RadonXTM Technical Manual and Installation Methods Guide 3

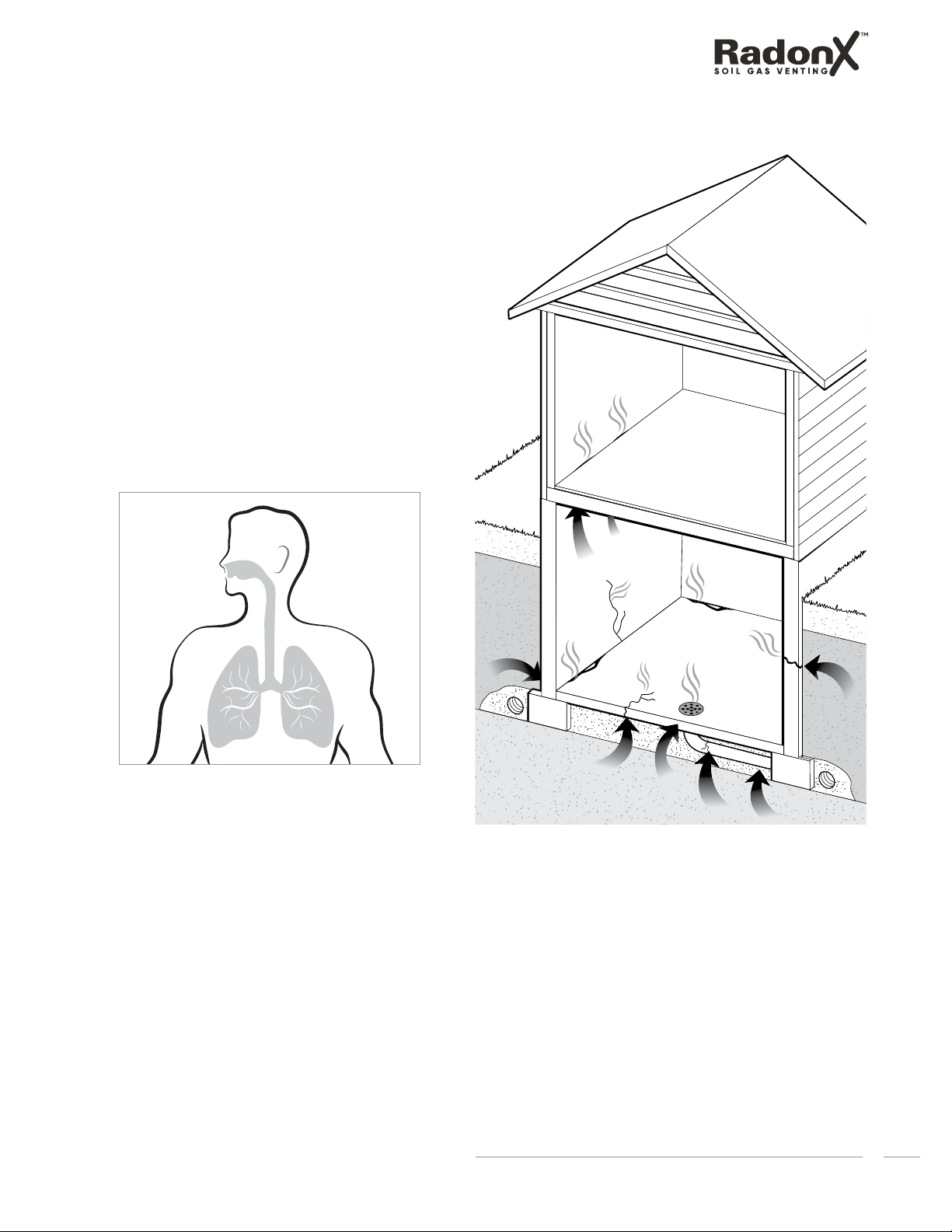

Product Application

RadonXTM Soil Gas Venting (SGV) Piping System is

intended to vent soil gases and help reduce indoor

radon concentrations in low-rise construction. RadonX

pipe and fittings satisfy the requirements of the National

Building Code 2015.

Limits of Use and Application

(a) RadonX does not treat or cure lung cancer.

(b) All RadonX soil gas venting pipe and fittings must

be carefully examined for possible damage prior

to installation. Any damaged product must be

replaced. No attempt at repairs are to be made at

the job site.

(c) Soil gas venting application will cause the piping

system to expand and contract accordingly. Proper

care must be taken to allow for this movement

through walls, ceilings, and roof penetrations. The

venting system must be supported in accordance

with these instructions.

(d) Use RadonX cement and System 636®primer to

assemble RadonX soil gas venting systems.

(e) Venting should be as direct as possible with a

minimum number of fittings.

(f) Horizontal runs should be minimized.

(g) All horizontal sections of the venting system must be

installed with a slope not less than 1% down towards

the riser in order to collect condensate and remove

condensate generated inside the line. The removal

of condensate will help reduce the possibility of ice

buildup and blockage.

(h) All framing requirements for floor and ceiling

penetrations shall be in accordance with the

local building code and/or the local regulatory

authority. All penetrations of fire rated floors and

walls in multi-unit residential shall be firestopped as

described in the Firestop section of this guide.

(i) Roof penetrations should be sealed with a

plumbing roof boot or equivalent flashing as per

the local building code, or as permitted by the local

regulatory authority.

(j) If spray foam insulation comes in contact with

RadonX, it is recommended that foam be applied in

a maximum layer thickness of 50mm (2 inches) until

the required thickness of insulation is achieved.

(k) Do not use or install perforated RadonX pipe above

ground.

(l) All RadonX piping system in unconditioned space

shall be insulated as described in the Above Grade

RadonX piping system installation section of this

guide.

DO NOT mix pipe, fittings or joining methods from

different manufacturers as they have different joint

systems and adhesives. This can result in unsafe

conditions and cause radon gas leak.

WARNING

DO NOT use or mix RadonX components with other IPEX

pipe and fittings. DO NOT use RadonX in applications

other than soil gas venting. These can result in unsafe

conditions.

WARNING

RadonX is a combustible piping system and as such

will be subjected to all conditions and limitations

of the Building Code for above-ground use in Non-

Combustible (commercial) buildings. For further

information, contact IPEX.

NOTICE

Follow IPEX solvent welding procedures as shown in

this guide, and check for proper joint construction

when joining pipe to fittings.

NOTICE

RadonX is a PVC piping system to be used in soil gas

depressurization systems to reduce indoor radon

concentrations. Once the building is occupied,

continued radon concentration measurements shall

be performed. Consult the C-NRPP, National Radon

Proficiency Program at c-nrpp.ca for details as to

frequency and guidelines to follow. If measured

radon gas concentrations exceed the Canadian

guideline level, contact a mitigation professional

certified by a C-NRPP.

WARNING