Allen-Bradley, Kinetix, Rockwell Automation, and Rockwell Software are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Rockwell Otomasyon Ticaret A.Ş., Kar Plaza İş Merkezi E Blok Kat:6 34752 İçerenköy, İstanbul, Tel: +90 (216) 5698400

Rockwell Automation maintains current product environmental information on its website at

http://www.rockwellautomation.com/rockwellautomation/about-us/sustainability-ethics/product-environmental-compliance.page.

Publication 2198-IN018A-EN-P - May 2019

Copyright © 2019 Rockwell Automation, Inc. All rights reserved. Printed in the U.S.A.

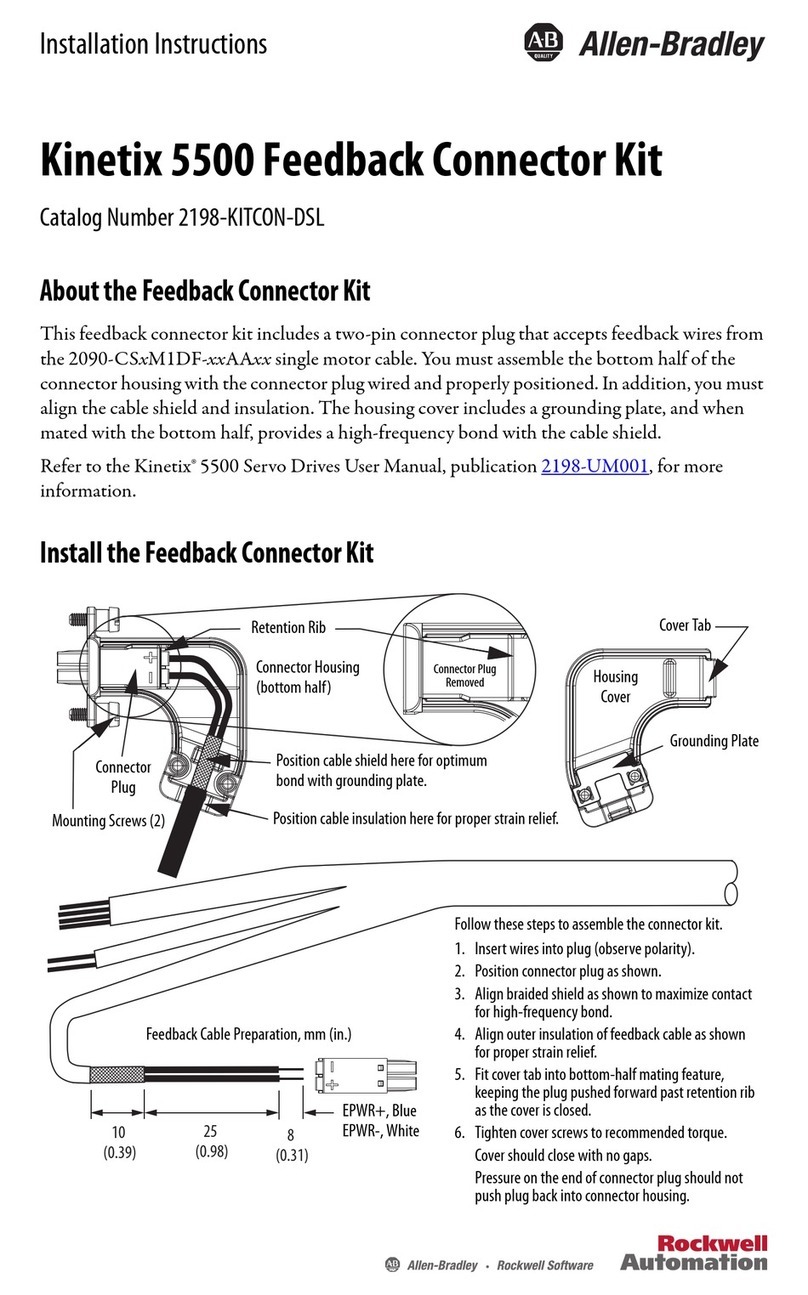

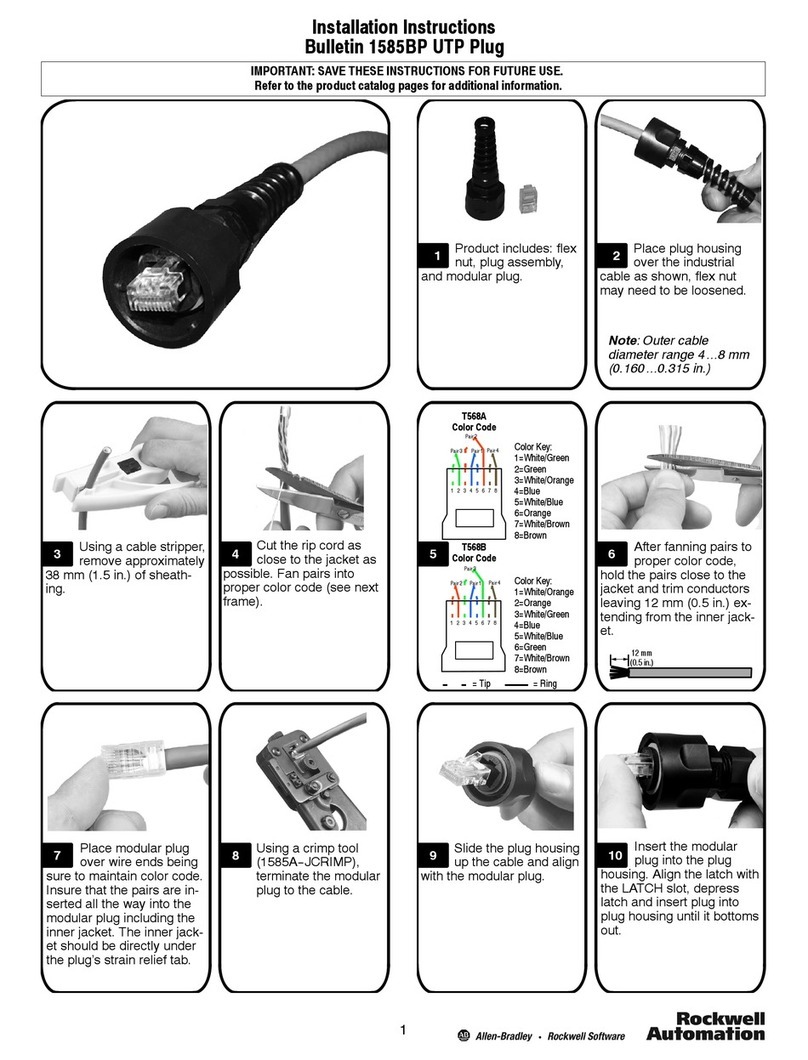

Feedback Cable Requirements

• Shielded twisted-pair cable.

• Eight conductors minimum with four twisted pairs. One pair of 0.82 mm2 (18 AWG)

for EPWR5V and ECOM signals and three pairs of 0.051…0.82 mm2(30…18 AWG).

• 7…9 mm (0.27…0.35 in.) in diameter.

• Maximum of 30 m (98.4 ft) in length.

Additional Resources

These documents contain additional information concerning related products from Rockwell

Automation.

You can view or download publications at http://www.rockwellautomation.com/global/

literature-library/overview.page.

Rockwell Automation Support

For technical support, visit http://www.rockwellautomation.com/support/overview.page.

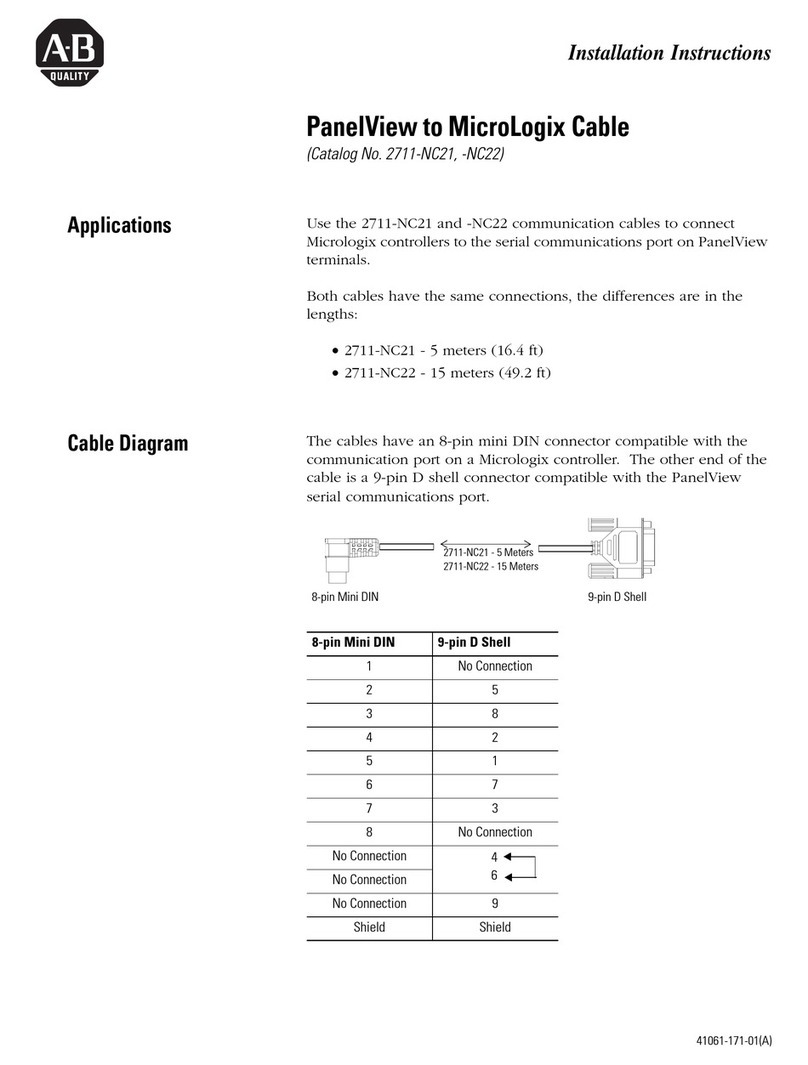

Resource Description

Kinetix Servo Drives Specifications Technical Data,

publication KNX-TD003

Provides product specifications for the Kinetix Integrated Motion

over EtherNet/IP network, Integrated Motion over Sercos interface,

EtherNet/IP networking, and component servo drive families.

Kinetix Motion Accessories Specifications Technical Data,

publication KNX-TD004

Provides product specifications for Bulletin 2090 motor and interface

cables, low-profile connector kits, drive power components, and

other servo drive accessory items.

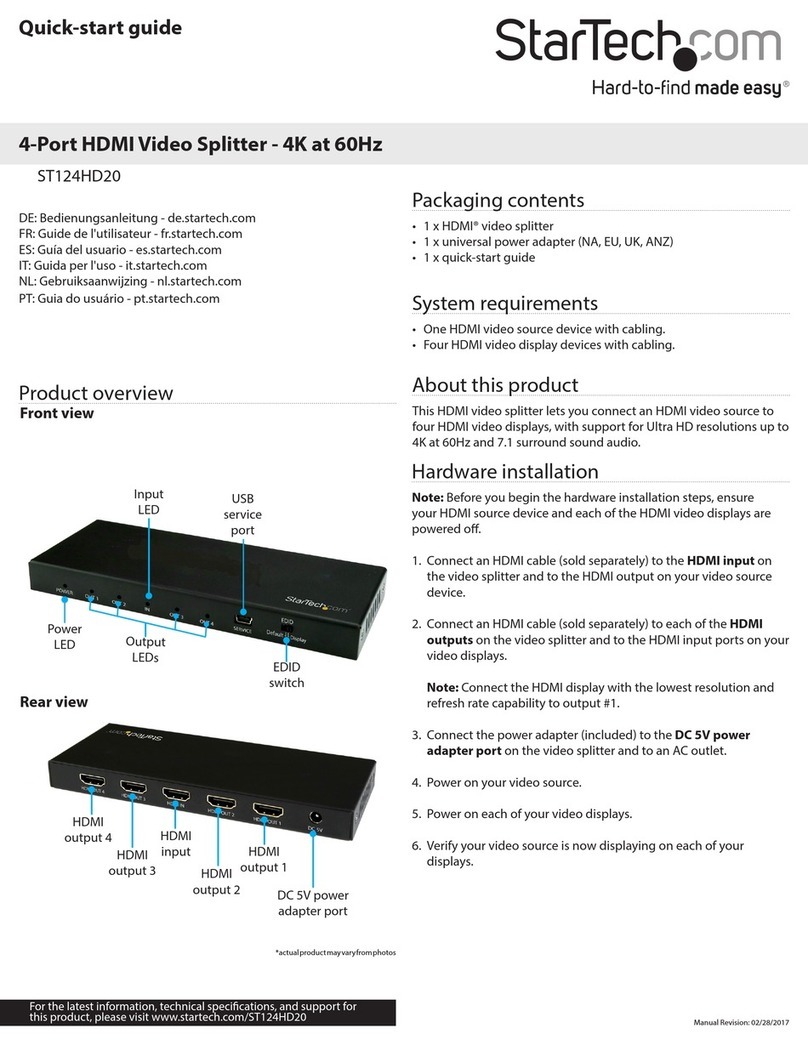

Kinetix 5100 Single-axis EtherNet/IP Servo Drives Users

Manual, publication 2198-UM004

Information on how to install, configure, start, and troubleshoot

your Kinetix 5100 servo drive system.

Industrial AutomationWiring and Grounding Guidelines,

publication 1770-4.1

Provides general guidelines for installing a Rockwell Automation

industrial system.

Product Certifications website rok.auto/certifications Provides declarations of conformity, certificates, and other

certification details.