Progres AGRONIC 54 User manual

1

INSTRUCTION

MANUAL

24 Vac

INDEX

Sec. Theme Page

INDEX / PRESENTATION 1

1. INTRODUCTION 1

2. SCREEN DATA 2

3. TECHNICAL CHARACTERISTICS 2

4. DIMENSIONS 3

5. TITLE PAGE 3

6. INPUTS AND OUTPUTS 3

6.1. Inputs 3

6.2. Outputs 4

7. CONFIGURATION OF THE INSTALLER

5

8. CONSULTATION 6

9. PROGRAMMING 6

10. CONFIGURATION OF THE USER 6

11. CALIBRATION 7

12. MALFUNCTIONS 7

13. FUNCTION CHART 8

PRESENTATION

We wish to take this opportunity to thank you for

the confidence in us which you have demonstrated in

expressing interest or acquiring Agrónic 54.

This confidence, for our part, stimulates our efforts

to meet and surpass the expectations of our clients to

justify the traditional quality of our products.

This Manual will allow you to see the capacity of

the unit as well as its installation and use.

However, if after reading this you still have any

doubts, contact us and we will happily answer them.

1. INTRODUCTION

Agrónic 54 is a unit which regulates both the

electrical conductivity (EC) of irrigation water, injecting

2 possible fertilizers, and its pH, injecting acid or base.

There are 3 formulas or programs, which are

started by external orders received by the correspond-

ing inputs, so this unit itself does not control the irriga-

tion sectors.

There are 2 versions, according to the way in

which the dosage is done: one with “pulsed injection”,

which works on the solenoids, another one with “ana-

log injection”, which works on frequency variators.

In the “by pulsed injection” version, to maintain

the EC, the unit applies every certain seconds, a dose

of every fertilizer, which is related to the desired pro-

portion between fertilizers and the programmed refer-

ence. To maintain the pH the unit works in a similar

way.

In the “analog injection” version, to maintain the

EC and/or the pH, the unit changes the injection

speed of the engines until it gets the programmed

references.

In the version with pulsed injection, there are out-

puts for 2 fertilizers and 1 acid or base.

In the version with analog injection (0-10 Vdc),

there is an output for fertilizer and another one for acid

or base.

In both versions, there is also a general output

and another one for alarm and/or mixer.

Feeding of the unit at 24 Vac. Optionally, 12 Vdc.

Outputs at 24 Vac in the version with pulsed in-

jection and at 0-10 Vdc in the version with analog in-

jection.

There are 3 inputs for the start of the fertilization

programs and 1 input to detect malfunctions.

There is also 1 input for the conductivity sensor

and 1 for the pH sensor, with a transmitter, which is

integrated in the unit circuitry.

The calibration of sensors is done with the key-

board.

2

It is possible to program three different crops.

The EC reference, pH reference and the proportion of

two fertilizers to be applied (this is in the version with

pulsed injection) are given to every one of the three

programs.

There are independent EC and pH alarms, being

possible to configure the high value, the low one and

the delay in the detection of an irregularity.

Start and stop times are programmable for the

pre-mixing, mixing and alarm.

Configurable lag for the detection of the start up

and malfunction inputs.

It is easy to use and program by means of three

keys and a LC screen with 13 millimeter-high digits.

The unit is located in a poly-carbonate closed

box.

Agrónic 54 follows the CE guidelines.

2. SCREEN DATA

Information is displayed on the screen in the fol-

lowing way: the first two digits indicate the code in

which we are in. The following block of digits always

gives information about the electrical conductivity or

fertilizer 1, while the last block of digits makes refer-

ence to the pH or fertilizer 2.

Use the “C” key to go from one code to the next

one. If you keep pressing this key, the code will

change rapidly.

Use the “+” and “-“ key to modify the values

which are displayed on the screen. These keys will

increase or decrease the active value, which is dis-

played in that moment. If you keep pressing the key, it

increases or decreases rapidly.

3. TECHNICAL CHARACTERISTICS

Power supply

Power source 24 Vac ±10%

Energy consumption Average consume: 8.5VA

Input fuse 2.5 A, F type, 250 V (fast)

Outputs Inputs

Number 5 Number 4

Type Relay, Triac optolinked Type Optolinked

Environment Weight (approximate) Memory backup

Temperature 0 °C a 45 °C 1 Kg. Parameters, programs It cannot be erased

Humidity < 85 %

Height 2000 m.

Pollution Grade II

DECLARATION OF CONFORMITY

It follows the 89/336/CEE Guidelines for the Electromagnetic compatibility and the 73/23/CEE

Guidelines of Low Tension for the Fulfillment of the Product Security. The fulfillment of the follow-

ing specifications was demonstrated as indicated in the Official Diary of the European Communi-

ties.

Symbols which can be displayed on the product Double insulation

This symbol indicates that the electrical and electronic equipment should not be disposed of as gen-

eral household waste at its end-of-life. Instead, the product should be handed over to the applicable

collection point for the recycling of electrical and electronic equipment for proper treatment, recovery

and recycling in accordance with your national legislation.

3

4. DIMENSIONS

All measures in mm.

5. TITLE PAGE

6. INPUTS AND OUTPUTS

6.1. INPUTS

The unit has four digital inputs (D1, D2, D3, D4).

Three of them work as switches (D1, D2 and D3),

starting or stopping the corresponding program, while

the fourth one is a malfunction input (D4).

The activation of inputs is done through their

connection to the common.

A time for the detection delay can be configured

for every input, but the deactivation is immediate.

The pH and conductivity reference, as well as the

proportion between fertilizers can be configured for

every input or program 1, 2 and 3. If more than one

input is activated at the same time, the program which

has priority is the one with the lowest cardinal number.

Input 4, malfunction, is only taken into account if

a program is working.

The unit also has an input for pH sensor (terminal

type BNC) and another one for conductivity sensor.

4

SECTION OF THE UNIT SUPERIOR BOARD

VERY IMPORTANT: The grid must be connected

to the box terminal of the unit.

6.2. OUTPUTS

The unit has 4 or 5 outputs, 2 of them are digital

and the other can be 3 digital, in “pulsed injection”

units, or 2 analog outputs in units with “analog injec-

tion”.

Output 1 Output 2 Output 3 Output 4 Output 5

A-54

pulsed

injection

Digital Digital Digital Digital Digital

A-54

Analog

injection

Analog

0-10V

Analog

0-10V

Analog

outputs

common

Digital Digital

Outputs are protected by a 2.5 A fuse type F

(fast). Replace it with a similar one if it fuses.

SECTION OF THE UNIT INFERIOR BOARD

-S1, S2 and S3 (A-54 pulsed injection): Digital out-

puts for the injection of acid or base and fertilizer

by pulses. The acid or base electrovalve is con-

nected to S1, the fertilizer number 1 electrovalve

to S2 and the fertilizer number 2 electrovalve to

S3. Electrically, the electrovalves will be con-

nected directly to the outputs without any relay in

between and hydraulically they will be connected

to the Venturis or to the magnetic pumps.

5

-A1, A2, (A-54 analog injection): Analog outputs

from 0 to 10 volts to connect to frequency varia-

tors or regulators. It is important neither to short-

circuit these signs nor to put the cables near

power lines. Output A1 corresponds to fertilizer

and A2 to acid or base. The symbol is the

common output or 0 volts.

-S4 (in two versions): Digital output, which is acti-

vated during the whole irrigation, except when

there is a malfunction.

-S5 (in two versions): Digital output used both for

the start and stop of mixers and for malfunction

detection. For a shared use of both functions, it is

necessary to use a relay activated by the general

output. If it is activated, the mixers will work, but if

it is deactivated, the alarm device will work.

7. CONFIGURATION OF THE INSTALLER

This configuration must be done by the unit in-

staller. Press the “+” and “-“ keys at the same time to

access it. Press the “C” key to go to the following

code. Press the “+” and “-“ keys to change the val-

ues. Press the “C” key until the C0 code is displayed

to go back to CONSULTATION.

-Code 00: Delay until the first regulation. Indicate

the time in seconds that the programmer must

wait to calculate the regulation when a program is

started. During this time, the % of applied injec-

tion will be the one memorized in the last irriga-

tion. This allows the injection stabilization. The

value must be between 0 and 250.

-Code 01: Reaction delay. Indicate the time in

seconds that the programmer must use to carry

out the adjustment to be done. The maximum

time is 5 seconds. Time 0 indicates that the ad-

justment must be done as soon as it is detected.

-Code 02: Self adjustment delay. Indicate the time

in seconds that must go by between a self-

adjustment attempt and the next one. The self-

adjustment is a small increase or decrease of the

% of injection which is introduced when the sen-

sor value is outside the programmed reference

value but within the allowed error. The minimum

time is 4 seconds and the maximum is 15.

-Codes 03, 04 and 05: Proportional bands. The

limits, within which the % of injection will be cal-

culated, must be indicated in these three codes,

one for every program. The lower the limit, the

more abrupt the changes will be when trying to

obtain the desired reference. The value can be

between 0 and 9.9, although the normal is 2.0.

-Code 06: Modulation cycle (*). Indicate, in sec-

onds, the frequency in which the injection im-

pulses will be repeated. A suitable value would be

between 2.0 seconds and 4.0 seconds, although

it can go from 2.0 to 9.9 seconds.

-Codes 07, 08, 09 and 10: Delay. Indicate, in sec-

onds, the time that has to go by from the moment

the activation of an input is detected until the pro-

grammer takes it into account. The value must be

between 0 and 250.

-Code 11: Acid o base. In this code it can be se-

lected how it will work the pH regulation in the ir-

rigation water, by means of acid or base. If it

leaved the value to 0 it will work like an acid, and

if it is modified with the “+” key and leaved to 1 it

will work like a base. Then, it will be determinate if

there is an acid or base tank.

(*) In the “by impulse” version, to maintain the EC, the

unit applies every certain seconds, a dose of every fertilizer,

which is related to the desired proportion between fertilizers and

the programmed reference. To maintain the pH the unit works in

a similar way. In the “analog” version, to maintain the EC and/or

the pH, the unit changes the injection speed of the engines until

it gets the programmed references.

6

8. CONSULTATION

The first two codes of the programmer corre-

spond to consultations of the unit state (C0 and C1).

-Code C0: It shows the conductivity and pH read-

ing that reach the unit through the sensors. If a

malfunction takes place, the programmer shows

this code and the alarm origin (program number)

intermittently, and the reason for it (high or low

conductivity, high or low pH, malfunction input).

For further information read the section MAL-

FUNCTIONS.

C

0

2.

4

6.

5

Reading of the

conductivity sensor

Reading of the

pH sensor

-Code C1: It shows the percentage of fertilizer in-

jection, which has the highest proportion, as well

as the percentage of acid or base, which is being

injected.

C

1

2

1

3

3

% of fertilizer be-

ing injected

% of acid or base

being injected

9. PROGRAMMING

The codes that go from C2 to C7 are used to de-

fine every program, having to specify the desired level

of conductivity and pH, as well as the relationship

between the injection of the two fertilizers.

Every code is divided into two sections. The first

one corresponds to values of conductivity or values

from the first fertilizer, while the second one corre-

sponds to values of pH or of the second fertilizer.

Press the “C” key to change section or code and the

“+” and “-“ keys to increase or decrease the value of

the section which is active, that is to say the one which

has a blinking point on its left.

A point showed just after the code means that

the program is activated.

-Codes C2, C3 and C4: Indicate the desired refer-

ence value for conductivity (value from 0 to 9.9)

and pH (value from 0 to 9.9) which is to be

reached when program 1, 2 and 3 are activated.

The value 00 means that this part is not to be

regulated.

C

2.

2.

6

6.

3

Activated

program

Conductivity reference

(program 1)

pH reference

(program 1)

-Codes C5, C6 and C7: Indicate the desired pro-

portion between the fertilizers of every one of the

three programs.

C

6

3

0

11

Non activated

program

Proportion of fertilizer

1. (program 2)

Proportion of fertilizer

2. (program 2)

10. CONFIGURATION OF THE USER

In this section we can find the parameters which

allow you to adjust the working of the unit, as well as

the sensor calibration. To access this section, press

the “C” and “+” keys at the same time when the pro-

grammer is at code C0 of consultation. If no input is

activated, the programmer goes to sensor calibration;

otherwise, it goes directly to the first configuration

code (code 04).

Press the “C” key to go from one code to an-

other. Use the “+” and “-“ keys to change values.

Press the “C” key until the code C0 appears to go

back to consultation.

Codes from 00 to 03, corresponding to calibra-

tion are explained in the CALIBRATION section.

-Code 04: EC high alarm. Indicate the value at

which the indicated reference has to be sur-

passed (between 0 and 9.9) in order to activate

the alarm because the conductivity level is too

high.

-Code 05: EC low alarm. Indicate which value (be-

tween 0 and 9.9) can be reached below the de-

sired reference in order to activate the alarm be-

cause the conductivity level is too low.

-Code 06: pH high alarm. Indicate the quantity of

points (between 0 and 9.9) the indicated refer-

ence can be surpassed in order to activate the

alarm because the pH level is too high.

-Code 07: pH low alarm. Indicate the quantity of

points (between 0 and 9.9) below the indicated

reference must be reached in order to activate

the alarm because the pH level is too low.

7

-Code 08: Delay in the EC alarm detection. Indi-

cate the number of seconds during which con-

ductivity must be at an alarm level before its acti-

vation. The value must be between 0 and 999.

-Code 09: Delay in the pH alarm detection. Indi-

cate the number of seconds during which pH

must be at an alarm level before its activation.

The value must be between 0 and 999.

-Code 10: Pre-mixing. Indicate the number of sec-

onds during which the mixer must be working be-

fore injection is started. The value must be be-

tween 0 and 250.

-Code 11: Mixer working. Indicate the number of

seconds the mixer must be working in the mixing

cycles, which take place during the fertilization.

The value must be between 0 and 250.

-Code 12: Mixer at stop. Indicate the number of

seconds the mixer must be at stop in the mixing

cycles, which take place during the fertilization.

The value must be between 0 and 250.

-Code 13: Alarm working. Indicate the number of

seconds the alarm must be working in the cycle

of alarm signal. The value must be between 0 and

250.

-Code 14: Alarm at stop. Indicate the number of

seconds the alarm must be at stop in the cycle of

alarm signal. The value must be between 0 and

250.

11. CALIBRATION

In the configuration of the user, codes from 00 to

03 are used to calibrate sensors. On entering in eve-

ryone of the codes, the code and value which is ex-

pected from the sensor appears for a few seconds.

After these seconds, the screen blinks and displays

the reading, which is being obtained from the sensor.

If the reading is stable enough and similar to the de-

sired one, the screen stops blinking after approxi-

mately 10 seconds, indicating that the sensor has

been calibrated. If you press the “+” and “-“ keys

simultaneously the unit is forced to accept the value

which is displayed at this moment.

If the calibration of sensor is not to be done,

press the “C” key during the initial seconds or press

the “C” key until the code changes, when the screen

is blinking.

In order to have a good calibration, the sensor

and the liquid have to be as close as possible to 25°C

degrees. Then, the liquid value and the automatic

compensation that the sensor have will be correct. If

the irrigation water is cooler than 25°C the sensor it

should be taken out for several minutes because the

sensor has and inertia to the temperature changes.

The calibration codes go in pairs. So, codes 00

and 01 are used to calibrate the conductivity sensor,

while codes 02 and 03 correspond to the calibration of

the pH sensor. If a suitable calibration is not done in

the first code, the second one does not appear. So, to

do a valid calibration of the sensor, it is necessary to

do the two codes, which correspond to the sensor

correctly.

Finished the calibration process, the result can

be verified on consultation screen, introducing the pH

or EC sensors in the calibration liquids.

12. MALFUNCTIONS

When the unit detects a malfunction, because a

non desired level of conductivity or pH has been

reached or because input 4 has been activated, the

program stops automatically and injection also stops.

The screen displays the consultation code C0 and the

information about the reason of the malfunction in a

blinking way. The program will not be started again

until the malfunction is not deactivated by pressing the

“C” key.

Option code Origin of the alarm

(EC, pH, E4)

C

0

A

1

P

H

_

Indicator of the

alarm and num-

ber of program

Type of alarm

(low, a dash below,

high, a dash above)

8

13. FUNCTION CHART

R-903-3

Table of contents

Other Progres Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Utilicor

Utilicor MTC-100 Operator's manual

CLEAN ROOM DEVICES

CLEAN ROOM DEVICES CRD500SS Operation manual

Habasit

Habasit Rossi A Series operating instructions

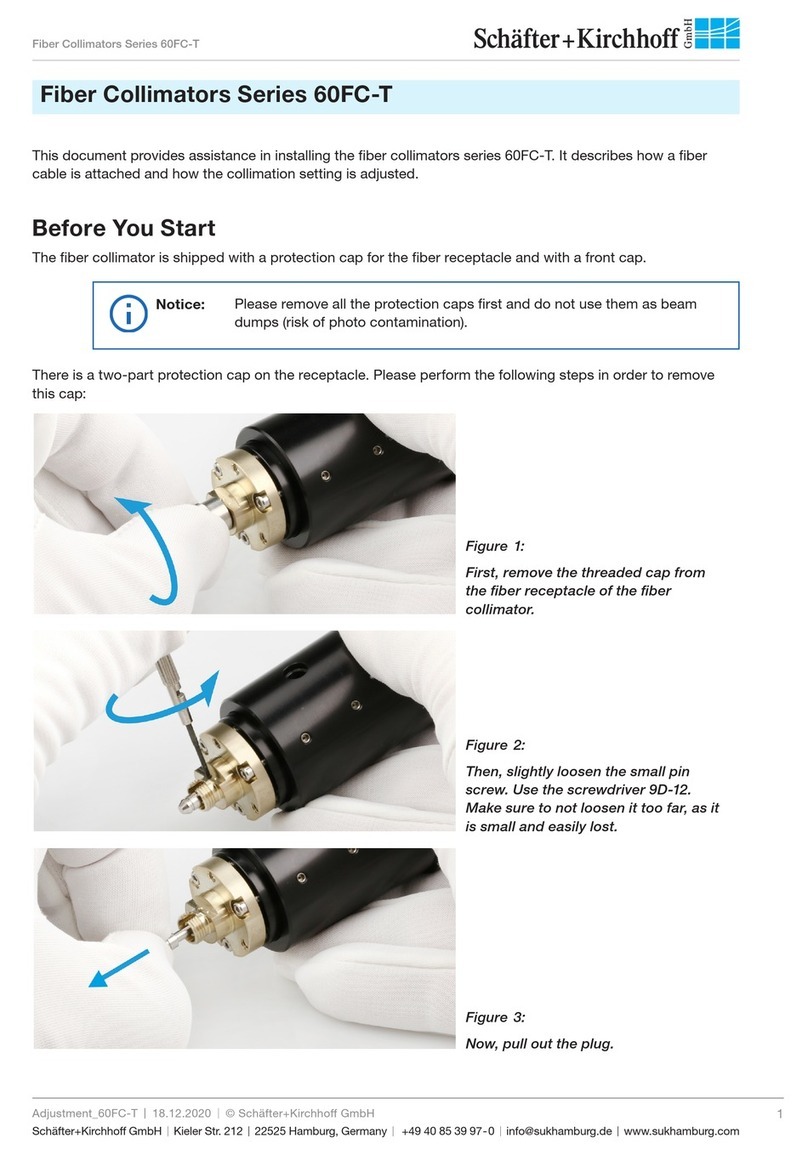

Schäfter+Kirchhoff

Schäfter+Kirchhoff 60FC-T Series quick start guide

Graco

Graco ProBell 24Z168 quick start guide

Panasonic

Panasonic Aicure UD40 Series user manual