Alke Global-8 Series Operating manual

Version: April 2016 1 manual number: 0009 0440EN

User and Installation Manual

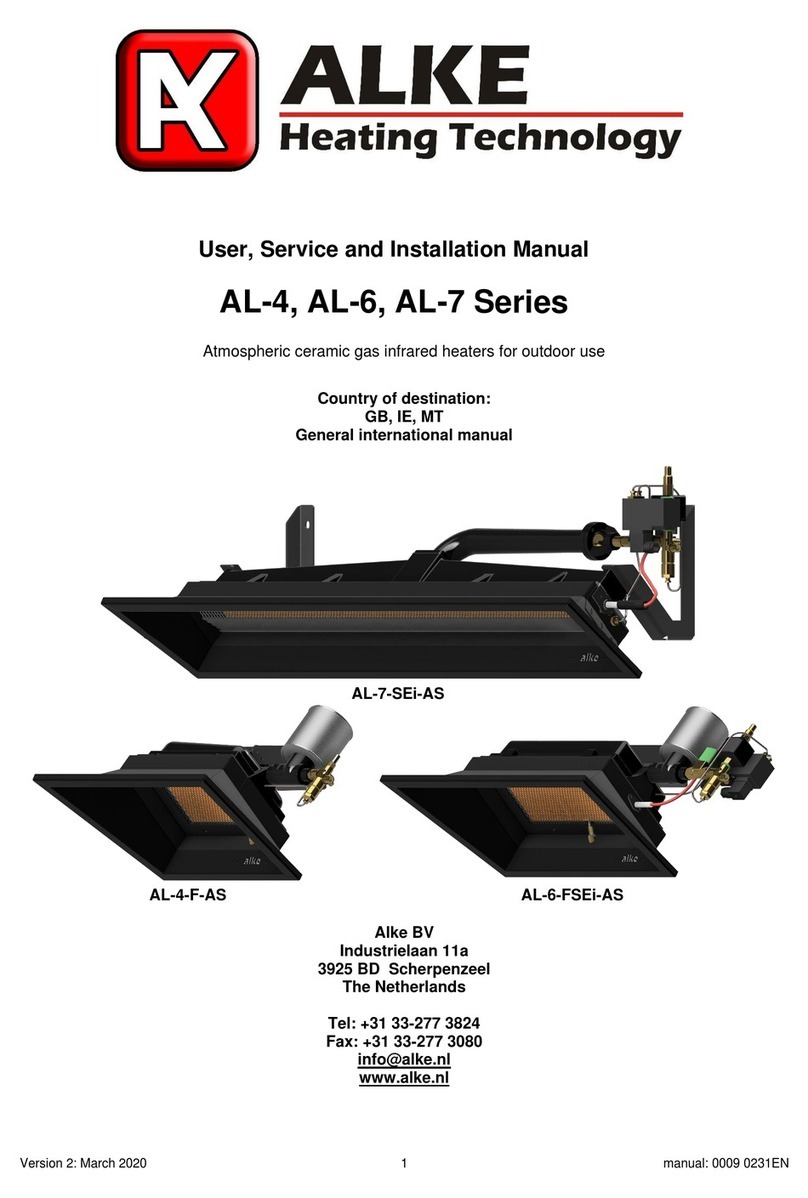

Global-5, Global-8

Series

Atmospheric stainless steel gas infrared heaters for use in well ventilated areas

Global-5 Global-8

Global-5(..)TE Global-8(..)TE

Global-5(..)TETH Global-8(..)TETH

Global-5(..)TEMK Global-8(..)TEMK

Alke BV

Industrielaan 11a

3925 BD Scherpenzeel

The Netherlands

Tel: +31 33-277 3824

Fax: +31 33-277 3080 info@alke.nl

www.alke.nl

Version: April 2016 2 manual number: 0009 0440EN

Version: April 2016 3 manual number: 0009 0440EN

Warnings

Do:

•Read this manual carefully before installation and use and keep it for future reference. Make sure that

all daily users know the content of this manual.

•Install these heaters only in according with all applicable local and/or national regulations for

installation and ventilation of gas heaters.

•Use these heaters only in well ventilated environment.

•Before installation and use make sure that the required type of electricity, gas and gas pressure, as

mentioned on the data plate, is in accordance with the local situation.

•Store gas cylinders always in accordance with national and local regulations.

•Use only gas cylinders with a gas isolation valve or gas lines with a main gas valve at the beginning.

In case more than one heater is connected to a gas system, place also a gas tap directly before the

heaters. Close these taps when the heaters are not in use.

•Installation and maintenance shall only be done by competent and experienced installers.

•Make sure that during service, maintenance, cleaning and other work on the heaters, gas lines and

electricity are closed and the heaters are cooled down

•These heaters are intended for heating of animals, poultry, barns, workshops, local outside heating

projects and other similar heating purposes in agro or industrial environment.

•When gas is smelled or a leak is detected, directly close the gas supply and immediately take care for

good ventilation. Do not touch any electrical switch or do not create sparks in another way. Do not use

the system before the leaks are solved and the system is safe again. Consult an installer.

•If a heater is not safe to use anymore, remove it so that nobody accidentally operates the heater. Store

the heater in a safe place, mark that it cannot be used, and contact a service agent or gas installer to

solve the problem.

Do not:

•These heaters are not intended for domestic use or for use in habitable parts of buildings and houses.

•Never use LPG heaters below ground level or in cellars or basements.

•Never use these heaters in small rooms or insufficient ventilated areas. This can be dangerous and is

forbidden.

•Do not use these heaters for other purposes than room heating. Other use is not foreseen or evaluated

and maybe will be dangerous.

•Do not use another electricity, gas or gas pressure than what is written on the data plate.

•Never use these heaters in rooms or areas where combustible liquids or vapours are used or stored

or where there is a danger for dust explosions. These heaters are not ATEX approved.

•Never cover these heaters with cloths or other materials for drying purposes.

•Make sure that never gas lines, gas hoses, electric lines, etc. are mounted directly above the heaters

or are heated by these.

•Take care that gas hoses are not heated above 40 degrees Celsius.

•Never modify heaters. The manufacturer does not take any responsibility for modified heaters.

•Bad installation, wrong adjustment or incorrect maintenance can cause damage, accidents or even

personal injury or death.

•Do not touch, move, handle or service the heater when it is burning or in operation.

Version: April 2016 4 manual number: 0009 0440EN

General information

Model identification

The main identification of the different models is Global-5 and Global-8. These are independent

atmospheric stainless steel infrared heaters. Suffixes are used behind these model names to add

additional type information about the models (e.g. Global-5 CETETHi).

CE:

that particular type is CE approved

DS:

equipped with a dual dust filter connection

TE:

equipped with a thermocouple safety device

TH:

equipped with an independent thermostat and remote sensor (1,25 meter long)

THi:

equipped with an independent thermostat and integrated sensor

DI:

double injection system

MK:

solenoid valve for hi-low application on 24VAC or 230VAC

Packaging

Normally (depending model and order quantity) the heaters are packed per 1, 2 or 4 in a box. Always

check the heaters for transport damage directly after receiving them. Note that the heaters will be a bit

discoloured by temperature due to a 5 minutes quality check after manufacturing.

The heaters are pre-assembled. In some cases, if there is a risk for damaging during transport, the

thermocouple sensor is separated from the gas safety device. Re-assembly can be simply done by

screwing the M8 nut (18) of the sensor back on the safety device (17). Do not tighten too strong.

In most cases the reflector is delivered separately from the burner part to save on transport costs.

Reassembly is easy: move the burner tube through the hole in the reflector. Slide the reflector over the

tube till it rests on the upper plate of the burner. Secure the reflector with 4 nuts and washers and 2 eye

bolts.

The thermostat knob is always delivered separated from the thermostat valve.

1) Remove the protection cover from the thermostat valve.

2) Turn the knob on maximum temperature and push the knob on the valve.

3) Fix the knob by turning the large metal screw ring till it stops (at least 2 turns, hand tight).

For thermostats with a remote sensor only: bend the sensor line carefully (no sharp bends) to the

thermostat valve and secure the sensor line with a ty-rap around the red protection lining and the

thermocouple safety device (see picture). Note that the tubing is hollow, a sharp bend will close the

tubing and makes the sensor worthless. The chance of breaking the line at the entrance of the

thermostat knob is largely limited now.

Version: April 2016 5 manual number: 0009 0440EN

Installation

Place of installation

The heaters are intended for use in well ventilated areas only. Do not install the heaters in situations

that are not well ventilated. See also below for more ventilation information. Check also your local

regulations for the ventilation and room size requirements. The amount of heaters per building is

depending the type of building, the animals, the insulation, the climate and local wind conditions. Check

with your installer or distributor for a heat transmission calculation to determine the amount of heaters

needed.

Make sure that the place of installation is free of draft (less than 1 m/s). Too much draft will make the

flames unstable and will result in a lower infrared heat efficiency. It is advisable to install an alarm system

that reacts on temperature in case a temperature drop will cause damage. Find in the table below a

rough guideline for the installation height to start with. Adjust later on to the height based on your

personal preference and experience.

Operational Distances

Global-5

Global-8

To the ground

1,3 –1,6 m

1,7 –2,0 m

Safety distance to combustible materials

The heaters produce heat by radiation and by combustion gases. It is important to take the following

distances in account from the heaters to combustible materials. This is to avoid fire or overheating. Do

not use the heaters in situations where the distances to combustibles are smaller. Never store gases or

inflammable liquids or easy combustible materials in close vicinity of the heaters.

Safety Distances

Global-5

Global-8

to the ceiling

>75 cm

>75 cm

in front of the heater

>100 cm

>120 cm

to side walls

>90 cm

>110 cm

to the ground.

>100 cm

>140 cm

The minimum distance to non-combustible materials depends on the specific local situation. Keep in

mind that there must be sufficient free space left to vent the combustion gases away. Otherwise, they

will influence the combustion and proper function of the heater. On locations where the combustion

gases can vent away easily, a minimum of 25 cm to the ceiling is advisable. Note: Be aware that some

non-combustible materials can be subject to discolouring when they become too hot.

Warning: be careful with the use of heaters in places with storage of manure. Manure can contain large

amounts of methane and other inflammable gases.

Ventilation

A proper ventilation is extreme important for safe and convenient operation. Lack of ventilation can cause

production of carbon monoxide (very poisonous). Sufficient ventilation shall be guaranteed by a

monitored fan or by permanent, non-adjustable, ventilation openings. Consult EN13410 for more details.

Beside other important requirements this standard states in short that a 1,5 times room air replacement

per hour is sufficient in most situations. Also a maximum of 5W heat input per m3 room content is

considered to be safe. If this is not the case make sure that a minimum of 10m3/h air replacement per

1 kW heat input is guaranteed by means of fans or ventilation openings.

In case local requirements ask for more stringent ventilation, or when animals ask for more ventilation,

always follow the most stringent requirements. In case there are no requirements or standards for

ventilation in the country of installation, we advise to keep a minimum ventilation of 20m3/h per kW heat

input. Check regularly if fans are working properly and ventilation openings are not closed.

Installation

The heaters are intended for suspension only. The chain and S-hooks shall be galvanised or made of

stainless steel. Do not use the gas line, gas hose or electric lines for suspension purposes. Never use

rope or plastic mounting materials. Close all S-hooks when the heater is in correct position.

•Mount three short chains (of approx. 40 cm) with S-hooks to the three suspension eyes on the heater.

•Combine the ends of the three short chains together in the fourth S-hook and hang it on the main

chain. Mount the main chain to a rigid part of the construction of the building.

Version: April 2016 6 manual number: 0009 0440EN

•Place the chain ends in such a way at the fourth S-hook that the heater reflector makes an angle of

approximately 15 (DI=3) degrees to the horizontal. The gas safety device shall be at the lower end.

Never hang the heater horizontally while in that case the flue gases will influence a proper

combustion.

The gas safety device can handle a maximum temperature of 60 degrees Celsius. Be sure that the

heater is not mounted in such a way that this temperature will be reached (e.g. by other heaters in close

vicinity). Take into account the safety distances mentioned on page 3. After installation always check if

the gas type and gas pressure complies with the technical table and data plate information. Remove the

black end cap from the safety device.

The gas hose shall be hanging free and have a distance of minimal 1 meter from the ground. This to

make sure animals will not damage the hose. Connect the hose via an individual gas tap to the central

gas supply.

A guideline for placement of the sensor of the temperature regulation is 60 cm above the ground and

minimal 40 cm away from a heater. Use sensors with a black surface in case the regulation is based on

measuring the infrared temperature.

Gas line supply

In case a main gas line supplies the gas to the heaters, make sure that an authorised company in your

country, in accordance with the local rules and requirements, install the system. To avoid problems use

galvanised or copper tubing for the gas line. First make a calculation to determine the capacity of the

whole system and the diameters of the piping in each section. Use the common available calculation

methods as written in most gas installation standards. Contact an installer or the distributor in case this

calculation method is not available in your area. For data needed to calculate the dimensions of the gas

line, see the technical table on the last page.

The most common way to install a gas line is in the centre of the barn (at least 2 meter high) with every

3 to 5 meter a “T” or “cross” connection for gas supply to the heaters. Always mount a (easy reachable)

gas tap at the beginning of the gas hose to the heaters. This gas tap is needed to close the gas supply

to the burners to extinguish the flames. In addition, it makes it possible to remove the heaters after use

or to service the heaters safely. The gas inlet at the heater side is standard a 8 mm hose nipple (optional

a smooth hose nipple or a G1/8” right handed thread. Other connections are possible after consultation).

Always use approved gas sealant to close the gas connections.

Gas cylinder supply

The gas can also be supplied from LPG gas cylinders. The minimum size is a 11 kg cylinder or larger.

Before buying a cylinder make sure that the connections of the gas regulator and the gas valve of the

cylinder are of the same type. Check with your gas supplier for the correct size of gas regulator. Check

the technical table for the maximum gas consumption and gas pressure.

Version: April 2016 7 manual number: 0009 0440EN

Store the gas cylinders always on ground level in a well-ventilated place, preferably outside the room

where the heater is. In case the gas cylinder is placed in a cylinder housing, or cover, make sure that

there is enough ventilation as requested by the applicable regulations or standards. Never obstruct these

ventilation holes. Make sure that the gas cylinders are used in upright position only and are secured

again tipping over during use. Gas cylinders laying on their side will give liquid gas. This is very

dangerous and will give a fire ball when it reaches the heaters.

In case the gas cylinder is placed in the same room as the heater is, keep it at a safe distance from the

heater so it will not be over heated. Advisable is at least 2 meters. Make sure that the gas cylinder valve

can easily be reached to close the gas supply in an emergency situation. Pay special attention how to

change the gas cylinders in a safe way.

For the Global-5 a minimum of 1,5 gas cylinder (11 kg or larger) per heater is needed. For the Global-8

a minimum of 2 gas cylinders (11 kg or larger) per heater are needed for a guaranteed gas supply. For

a 45 kg gas cylinder a maximum of two Global-5 heaters is recommended. Having more heaters on the

gas cylinders as recommended above will give gas capacity problems, especially when it becomes

colder, due to limited vaporisation of the gas.

Biogas

While biogas can be corrosive under certain conditions it is important that the biogas is clean before

entrance to the appliances. The gas shall be dry and free from dust, oily and greasy particles to avoid

internal blockage of the appliances. Also halogens, chlorides, H2S and NH3 shall be removed to avoid

corrosion. The tolerance on biogas composition with CH4=60% is +/- 4% CH4.

Gas hose

In most installations the heaters are not connected directly to the gas system but a gas hose is used.

Keep the hoses always as short as possible, especially for natural gas and low pressure LPG. For high

pressure LPG the maximum length (concerning capacity issues) is 5 meter.

The gas hoses must be inspected frequently and must be changed within the prescribed intervals. Check

the hose at least every 6 weeks. Avoid twisting or stress of the gas hose. Twisting or stress will shorten

the live time of the gas hose. During inspection, check the hose for damage, splitting, ageing and

cracking. Pay special attention to the connections. If a defect is seen directly change the gas hose by a

new one of the same type. Keep the hoses clean from dirt, moisture and dust.

Some countries have regulations that gas hoses must be replaced every 2 or 3 years. Please check with

your gas supplier. Always use official approved gas hoses, suitable for the pressure concerning. Replace

a gas hose always by a type of the same length, internal diameter and equivalent quality. For safety

reasons: never use air hoses or water hoses, these are very dangerous for gas transportation and will

leak soon!

The gas hose shall always be connected to the heater with the help of hose clips. Not using hose clips

at both ends of the gas hose is very dangerous. Make sure that the gas hose never is heated above 40

degrees Celsius.

Changing gas cylinders

In case gas cylinders are used, changing or connecting gas cylinders must be done preferably outside,

or in a well-ventilated area, in a flame-free environment and away from other people.

•Check if there are no other operating heaters, other gas heaters, burning candles or people smoking

cigarettes in the area.

•Be sure that the valve on the gas cylinder is closed and the burner of the heater is extinguished.

•Unscrew the nut by which the gas regulator is connected to the gas cylinder valve. (Note that most

connections are with left-handed threads. They open in clockwise direction).

•Before connecting the (new) gas cylinder, first check if the rubber seals on the cylinder valve or on

the regulator connecting nut are fitted properly and able to fulfil its function and are not damaged or

worn. If the last case is true, do not use it and replace the seals first.

•After connecting the regulator firmly, open the cylinder valve and check with soapy water if the

connection is leak tight. If bubbles appear, the connection leaks. Do not use the heater unless the

system is sound.

Version: April 2016 8 manual number: 0009 0440EN

Soundness check

Before using a new built gas system, first make sure that the installer made a careful and extensive

check for gas leakage. After executing a pressure drop test to determine that there are not large leaks,

check every connection with soapy water or gas detection liquid with all gas valves open and with

maximum gas pressure. Pay special attention to the hose connections. Maintain maximum air ventilation

during the test. Repeat this check at least every year. This soundness check shall be done by a

competent installer only.

Gas leakage

When a gas leak is detected, immediately close the gas supply and disconnect electricity. Keep flames

away. Do not use the heater anymore. Contact an authorised gas technician, gas installer or gas service

agent to determine if the gas leakage can be repaired. Never try to do gas repairs by yourself. Do not

use the heater anymore until the problem is solved.

Version: April 2016 9 manual number: 0009 0440EN

Operation

New heaters

New heaters need a cleaning period before they are ready for operation. Turn the ventilation to maximum

position or place the heaters outside in the open air. Fire the heaters for at least two hours on full capacity

to burn-off oily and greasy remnants of the production. Make sure that after two hours all smoke and

smell is disappeared. The smoke and smell can be unhealthy, so keep animals and human beings away

till the heaters and the environment air is clean.

Ignition of the heater

Warning: after an heater is extinguished (intentionally or unintentionally) wait always for 3 minutes before

(re)ignition. This is a worldwide safety rule and intended to ventilate unburned gases away and to leave

enough time for the thermocouple device to close.

TE, TEMK, TETH and TETHi versions:

1) Open all gas taps (and turn the thermostat or gas pressure regulator on maximum, open the MK valve

by electricity).

2) Keep a flame of a BBQ lighter (or long match) in the ignition hole of the burner globe.

3) Press the knob of the gas safety device and wait for 10-25 seconds after ignition before releasing the

knob.

4) The burner will stay on now.

5) Repeat al steps again in case the burner directly extinguishes.

Heat regulation of the heater TE

version:

The heat input of this heater can only be changed by adjusting the pressure of the gas supply. Check

the gas supply pressure information on the data plate of the heater for the minimum and maximum

values. If only one pressure is mentioned, adjustment is not possible and only continuous operation or

on-off operation is allowed.

TEMK version:

Make sure that the gas supply pressure remains constant at the value indicated on the data plate. Adjust

the heat input between high and low by opening or closing the MK solenoid valve.

TETH, TETHi versions:

Make sure that the gas supply pressure remains constant at the value indicated on the data plate. Adjust

the heat input by setting the thermostat knob at the desired value. Note that the temperature on the

ground will be several degrees higher than at the sensor. So use the setting on the thermostat knob as

a rough guideline and always check the real temperature on the ground

Approx. Ground temp Temperature (THi)

Δ = 15 °C

* = 20 °C

1 = 22 °C

2 = 28 °C

3 = 33 °C

4 = 36 °C

5 = 38 °C

Extinguishing the heater

TE, TEMK, TETH and TETHi versions:

Close the gas tap or the central gas supply. The burner will extinguish now. The thermocouple safety

valve will close after 60 seconds.

Visual examination of the flame

Check after every ignition (and also during regular barn inspection) if a heater still burns correctly. The

flame shall remain always inside the outer burner globe. The burner globe shall be equal red/orange in

high firing position and having a blue flame. Some types will have in high fire position a dark ring on the

Version: April 2016 10 manual number: 0009 0440EN

globe. This will not give a problem and is created by cooling air around the flame. A little bit yellow tipping

or yellow glow in low fire is allowed.

A burner does not operate well in case there is a (green)-blue cloud inside the reflector and/or (green)

blue flame tongues are coming out the exhaust holes in the reflector. Soot deposit on the reflector and

yellow flames are also a sign of bad functioning and are not allowed. Cleaning will solve these problems

in most cases. When gas is used with a lot of butane instead of propane the centre of the outer globe

will become overheated. The centre will be white-yellow hot coloured; small flames of a few mm will

come through the perforation of the globe. The globe will burn through after some time. Take action

when this is noted.

In high fire position the flame makes a soft roaring noise. In case the burner makes a loud roaring noise

and the burner globe does not become equal red/orange, the inner burner globe is damaged and the

flame is burning inside the venturi tube (back firing). The venturi tube becomes very hot now behind the

venturi. Directly extinguish the heater and replace the damaged unit by a new one.

Birds and temperature

The following list gives a rough guideline about birds, days and temperature. Realize that this depends

on the conditions in the barn and the kind and the breed of the birds.

Age

Broilers

Turkeys

Guinea fowl

Ducks

(days)

Temp A

Temp B

Temp A

Temp B

Temp A

Temp B

Temp A

Temp B

1 - 3

38

28

40

28

40

28-30

38

28

3 - 7

35

28

37

28

40

28-30

35

27

7 - 14

32

28

34

26

40

28-30

32

25

14 - 21

29

28

31

25

40

28

32

24

21 - 28

-

22-28

30

24

38

28

29

23

28 - 35

-

20-23

27

23

35

28

-

18-22

35 - 42

-

18-23

-

18-22

32

27

-

-

42 - 49

-

17-21

-

-

-

26

-

-

42 - 84

-

-

-

-

-

26

-

-

Temp A = Required temperature under gas brooder in °C

Temp B = Required ambient temperature in °C

Game rearing

Global heaters are used a lot for game rearing. Especially for game rearing, due to the small cages and

active birds, pay a lot of attention to cleaning and ventilation. While the cages are small, the effect of

lack of ventilation and not cleaning will be directly the death of birds in a short time. While normally one

heater is used for one cage, we advise to add an independent temperature alarm system for those

situations where a temperature drop due to a (gas) failure will result in bird loss.

Version: April 2016 11 manual number: 0009 0440EN

Maintenance

General

The frequency of maintenance is strongly depending on the quality of the combustion air and the

intensity of use. When used in poultry houses, maintenance is advised every 6 weeks or by changing

the animals. By use in clean environment conditions, the maintenance period can be extended but not

longer than 6 months. In case heaters are not used for a long period, always do maintenance first before

using them again. Wear safety goggles during cleaning with compressed air.

Parts that are broken, or are not functioning well, must be replaced directly by identical ones of same

brand and type. Consult the dealer or manufacturer in case of doubt.

Order of maintenance

•First clean the heater and filters as described below by daily maintenance. Take the venturi out

during cleaning to remove dust directly behind it.

•Clean the reflector and other parts with water and mild detergent and a cloth or soft brush.

•Carefully inspect the outer and inner burner globes on damage, cracks and holes. Replace when

needed.

•Check the injector for obstructions. Remove obstructions by brushing them away and by using a pin

or drill to clean the injector hole. Make sure that the injector hole does not become wider by using a

pin or drill that is larger than the size stamped on the side of the injector.

•Pay special attention to the dual injection model. (See parts list for numbers). Clean the holes in

injector 44 very carefully. Gas soundness is achieved by a metal to metal connection with part 42.

So keep clean and inspect for damage and avoid making scratches on the contact surfaces of both

parts. Make sure that the small o-ring 47 (4 mm) is still in place in the seat behind the injector and

does not get lost during cleaning.

•Clean the inside of the gas safety device and injector with compressed air. Make sure that the

pressure of the compressed air is not larger than the 1,5x the pressure mentioned on the data plate

(300 till 1400 mbar). Otherwise the rubber seals inside the safety device will become damaged.

•Check the condition of the thermocouple sensor. Replace in case the tip is burnt-in already to avoid

unnecessary shut down later on. The tip of the thermocouple shall be 8 mm below the bottom plate

(27 or 28) of the burner.

•Check all gas carrying parts and connections for gas tightness with leak detection liquid or soapy

water according the procedure in the standards applicable in the local installation situation. Never

use a flame for soundness checks!

•In case a gas hose is used, check this carefully for cracks, wear and other signs of damage or

alteration. Replace it also when the maximum lifetime printed on the hose, or the maximum allowed

by local requirements, has been passed.

•Commission the heater after maintenance and check it carefully during first ignition, firing and

extinguishing.

In case the heaters need to be stored for a long time, make sure that no dust, spiders, etc. can enter the

heater. Use the carton packaging box to store the heater, or a plastic bag if the box is not available

anymore, and close this carefully.

Daily maintenance

In dusty or dirty environments check and clean a heater every day. In case a heater is not cleaned

internally the heat efficiency will drop and the lifetime of the inner and outer burner globe will become

shorter or they will be destroyed. Also there is a possibility that carbon monoxide (poisonous) will be

produced and soot deposit will occur. To keep the heater free of dust is important.

Dust filter (if applicable)

Dust filters must be check every day and cleaned in case needed. Remove a filter before cleaning. Dry

dust can be removed by tapping the filter softly against a solid surface like the sole of a shoe. The dust

will fall off easy now. In case the filter is still not clean, brush the surface gently with a brush or clean it

with compressed air from inside to the outside. In case the dust is greasy, clean the filter in warm water

with a bit detergent. Make sure that filters are dry before placing them back. Even with the use of a filter

still check the heater regularly inside while very fine dust still will pass the filter and pollute the heater

internally.

Advice: Lots of farmers use a second set of dust filters. They replace the dusty ones directly with the

clean ones and clean the filters outside the barn to avoid unneeded disturbance of the animals.

Version: April 2016 12 manual number: 0009 0440EN

Internal cleaning

The internal part of a heater can be cleaned with compressed air or with a tube brush. If needed do this

every day. First clean the outside of the burner globe. Then the inside of the venturi and burner tube

via the dust filter connection. Repeat this 3 times to be sure the dust is removed.

Water

Never wash the heater with water when it is operating or still hot. Do not clean the heater with steam or

chemicals or high pressure jets. The lifetime of the burner globes will go down in those cases. It is

allowed to wash the inside of the venturi and burner globes with low pressure (warm)water from a normal

hose (so not pressurized) to remove greasy dust. Be sure that the burner is completely dry before using

it again. Also make sure that the gas safety device and injector remains dry all the time.

High fire

The lifetime of infrared heaters in a dusty environment will be extended in case these heaters are

operated on high fire every 12 to 24 hours for minimal 15 minutes. This burns off dust in the burner that

accumulates during low-fire operation. This is only needed in case heaters operate on lower setting for

a longer period. When a barn computer is used for heating and ventilation, it will be easy to modify the

program to add a 15 minutes high fire operation every day. In case a mechanical thermostat TH is used

a solution can be to put the sensor for 15 minutes in a bucket with cold water during daily inspection of

the barn.

Version: April 2016 13 manual number: 0009 0440EN

Fault finding table

Trouble

Action

Burner does not light.

•Check if gas valve of the gas cylinder or gas line is open

•Check if gas cylinder is empty

•First ignition will take up to 60 or more seconds before gas is available

•Check if the injector is blocked

•Check if the gas pressure/gas quality is identical to the pressure

indicated on the data plate

Burner extinguishes after

lighting

•Keep button safety device pressed for a longer period (up till 25

seconds)

•Check if the thermocouple is connected properly to the gas safety

device

•Check if the thermocouple tip is 8mm under the bottom plate (27 or 28)

Thermocouple or magnetic coil of the safety device is broken.

•Gas pressure lower than minimum requested

•Heater not suspended at 15 degrees angle

Flames leave the

- confines of

the burner,

- or are

sooting, - or a blue

cloud is under the

reflector

•Gas pressure is too high. Check the gas pressure with the data

plate Check if the gas pressure regulator is broken.

•Wrong gas is used. Check data plate for the correct gas supply

•Venturi/air inlet is blocked/dirty

•Valve dual injection model DI is leaking

•Check the size of the venturi and injector with the table

•Not enough fresh air available due to mounting situation

•Air filter is dirty

•Heater not suspended at 15 degrees angle

•Small o-ring (47) DI is missing or leaking

The burner is only partly

glowing

•Wrong gas or pressure is used. Check data plate with the gas supply

•Check if the injector or venturi are blocked or dirty

•Check the injector and venture size with the table

•Check if pipe sizes or gas hoses have sufficient capacity

•Check the setting of the thermostat

•Valve dual injection model DI is blocked

The burner makes a lot

of noise after ignition or

after several minutes

•Wrong gas is used. Check data plate with the gas supply

•Check if the inner globe is broken or damaged so the flame burns

inside the venturi tube

The burner do not work

at minimum position

•Gas pressure is not correct. Check the gas pressure with the data plate

•Wrong gas is used. Check data plate for the correct gas supply

•Check the size of the venturi and injector with the table

•Sensor or wire thermostat TH is broken

•Thermostat TH valve adjusting mechanism is blocked

•By-pass hole thermostat TH or solenoid valve MK is blocked

•Injector (partly) blocked

•Centre hole dual injector DI is blocked

•Check if the thermocouple tip is 8mm under the bottom plate (27 or 28)

Heater will not attain the

desired temperature

•There is insufficient heat in the building for heat loss (i.e., not enough

brooders).

•The thermostat TH sensing bulb is incorrectly placed

•The thermostat TH is out of calibration or broken

•The solenoid valve MK is not functioning

•One of the two holes of the dual injector DI is blocked Injector

partly blocked

Version: April 2016 14 manual number: 0009 0440EN

Parts list

The parts list below is a combination list of both Global 5 and 8 models. Most parts of both models are

identical. Parts that differ are specified with the Global model identification. Consult the data plate to

determine the model you have before using this list.

No. Part # Description

No.

Part #

Description

1

08896000

Venturi tube

28

02222000

Bottom plate SS (Global 5)

2

013080xx

Venturi 30x75-consult factory

29

08892000

Distance tubes SS

3

07426010

Nut M5 SS

30

07073000

Blind rivet nut M4

4

07850000

Eye bolt M5x15x8 SS

31

02226000

Top plate SS (Global 8)

5

01813000

Connection piece complete (Global 8)

32

02223000

Top plate SS (Global 5)

6

01811000

Connection piece complete (Global 5)

33

07781000

Toothed spring washer M5

7

07135000

Screw M5x10 SS

34

07426010

Nut M5 SS

8

01161xxx

Injector M8x0,75-consult factory

35

01381000

Nut M8x1

9

01301000

Injector holder

36

07845000

Eye bolt M4x15x6

10

07005000

Distance ring

37

07401000

Nut M4

11

01405000

Reducing ring ⅜”x ⅛” (TH)

38

07800000

Washer 4,3 mm

12

0092xxxx

Thermostat assembly-consult factory (TH)

39

02530000

Filter small 80x90mm

13

01429000

Reducing nipple ⅛” x ⅜” (TH)

39a

02533000

Filter large 80x180mm

14

07000000

End cap, black PVC

40

01803000

Double filter connection piece (DS)

15

01327000

Hose nipple 8 mm

41

01360000

Nipple ⅛”x ⅛” (DI)

15a

01328000

Hose nipple 8 mm, smooth

42

01812021

Insert part connection piece (DI)

16

00101000

Gas safety device ⅛”

43

07135005

Screw M5x12 SS (DI)

16a

00106000

Gas safety device with hose nipple

44

0128601x

Dual Injector-consult factory (DI)

17

00158000

Safety device nut M8x1

45

01812020

Housing connection piece (DI)

18

00202000

Thermocouple M8x450mm Alu

46

01368xxx

Valve assembly (DI)-consult factory

19

02354000

Reflector SS (Global 5)

47

81113017

o-ring 2x1mm (DI)

20

02355000

Reflector SS (Global 8)

48

81113013

o-ring 7,5x1,5mm (DI)

21

07065000

Blind rivet bolt M4

49

01400000

Reducing ring ¼”x⅛” (MK)

22

02527000

Burner globe large SS (Global 5)

50

01421000

Reducing nipple ⅛”x¼” (MK)

23

02525000

Burner globe large SS (Global 8)

51

03028000

Electric connector complete (MK)

24

07734000

Bolt M5x30 SS

52

00612000

MK solenoid valve 24VAC complete (MK)

25

02224000

Mounting ring SS

53

00611000

MK solenoid valve 230VAC complete (MK)

26

02524000

Burner globe small SS (Global 5,8)

54

00698010

MK coil 24VAC (MK)

27

02225000

Bottom plate SS (Global 8)

55

00698000

MK coil 230VAC (MK)

12005000

Burner replacement kit Global 5

(set of parts: 1, 21, 23, 24, 25, 26, 28, 29,

30, 32, 33, 34)

12006000

Burner replacement kit Global 8

(set of parts: 1, 21, 22, 24, 25, 26, 27, 29,

30, 31, 33, 34)

Technical table

Category

Gas

Maximum

Supply

pressure

Minimum

Supply

pressure **

Maximum

Heat Input

Minimum

Heat Input

Gas

consumption

Main

Injector

By-pass

hole

**

Venturi

Ring

Injector

Holder

Weight

Remarks

(-) (-)*

(mbar)

(mbar) (kW Hs)

(kW Hs)

(g/h or m3/h)

(mm)

(mm)

(mm)

(-)

(kg)

(-)

Global-5 series

I2H, I2E

G20

300

10

5,2

0,87

0,50 m3/h

0,77

-

13

0

2,2

I2H, I2E

G20

300

20

4,8

0,63

0,46 m3/h

0,60/0,59

0,31

12

-

2,3

DI

I3P

G31

300

20

4,6

0,60

330 g/h

0,50/0,47

0,24

18

-

2,3

DI

I3P

G31

1000

20

5,7

0,80

410 g/h

0,52

0,25

10

4

2,2

I3P

G31

1400

20

4,6

0,55

330 g/h

0,45

0,25

11

4

2,2

(>1200 m)

I3P

G31

1400

20

5,6

0,65

400 g/h

0,47

0,22

10

4

2,2

0063AT3389

I3P

G31

1400

20

5,6

0,65

400 g/h

0,47

0,22

12

4

2,2

DS

I3B/P

G30

1000

10

5,1

0,50

370 g/h

0,47

-

11

4

2,2

Biogas

BG

100

5

5,1

0,90

0,74 m3/h

1,55

0,75

10,5

4

2,2

Global-8 series

I2H, I2E

G20

300

50

8,8

3,6

0,84 m3/h

1,05

-

15

6

3,7

I2H, I2E

G20

1400

20

8,5

1,0

0,81 m3/h

0,70

-

10

4

3,7

(air=4x17mm)

I3P

G31

300

100

8,0

4,6

570 g/h

0,83

-

16

7

3,7

I3P

G31

1400

20

8,7

1,0

640 g/h

0,59

0,28

13

6

3,8

DS

I3P

G31

1400

20

8,7

1,0

640 g/h

0,62

0,28

13

6

3,8

0063AT3389

I3P

G31

1400

20

8,7

1,0

620 g/h

0,58

0,28

14

6

3,8

(>1200 m)

I3P

G31

2000

20

8,8

0,8(TH=1,4)

630 g/h

0,53

0,22

12

6

3,8

I3P

G31

2000

20

8,8

0,8(TH=1,4)

630 g/h

0,53

-

13

6

3,8

DS

* G31 = propane, G20 = natural gas (100% methane), BG = 60%CH4, 40%CO2

** In case the heater is equipped with a bypass hole (TH, THi or MK version) the heater shall be operated on maximum supply pressure only. See also the

pressure information on the data plate

Electric ratings solenoid valve MK: 24VAC - 50/60Hz - 1Amp - 24VA - IP44

230VAC - 50/60Hz - 0,13Amp - 24VA - IP44

Declaration of conformity

We, Alke B.V., located in Scherpenzeel, The Netherlands, hereby declare that the Global 5 and 8 series, marked on their dataplates with CE and with CE

approval/production supervision by Kiwa Gastec (number 0063) are in compliance with the following EU directive: - Directive on appliances burning gaseous

fuels (2009/142/EC) (ex 90/396/EEC)

Scherpenzeel, 01-01-2010

Adri van Alphen Derk Jan Keurhorst

Managing Director Managing Director

This manual suits for next models

1

Table of contents

Other Alke Heater manuals

Popular Heater manuals by other brands

Pinnacle International

Pinnacle International HH-125-OFR-A User's manual and operating instructions

DeLonghi

DeLonghi TRN0812T user manual

L.B. White

L.B. White Tradesman CP400 Owner's manual and instructions

Daikin

Daikin KEH041A41 installation manual

SKF

SKF TMBH 5 Instructions for use

Prem-I-Air

Prem-I-Air C307 instruction manual

Propex

Propex COMPACT 1600W X1 operating instructions

Black & Decker

Black & Decker HX230 Original instructions

Rowi

Rowi HQH 1500/3/2 operating instructions

EOS

EOS Mega S HD Installation and operating instructions

camry

camry Premium CR 7724 user manual

Space-Ray

Space-Ray LTS 100 Installation and operation instructions