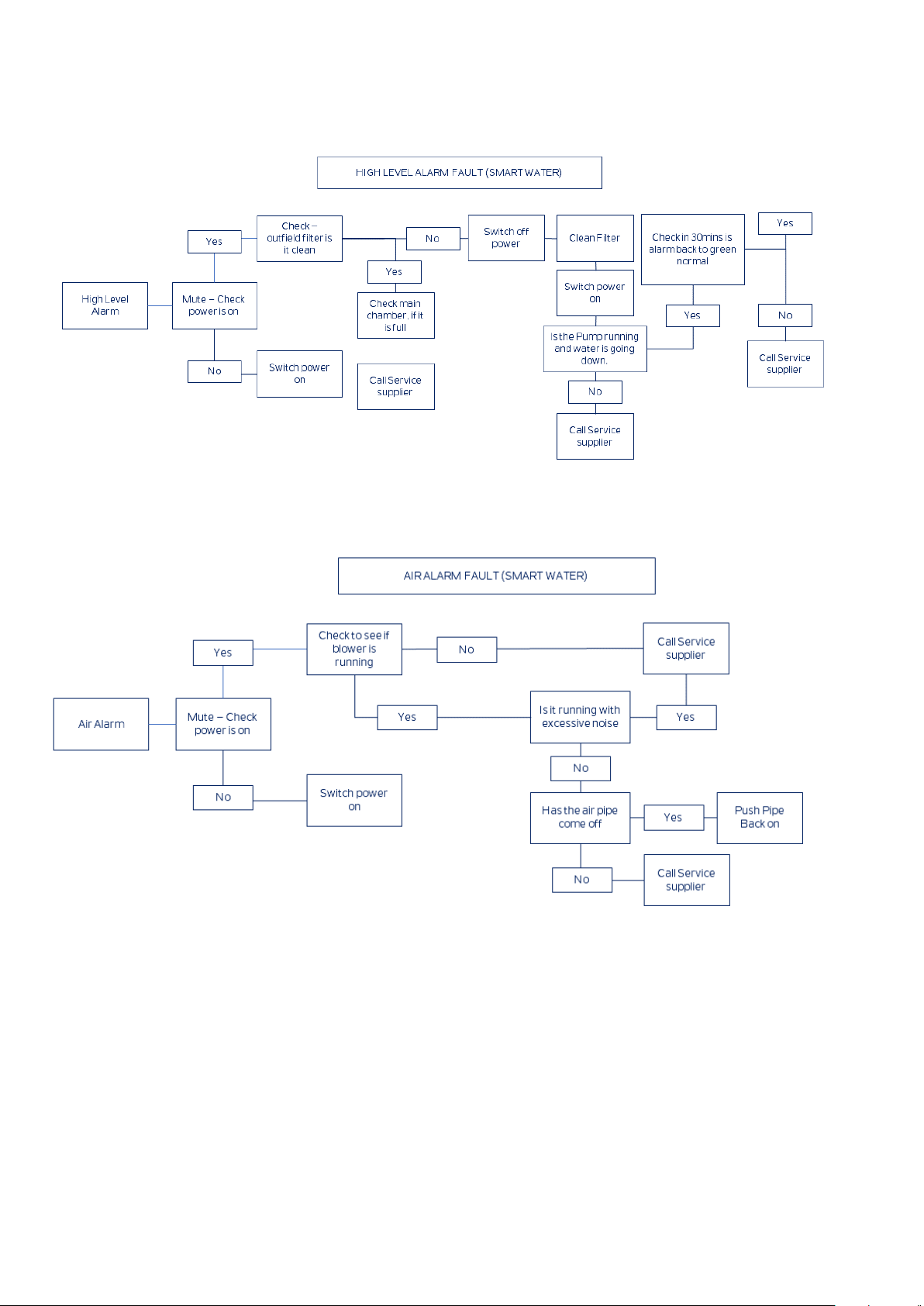

• What does the alarm do?

The alarm system doesn’t run the AirTech™ system, it is

an audible and visual alarm to alert the homeowner of

possible issues with the system

• My septic tank is starting to smell, what do I do?

Your systems anaerobic bacteria has died or is dying –

check the points in the guidelines section (pages 6 & 7) of

this manual. If you are still not happy with the results, please

consult your independent service supplier for assistance

• My septic tank is overflowing, what do I do?

Either the internal/external filter is blocked and needs

cleaning, the power is off, or the pump has failed. Firstly,

check that the power is turned on to your system, if it is,

check to see if the internal or outlet filter is blocked and

needs cleaning. If the pump has failed, call your

independent service agent/installer for assistance

• Will reception be reduced if trees or walls are in

between the AirTechTM and LCD unit?

Any wireless system will have range and reception reduced

by obstacles. Similar to the poor reception of radio stations in

valleys and near power lines. It is recommended to minimise

obstructions in the direct path of the wireless signal. Metal

clad walls will cause a drop in signal and use of an external

aerial should be considered if tank is downhill of house.

• What happens if there is a power cut or the power to

the LCD is interrupted?

Once power is restored the LCD unit will communicate

with the tank and previous readings/data will be restored

to the screen automatically. No data will be lost and you

will not need to re-connect the LCD to the AirTech™ unit.

If power is lost to the outside tank unit an alarm will sound

only after 3 hrs, alerting the home owner to this signal loss

as (septic 1 not reporting). If an electrical strike has

occurred it is possible for the LCD screen to revert to it’s

original state of a water tank monitor the picture of an

empty water beaker will be displayed in this instance a

reset and repairing will be required.

Frequently asked

questions:

General do’s and don’ts

- Don’t turn your system off

- Do call your supplier when you encounter a

problem

- We recommend that you do your washing up on a

daily basis so as not to shock load the system

- Try to avoid using showers, washing machines,

dishwashers etc. all at the same time

- Don’t try to service the system yourself as

there are health risks to consider and you may

compromise your warranty

- Do use common sense, adhering to the basic

rules provided throughout this manual will ensure

a trouble free, and cost effective system

Suitable plants for

Evapo-transpiration systems

Evapo-transpiration systems employ the combined

effects of evaporation from soil and transpiration

from plants to dispose of wastewater effluent to the

atmosphere. Moisture is wicked up to plant roots and

to the soil surface. The plants use the moisture in their

growing processes and subsequently transpire the

excess through their leaves to the atmosphere.

Native Shrubs and Trees

Coprosma Coprosma Propinqua

Hebe Lacebark (fast)

Manuka Leptospermum Scoparium

Flax (fast) Phormium Tenax

Grasses

Jointed Twig Sedge Baumea Articulata

Longwood Tussock Carex Comans

Pukio Carex Secta

Introduced Species

Canna Lillies Taro

Aralia Fuschia

Philodendrons Begonias

| 7