All Power Labs PP30 User manual

PP30 Operation Manual

PP30 Cogeneration System

Table of Contents

1. Technology Foundations 3

2. Power Pallet Crate Contents 6

3. Safety Procedures 7

4. Required Tools 8

O&M Tool List (Required) 8

Technician Tool List (Nice to Have) 9

5. Power Pallet Set Up 10

5.1. Facility Requirements 10

5.2. Connecting to Loads 12

5.3. Connecting to the Grid 12

6. Feedstock Requirements 13

7. Operating Procedures 16

7.1. PP30 Engine Pre-Start Duties 16

7.2. PP30 Gasifier Prestart Duties 22

7.3. PP30 Gasifier-Engine Startup 30

7.4. PP30 Shutdown 33

7.5. Refilling the PP30 36

8. Maintenance Schedule 37

9. Spare Parts 39

10. Service Record Form 40

2 of 41

FILE-004209 - Power Pallet Operation Manual (PP30)

1. Technology Foundations

Gasifier Supersystem (gasifier Module)

- The gasifier system

Power Generation Supersystem

- Power generation system

Combined Supersystem

- Power generation supersystem

- The gasifier supersystem

3 of 41

FILE-004209 - Power Pallet Operation Manual (PP30)

4 of 41

FILE-004209 - Power Pallet Operation Manual (PP30)

5 of 41

FILE-004209 - Power Pallet Operation Manual (PP30)

2. Power Pallet Crate Contents

1. Power Pallet Gasifier System

2. Power Pallet Generator System

3. Charcoal for first start of reactor

4. CO Monitor

5. Basic Tool Assortment

6. Set of Essential Spares

7. Miscellaneous supplies for maintenance operations

6 of 41

FILE-004209 - Power Pallet Operation Manual (PP30)

3. Safety Procedures

CAUTION: Operator must wear

personal protective equipment when

operating this machinery.

● Whenever filling or emptying

feedstock or char a mask appropriate to

protect against fine particulates must be

worn.

● Read all instructions and

documentation carefully before operating

or servicing.

● Service or operate only in a well

ventilated area.

● All vessels contain high

concentrations of toxic Carbon

Monoxide (CO) gas even when cool.

● Keep supplied CO alarm nearby

when operating or servicing.

● Do not service until machine has

been purged as described in section

7.3 of this manual.

● Do not service while machine is in

operation.

● Allow reactor to cool to room

temperature before servicing.

7 of 41

FILE-004209 - Power Pallet Operation Manual (PP30)

4. Required Tools

O&M Tool List (Required)

The following tools are required to perform regular Power Pallet O&M activities.

● Gas line wire brush

● 7mm wrenches

● 8mm wrenches

● ½” sockets and wrenches

● 9/16” sockets and wrenches

● 7/16” deep sockets

● ¾” wrenches

● ⅞” wrenches

● 9/64” Allen/hex wrench

● Allen/hex wrenches various sizes

● Crescent wrenches various sizes

● Phillips screwdriver various sizes

● Flathead screwdriver various sizes

● Scissors

● Sharpies or permanent marker alternative

● Blue paper tape

● Electrical tape

● Propane Torch

● Teflon pipe tape

● Denatured alcohol

● Paper towels

● Graphite paste

● ⅛” graphite rope

● ⅜” graphite rope

● Windows Computer

● Scale for measuring weight of fuel

● ½” pipe tee for lighting

● 12’ ladder

● 6x ~30 gal trash cans or equivalent for fuel loading

● 2x - 3x Carbon Monoxide Sensor

● ABC Fire extinguisher

● Water Hose

● Fork lift

● Big Wipes Heavy Duty Textured Scrubbing Wipes

8 of 41

FILE-004209 - Power Pallet Operation Manual (PP30)

Technician Tool List (Nice to Have)

The following tools will allow more complex Power Pallet O&M activities.

● Pliers

● Needle nose pliers

● Wire strippers

● Crimpers (ABCDE kind)

● Wire cutters

● Timing Light

● Voltmeter

● Cables/dongles for connecting computer to PP to load firmware

● Firmware

● Configuration tools

● DSE Software

● Tunerstudio Software for MS3 Pro

9 of 41

FILE-004209 - Power Pallet Operation Manual (PP30)

5. Power Pallet Set Up

5.1. Facility Requirements

The facility to house the power pallet must have the following characteristics:

● Level flooring made of non-flammable material capable of supporting the weight of the

machine (listed in the Specifications section).

● Facility must have a covered location to protect the power pallet from direct rain or water,

as some aspects of the system are not water/weather resistant.

● The system is to be installed with a 92 cm clearance around the footprint of the machine

and at least a 173 cm clearance above the machine. See illustration on the next page.

● Sufficient ventilation through an exhaust hood with air flow capacity adhering to local

regulations.

● Install the CO meter provided with the power pallet and verify that it functions properly.

Have a CO meter near the operating floor at all times even when the machine is not in

operation and especially when performing maintenance.

● Operate the power pallet in locations having a max temperature of 40 °C and at an

altitude of 1000m or less. The power pallet’s power output will be derated at higher

altitudes. In case of different conditions, please consult ALL Power Labs.

● Install the PP30 out of direct sunlight. UV from sunlight will damage parts over time.

10 of 41

FILE-004209 - Power Pallet Operation Manual (PP30)

11 of 41

FILE-004209 - Power Pallet Operation Manual (PP30)

5.2. Connecting to Loads

•Hook up the cam lock connections to an off load system you want to send

power to that is within the power pallet electricity load range. (5-25 kW)

• Press Close Generator button to close the contactor and start sending power to

an external load.

5.3. Connecting to the Grid

• Connect cam locks to interconnection point with grid.

• Press Close enerator button to close the contactor and start generator

synchronization process with the grid. If generator does not synchronize, please

look at technician manual for troubleshooting steps.

12 of 41

FILE-004209 - Power Pallet Operation Manual (PP30)

6. Feedstock Requirements

For your gasifier to operate properly, you must use the correct biomass feedstocks which have

been properly prepared and sifted. Certain material shapes and sizes flow better in solid

material handling systems. For example, long stringy pieces, similar to toothpicks, do not flow

well, as they get stuck in feeds. Materials in circular shapes such as walnut shells or macadamia

nut shells flow well.

Feedstock biomass must be dry, of the correct shape and size to flow through the reactor, and

free of dust, sand and contaminants:

●Particle size: 1 cm – 4 cm (0.5 in. – 1.5 in.)

●Moisture content (% by dry weight): 5% – 30%

●Ash content <5%

The following Table of Feedstocks shows the most common ones that have been tested and are

known to work, which ones are known to be unusable, and which ones need more testing. For

more information on fuel preparation, contact APL For more information on fuel preparation,

contact APL.

LEGEND

Green

Known to work with standard operations and maintenance

effort

Yellow

Known to work with increased operations and maintenance

effort

Grey

Not enough testing to approve at this time. Use voids warranty

Red

Known to not work. Use voids warranty.

13 of 41

FILE-004209 - Power Pallet Operation Manual (PP30)

Feedstock

Notes

Wood Chips (e.g: Oak, Rubber,

Pine)

Use only chips; chunks or long shards can bind au ger

or bridge in the reactor

Nut Shells (e.g: Coconut, Walnut,

Hazelnut)

Not all shells will work, please contact us to discuss

your particular feedstock

Corn Cobs

Must be broken to size and must not include husks.

Increased chance of slagging

Palm Kernel Shells

Risk of high temperatures. May need to be blended or

other steps taken to lower temperatures

Macadamia Nut Shells

Excellent shape, not enough testing

Cashew Nut Shells

Known toxicity, not enough testing

Wood Pellets

May work depending on size & makeup, pellets prone

to decompose

Coffee Grounds

Too fine for physical compatibility, pelletization may

allow use

Saw Dust

Too fine for physical compatibility, pelletization may

allow use

Corn stover

High ash content; silica content leads to slag

Rice Husk

High silica content leads to slagging

Bamboo

Difficult to prepare to correct size and shape

Grasses: Switchgrass, Miscanthus,

etc.

High silica and low bulk density.

Paper, Sugarcane Bagasse,

Coconut Husk

Shapes not physically compatible

14 of 41

FILE-004209 - Power Pallet Operation Manual (PP30)

Municipal Solid Waste/Trash

Slag risk; heavy metals; plastic content not suitable

Coal

Burns too hot, releases sulfur and heavy metals

Plastics

Melts and fouls auger/reactor

Manure: Cow, Pig, Chicken, etc

High slag, low energy density

Tires

Not chemically compatible

15 of 41

FILE-004209 - Power Pallet Operation Manual (PP30)

7. Operating Procedures

The following procedures assume that the Power Pallet has been assembled and installed

correctly. Training by a certified APL trainer is recommended before operating the PP30 for the

first time. For a list of all parts of the Power Pallet including a list of parts, definitions and all

other useful information see the PP30 Component Reference document.

7.1. PP30 Engine Pre-Start Duties

Power Generation Supersystem

1. Check DC battery voltage is over 12V (DSE->Engine->Battery Voltage)

a. Turn the the Power Pallet on by flipping the power switch up (Image 1)

Image 1

b. Starting from the Status screen press right arrow one time to get to the screen to

Engine screen (Image Set 2)

c. Then press down arrow 4 times to get to Engine Battery Voltage screen

d. If voltage is under 12V, connect and power on-board or external battery charger

16 of 41

FILE-004209 - Power Pallet Operation Manual (PP30)

Image Set 2

2. Check radiator coolant level and refill if needed (see PP30 Engine Check for fill instructions)

WARNING: Do not open the radiator cap when the unit is hot

Image Set 3

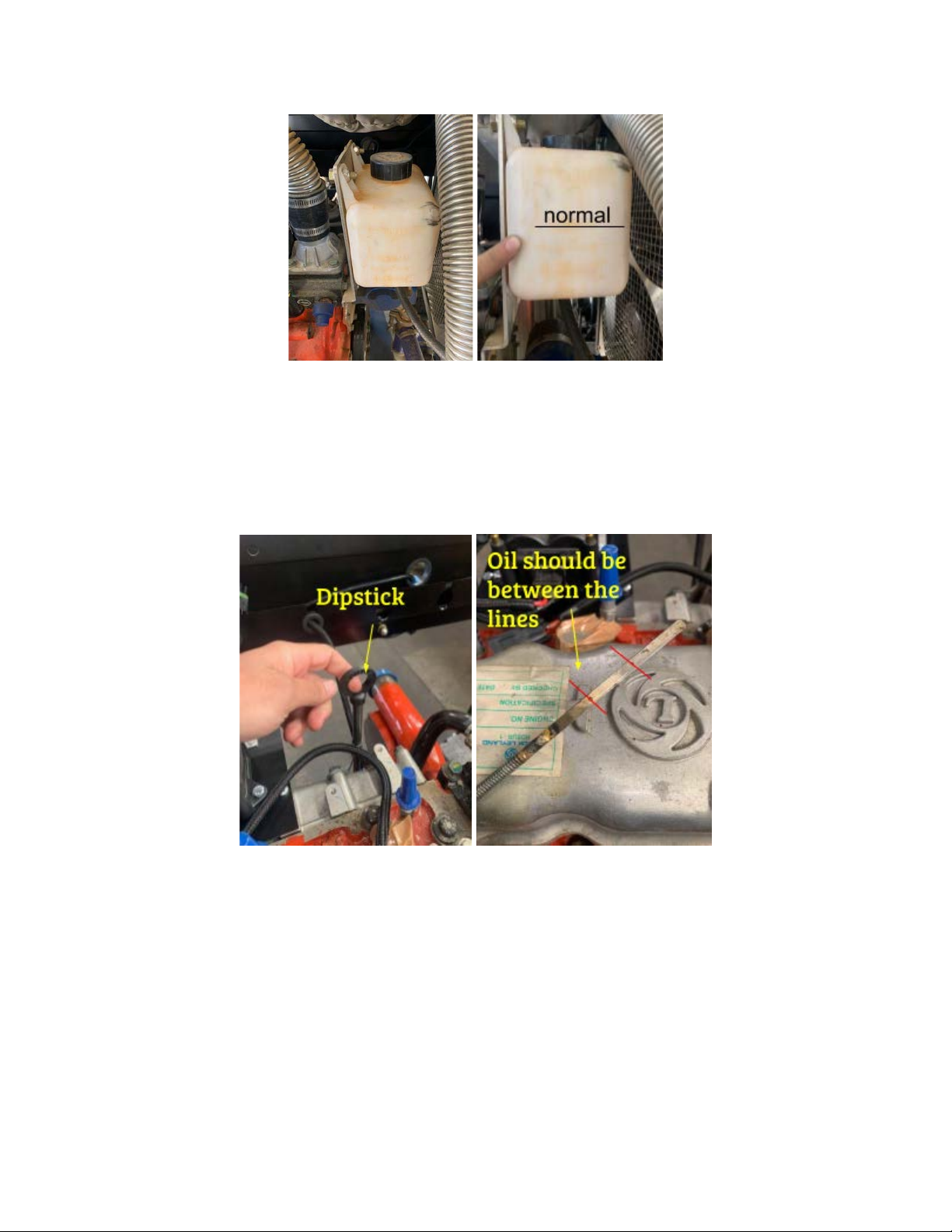

3. Check expansion tank fluid and refill if necessary (Image Set 4)

a. Fluid should reach the Normal line indicated in the picture

i. if it is below this line, fill up to the line

17 of 41

FILE-004209 - Power Pallet Operation Manual (PP30)

Image Set 4

4. Check engine oil level and refill if necessary (See PP30 Engine Check for fill instructions)

a. Pull the dipstick and clean it. Reinsert and pull it again and then check to see if

the oil is between the marking on the dipstick

b. If the oil level is low, add oil according to SOP

Image Set 5

5. Check Governor (Image Set 6)

a. Unplug the governor

b. Remove sanitary clamps and gaskets

18 of 41

FILE-004209 - Power Pallet Operation Manual (PP30)

Image Set 6

c. Physically check if the governor throttle plate moves freely (Image 7)

i. When pressed all the way open the throttle plate should close all the way

on its own with a snappy motion

Image 7

d. If check fails, clean governor (see PP30 Engine Check for cleaning instructions)

e. Re-install governor using sanitary gaskets and clamps and plug back in

19 of 41

FILE-004209 - Power Pallet Operation Manual (PP30)

i. Make sure to clean gaskets of tar and dirt before installation by wiping

them with a paper towel

ii. Ensure that the governor plug is facing downwards when you install it

Image Set 8

6. Check Polishing filter (Image 9)

a. Remove V-band clamp and sanitary clamp from lid and pull out the polishing filter

Pliers can help with the removal of the filter element

Image Set 9

b. Remove and inspect filter element (Image Set 10)

i. Inspection fails if the polishing filter

1. Appears dark black with no yellow on the far said

2. Is noticeably wet

20 of 41

FILE-004209 - Power Pallet Operation Manual (PP30)

Other manuals for PP30

3

Table of contents

Other All Power Labs Industrial Equipment manuals