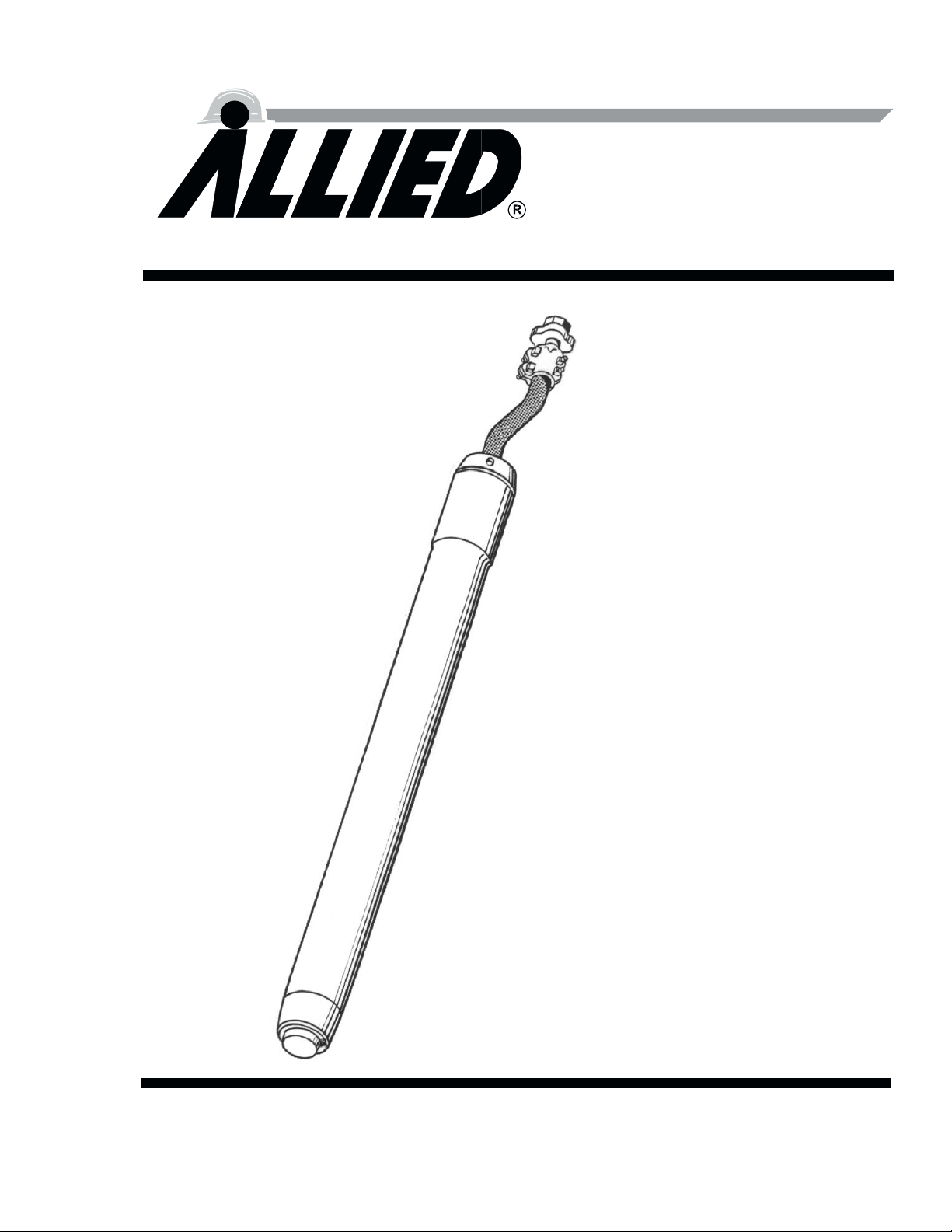

ALLIED Model 5500 Hole-Hog

08/25/00 v

LIST OF FIGURES

Figure Page

Figure 2-1. Major Components: Hole-Hog, Model 5500 ................3

Figure 3-1. Hole-Hog Decal Location ..........................6

Figure 8-1. Spanner Wrench 835758...........................19

Figure 8-2. Loosening the End Cap. ..........................20

Figure 8-3. Removing Tail Assembly...........................20

Figure 8-4. Access the Striker with a Hook. ......................20

Figure 8-5. Tilting the BodyAnvil to Access the Striker. ...............21

Figure 8-6. Tail Assembly and Striker Removed from Body/Anvil. ..........21

Figure 8-7. Pad the vise jaws to protect the End Cap threads. ............21

Figure 8-8. Secure End Cap for Disassembly. .....................22

Figure 8-9. Hose Coupling Clamp ...........................22

Figure 8-10. Remove Hose from Coupling. .......................22

Figure 8-11. Remove hose completely from the coupling plug and clamp. ......22

Figure 8-12. Secure End Cap in Vice or Saddle Clamp ................23

Figure 8-13. Hose Adapter, and Whip Hose ......................23

Figure 8-14. Remove Whip Hose from the Adapter ..................23

Figure 8-15. Remove Hose Socket from Valve Stem. .................23

Figure 8-16. Loosen Hex Head Cap Screw........................24

Figure 8-17. Loosen the Hose Adapter on the Valve Stem. ..............24

Figure 8-18.Remove Hose Adapter from the Valve Stem ...............24

Figure 8-19. Thread the Valve Stem From the Valve Body Nut and End Cap. . . . 24

Figure 8-20. Inspect Hose Socket. ...........................24

Figure 8-21. Valve Stem and Valve Components in Vise. ...............25

Figure 8-22. Remove Valve Nut and Nut Bushing from Valve Stem. .........25

Figure 8-23. Remove Valve and the upper Spacers, and O-ring. ...........25

Figure 8-24. Remove the lower Spacers and O-ring. ..................26

Figure 8-25. Removing the Valve Seal from the End Cap ...............26

Figure 8-26. End Cap in Arbor Press .........................27

Figure 8-27. Remove Valve Body Nut .........................27

Figure 8-28. End Cap, Shock Absorber and Push Bar in Press.............27