Version 1: December 2020 10 manual: 0009 0251EN-Alke

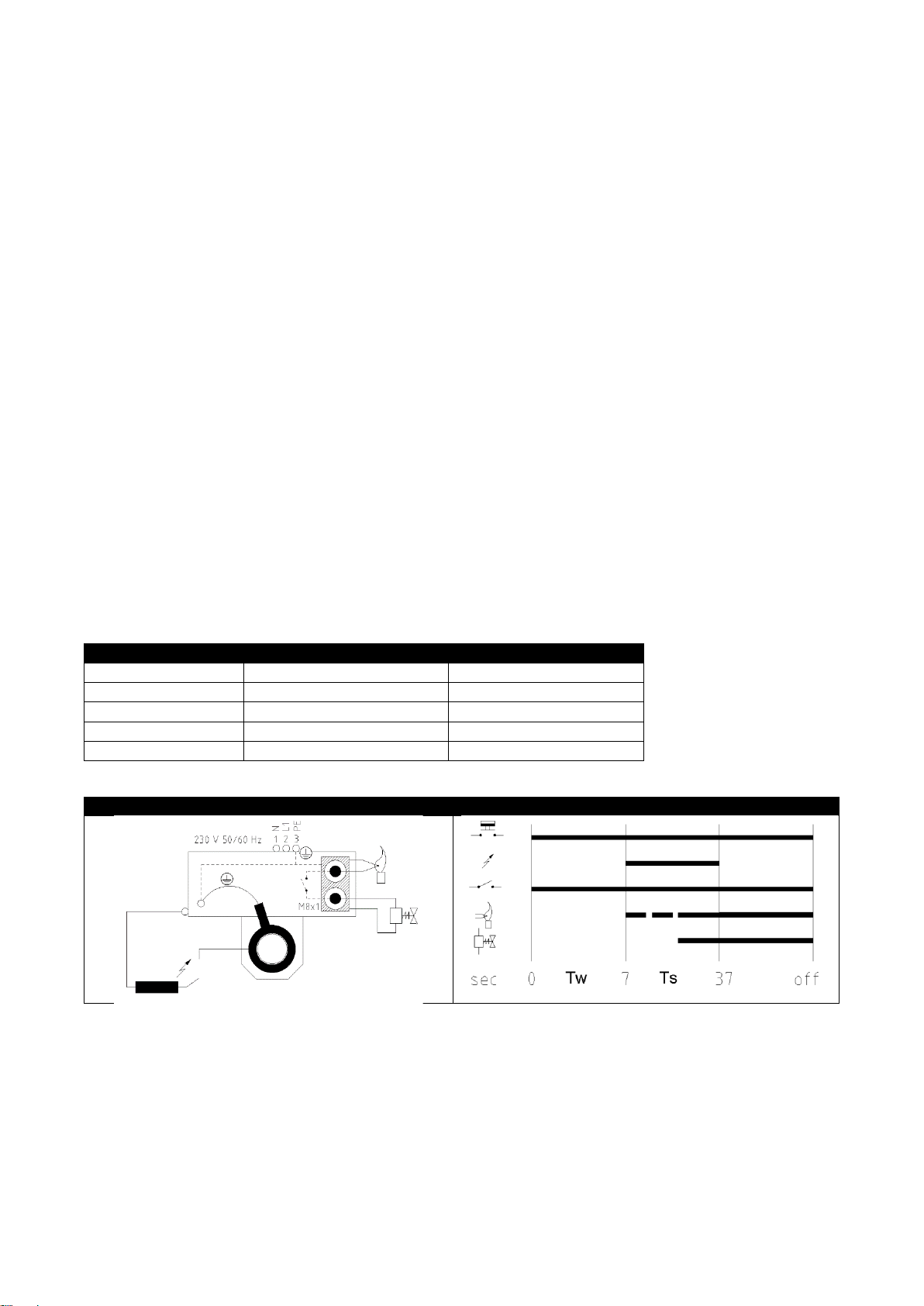

How to check correct operation of the burner

Directly after ignition the burner flames are blue (difficult to see during daylight). After 15 seconds the ceramic

burner stone starts glowing and becomes red/orange. After 2-5 minutes the heater reaches the maximum heat

output. During normal functioning, the ceramics are glowing red/orange. The burner gauze (20) in front of the

ceramics will be a bit red, but flames (blue or yellow) shall not appear outside the gauze. The burner shall only

make a soft buzzing noise. Other noises or roaring noise indicates that cleaning or maintenance is needed.

Note: during pre-heating (or cooling down) the heater can make a ticking noise. This is created by the expansion

of the material during the temperature change and is not harmful for the heater.

What to do if the heater is not used for a period of time

The heater can stay in place when it will not be used for a period of time. Close all gas valves. When the heater

is mounted in a location protected against wind and rain, no other protection is needed. In case the heater will

become wet by rain or snow (combined with wind) it is better to protect the heater outside the season with a

plastic bag or otherwise. This also protects against dirt.

Take into account the local requirements for long-time storage of the gas bottles out of season. In most places

it is only allowed outside in a protected location or in a well ventilated area. The local fire department,

environmental department of the municipality or gas supplier can inform you about the regulations.

Note: a wet heater can be damaged by frost

Note: do not forget to remove the protection material before using the heater again

7. Cleaning, maintenance and servicing

General

Always shut off the gas valve and disconnect electricity before maintenance or service is done on the heater.

General maintenance and service shall be done at least once a year before the heating season starts or after

a long period the heater is not used. Parts that are broken, or are not functioning well, must be replaced directly

by identical ones of same brand and type. Consult the dealer or manufacturer in case of doubt.

Dust filter (Optional)

Optional dust filters must be checked a few times during the heating season and cleaned in case needed.

Remove a filter before cleaning. Brush the surface gently with a brush or clean it with compressed air from

inside to the outside. In case the dust is greasy, clean the filter in warm water with a bit detergent. Make sure

that filters are dry before replacing them. For heaters with a dust filter still check the venturi (14) inside regularly

while very fine dust still will pass the filter and pollute the heater internally.

Order of maintenance

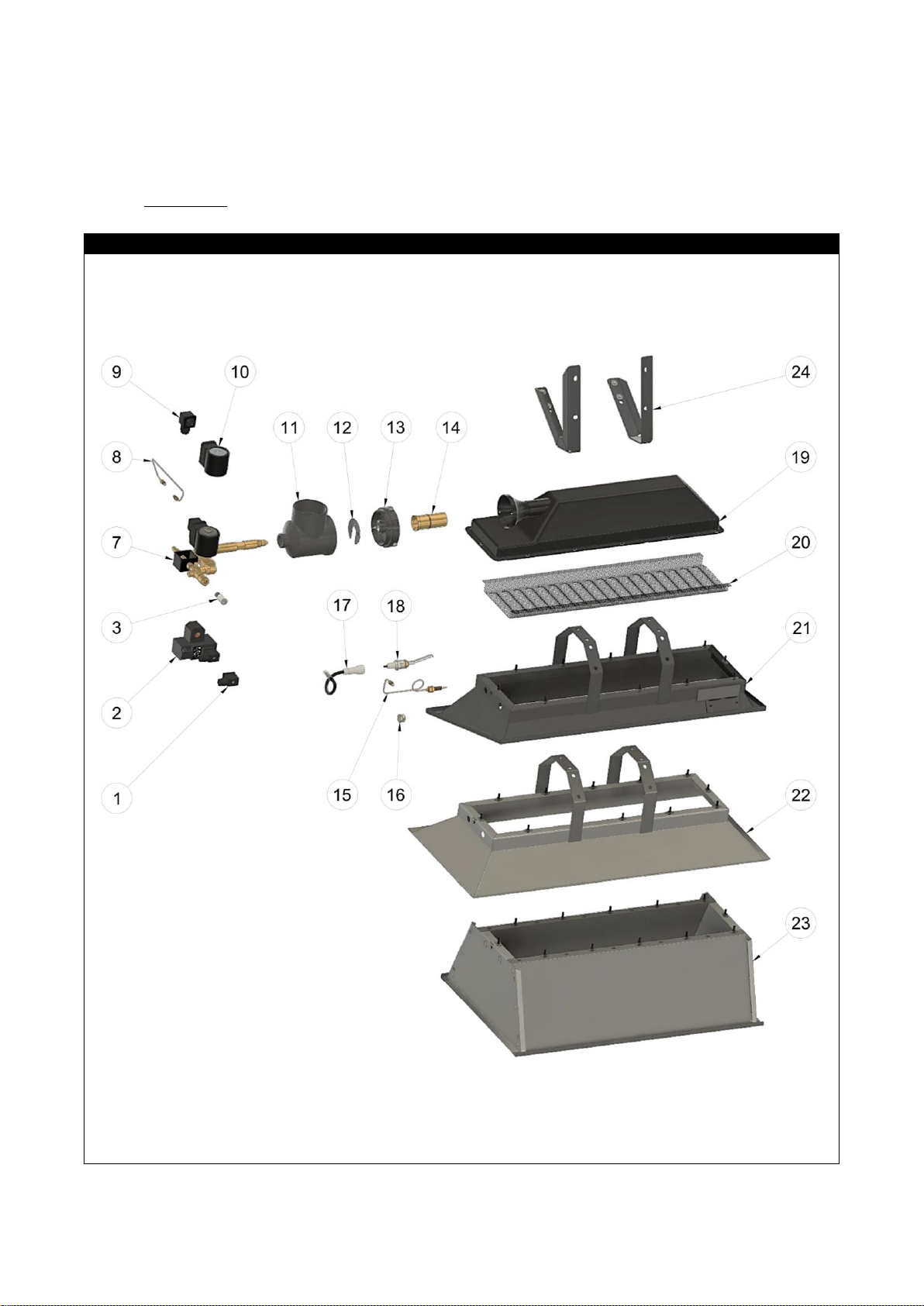

•First clean the heater (and the optional filters) as described above.

•Clean the reflector (21, 22, 23) and other parts with water, mild detergent and a cloth or soft brush.

•Clean the inside of the venturi (14) and burner tube via the connection piece (11) with compressed air and

a tube brush. Repeat this 3 times to be sure that all the dust is removed.

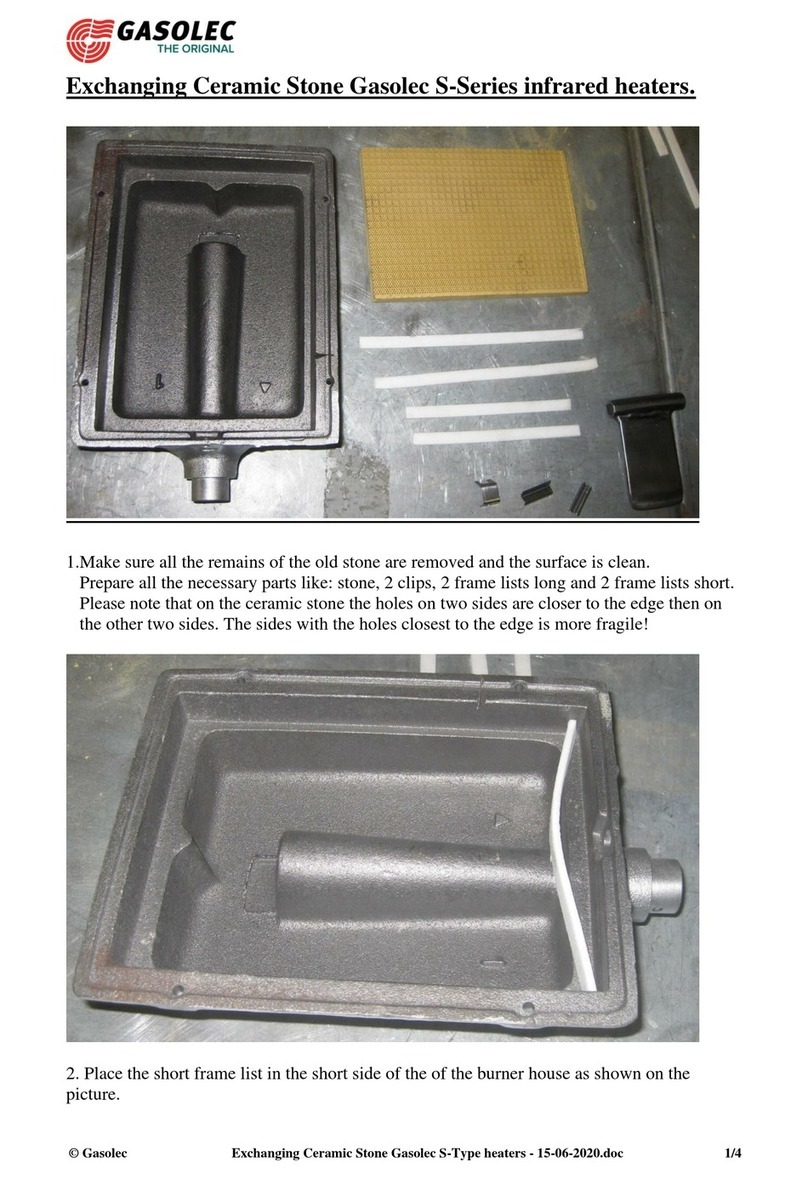

•Carefully inspect the burner ceramics on damage, cracks and holes and if they are still mounted properly.

Replace when needed. To clean the burner ceramics, use low pressure air. Clean first the ceramic stones

with air from the front side through the gauze. Then clean the inside of the burner with air via the venturi

tube. Do not use compressed air above 2 bar because higher pressure will damage the ceramic stones.

Never clean the burner stones with water.

•Check the gas injector for obstructions. Remove obstructions by brushing them away and by using a pin or

drill to clean the injector hole. Make sure that the injector hole does not become wider by using a pin or drill

that is larger than the size stamped on the side of the injector.

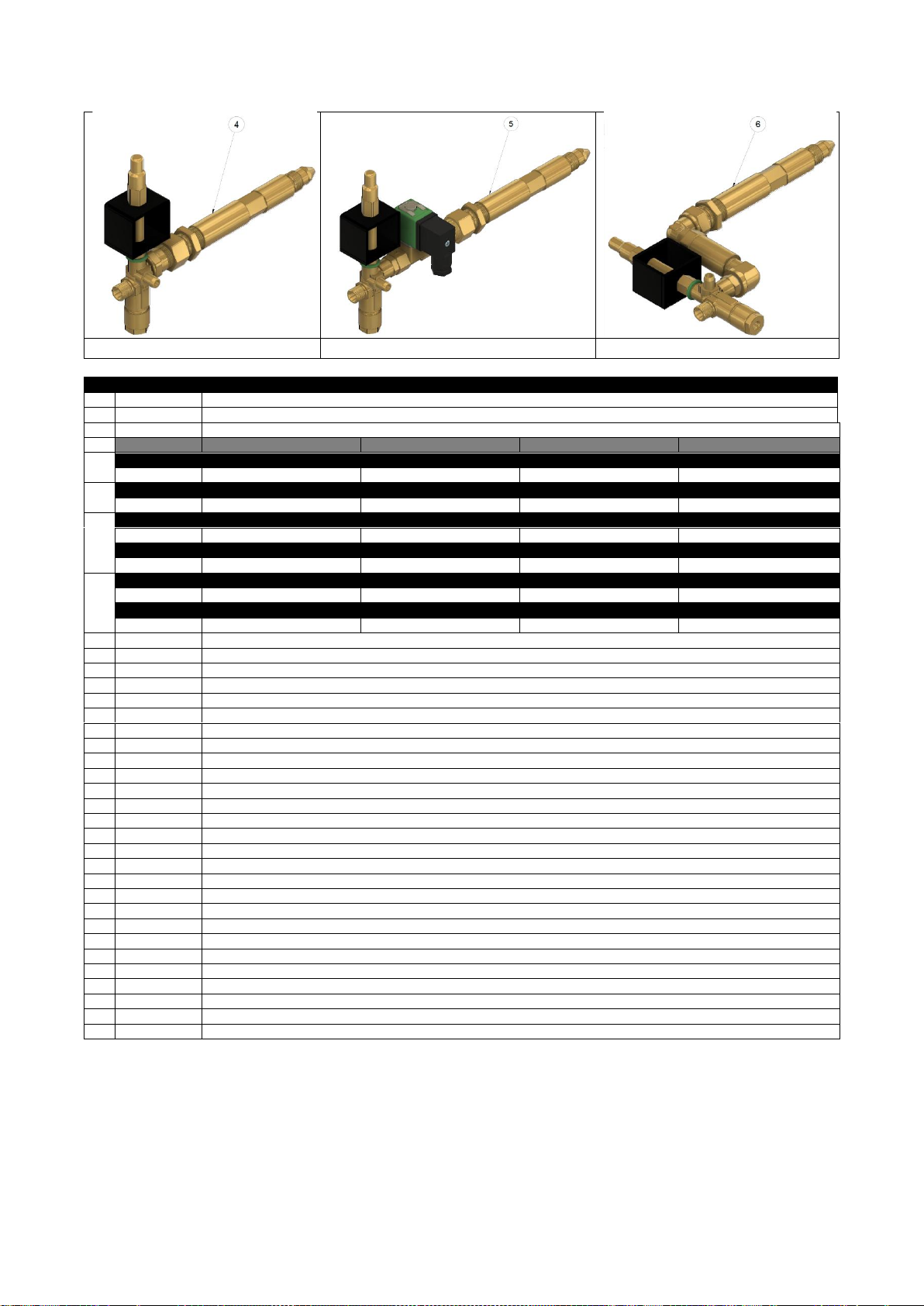

•Clean the inside of the gas safety device (4, 5, 6 or 7) and injector with compressed air. Make sure that the

pressure of the compressed air is not higher than the 0,5 bar. Otherwise the rubber seals inside the safety

device will become damaged.

•Check the condition of the thermocouple tip (15). Replace in case the tip is burnt-in already to avoid

unnecessary shut down later on. See additional information for the location of the thermocouple.

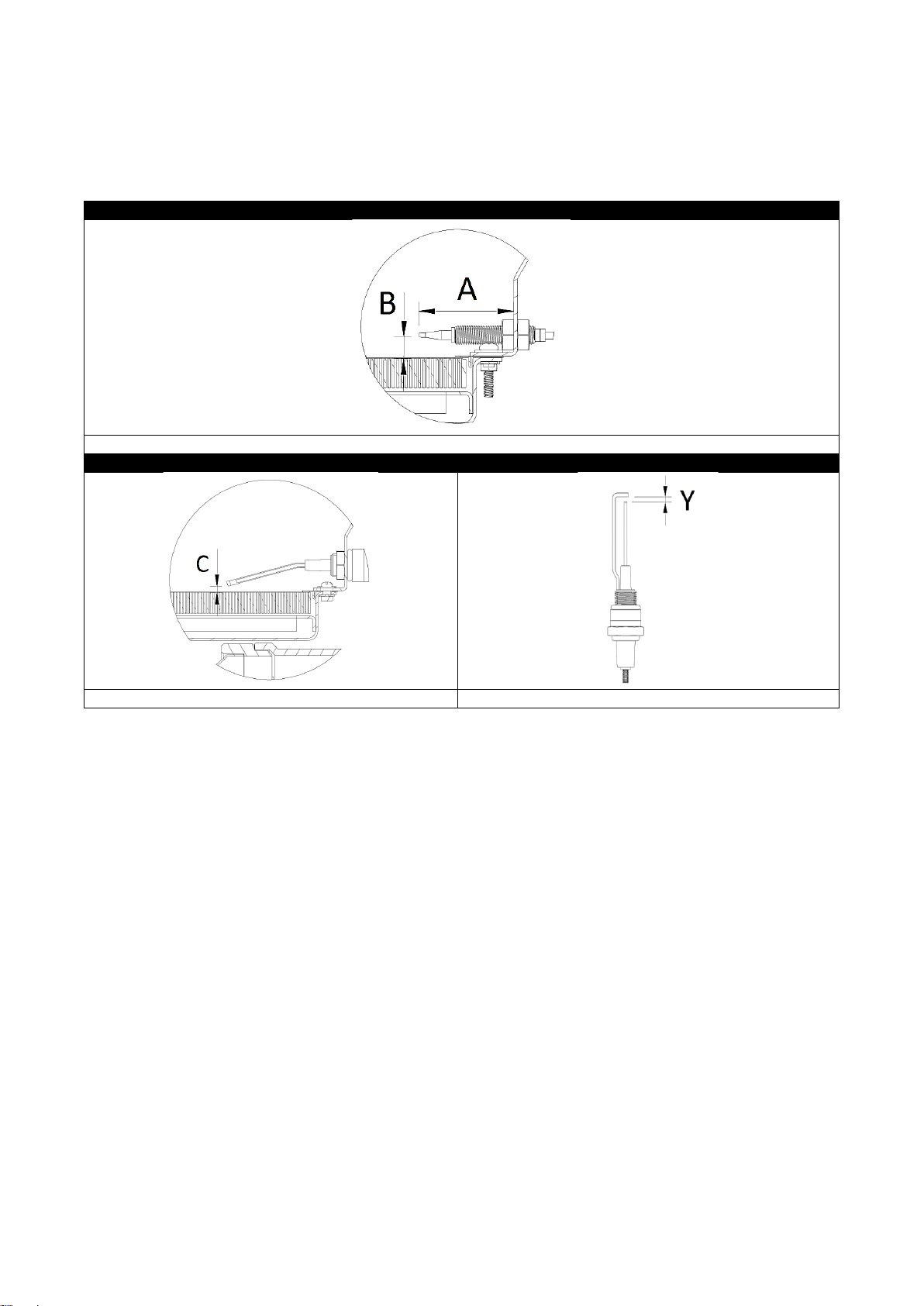

•Check the condition of the spark plug (18); no cracks of the ceramic and a spark gap of 3-4 mm. Check if

the metal spark wire and earthing wire still makes a 15 degrees angle directly above the ceramics and are

not bending away to smaller angles. Clean the electrodes with grinding paper in case they are corroded.

•Clean the ignition device and check the connection of the ignition wire for proper contact and waterproofing.

Check if the ignition wire is not damaged and has no cracks.

•Check all gas carrying parts and connections for gas tightness with leak detection liquid or soapy water

according the procedure in the standards applicable at the local installation situation. Never use a flame for

soundness checks!