, gg

~

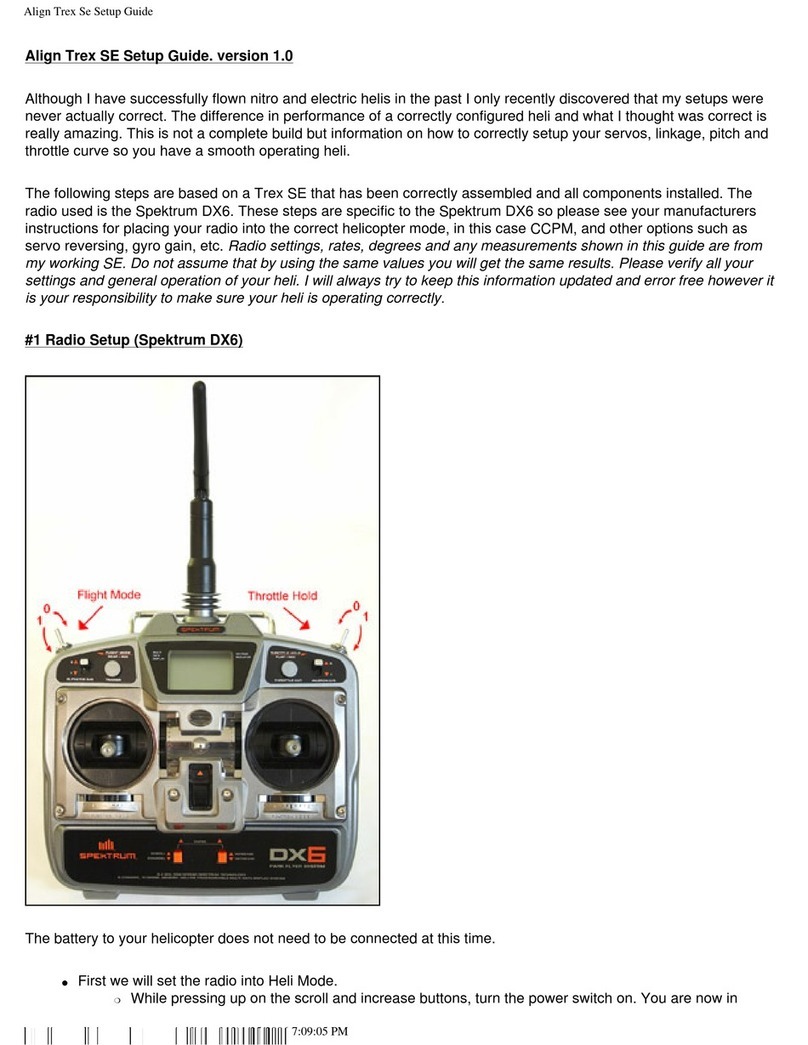

5.SAFETY CHECK]BEF_ORE~'E~MING

'mamJ~~~~m ,

,L\UIC:N~..

CAREFULLY INSPECT BEFORE REAL FLIGHT ••

m~BmBmrZttt~IU

*Before ftying, please check to make sure no one else is operating on the same frequency for the safety.

*Before Hig please check if the batteries of transmitter and receiver are enough for the flight.

*Before turn on the transmitter, please check if the throttle stick is in the lowest position. IDLE switch is OFF.

*When turn off the unit, please follow the power on/off procedure. Power ON- Please turn on the transmitter first, and then turn on

receiver. Power OFF- Please turn off the receiver first and then turn off the transmitter. Improper procedure may cause out of

control, so please to have this correct habit.

*Before operation, check every movement is smooth and directions are correct. Carefully inspect servos for interference and

broken gear.

*Check

for

missing or loose screws and nuts. See if there is any cracked and incomplete assembly of parts. Carefully check main

rotor blades and rotor holders. Broken and premature failures of parts possibly cause resulting in a dangerous situation.

*Check

a

ball links to avoid excess play and replace as needed. Failure to do so will result in poor flight stability.

*Check if e battery and power plug are fastened. Vibration and violent flight may cause the plug loose and result out of control.

*.~RE-~~~~MRffl~~.~~.~~@A·~~~b§§N@A~~~·

*.~R5~~E~~~~Nm~~~~~~.~tt~~mB~~~·

HU §Y~~E~~~~~fi1tHljg;15 . :@*~~~Im . :@~~Im(IDLE)~~~lml?JJirr~·

*~ft~ ~g~~~Im~~~~·~~~~~~~~~~~·~~~m~~~~:Im~~~~lml?JJm~~~·~~I?JJ~~~m~·

~~~~~~~~~~~~~~~m~·~~§§N@A@~~·~.~~~~~~·

*~~~7&~~~~ft~ei[QIi1Ji'F~~)Ill~ • &D[qJ~~~~ . llt ~~{qJ~~~~i1Ji'F~~~~;W~fj~~'Ift~ .

Rfflm~~~:~~~~~~~~~~~·

*mB§y~~&~il;':l>-5iU~.m~iIm~NiIm~~ . ~~~~n\§~Ho/i;m~m~~~i4- . i3KffiW~±l EJ H~i§1§~1 .. W8 •••

m1 .~~~A~~~~~~~~~mB·~~~~~~~~~~~·~~;.~mB®~~~~~'~ &~~

~~:~~5~~~~~·

*~~M~: ~~~~~~~.m~m~ ·lIU~@lI~jjj:j~~~~·~li U~~~i§[~~jjft,

~~ffiNe;ll

0

*~~~j@'&~~§~~~I?jJ:@~~.mBcp@ lan~j~l}i,~@mB'~ml~~~ilifK.miffi~ E&~~.

700HB4

700HB7

M1Slantthreadmain

drivegearset

M1 'i1~ii~m

700HC1

'i1 t?i0 2W~

700FLT5

Aluminum Tail Boom x 1

3K Carbon Fiber Tail Boom x 1

&S3~iH~~X1

3K~.~~X1

700EFLZ

700FLH6

690

3G

Carbon Fiber Blades x 1set

6903G

DU.

x

HE

700NT2

..

~~

~ - 6AExternaIBECw/5.1V

Castle ICE

HV

Two·wayStep-down

DS650 Digital Servo x 1 120 ESC x 1 voltage regulator

DS650J:{lli<ili~x

1 CastleICEHV120

Umillx 1

6A\'ImABEC(g5.11J'j~B i 1

M4x4 Set Screw x2

IMx4

JJ:lll**

x2

Motor Slant Thread

Pinion Gear 12T x1

~iUi12Tx1

DS610

DigitalServo

x

3

DS610I'J:llijqJ lil~

x3

3GX CNC

Flybarless System MetalservohomX3

3Gxlft l¥lIi.~~

CNCIiZ.jqJ lil~mh

x

3

When you see e marks as below, please use glue or

grease to ensure ftying safety.

bJ

~~~~~~~~W·~~3L~~L~·~~~Rm2~~M· ~

CA : Apply CA Glue to fix.

Grease

AB : Apply AB Glue to fix. R48

R48 : Apply Anaerobics Retainer to fix.

43 : Apply Thread Lock to fix. G G

01 : Add Grease. ~m~e

r;~n

~.:Wl3~r.\l~I?jJ:@

~:~AB~I?jJ:@

~.~:~3lZII i~~I?jJ:@iIi/(.~I?jJ:@

-~:~m~~

=-:D~~~

When asse fi g ball links, make sure the "A"

character faces outside.

e~~~F$? ~ .

A~~Mi.l9l-·

,

Blue

Self·furnished Self·furnlshed

g~

IIilIl lIll

(§Iii) ABIIlI<§lIIi) T43Gluewidth, approx. 1mm

T

43..t1l J

Jim:~

lnrn

R48 metal tubular adhesive (eg. Bearings). T43 thread lock. apply

a small amount on screws or metal parts and wipe surplus off.

When disassembling, recommend to heat the metal joint about 15

Seconds. (NOTE ; Keep plastic parts away from heat.)

R48ff.l,5 IlJJ iZ.~~(lZDfIlI~)m~j jIj· T43ff.1,~~~· ~3.~~ iZ.~9l-1 l alU~ill\\

':l>-_Rffl.ill\\~~~fflgo~~~~~•.

W\m:ffiJ~~~ iZ.mglSlllli~~nro15fi»•

()±~

I

~~iU¥Si'J~j[[~~)

4

r