Version 1.0: March 2018 2 manual number: 0009 0520EN

Warnings

Do:

•Read this manual carefully before installation and use and keep it for future reference. Make sure

that all daily users know the content of this manual.

•Install these heaters only in according with this manual and all applicable local and/or national

regulations for installation and ventilation of gas heaters.

•Improper installation, adjustment, alteration, service or maintenance can cause injury, damage or

death. For assistance or additional information consult your dealer, gas supplier or installer.

•Use these heaters only in well ventilated environment.

•Before installation and use make sure that the required type of gas and gas pressure, as mentioned

on the data plate, is in accordance with the local situation.

•Store gas cylinders always in accordance with national and local regulations.

•Use only gas cylinders with a gas isolation valve or gas lines with a main gas valve at the beginning.

In case more than one heater is connected to a gas system, place also a gas tap directly before the

heaters. Close these taps when the heaters are not in use.

•Installation, maintenance and conversion to other gases shall only be done by competent, qualified

and experienced installers.

•Make sure that during service, maintenance, cleaning and other work on the heaters, gas lines are

closed and the heaters are cooled down.

•These heaters are intended for heating of animals, poultry, barns, workshops, local outside heating

projects and other similar heating purposes in agricultural environment.

•When gas is smelled or a leak is detected, directly close the gas supply and immediately take care

for good ventilation. Do not touch any electrical switch or do not create sparks in another way. Do

not use the system before the leaks are solved and the system is safe again. Consult an installer.

•If a heater is not safe to use anymore, remove it so that nobody accidentally operates the heater.

Store the heater in a safe place, mark that it cannot be used, and contact a service agent or gas

installer to solve the problem.

•This heater has an open flame. Make sure and take action that small children, mentally disabled

persons or elderly people never can touch the appliance or are in the vicinity without supervision.

Do not:

•These heaters are not intended for domestic use or for use in habitable parts of buildings and

houses.

•Never use LPG heaters below ground level or in cellars or basements.

•Never use these heaters in small rooms or insufficient ventilated areas. This can be dangerous and

is forbidden.

•Do not use these heaters for other purposes than room heating. Other use is not foreseen or

evaluated and maybe will be dangerous.

•Do not use another gas or gas pressure than what is written on the data plate.

•Never use these heaters in rooms or areas where combustible liquids or vapours are used or stored

or where there is a danger for dust explosions. These heaters are not ATEX approved.

•Never cover these heaters with cloths or other materials for drying purposes.

•Make sure that never gas lines, gas hoses, electric lines, etc. are mounted directly above the heaters

or are heated by these.

•Take care that gas hoses are not heated above 40 degrees Celsius.

•Never modify heaters. The manufacturer does not take any responsibility for modified heaters.

•Bad installation, wrong adjustment or incorrect maintenance can cause damage, accidents or even

personal injury or death.

•Do not touch, move, handle or service the heater when it is burning or in operation.

General information

Model identification

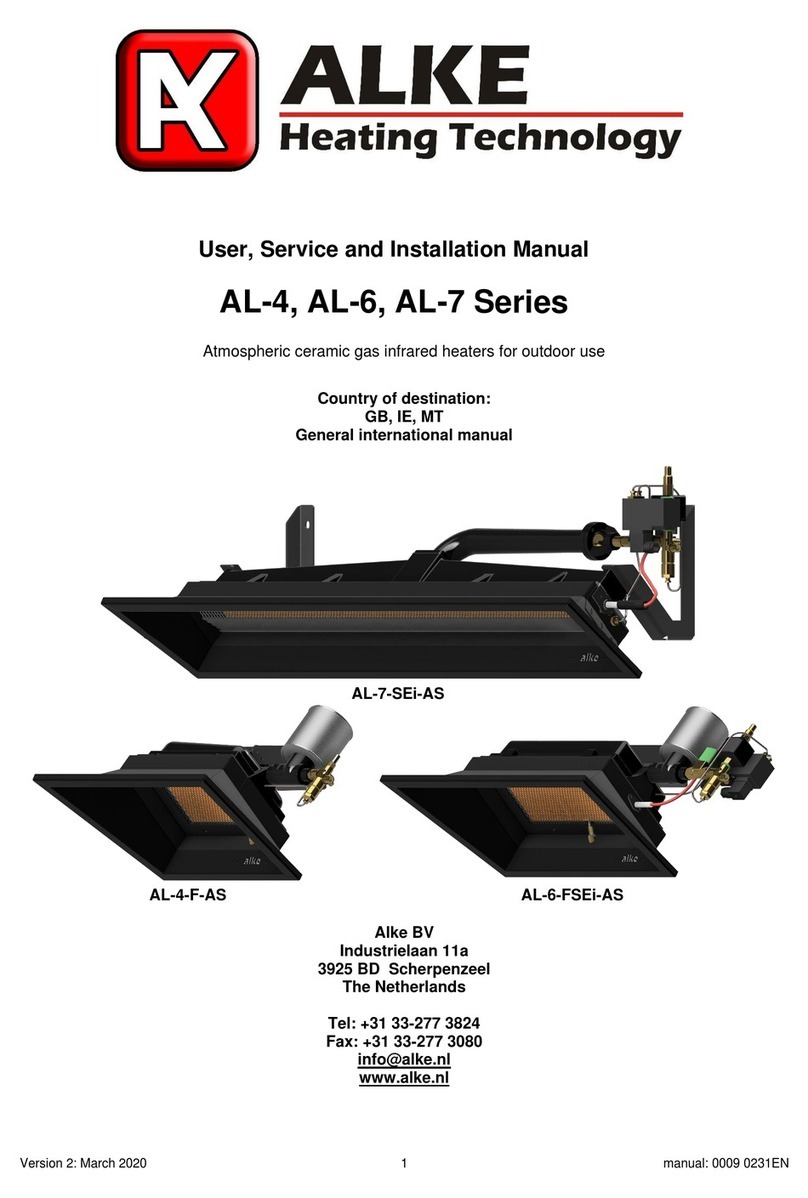

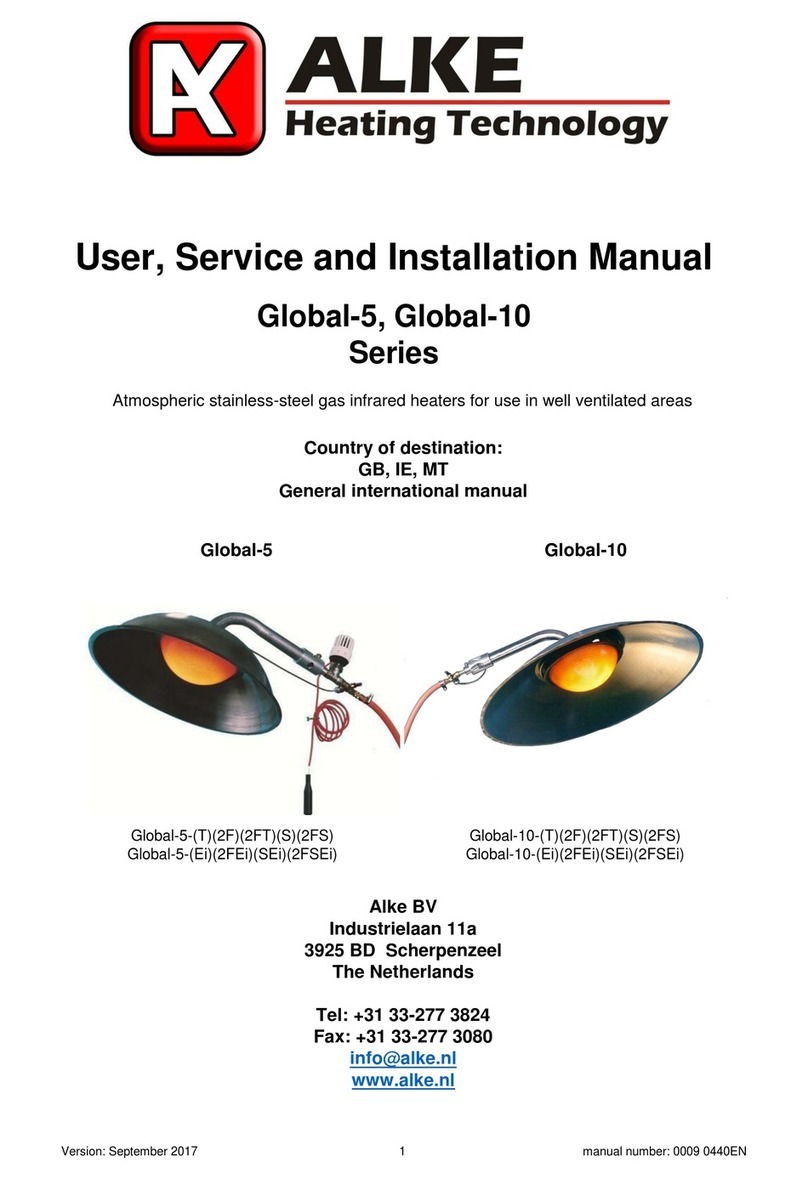

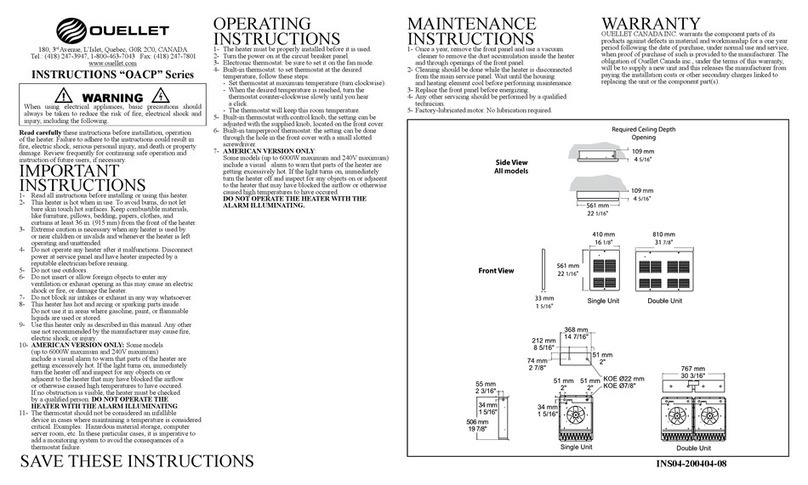

The main identification of the different models is 41, 61 and 81. These are independent atmospheric

ceramic luminous infra-red heaters. Suffixes are used behind these model names to add additional type

information about the models (e.g. 81-FT).

F: equipped with a single dust filter

T: equipped with an independent manual thermostat with remote sensor (Ti = integrated sensor)

Packaging

Normally (depending model and order quantity) the heaters are packed per 1, 2, or 4 in a box. The

heaters are pre-assembled. Always check the heaters for transport damage directly after receiving them.