Allied Radio Knight-Kit T-150 User manual

Ce

te

gg

=

knight-kit

T-150

TRANSMITTER

.

The

T-150

is

a

compact,

high-power

AM-

CW

transmitter

that's

sure

to

rate

a

place

in

your

Ham

setup.

Providing

bandswitch-

ing

coverage

of

the

80

through

6

meter

8

bands,

the

T-150

operates

at

a

power

input

waren

sont

——

i

-

of

150

watts.

Built-in

AM

modulation

is

,

provided

by

a

combination

of

screen

mod-

ulation

and

controlled

carrier.

Thus,

at

low

cost,

practically

the

equivalent

talk-power

of

plate

modulation

is

obtained.

Designed

to

provide

a

minimum

of

TVI,

¢

all

leads

going

in-and-out

of

the

cose

are

bypassed

for

RF.

There

is

more

than

ample

goin

in

the

audio

circuit

to

operote

from

any

high-impedance,

dynomic

or

crystal

microphone.

Keying

is

clean

and

chirpless

A

QWER:

ed

ATTS.

INPUT:

ON.

&

iy

Fi

-

|

with

no

hazardous

voltages

at

the

key

con-

THROUGH

10;

100

ON6

os

:

Pe

car

1

tacts.

OUTPUT

FREQUENCIES

POWER

INPUT

TO

FINAL.

~

FREQUENCY

CONTROL

+

OUTPUT

CIRCUIT

\

VFO

DRIFT

«

ACCESSORY

OUTPUTS

TUBES

*

MODULATION

*

TVI

REDUCTION

\V

MICROPHONE

INPUT

.

CW

KEYING

‘TYPES

OF

EMISSION

-

POWER

SOURCE

POWER

CONSUMPTION

SPECIFICATIONS

3.5-4

MC

7.0-7.3

MC

14,0-14.35

MC

21.0-21.45

MC

28.0-29.7

MC

50.0-54.0

MC

150

Watts

nominal

on

80-10

meters

100

Watts

on

6

meters

Crystal

or

VFO

Pi-Network,

40-600

ohms,

coax

output

connector.

Only

200

cycles

from

10

to

30

minutes

700

V

DC

at

50

MA

6.3

VAC

at

1

amp

+

12BY7

Variable

Frequency

Oscillator

(VFO)

-

6CL6

Crystal

Oscillator

>

7189

Buffer/Multiplier

«

12AX7

Speech

Amplifier

-6DR7

Modulator

‘

OA2

Voltage

Regulator

+

2-6146

RF

Output

Amplifiers

Controlled

carrier,

screen

modulation.

The

transmitter

is

fully

shielded

by

its

cabinet,

thus

assuring

minimum

_har-

monic

radiation.

Filtering

and

bypassing

of

AC

and

keying

leads

is

provided,

and

generous

bypassing

of

the

meter

and

heater

circuits

is

included.

Accepts

crystal

microphone

on

front

panel.

Key

jack

accepts

standard

2

connector

Y,”

plug.

AM-Amplitude

Modulation

CW-Continuous

Wave

105-125

Volts,

60

cycles,

AC

Standby:

180

watts.

AM:

280

watts.

CW:

350

watts.

CONSTRUCTION

HINTS

UNPACKING

L)

If

you

are

not

familiar

with

electronic

parts,

we

suggest

that

you

check

each

part

against

the

parts

list

in

the

rear

of

the

manual.

If

you

are

unable

to

identify

some

of

the

parts,

find

their

pictures

on

the

wiring

illustrations

or

on

the

parts

identification

photo.

As

you

check

off

the

parts,

assort

them

so

they

are

readily

available.

You

may

find

it

advantageous

to

sort

the

hardware

(screws,

nuts,

lockwashers,

etc.)

into

suitable

containers.

This

step

will

acquaint

you

with

the

various

parts

and

thus

simplify

building.

HELPFUL

CONSTRUCTION

HINTS

This

book

uses

some

symbols

for

the

value

of

the

parts.

“©’’

means

ohm,

“KK”

means

one

thousand

ohms,

“meg”

means

one

million

ohms,

»f

means

microfarad,

and

ppf

means

micromicrofarad.

Capacitor

markings

may

be

pf

or

MF

for

microfarad;

pyf

or

MMF

for

micromicrofarad.

Several

types

of

wire

are

supplied.

It

is

important

to

use

the

wire

called

for

in

the

building

step.

Insulated

solid

and

stranded

wire,

identified

by

color,

has

been

cut

to

length

and

prestripped

for

your

convenience.

Use

only

the

color

given

in

the

step.

The

construction

of

this

kit

will

require

the

use

of

a

soldering

iron,

rated

at

about

100

watts,

a

pair

of

long-nose

pliers,

a

pair

of

diagonal

cutters,

and

a

screwdriver.

Follow

the

step-by-step

instructions

exactly.

DO

NOT

ATTEMPT

TO

WIRE

THIS

KIT

FROM

THE

PICTORIALS

OR

SCHEMATIC

DIAGRAM

ALONE

because

a

definite

wiring

sequence

must

be

followed.

Occasion-

ally,

several

parts

are

mounted

with

the

same

hardware,

so

BE

SURE

TO

READ

THE

ENTIRE

STEP.

Check

off

each

step

after

you

have

completed

it.

To

make

a

good

mechanical

connection,

simply

insert

the

end

of

the

lead

through

the

hole

in

the

terminal;

wrap

the

lead

around

the

terminal

and

cut

off

the

excess

wire.

Clamp

the

connection

with

your

long-nose

pliers.

Flexible

tubing

is

used

to

cover

bare

wire

or

leads

where

there

is

a

chance

they

may

touch

other

bare

wires

or

the

chassis.

BARE

WIRES

AND

BARE

LEADS

NOT

CONNECTED

TO

THE

SAME

TERMINAL

MUST

NOT

ACCIDENTALLY

TOUCH

EACH

OTHER

OR

THE

CHASSIS.

a

te

4

Oe

= |

Od

0

O) od

0

1

O)]

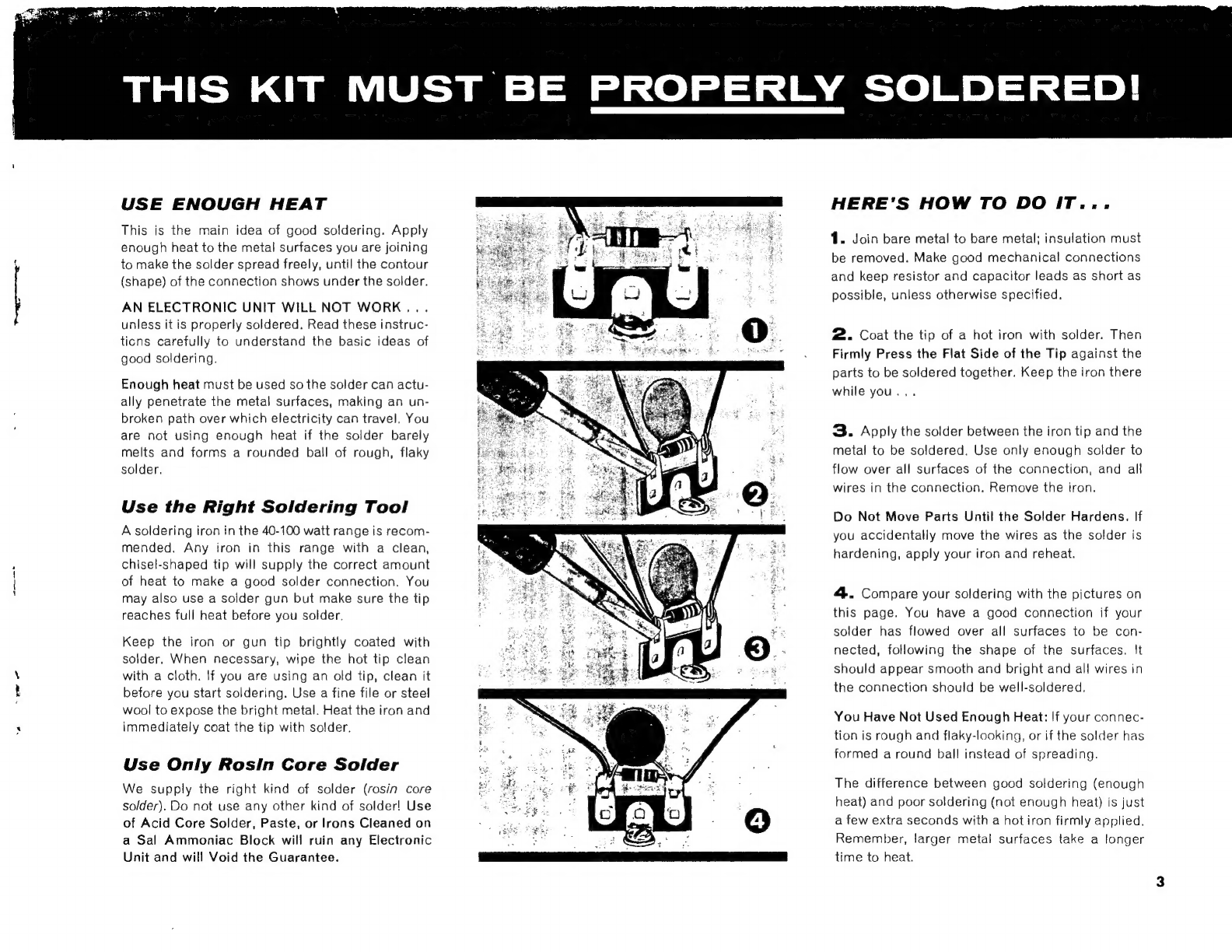

USE

ENOUGH

HEAT

This

is

the

main

idea

of

good

soldering.

Apply

enough

heat

to

the

metal

surfaces

you

are

joining

to

make

the

solder

spread

freely,

until

the

contour

(shape)

of

the

connection

shows

under

the

solder.

AN

ELECTRONIC

UNIT

WILL

NOT

WORK...

unless

it

is

properly

soldered.

Read

these

instruc-

ticns

carefully

to

understand

the

basic

ideas

of

good

soldering.

Enough

heat

must

be

used

so

the

solder

can

actu-

ally

penetrate

the

metal

surfaces,

making

an

un-

broken

path

over

which

electricity

can

travel,

You

are

not

using

enough

heat

if

the

solder

barely

melts

and

forms

a

rounded

ball

of

rough,

flaky

solder,

Use

the

Right

Soldering

Tool

A

soldering

iron

in

the

40-100

watt

range

is

recom-

mended,

Any

iron

in

this

range

with

a

clean,

chisel-shaped

tip

will

supply

the

correct

amount

of

heat

to

make

a

good

solder

connection.

You

may

also

use

a

solder

gun

but

make

sure

the

tip

reaches

full

heat

before

you

solder.

Keep

the

iron

or

gun

tip

brightly

coated

with

solder.

When

necessary,

wipe

the

hot

tip

clean

with

a

cloth.

lf

you

are

using

an

old

tip,

clean

it

before

you

start

soldering.

Use

a

fine

file

or

stee!

wool

to

expose

the

bright

metal.

Heat

the

iron

and

immediately

coat

the

tip

with

solder.

Use

Only

Rosin

Core

Solder

We

supply

the

right

kind

of

solder

(rosin

core

sofder).

Do

not

use

any

other

kind

of

solder!

Use

of

Acid

Core

Solder,

Paste,

or

lrons

Cleaned

on

a

Sal

Ammoniac

Block

will

ruin

any

Electronic

Unit

and

will

Void

the

Guarantee.

HERE'S

HOW

TO

DO

IT...

1.

Join

bare

metal

to

bare

metal:

insulation

must

be

removed.

Make

good

mechanical

connections

and

keep

resistor

and

capacitor

leads

as

short

as

possible,

unless

otherwise

specified.

2.

Coat

the

tip

of

a

hot

iron

with

solder.

Then

Firmly

Press

the

Flat

Side

of

the

Tip

against

the

parts

to

be

soldered

together.

Keep

the

iron

there

while

you...

3.

Apply

the

solder

between

the

iron

tip

and

the

metal

to

be

soldered.

Use

only

enough

solder

to

flow

over

all

surfaces

of

the

connection,

and

all

wires

in

the

connection.

Remove

the

iron.

Do

Not

Move

Parts

Until

the

Solder

Hardens.

If

you

accidentally

move

the

wires

as

the

solder

is

hardening,

apply

your

iron

and

reheat.

4.

Compare

your

soldering

with

the

pictures

on

this

page.

You

have

a

good

connection

if

your

solder

has

flowed

over

all

surfaces

to

be

con-

nected,

following

the

shape

of

the

surfaces.

It

should

appear

smooth

and

bright

and

all

wires

in

the

connection

should

be

well-soldered.,

You

Have

Not

Used

Enough

Heat:

If

your

connec-

tion

is

rough

and

flaky-looking,

or

if

the

solder

has

formed

a

round

ball

instead

of

spreading.

The

difference

between

good

soldering

(enough

heat)

and

poor

soldering

(not

enough

heat)

is

just

a

few

extra

seconds

with

a

hot

iron

firmly

applied.

Remember,

larger

metal

surfaces

take

a

longer

time

to

heat.

PARTS

MOUNTING

ON

THE

CHASSIS

CHASSIS

SEE

FIGURES

1

AND

2.

~——

rH

Position

the

chassis

as

shown

in

Figure

1.

The

following

control

and

switch

have

locating

tabs

which

are

inserted

in

the

ie

holes

in

the

chassis.

Mount

each

part

with

a

34”

nut.

8-4,

single

wafer

switch.

pase

7

R-23,

100K

control

(the

control

with

the

short

shaft).

—

fea

9-pin

tube

socket

without

center

pin

for

V-5.

Position

with

the

keyway

(the

wide

space

between

two

of

the

pins)

as

shown.

Mount

with

two

4-40

x

144”

screws,

lockwashers

and

nuts.

~—-

[gq

Four

9-pin

tube

sockets

and

four

shield

bases

for

V-1

through

V-4.

The

socket

with

the

center

pin

is

V-1.

Position

the

shield

bases

on

top

of

the

chassis

and

the

sockets

on

the

bottom

with

the

keyways

positioned

as

shown.

Mount

each

with

two

4-40

x

14”

screws,

#4

lockwashers

and

nuts

as

shown

in

Figure

3.

—_

ea

Bend

down

the

four

ground

lugs

on

each

of

the

five

sockets

mounted.

A

Ste

Ly

7-pin

tube

socket

for

V-6.

Position

with

keyway

as

shown.

Mount

with

two

4-40

x

144”

screws,

lockwashers

and

nuts.

q

SCREW

e~

HK

he

SHIELD

BASE

FIGURE

3.

SHIELD

BASE

MOUNTING

NUT

:

FUSE

HOLDER

0)

RUBBER

LOCKWASHER

WASHER

FIGURE

4.

FUSE

HOLDER

MOUNTING

em

Da

8-pin

tube

sockets

for

V-7

and

V-8,

and

two

#6

solder

lugs.

Posi-

tion

the

sockets

with

the

keyways

(notch)

as

shown.

Mount

each

socket

and

a

solder

lug

with

two

6-32

x

14”

screws,

a

lockwasher

and

tw.

“huts.

women

Large

grommet.

Mount

in

the

hole

shown.

_—

{Four

medium

grommets.

Mount

in

the

holes

shown.

~~

ta

Fuse

holder.

Position

with

the

terminals

as

shown.

Mount

as

shown

in

Figure

4.

—

Ground

post,

a

10-32

screw,

lockwasher,

nut

and

wing

nut.

Assemble

as

shown

in

Figure

5.

FIGURE

5.

GROUND

POST

ASSEMBLY

7

SCREWDRIVER

a

[]

TS-10,

4-terminal

strip.

~e

[]

TS-11,

2-terminal

strip

(near

R-23).

oe

(J

TS-15,

3-terminal

strip.

pees

(]

Mounting

plate

for

C-48.

Mount

from

inside

the

chassis

with

two

4-40

x

14”

screws,

lockwashers

and

nuts.

LOCK

RING

-

£

C-48,

40/40

uf,

450

volt

electrolytic

capacitor.

Mount

by

inserting

the

:

mounting

tabs

in

the

holes

in

the

plate.

Fasten

by

twisting

the

tabs

Y,

turn.

_

NOTE:

The

following

20

watt

resistors

are

wire

wound

stand-ups.

—_

[]

R-32,

100,

20

watt

resistor.

Mount

with

a°6-32

x

14”

screw,

lock-

washer

and

nut.

—_—

R33,

1500,

20

watt

resistor

and

TS-16,

2-terminal

strip.

Mount

with

_p

common

6-32

x

4,”

screw,

lockwasher

and

nut.

—

pet

B-37,

4K,

10

watt

resistor.

Mount

with

a

6-32

x

4”

screw,

lock-

washer

and

nut.

ae.

prt

R-34,

1500,

20

watt

resistor

and

C-47,

40

pf,

450

volt

electrolytic

FIGURE

6.

MOUNTING

J-2

capacitor.

Position

the

capacitor

with

the

leads

as

shown.

Mount

C-47

and

R-34

with

a

6-32

x

%4”

screw,

lockwasher

and

nut.

J-7,

antenna

jack.

Mount

from

outside

the

chassis

using

three

4-40

x

Connect

the

black

lead

of

C-47

to

terminal

2

of

C-48.

14,”

screws,

lockwashers

and

nuts—in

the

holes

shown.

The

fourth.

<

(J

Connect

the

red

lead

of

C-47

to

terminal

11

of

J-2.

ounting

screw

will

be

used

later

to

mount

another

part.

ris

: : ‘

:

d

;

ein

se

yu

C-46,

40uf,

450

volt

electrolytic

capacitor,

and

an

angle

clip.

Insert

a

~

J-2,

11-pin

socket.

Mount

with

a

lock

ring

as

shown

in

Figure

6.

6-32

x

1,”

screw

through

the

angle

clip

and

position

on

top

Gene

CHASSIS

oe

Oe

ae

eget

meen

ha

J-1,

8-pin

socket

and

a

#6

solder

lug.

Position

the

keyway

to

the

chassis

as

shown

in

Figure

2.

Mount

C-46

on

the

screw,

leads

posi-

|

right,

away

from

J-2.

Mount

the

socket

and

the

solder

lug

with

two

tioned

as

shown,

and

fasten

with

a

lockwasher

and

nut.

6-32

x

14”

screws,

a

lockwasher

and

two

nuts.

~—

pol

Connect

the

black

lead

of

C-46

to

terminal

1

of

C-48.,

peor

NOTE:

There

are

different

types

of

2,

3

and

5-terminal

strips

used

in

:

C

i

1

£

0-4

A

‘b

fe

the

transmitter.

When

mounting

the

terminal

strip

be

sure

to

select

the

“""

6”

[a]

Contiect

the

red:

Jead

of

20.10

terminal

2

of

R-33.

correct

type.

See

the

parts

identification

in

the

rear

of

the

manual

for

¢

gel

T-1,

power

transformer.

Position

with

the

leads

as

shown.

Mount

the

terminal

strip

identification.

*

with

four

8-32

lockwashers

and

nuts.

Le

Position

the

following

terminal

strips

as

shown.

Mount

each

with

a

6-32

x

|

1,”

screw,

lockwasher

and

nut.

|

IMPORTANT

INSTRUCTIONS

wg]

TS-1.

5-terminal

strip.

=~

g¢{]

TS-2,

standup

6-terminal

strip.

tn

THE

INSTRUCTION

CONNECT

MEANS:

Connect

the

wire

or

lead

‘

a

: :

to

the

given

point.

Make

a

firm

mechanical

connection

BUT

DO

f-7

‘€]

TS-3

and

TS-4,

two

3-torminal

strips.

NOT

SOLDER

AT

THIS

TIME.

Later

another

wire

or

wires

will

be

eal

TS-5,

3-terminal

strip.

LEE

connected

to

this

point.

—_—

vin

TS-6,

2-terminal

strip.

a

IIE

INSTRUCTION

SOLDER

MEANS:

Connect

the

wire

or

lead

TS-7,

2-terminal

strip

and

an

angle

clip.

From

the

chassis

top,

to

the

given

point

and

then

solder

the

terminal

and

all

connections

insert

the

screw

through

the

angle

clip,

the

chassis

and

the

mount-

in

it.

If

there

is

more

than

one

wire

in

the

connection,

the

amount

ing

foot

of

TS-7.

Position

the

clip

as

shown

in

Figure

2

and

fasten

—

}

will

be

stated—for

example

(2

wires).

After

soldering

a

connection

-with

a

lockwasher

and

nut.

-

trim

all

wires

as

close

as

possible

to

the

terminal.

—

TS-8,

3-terminal

strip.

a

panes

ra

TS-9,

5-terminal

strip.

NOTE:

The

transformer

leads

may

be

shortened

for

neater

connections.

5

f

:

SHOULDER

|

WASHER

el

t

i

a

CHASSIS

1

FIBER

Ce)

WASHER

“Ne

'

AD~_

scree

LUG

wr

FIGURE

7.

MOUNTING

L-18

eth

the

leads

of

T-1

as

follows:

f

Fi

is

Fi

yO

¢

,

yO

eel

+

ere

~~

Either

of

the

red

leads.

Cut

4”

off

this

lead.

Remove

1”

insulation

from

the

end.

Twist

the

strands’

together

and

coat

lightly

with

solder.

Solder

this

lead

to

terminal

2

of

R-32.

Two

black

leads.

Cut

2”

off

each

lead.

Remove

%”

of

insulation

from

each

lead.

Twist

the

stranded

wires

together

and

coat

lightly

with

solder.

Connect

one

of

the

leads

to

terminal

2

of

TS;5.

Con-

nect

the

other

lead

to

terminal

3,

of

TS-5.

,

The

other

red

leall.

Connect

to

terminal

_8

of

J-2..

Either

of

the

green

leads.

Solder

to

terminal

A

of

J-2.

The

other

green

lead.

Cut

5”

off

this

lead.

Remove

1%,”

of

the

insulation

from

the

end.

Twist

the

stranded

wires

together

and

coat

lightly

with

solder.

Connect

to

terminal

2

of

TS-4.

/

Nee

oid

Shoulder

washer,

fiber

washer,

+8

solder

lug

and

an

8-32

nut.

Assemble

as

shown

in

Figure

7.

Do

not

overtighten

the

nut

as

the

coil

form

will

be

damaged.

—

Ey

Large

L

shaped

bracket.

Mount

on

the

top

of

the

chassis

with

two

6-32

x

14”

screws,

lockwashers

and

nuts.

~—-

NOTE:

When

mounting

the

variable

capacitors,

be

sure

the

blades

are

closed

all

the

way.

yo

C-16

and

C-21,

two

variable

capacitors

(part

#£

286053).

Mount

each

with

three

6-32

x

4%”

screws

and

lockwashers.

The

lockwashers

go

under

the

screw

heads.

Bend

the

terminals

of

C-16

and

C-21

up

as

-

shown.

eye

yee

+f]

C-35,

variable

capacitor

(part

4286056).

Mount

to

the

large

L

brac-

ket

with

two

6-32

x

14”

screws

and

lockwashers.

—,

yO

C-32,

variable

capacitor

(part

3286057).

Mount

to

the

large

L

brac-

ket

with

two

8-32

screws

and

lockwashers.

Z

nee

‘¥

Control

bracket.

Mount

with

two

6-32

x

1,”

screws,

lockwashers

and

nuts.

¥]

R-16,

100K

contro!

(long

shaft).

Mount

to

the

control

bracket

with

;a

34”

lockwasher

and

nut.

TS-12,

1-terminal

strip.

Mount

with

a

6-32

x

4,”

serew,

lockwasher

and

nut.

A

ceramic

spacer,

two

#8

solder

lugs,

two

6-32

x

1.”

screws

and

lockwashers.

Fasten

the

solder

lugs

to

the

spacer

as

shown

in

Figure

8.

Fasten

the

spacer

to

the

top

of

the

chassis

near

the

rear

edge

as

shown

in

Figure

2.

CHASSIS

SCREW

FIGURE

8.

SPACER

MOUNTING

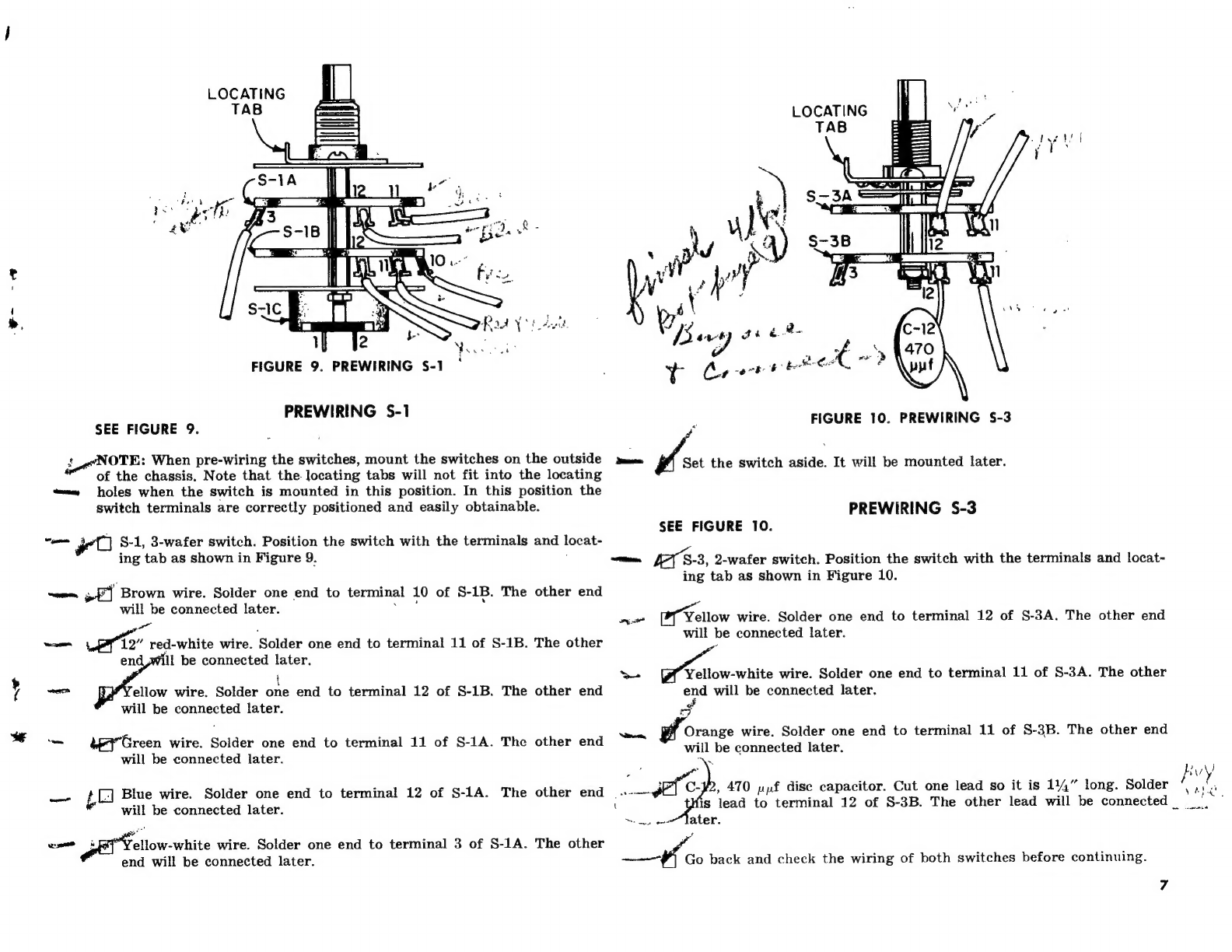

LOCATING

—

2D,

ma

&

soe

g

ce,

y

:

>,

a

Y

eee

FIGURE

9.

PREWIRING

S-1

°

PREWIRING

S-1

SEE

FIGURE

9.

io

NOTE:

When

pre-wiring

the

switches,

mount

the

switches

on

the

outside

of

the

chassis.

Note

that

the

locating

tabs

will

not

fit

into

the

locating

«=e

holes

when

the

switch

is

mounted

in

this

position.

In

this

position

the

switch

terminals

are

correctly

positioned

and

easily

obtainable.

vee

S-1,

3-wafer

switch.

Position

the

switch

with

the

terminals

and

locat-

ing

tab

as

shown

in

Figure

9.

me,

oF]

Brown

wire.

Solder

one

end

to

terminal

10

of

S-1B.

The

other

end

will

be

connected

later.

a“

.

——

12”

red-white

wire.

Solder

one

end

to

terminal

11

of

S-1B.

The

other

en

ll

be

connected

later.

i

y

ice

ellow

wire.

Solder

one

end

to

terminal

12

of

S-1B.

The

other

end

will

be

connected

later.

-

aey"Green

wire.

Solder

one

end

to

terminal

11

of

S-1A.

The

other

end

will

be

connected

later.

a

LC

Blue

wire.

Solder

one

end

to

terminal

12

of

S-1A.

The

other

end

will

be

connected

later.

ellow-white

wire.

Solder

one

end

to

terminal

3

of

S-1A.

The

other

end

will

be

connected

later.

week

FIGURE

10.

PREWIRING

S-3

—

Set

the

switch

aside.

It

will

be

mounted

later.

PREWIRING

S-3

SEE

FIGURE

10.

—

LAS-3,

2-wafer

switch.

Position

the

switch

with

the

terminals

and

locat-~-

ing

tab

as

shown

in

Figure

10.

Yellow

wire.

Solder

one

end

to

terminal

12

of

S-3A.

The

other

end

ae

will

be

connected

later.

ae

Yellow-white

wire.

Solder

one

end

to

terminal

11

of

S-3A.

The

other

end

will

be

connected

later.

Namen,

Orange

wire.

Solder

one

end

to

terminal

11

of

5-3B.

The

other

end

will

be

connected

later.

heen

is

lead

to

terminal

12

of

S-3B.

The

other

lead

will

be

connected

Fh

be

back

and

check

the

wiring

of

both

switches

before

continuing.

Buy

,

470

pf

dise

capacitor.

Cut

one

lead

so

it

is

114”

long.

Solder

if

yan

/

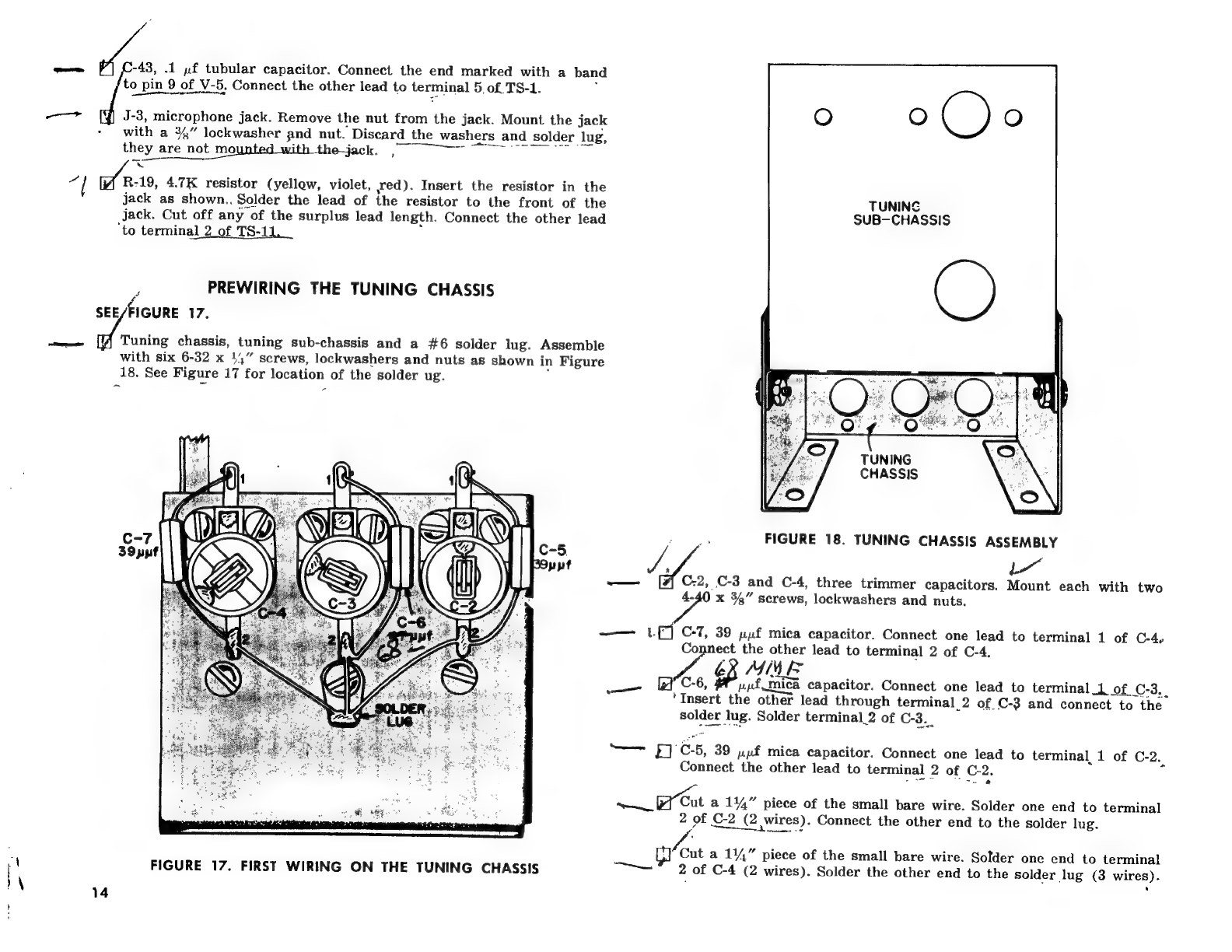

FIRST

WIRING

ON

THE

BOTTOM

OF

THE

CHASSIS

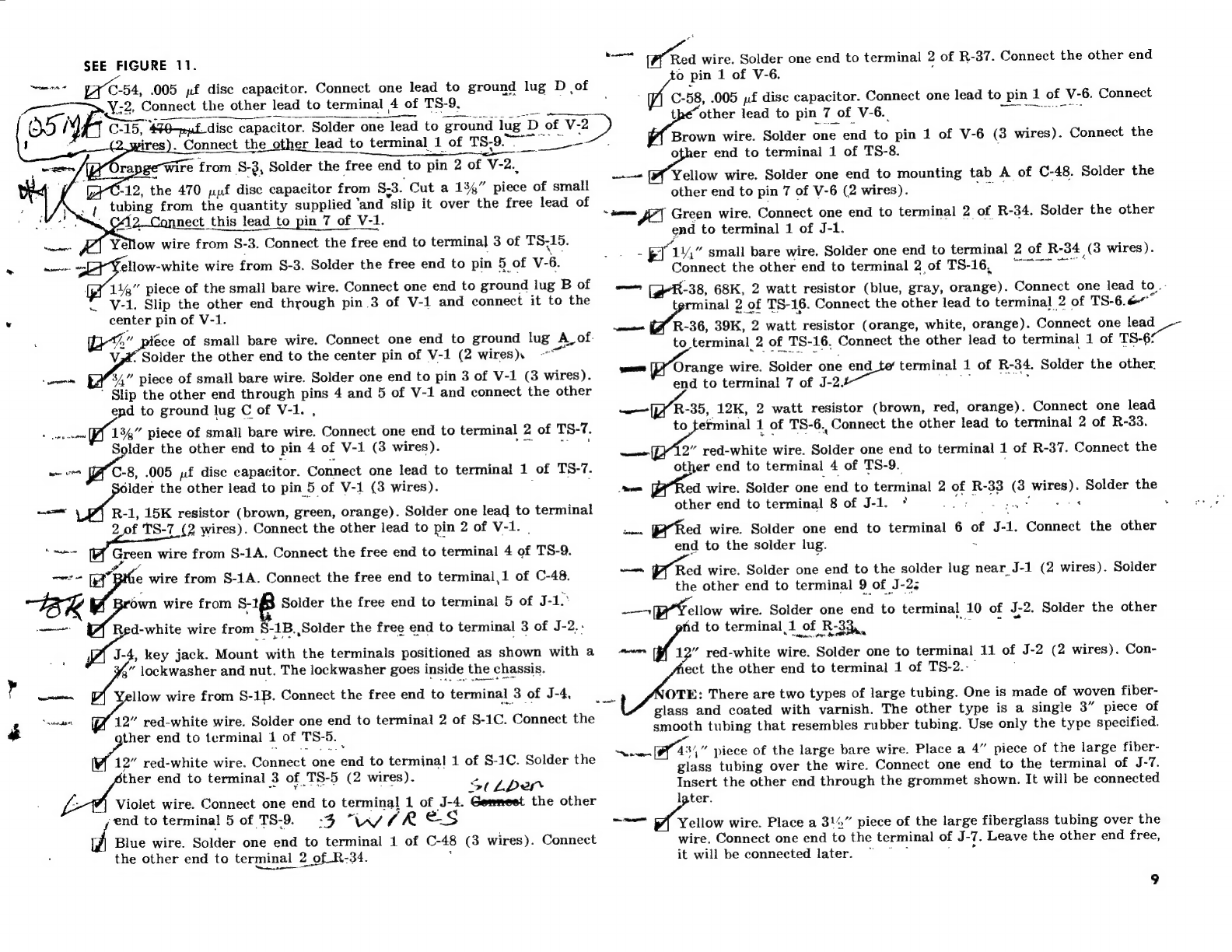

EE

FIGURE

11.

NOTE:

Position

the

chassis

so

it

is

not

resting

on

L-18,

to

prevent

its

eet

ing

damaged.

Dire

shield

and

an

angle

clip.

Fasten

the

angle

clip

to

the

bottom

shield,

as

shown,

with

a

6-32

x

3/16”

screw

and

lockwasher.

al

S-3,

the

pre-wired

switch

and

the

bottom

shield.

Insert

the

shaft

of

S-3

through

the

bottom

shield,

the

chassis

and

fasten

on

the

outside

of

the

chassis

with

a

%”

nut.

Be

sure

the

locating

tab

enters

the

locating

hole.

Ceramic

spacer,

+wo

#8

solder

lugs,

two

6-32

x

4,”

screws

and

lock-

washers.

Place

a

lockwasher

over

one

screw

and

insert

the

screw

a

/

through

the

angle

clip

mounted

to

the

bottom

shield,

and

through

the

chassis.

Mount

the

ceramic

spacer

on

the

screw

as

it

protrudes

through

the

top

of

the

chassis.

Fasten

the

solder

lugs

to

the

top

of

the

space

and-position

as.shown

in

Figure

2.

S-1,

the

other

pre-wired

switch.

Fasten

to

the

chassis,

locating

tab

in

the

locating

hole,

with

a

34”

nut.

ne

NOTE:

Position

all

wires

as

close

to

the

chassis

as

possible.

£+t

Orange

wire.

Connect

one

end

to

ground

lug

A.

of

V-5.

Insert

the

other

end

through

the

cutout,

it

will

be

connected

later.

bal

cist

red-white

stranded

wire.

Solder

one

end

to

ground

lug

A

of

5

(2

wires).

Insert

the

other

end

through

the

cutout

shown,

it

will

i

cobnerted

later.

we

TP

a

ee

A

erean

ie

acl

meet

eine

serene

“Green

wire.

Solder

one

end

to

terminal

11,

of

S-4.

Insert

the

other

as

end

through

the

cutout

shown,

it

will

be

connected

later.

a

—

Yellow

wire.

Solder

one

end

to

terminal

10

of

S-4.

Insert

the

other

end

through

the

cutout

shown,

it

will

be

connected

later.

ans

Gray

wire.

Solder

one

end

to

terminal

9

of

S-4.

Connect

the

other

nd

to

the

solder

lug

between

V-3

and_V-

LEN

mate

0

Orange

wire.

Solder

one

end

to

o

terminal

7

of

S-4.

Connect

the

other

.

end

to

terminal

J

of

TS-10.

.

ry

range

wire.

Solder

one

end

to

pin,

4.0f,

V-5.

Connect

the

other

end

to

pin

9

of

V-4.

7

:

=

ee

|

R-28,

1

meg

resistor

(brown,

black,

green).

Insert

one

lead

through

_

pin 2

of

v‘5

and

solder

the

end

to

pin

§

of

V-5.

hoes

the

other

lead

to

terminall

of

TS-1.

a

pieces

of

small

bare

wire.

Connect

as

‘follows

:

Solder

pin

2

of

V-5.

nee

ae

wire.

Solder

one

end

to

pin

5

of

Ve.

Solder

the

other

end

to-fround

lug

C

C

of

of

V-5

~

are

wire.

Solder

one

end

to

pin

8

of

.V-5.

Solder

the

other

end

——

to

ground

lug

D

of

V-5,

/

NOTE:

There

are

two

.005

yf

dise

capacitors

rated

at

1000

volts

used

in

KX

this

kit.

They

are

stamped

IKV

and

should

only

be

used

where

specified.

(

7

The

remainder

ive

.005

pf

disc

capacitors

are

rated

at

600

volts

and

—

meee,

aan

are

unstamped.

x

,

€

of

V-2

(2

wires).

Connect

the

other

lead

to

terminal

(

one

bY

c:

49,

.005

pf

disc

capacitor.

Connect

one

lead

to

terminal

1

of_TS-1.

Connect

the

other

lead

to

terminal

2

of

TS-1.

we

yal

C-41,

1

pf

tubular

capacitor.

Solder

the

end

marked

with

a

band

to

ground

lug

/D.of.V-3.

Connect

the

other

lead

to

terminal_4

of

TS-1.

‘ellow-white

wire

from

terminal

3

of

§-1A.

Connect

the

free

end

to

terminal

5_

5_of

TS-1.

“Orange

wire.

Connect

one

end

to

pin

9

of

V-4.

Connect

the

other

end

to.pin

4

¢

of

V

V-3,

"Yellow

wire.

ire.

Connect

one

end

to

pin

4

of

V-

“3.

Connect

the

other

end

to-pin

7

of

V-

7.

WA”

féce

of

the

small

bare

wire.

Solder

one

end

to

pin

5

of

V-3.

Con-

t

the

other

end

to

ground

lug

C

of

V-3.

C-33,

.005

pf,

1000

volts

(stamped

IKV)

disc

capacitor.

Connect

one

C-52,

.005

pf

disc

capacitor.

Solder

one

lead

to

ground

lug

C

of

V-3

(3

wires).

Solder

the

other

lead

to

pin

4

of

V-3,

(3

wires).

C-20,

.005

pf

disc

capacitor.

Connect

one

lead

to

pin

3

of

V-3.

Con-

-nect

the

other

lead

to

ground

lug

A

of

V-3.

C-18,

.005

yf

disc

capacitor.

Connect

one

lead_to

pin

9

of

V-3.

Con-

nect

the

other

lead

to

ground

lug

A

of

V-3.

Samael

ST

R-

-9,

390

©,

1

watt

resistor

(orange,

white,

brown).

Solder

one

lead

to

wires).

Connect

the

other

lead

to

termina]

4

of

TS-10.

im,

n3-of.

V-3.

¥

Green

wire.

Connect

one

end

to

termipal

4

4

of

TS-10.

Contiect

the

other

end

to

terminal

5

of

T§-9.:

rae

R-15,

10

Q,

5%

1

watt

resistor

(brown,

black,

black,

gold).

Connect

ne

lead

to

terminal

2S

of

|

TS-

-8.

Solder

the

other

lead

to

the

solder

lug

(3

wires).

White

wire.

Connect

one

end

to

terminal

2

of

TS-8,

Insert

the

other

nd

through

the

cutout

shown.

Orange

wire.

Solder

one

end

to,

pin.6

of

V-2.

Connect

the

other

end

terminal

2

of

C-16

”

piece

of

the

small

bare

wire.

Solder

one

end

to

pin

7

of

MG

-2.

Connect

the

other

end

to

ground

lug

C

of

V-2.

C-51,

.005

pf

disc

capacitor.

Connect

one

lead

to

pin

5

5

of

V-2.

Solder

the

other

lead

to

ground

lug

C.

of,

V-2

(2

wires).

OTE:

The

coils

in

this

kit

are

coded

with

a

color

dot,

or,

if

encased

in

plastic,

by

the

color

of

the

case.

Coils

L-21,

L-22,

and

L-23

ne

BY

BPS

ave-no

color

dot;

or

if.

encased,

are

in

clear-

plastic}

L-23,

2.2

xh

coil.

Connect

one

lead

to

terminal

1,

of

TS-7.,

Connect

the

lead

to

pin

6

of

V-1.

C-14,

.005

pf

disc

capacitor.

Insert

one

lead

through

ground

lug

B.

of

.V-2

and

solder,to-pin

.4

of

.V.2.

Solder

ground

lug

,

B.

Connect

the

other

lead

to_pin

1

of

V-

32

R-6,

390

©

resistor

(orante:

white,

brown).

Solder

one

lead

to

pin

1.

ale

OE

ad

to

ground

lug

Co

of

V-3.

Connect

the

other

lead

to

the

e

solder

lug.

De}

é

“BR

SEE

FIGURE

11.

rarer:

C54,

005

pf

disc

capacitor.

Connect

one

lead

to

ground

lug

D

of

>.Y:2,

Connect

the

other

lead

to

terminal

4

of

TS-9,

,

O51

N,

C-15,

440-puf-dise

capacitor.

Solder

‘one

lead

to

‘ground

lug

D

of

V-2

)

t

Me

eS

res).

Connect

the

other

lead

to

terminal

1

of

TS-9.

fog

nage

ae

nae,

ents

eee

rapgewire

from

S-3,

Solder

the

free

end

to

pin

2

of

V-2.,

-12,

the

470

pyf

disc

capacitor

from

$3.

Cut

a

134”

piece

of

small

bing

from

the

quantity

supplied

‘and

slip

it

over

the

free

lead

of

¥12.Connect

this

lead

to

pin

7

of

V-1.

Yellow

wire

from

S-3.

Connect

the

free

end

to

termina]

3

of

TS,15.

meee

eae

wire

from

S-3.

Solder

the

free

end

to

pin

5

of

v-6.

{p¥

1144”

piece

of

the

small

bare

wire.

Connect

one

end

to

ground

lug

B

of

*

V-1.

Slip

the

other

end

through

pin

3

of

V-1

and

connect

it

to

the

center

pin

of

V-1.

:

oe”

piece

of

small

bare

wire.

Connect

one

end

to

ground

lug

A_of.

Ene

Solder

the

other

end

to

the

center

pin

of

V-1

(2

wires).

~~

34”

piece

of

small

bare

wire.

Solder

one

end

to

pin

3

of

V-1

(3

wires).

’

Slip

the

other

end

through

pins

4

and

5

of

V-1

and

connect

the

other

end

to

ground

lug

C

of

V-1.

,

«

renew

PF

134”

piece

of

small

bare

wire.

Connect

one

end

to

terminal

2

of

TS-7.

Solder

the

other

end

to

pin

4

of

V-1

(3

wires).

re

men

ce

C-8,

.005

,f

disc

capacitor.

Connect

one

lead

to

terminal

1

of

TS-7.

sider

the

other

lead

to

pin

5

of

V-1

(3

wires).

;

,

ei

R-1,

15K

resistor

(brown,

green,

orange).

Solder

one

lead

to

terminal

2.

of

TS-7

(2

wires).

Connect

the

other

lead

to

pin

2

of

V-1.

|

cee

Green

wire

from

S-1A.

Connect

the

free

end

to

terminal

4

of

TS-9.

”

“+

[a

Bthe

wire

from

S-1A.

Connect

the

free

end

to

terminal,1

of

C-48.

aes

wire

from

ag

Solder

the

free

end

to

terminal

5

of

J-1.°

:

R

ioe

d-white

wire

from

*

-1B.,Solder

the

free

end

to

terminal

3

of

J-2.-

;

J-4,

key

jack.

Mount

with

the

terminals

positioned

as

shown

with

a

3”

lockwasher

and

nut.

The

lockwasher

goes

inside

the

chassis.

—e

Yellow

wire

from

S-1B.

Connect

the

free

end

to

terminal

3

of

J-4,

neat

a

red-white

wire.

Solder

one

end

to

terminal

2

of

S-1C.

Connect

the

one

end

to

terminal

1

of

TS-5.

al

12”

red-white

wire.

Connect

one

end

to

terminal

1

of

S-1C.

Solder

the

ther

end

to

terminal

3

of

TS-5

(2

wires).

x

Eee

a

Sthbper

Z

Violet

wire.

Connect

one

end

to

terminal

1

of

J-4.

Gommeet

the

other

jend

to

terminal

5

of

TS-9.

-3

“W/SKR

es

Blue

wire.

Solder

one

end

to

terminal

1

of

C-48

(3

wires).

Connect

the

other

end

to

terminal

2

of

R-34.

;

‘

ra

|

meal

Red

wire.

Solder

one

end

to

terminal

2

of

R-37.

Connect

the

other

end

o

pin

1

of

V-6.

:

C-58,

.005

pf

disc

capacitor.

Connect

one

lead

to

pin

1

of

V-6.

Connect

other

lead

to

pin

7

of

V-6._

Tee

ES

Brown

wire.

Solder

one

end

to

pin

1

of

V-6

(3

wires).

Connect

the

other

end

to

terminal

1

of

TS-8.

Yellow

wire.

Solder

one

end

to

mounting

tab

A

of

C-48.

Solder

the

other

end

to

pin

7

of

V-6

(2

wires).

nat

’

Green

wire.

Connect

one

end

to

terminal

2

of

R-34.

Solder

the

other

end

to

terminal

1

of

J-1.

-

p14”

small

bare

wire.

Solder

one

end

to

terminal

2

of

R-34

(3

wires

).

Connect

the

other

end

to

terminal

2

of

TS-16.

9

~~~"

7

—

[eR-38,

68K,

2

watt

resistor

(blue,

gray,

orange).

Connect

one

lead

to,

terminal

2

of

TS-16.

Connect

the

other

lead

to

terminal

2

of

TS-6.6

omnes

R-36,

39K,

2

watt

resistor

(orange,

white,

orange).

Connect

one

lead

to

terminal

2

of

TS-16,

Connect

the

other

lead

to

terminal

1

of

TS-6!

Se

naa

Orange

wire.

Solder

one

end

terminal

1

of

R-34.

Solder

the

other.

end

to

terminal

7

of

J-2.

w——

[PY

R-35,

12K,

2

watt

resistor

(brown,

red,

orange).

Connect

one

lead

to

terminal

1

of

TS-6.,

Connect

the

other

lead

to

terminal

2

of

R-33.

ener

2”

red-white

wire.

Solder

one

end

to

terminal

1

of

R-37.

Connect

the

other

end

to

terminal

4

of

TS-9.

,

Semen

ed

wire.

Solder

one

end

to

terminal

2

of

R-33

(3

wires).

Solder

the

other

end

to

terminal

8

of

J-1.

*

dye

eRe

apgger

|

as

SM

cn

py

Rea

wire.

Solder

one

end

to

terminal

6

of

J-1.

Connect

the

other

end

to

the

solder

lug.

~

evans:

Red

wire.

Solder

one

end

to

the

solder

lug

near_J-1

(2

wires).

Solder

the

other

end

to

terminal

9

of

J-2;

——

ellow

wire.

Solder

one

end

to

terminal

10

of

J;2.

Solder

the

other

fd

to

terminal

1

of

R-33,,

ares

12”

red-white

wire.

Solder

one

to

terminal

11

of

J-2

(2

wires).

Con-

ect

the

other

end

to

termina]

1

of

TS-2.-—

OTE:

There

are

two

types

of

large

tubing.

One

is

made

of

woven

fiber-

glass

and

coated

with

varnish.

The

other

type

is

a

single

3”

piece

of

smooth

tubing

that

resembles

rubber

tubing.

Use

only

the

type

specified.

aes

434”

piece

of

the

large

bare

wire.

Place

a

4”

piece

of

the

large

fiber-

glass

tubing

over

the

wire.

Connect

one

end

to

the

terminal

of

J-7.

Insert

the

other

end

through

the

grommet

shown.

It

will

be

connected

igter.

a

Yellow

wire.

Place

a

31%”

piece

of

the

large

fiberglass

tubing

over

the

wire.

Connect

one

end

to

the

terminal

of

J-7.

Leave

the

other

end

free,

it

will

be

connected

later.

vs

ce”

9

SEE

FIGURE

IT.

R-17,

4.7K

resistor

(yellow,

violet,

red).

Cut

one

lead

so

it

is

14”

long.

Solder

this

lead

to

the

terminal

of

J-7_(3.

wires).

Leave

the

other

lead

free,

it

will

be

connected

later.

ok

NOTE:

Coils

L-21

and

L-22

are

identical.

These

two

coils

are

the

coils

BLACK!

POT

;

as

Fal

22,

2.2

phy

coil.

Solder

one

lead

to

terminal

1

of

TS-5

(2

wires).

onnect

the

other

lead

to

terminal

1

of

TS-4.

/

7

L-21,

2.2

phy

coil.

Connect

one

lead

to

terial

2

of

aa

5.

Connect

he

other

lead

to

terminal

1

Jot

TS-

4.

ant

ire

v

C-45,

.001

pf

disc

capacitor.

Connect

one

lead

to

terminal

1

of

TS-4,

Connect

the

other

lead

to

terminal

2

of

TS-4.

’

‘wewrm

[]

C-44,

.001

pf

disc

capacitor.

Solder

one

lead

to

terminal,

H.

of

TS-4.

Lye}

wires).

Connect

the

other

lead

to

terminal

3

of

TS-4.

is

Noe

meat

iy

Red

wire.

Solder

one

end

to

terminal

3

of

TS-

‘4

(3

wires).

Solder

the

*

other

end

to

terminal

2

of

the

fuse

holder.

fcr

C-29,

.005

yf

disc

capacitor.

Position

the

capacitor

in

the

center

of

Aube

socket

V-8

as

shown.

Solder

one

lead

to

pin

4

of

V-8.

Connect

the

other

lead

to

pin

2

of

V-8,

woe

1”

piece

of

the

small

bare

wire.

Solder

one

end

to

pin

8

of

V-

8.

Connect

He

other

end

to

pin

2

of

V-8.

Sapte

Orange

wire.

Connect

one

end

to

pin,

7

of

V;8.

Solder

the

other

end

pin

7

of

V-

U2

wires).

ae

Yellow

wire.

Selden:

one

end

to

pin.1

of,,V-8.

Connect

the

other

end

zto

pin

1

of.

V7.

v4

Bere

rN

Yellow

wire.

Conteh

one

end

to

Pin

3

of

V-8.

Connect

the

other

end

/

to

pin

3

of

V-T.

:

the

other

end

to

pin

2

of

V-7.

C-26,

.005

pf

disc

capacitor.

Position

the

capacitor

in

the

center

of

tube

socket

V-7

as

shown.

Sold

lee

one

lead

to

pin

4

of

V-

7.

Connect

the

;

other

lead

to

pin

FOF

|

V-7.

wom

om’

[|

C-24,

005

pf

disc

capacitor.

Connect

one

lead

to-terminal

"9

of

TS-3,

i

Connect

the

other

lead

to

terminal

3

of

TS-3.&”

al

antic

al

R-

11,

5600,

5%

resistor

(green,

blue,

brown,

gold).

older

one

lead

to

terminal

2

of-TS-3

(2

wires).

oa

the

other

lead

to

terminal

F

3

of

TS-3.

pitino

Orange

wire.

Solder

one

end

to

terminal

1

of

R-32.

Connect

the

other

ylead

to

terminal

6

of

TS-

2.

ah

Go

back

and

check

the

wiring

for

poor

solder

joints

and

proper

con-

,

nections

before

continuing.

4

to

”

piece

of

the

small

bare

wire.

Solder

one

end

to

pin

8

of

V-7.

Connect

ae

a

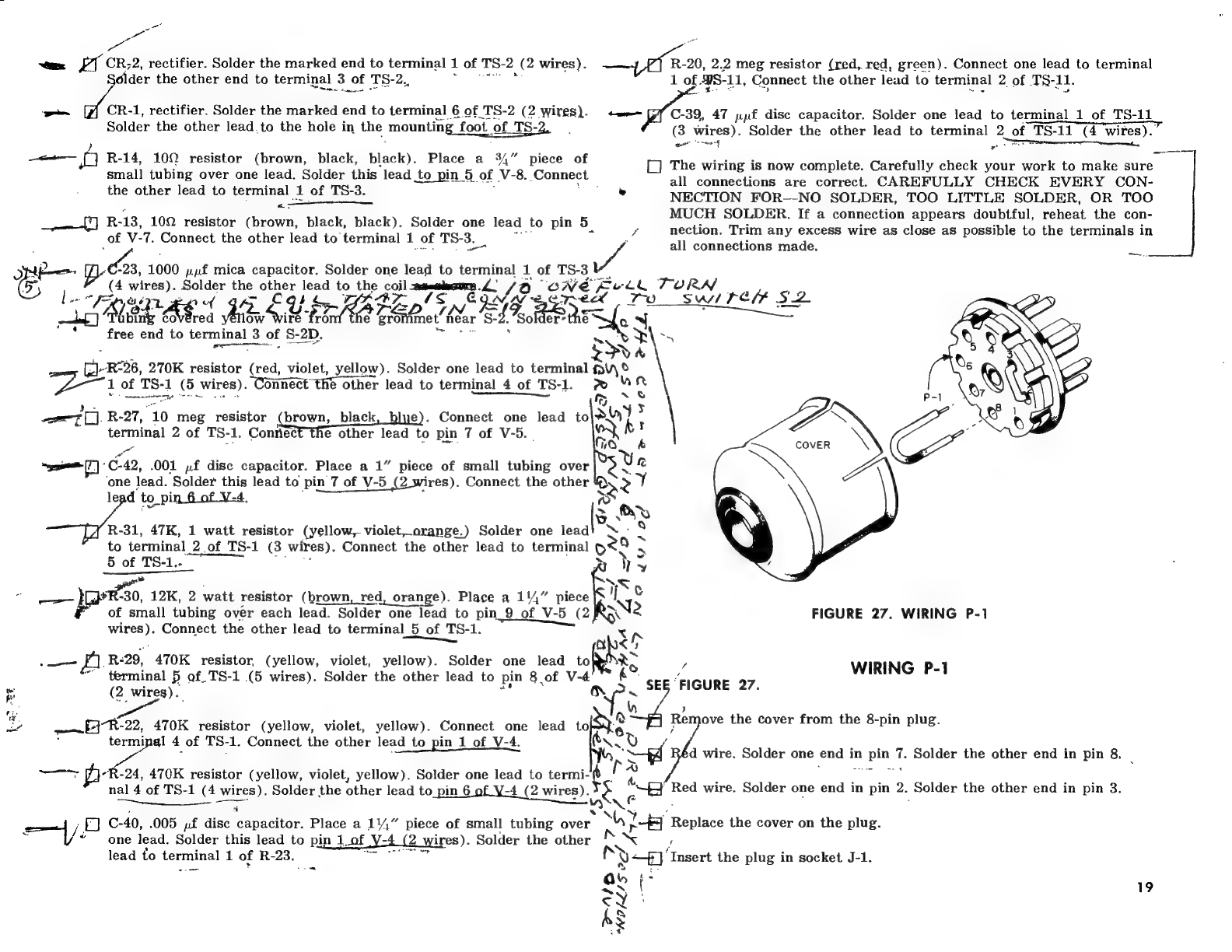

PREWIRING

S-2

SEE

FIGURE

12.

)

/

[{]

S-2,

the

4-wafer

switch.

Position

the

switch

with

the

locating

tab

as

shown

in

Figure

12.

“=—

fF]

Cut

a

114”

piece

of

the

small

bare

wire.

Solder

one

end

to

terminal

2

of

S-2A.

Insert

the

other

end

through

terminal

3

of

S-2A

and

con-

nect

to

terminal

4

of

S-2A.

Solder

terminal

3

of

S-2A.

fs

g

‘f

=

J

L-6,

coil

(marked

with

a

violet

dot)

and

R-40,

4.7K

sesistore

(yellow

violet,

red).

Wrap

the

leads

of

R-40

around

the

leads

of

L-6

as

close

to

the

coil

form

as

possible.

Clip

the

excess

and

solder,

the

leads

of

48

R-40

to

those

of

L-6

as

shown

in

Figure

12.

foe

£2

—.

rae

L-6

and

R-40.

Cut

one

of

the

leads

from

L-6

to

*4,”

long.

Solder

this

;

lead

to

terminal

1

of.S-2A.

The

other

lead

from

the

two

components

will

be

connected

later.

poe

L-6

L-6

oe

ee

/

pak

WRAP

AROUND

LEADS,

an

CUT

OFF

EXCESS

AND

SOLDER

ne

\

NSS

+

|

a

een

ee

cal

a

LOCATING

—-S-2A

S-2B

S-2C

S-2D

TAB

FIGURE

12.

PREWIRING

5-2

—

et

R-10,

1K,

2

watt

resistor

(brown,

black,

red).

Connect

one

lead

to

terminal

1

of

S-2B,

Connect

the

other

lead

to

terminal

1

of

S-2C.,

—

‘Orange

wire.

Solder

one

end

to

terminal

1

of

S-2B

,(2

wires).

The

other

end

will

be

connected

later.

—

ral

Violet

wire.

Solder

one

end

to

terminal

2

of

S-

2B.

The

other

end

will

be

connected

later.

—

ml

Brown

wire.

Solder

one

end

to

terminal

3

of

S-2B.

The

other

end

will

;

be

connected

later.

~—

131,”

heavy

bare

wire.

Solder

one

end

to

terminal

1

of

S-2D.

The

other

end

will

be

connected

later.

—_

Fy

Yellow

wire.

Solder

one

end

to

terminal

2

of

S-2D.

The

other

end

will

be

connected

later.

&

5

Tok

SS

ve

—

ai

==

:

es

g

5

12

A,

x

>

FIGURE

13.

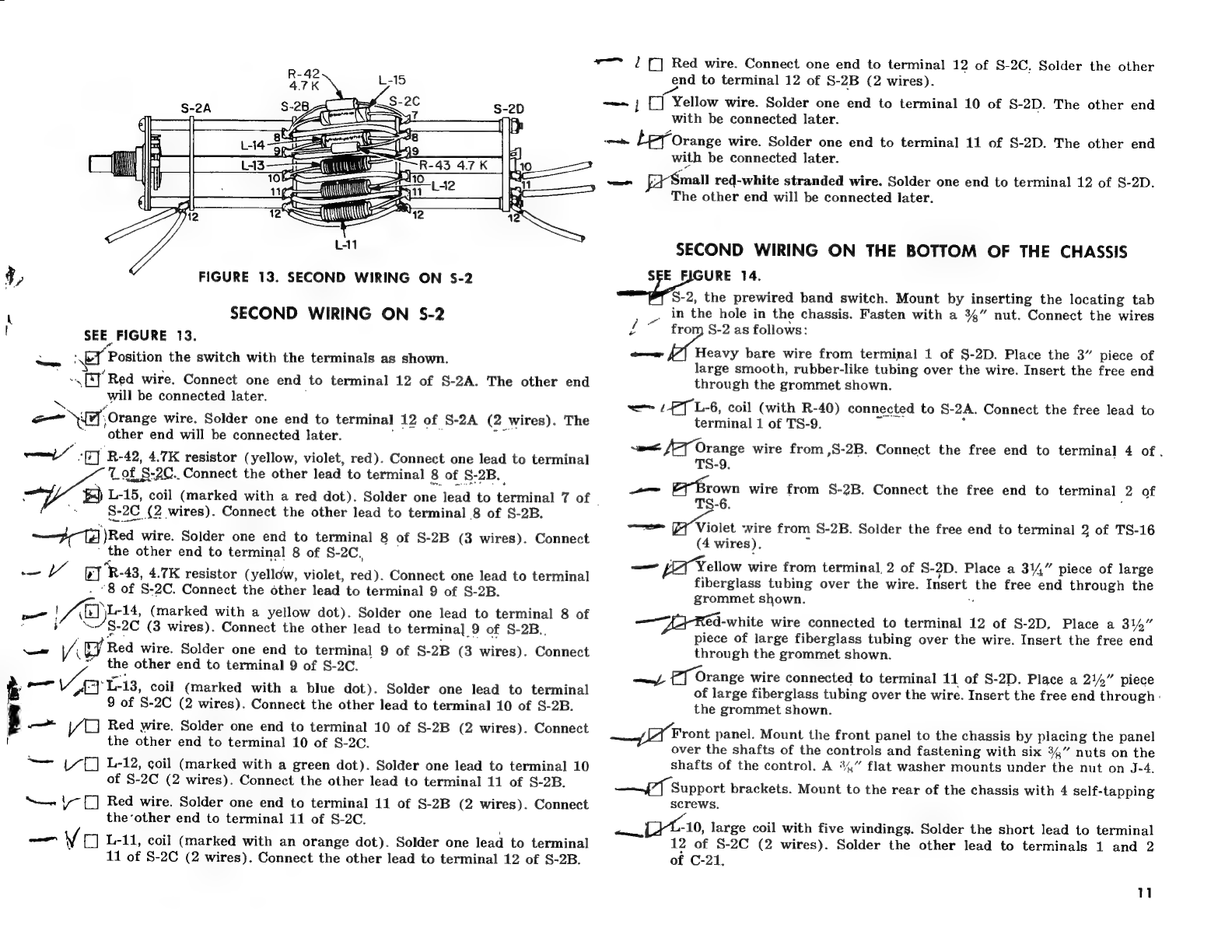

SECOND

WIRING

ON

S-2

SECOND

WIRING

ON

S-2

SEE

FIGURE

13.

py

Position

the

switch

with

the

terminals

as

shown.

~\

[J

Red

wire.

Connect

one

end

to

terminal

12

of

S-2A.

The

other

end

will

be

connected

later.

-_

fry,

Orange

wire.

Solder

one

end

to

terminal

12

of

S-2A

(2

wires).

The

‘other

end

will

be

connected

later.

—

ey

R-

42,

4.7K

resistor

(yellow,

violet,

red).

Connect

one

lead

to

terminal

—

Toft

§-2C.

Connect

the

other

lead

to

terminal

8

of

S-2B.

“yee

L-15,

coil

(marked

with

a

red

dot).

Solder

one

lead

to

terminal

7

of

|

S-

2c.

(2

wires).

Connect

the

other

lead

to

terminal

8

of

S-2B.

Fa)

Rea

wire.

Solder

one

end

to

terminal

8

of

S-2B

(3

wires).

Connect

the

other

end

to

terminal

8

of

S-2C,

—

YY

oT

‘R-

43,

4.7K

resistor

(yelldw,

violet,

red).

Connect

one

lead

to

terminal

“8 of

S-2C.

Connect

the

other

lead

to

terminal

9

of

S-2B.

—

1

Ayes

(marked

with

a

yellow

dot).

Solder

one

lead

to

terminal

8

of

S

2C

(3

wires).

Connect

the

other

lead

to

terminal

_

9

of

S-2B..

res

Vil

/

Red

wire.

Solder

one

end

to

terminal

9

of

S-

2B

(3

wires).

Connect

the

other

end

to

terminal

9

of

S-2C.

—

Vy

1-13,

coil

(marked

with

a

blue

dot).

Solder

one

lead

to

terminal

9

of

S-2C

(2

wires).

Connect

the

other

lead

to

terminal

10

of

S-2B.

—_

yo

Red

wire.

Solder

one

end

to

terminal

10

of

S-2B

(2

wires).

Connect

the

other

end

to

terminal

10

of

S-2C.

“——

1/{]

L-12,

coil

(marked

with

a

green

dot).

Solder

one

lead

to

terminal

10

of

§-2C

(2

wires).

Connect

the

other

lead

to

terminal

11

of

$-2B.

“—

1

[[]

Red

wire.

Solder

one

end

to

terminal

11

of

S-2B

(2

wires).

Connect

the‘other

end

to

terminal

11

of

S-2C.

—

Vo

L-11,

coil

(marked

with

an

orange

dot).

Solder

one

lead

to

terminal

11

of

S-2C

(2

wires).

Connect

the

other

lead

to

terminal

12

of

$-2B.

~~

?/

[]

Red

wire.

Connect

one

end

to

terminal

12

of

S-2C,

Solder

the

other

end

to

terminal

12

of

S-2B

(2

wires).

——~

;

[]

Yellow

wire.

Solder

one

end

to

terminal

10

of

S-2D.

The

other

end

with

be

connected

later.

—

Leforange

wire.

Solder

one

end

to

terminal

11

of

S-2D.

The

other

end

with

be

connected

later.

sitet

Small

red-white

stranded

wire.

Solder

one

end

to

terminal

12

of

S-2D.

The

other

end

will

be

connected

later.

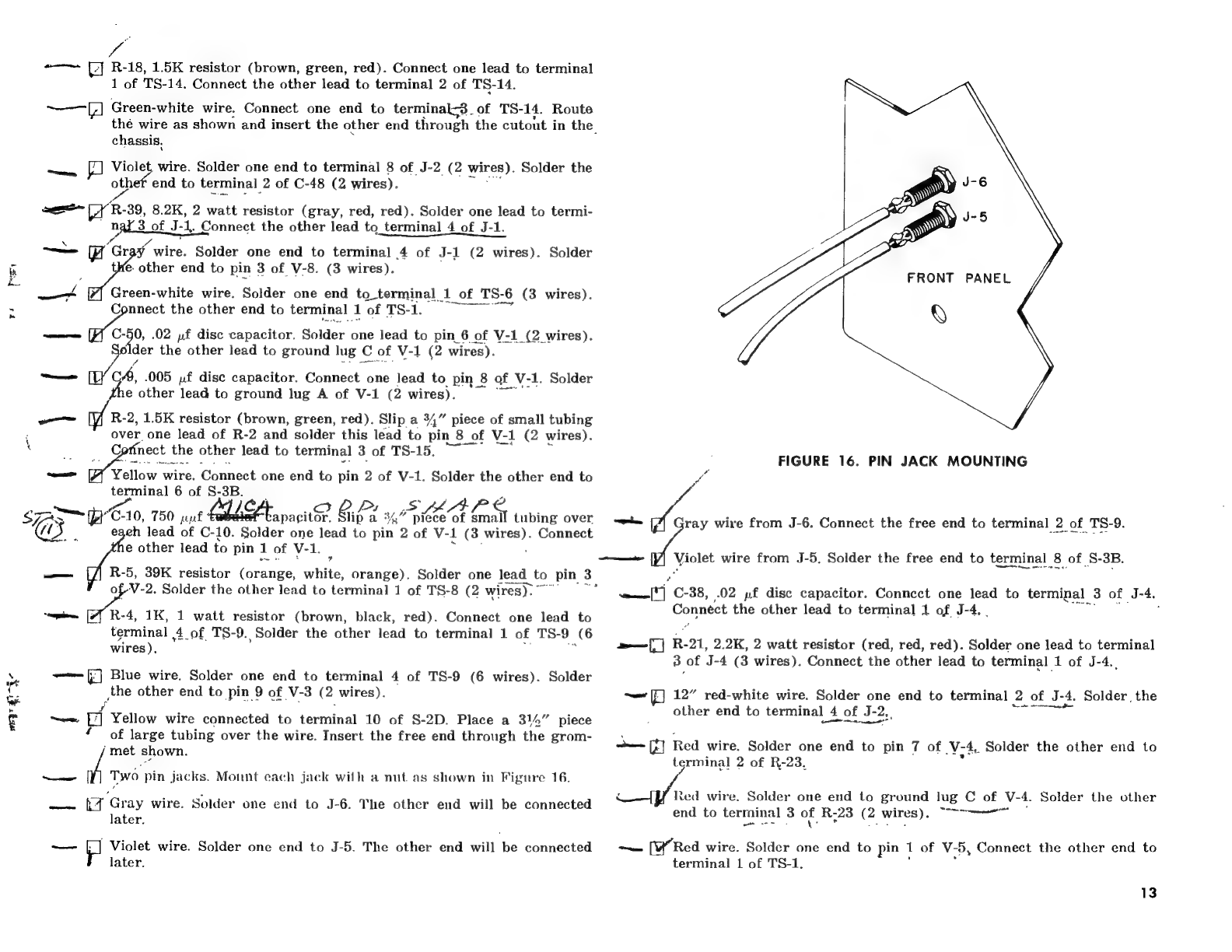

SECOND

WIRING

ON

THE

BOTTOM

OF

THE

CHASSIS

SEE

FIGURE

14.

8-2,

the

prewired

band

switch.

Mount

by

inserting

the

locating

tab

.

in

the

hole

in

the

chassis.

Fasten

with

a

34”

nut.

Connect

the

wires

io

See

of

from

S-2

as

follows:

—e

Heavy

bare

wire

from

terminal

1

of

S-2D.

Place

the

3”

piece

of

large

smooth,

rubber-like

tubing

over

the

wire.

Insert

the

free

end

through

the

grommet

shown.

—

LPT

L-

6,

coil

(with

R-40)

connected

to

S-

2A.

Connect

the

free

lead

to

terminal

1

of

TS-9.

<a

JT

Orange

wire

from

,S-2B.

Connect

the

free

end

to

terminal

4

of.

TS-9.

—

ex

Brown

wire

from

S-2B.

Connect

the

free

end

to

terminal

2

of

TS-6.

—

Violet

wire

from

S-2B.

Solder

the

free

end

to

terminal

2

of

TS-16

(4

wires).

—

[Yellow

wire

from

terminal,

2

of

S-

2D.

Place

a

314”

piece

of

large

fiberglass

tubing

over

the

wire.

lngent:

the

free

end

through

the

grommet

shown.

:

_—",

ed-white

wire

connected

to

terminal

12

of

S-2D,

Place

a

314”

piece

of

large

fiberglass

tubing

over

the

wire.

Insert

the

free

end

through

the

grommet

shown.

—y

£7

Orange

wire

connected

to

terminal

11

of

S-2D.

Place

a

214”

piece

of

large

fiberglass

tubing

over

the

wire.

Insert

the

free

end

through:

the

grommet

shown.

SA

Front

panel.

Mount

the

front

panel

to

the

chassis

by

placing

the

panel

over

the

shafts

of

the

controls

and

fastening

with

six

34”

nuts

on

the

shafts

of

the

control.

A

%4”

flat

washer

mounts

under

the

nut

on

J-4.

——7

Support

brackets.

Mount

to

the

rear

of

the

chassis

with

4

self-tapping

screws.

-10,

large

coil

with

five

windings.

Solder

the

short

lead

to

terminal

12

of

8-2C

(2

wires).

Solder

the

other

lead

to

terminals

1

and

2

of

C-21,

1

FIGURE

15.

CABLE

PREPARATION

UNRAVEL

SHIELD

WIRES,

TWIST

TOGETHER,

AND

COAT

TIP

WITH

SOLDER.

COAT

INNER

CONDUCTOR

SEE

FiGURE

14.

TIP

WITH

SOLDER.

L-24,

the

small

parasitic

suppressor.

Note

that

there

are

two

large

Sy

and

one

small

resistor

wrapped

with

several

turns

of

wire.

These

are

the

parasitic

suppressors.

The

small

one,

wound

on

a

15

watt

resistor,

ig

L-24.

Solder

one

lead

to

pin

7

of

V-3.

Solder

the

other

lead

to

the

ead

from

L-10.

—

C-19,

.005

pf

disc

capacitor.

Solder

one

lead

to

ground

lug

A

of

V-3,

B

wires)

Connect

the

other

lead,

to

erat

1

of

TS-10.

ORAL