II.Simplex

4604-9201 Graphical LCD Annunciator

Installation and Configuration Instructions

CaUtiOIIS

andwarnings

DONOTINSTALLANYSIMPLEXPRODUCTTHATAPPEARS

DAMAGED.

Upon unpacking your Simplex product, inspect the contents of the

carton for shipping damage. If damage is apparent, immediately file a claim with the

carrier and notify Simplex.

If>-

ELECTRICAL HAZARD

- Disconnect electrical power when making any internal

ii // adjustments or repairs. Servicing should be performed by qualified Simplex

Representatives.

Introduction

RADIO FREQUENCYENERGY

- This equipment generates, uses,and can radiate

radio frequency energy and if not installed and used in accordance with the instruction

manual, may cause interference to radio communications. It has been tested and found

to comply with the EMC Requirements of Standard GB47 17-93 of the People’s

Republic of China, as well asthe European Economic Community (EEC) standards

for EMC (EN50082-1, 1992) and EMI (EN55022, Class A), and is designed to

provide reasonable protection against such electro-magnetic interference when

operated in a commercial environment. Operation of this equipment in a residential

area is likely to cause interference in which casethe user at his own expense will be

required to take whatever measures may be required to correct the interference.

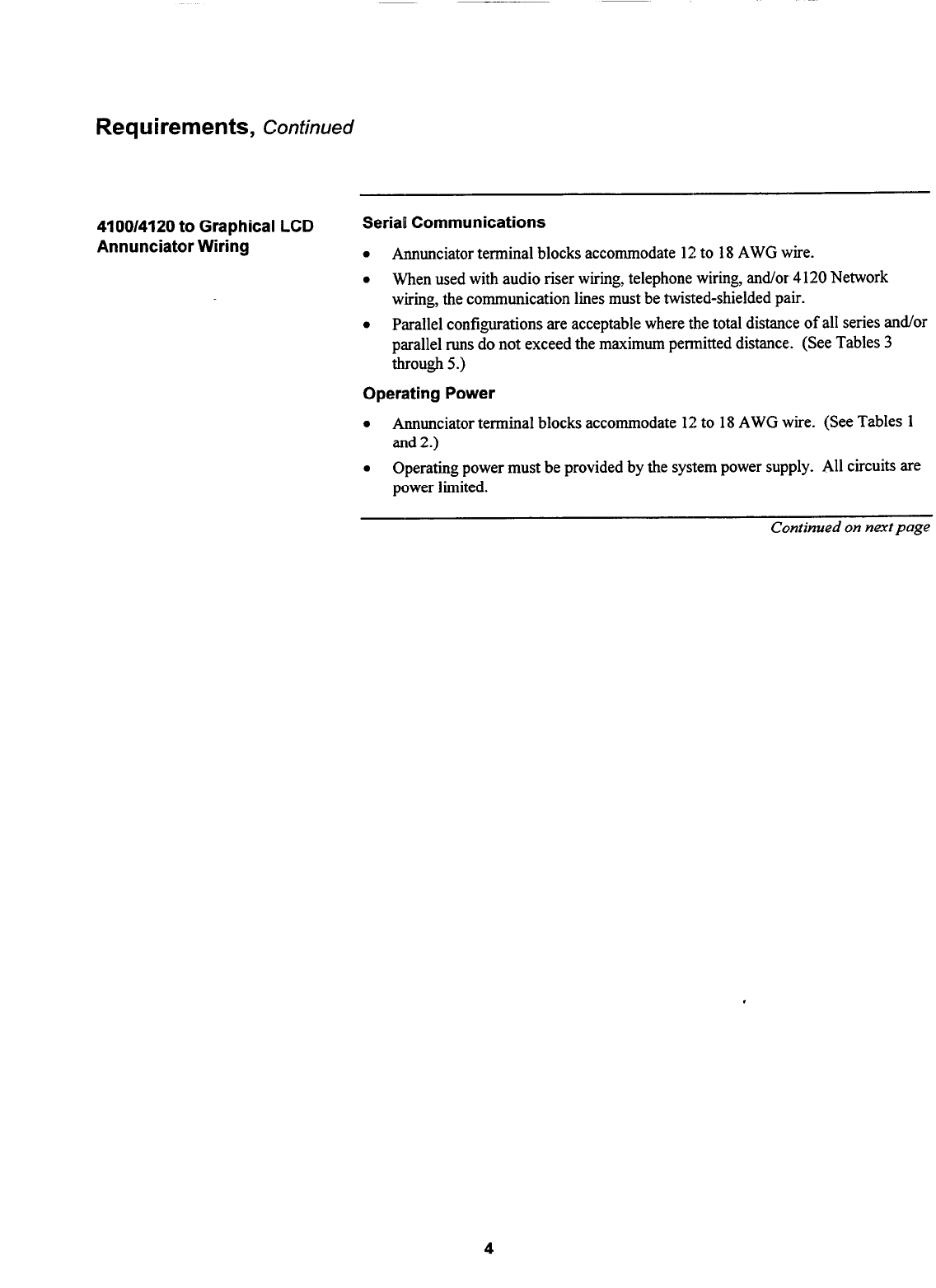

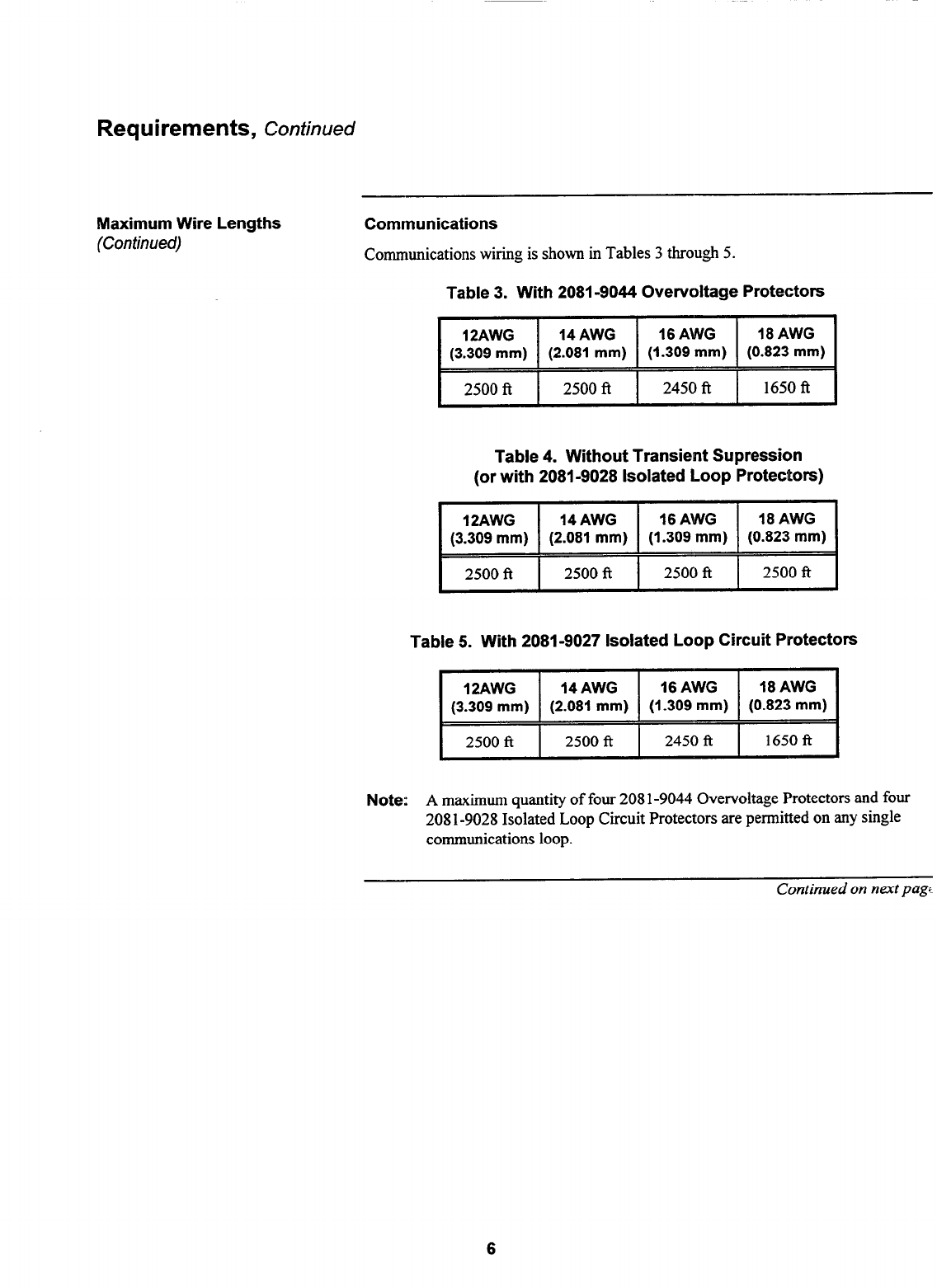

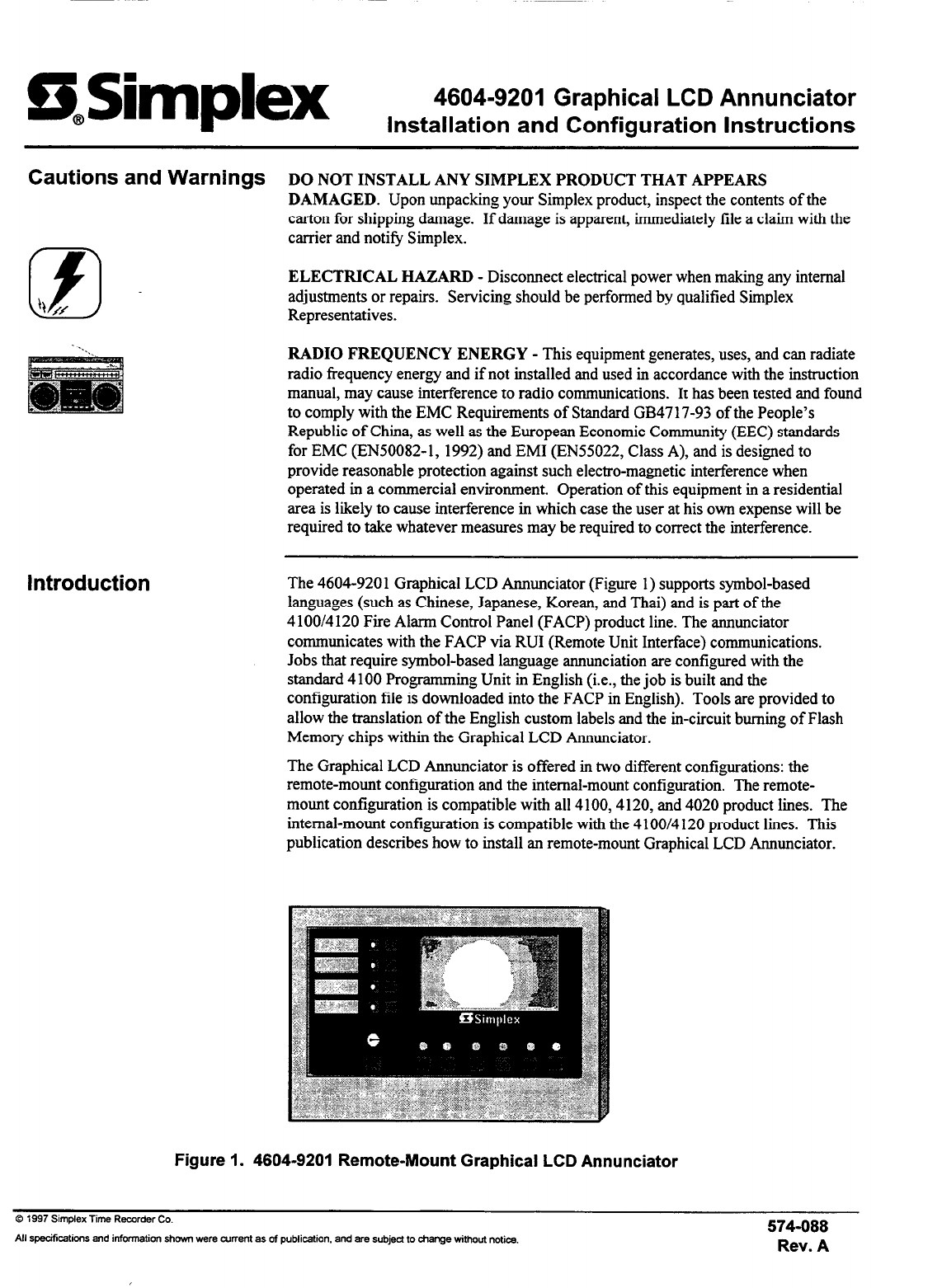

The 4604-9201 Graphical LCD Annunciator (Figure 1) supports symbol-based

languages (such as Chinese, Japanese, Korean, and Thai) and ispart of the

4100/4 120 Fire Alarm Control Panel (FACP) product line. The annunciator

communicates with the FACP via RUI (Remote Unit Interface) communications.

Jobs that require symbol-based language annunciation are configured with the

standard 4100 Programming Unit in English (i.e., the job isbuilt and the

configuration file is downloaded into the FACP in English). Tools are provided to

allow the translation of the English custom labels and the in-circuit burning of Flash

Memory chips within the Graphical LCD Annunciator.

The Graphical LCD Annunciator is offered in two different configurations: the

remote-mount configuration and the internal-mount configuration. The remote-

mount configuration is compatible with all 4100,4120, and 4020 product lines. The

internal-mount configuration is compatible with the 4100/4 120 product lines. This

publication describes how to install an remote-mount Graphical LCD Annunciator.

Figure 1. 4604-9201 Remote-Mount Graphical LCD Annunciator

0 1997 Simplex Time Recorder Co.

574-088

All specifcations and information shown were current as of publication. and are subjed to charge without notice.

Rev. A