2XL-AA20023TS-en-US Rev A · 2019-04-04 · Amendments and Errors Reserved · © SAF-HOLLAND, Inc., SAF-HOLLAND, HOLLAND, SAF,

and logos are trademarks of SAF-HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

Troubleshooting Guide

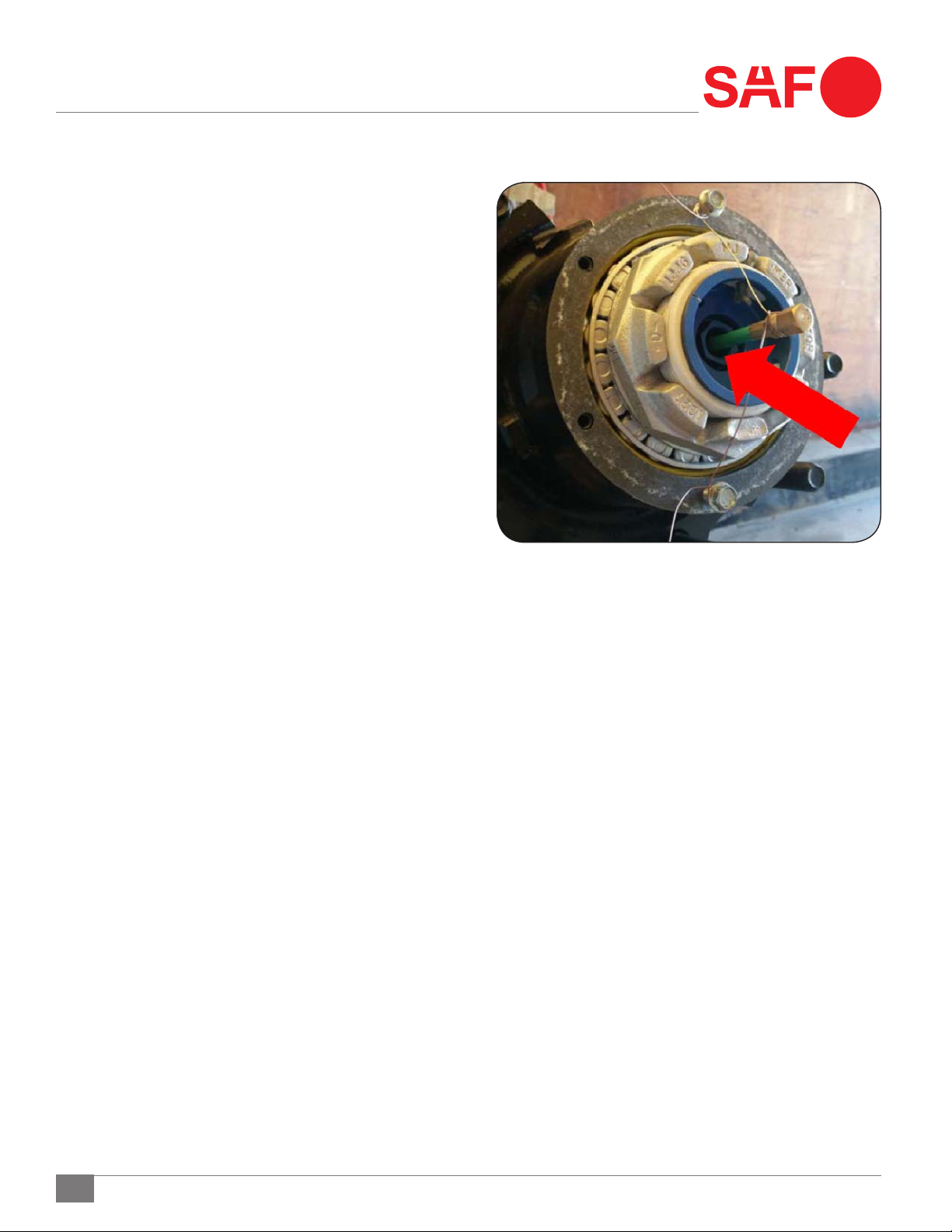

Figure 3

Symptom:

Air leaking from axle vent

Problem:

Air leak inside the axle or air leak inside the hubcap.

Solution:

Try to listen for the air leak on each side of the axle, and start

with the side that is the loudest. Relieve system pressure by

shutting off the air system valve. Relieve the system pressure at

the tire hose or hubcap. Remove the hubcap and the rotating

shaft from the hub cap and wire it to the hub using two hubcap

bolts as illustrated in Figure 3. Cap the rotating shaft end with

a 1/8" NPT cap as illustrated in Figure 3. Turn air system valve

on and allow pressure to build. Spray soapy water on the spindle

plug to rotating shaft seal. Replace spindle plug and rotating

shaft if leak is present around seal. If bubbles are present around

the two holes in the spindle plug for the vent, then the leak is

internal to the axle. Proceed with removing the spindle plug. The

spindle plug can be removed by using an appropriate size pipe

inside the hex of the spindle plug and applying force up and

down until free. Check connections and check airline. Repair or

replace as per procedures below.

Symptom:

Air leaks at spindle plug fittings.

Problem:

Fitting nut not tight, tubing cut by the fitting nut, or tubing

not pushed into the fitting far enough.

Solution:

If compression type fitting, tighten nut to 6-10 in-lbs or hand

tight plus two wrench flats if loose. For damaged tubing,

remove tubing from fitting and cut off just above leaking cut.

If damage is not present, re-insert tubing into fitting. For a

loose connection, loosen fitting nut and push tubing further

into fitting then retighten nut to 6-10 in-lbs or two wrench

flats. If push-to-connect type fitting, remove by pushing

outer ring toward fitting and pull air line free. Inspect air line

end. Recut square and push firmly into fitting until air line

bottoms out.

Symptom:

Brake air tank de-pressurized or low pressure.

Problem:

No pressure protection valve installed, defective pressure

protection valve, or leaking connection between air tank and

pressure protection valve.

Solution:

Replace pressure protection valve or dis-assemble connection,

apply pipe sealant and re-assemble with the direction of flow

arrow in the correct orientation.

Symptom:

Tire/System Pressure reading low/high

Problem:

The regulator setting could be set low or high. The system could

have an air leak. Another potential problem is insufficient air

tank pressure.

Solution:

Check the regulator setting by using a good quality digital

tire gauge to check the pressure at the valve located at the

regulator as illustrated in Figure 1. Reset regulator setting

to required pressure. Using a good quality digital tire gauge

check pressure at tank valve located adjacent to the regulator.

Pull up on the regulator knob and turn counter-clockwise until

system pressure is at least 20 psi less than desired system

pressure. While pulling up on regulator knob, slowly turn

knob clockwise until desired system pressure is achieved.

If pressure reading is greater than desired system pressure

repeat adjustment procedure above.

If the regulator setting is at the desired tire pressure, proceed

to check the system for leaks per the procedure for the

warning light on.

Verify the trailer system air tank pressure is higher than

the regulator setting. Follow procedure for Brake air tank

de-pressurized or low pressure above.

If no system leaks are found and regulator cannot be reset.

Replace regulator assembly.