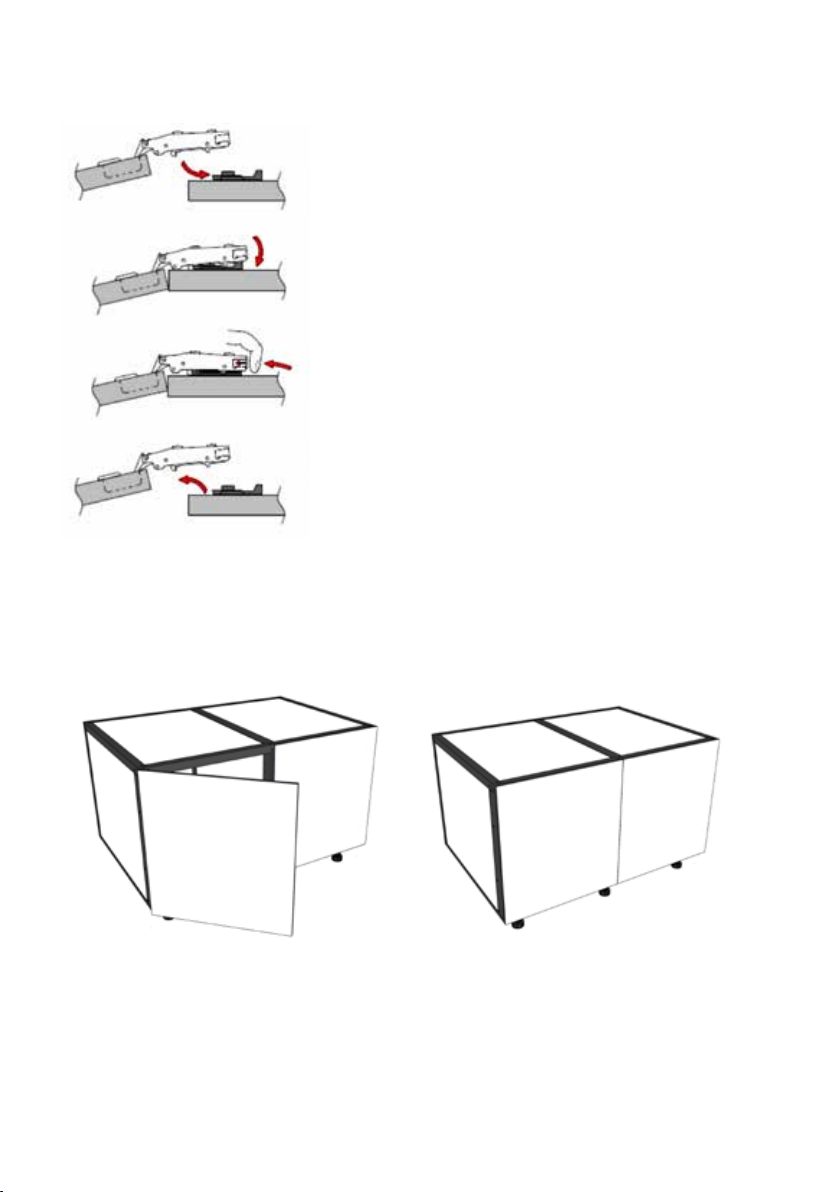

* Detailed INSTRUCTIONS on how to clip on the doors using clip-on-hinges.

Clamp hinge on to the mounting plate as

shown by direction arrow

Press down the hinge arm to lock the plate

as shown

The door can be quickly removed by

pushing the button

Unclipping the door from the mounting

plate leaves all adjustments unaltered

Firstly align the front hinge section with the front section of the hinge-plate, then press on

the back of the hinge-plate, an audible “Click” should be heard if the door has been correctly

hanged. Repeat the process to secure the bottom hinge and door.

Clip On Hinge Instructions:

*DetailedINSTRUCTIONSonhowtocliponthedoorsusingclip-on-hinges.

ForFurtherinstructionondooradjustmentandlevelingpleasevisit:_____________________________________

Firstlyalignthefronthingesectionwiththefrontsectionofthehinge-plate,thenpressonthebackofthehinge-plate,an

audible“Click”shouldbeheardifthedoorhasbeencorrectlyhanged.Repeattheprocesstosecurethebottomhingeand

door.

Atthisstageyourprogressshouldlooklikethe

aboveimage.Chooseanyseparatestyleofdoor

handleandfitaccordingtothemanufacturers

instructions.

Thedoorshouldfullyopenandcloseasnormal.

FIG. 18 FIG. 19

The door should fully open and close

as normal.

At this stage your progress should look

like the above image. Choose any separate

style of door handle and fit according to the

manufacturers.

*DetailedINSTRUCTIONSonhowtocliponthedoorsusingclip-on-hinges.

ForFurtherinstructionondooradjustmentandlevelingpleasevisit:_____________________________________

Firstlyalignthefronthingesectionwiththefrontsectionofthehinge-plate,thenpressonthebackofthehinge-plate,an

audible“Click”shouldbeheardifthedoorhasbeencorrectlyhanged.Repeattheprocesstosecurethebottomhingeand

door.

Atthisstageyourprogressshouldlooklikethe

aboveimage.Chooseanyseparatestyleofdoor

handleandfitaccordingtothemanufacturers

instructions.

Thedoorshouldfullyopenandcloseasnormal.

*DetailedINSTRUCTIONSonhowtocliponthedoorsusingclip-on-hinges.

ForFurtherinstructionondooradjustmentandlevelingpleasevisit:_____________________________________

Firstlyalignthefronthingesectionwiththefrontsectionofthehinge-plate,thenpressonthebackofthehinge-plate,an

audible“Click”shouldbeheardifthedoorhasbeencorrectlyhanged.Repeattheprocesstosecurethebottomhingeand

door.

Atthisstageyourprogressshouldlooklikethe

aboveimage.Chooseanyseparatestyleofdoor

handleandfitaccordingtothemanufacturers

instructions.

Thedoorshouldfullyopenandcloseasnormal.

For further instruction on door adjustment and leveling please visit: www.alfrescoplus.com.au

Positionmodulesinthedesiredconfigurations.Leveleachmoduleandensuretheheightsarecorrectsothatjoiningholes

lineup.Nowjointhetwomoduleswiththebarrelboltssupplied.DoNotovertightenbarrelbolts.PositionandLevelthe

wholeassemblyinfinalposition.(ViewImage33,34,35,36,37,38,39and40)

AttachingandLevelingtheMODULES

Makesurethecabinetsareleveledandaligned,readytobeconnectedbybarrelbolts.Pleasenotethebiscuit

insertedintothekickplateprovided,ensurethekickplateisalignedreadytobeconnected.