507369-03Issue 1737Page 4 of 4

Placing the Unit into Operation

IMPORTANT

Follow the lighting instructions provided on the unit.

If lighting instructions are not available, refer to the

following section.

Units are equipped with a hot surface ignition system. The

ignition system automatically lights the burners each time

the thermostat calls for heat.

1. STOP! Read the safety information at the beginning

of this section.

2. Set the thermostat to its lowest setting.

3. Turn off all electrical power to the furnace.

4. Do not try to light the burners by hand.

5. Remove the unit access panel.

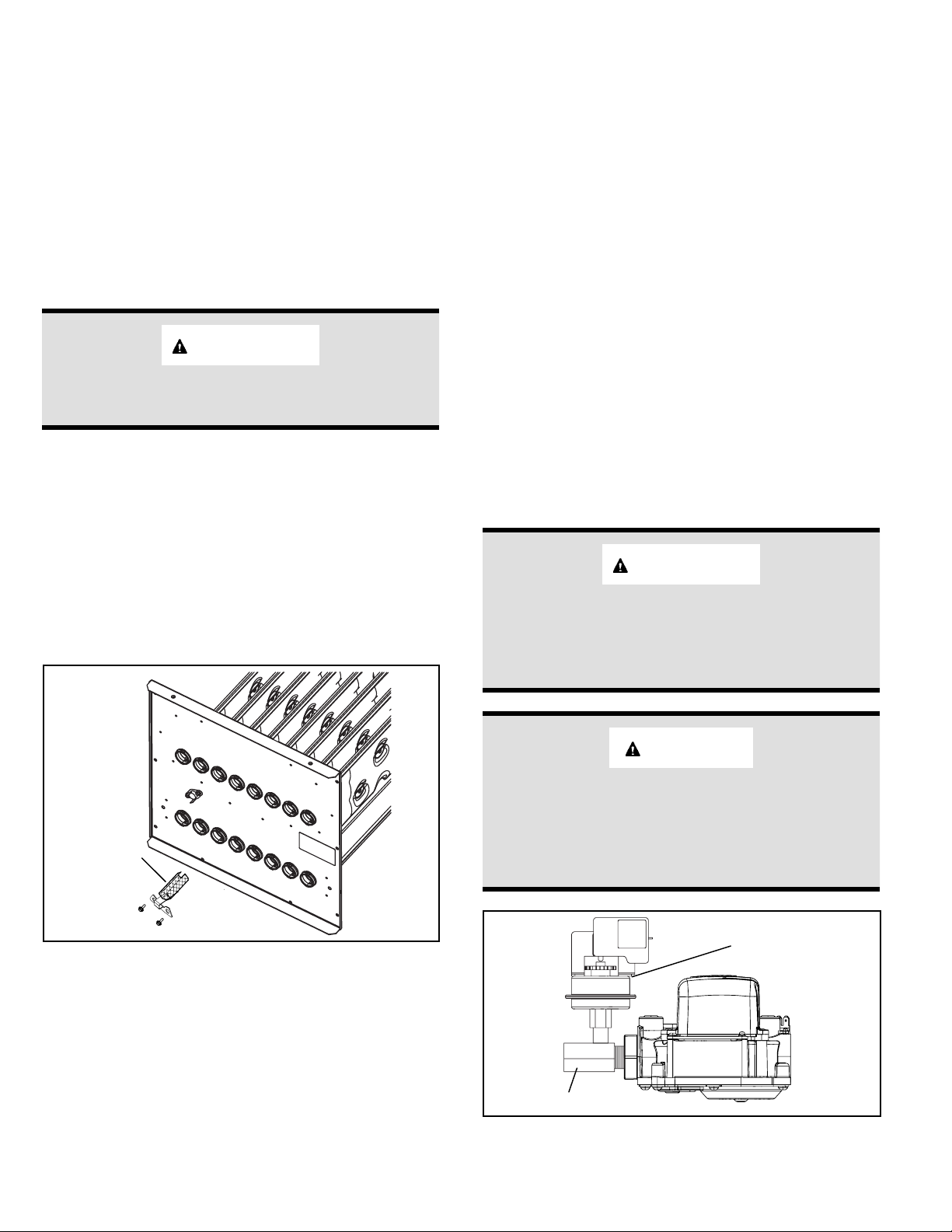

6. Move gas valve switch to OFF. See Figure 3.

7. Wait ve (5) minutes for any gas to clear out. If you

then smell gas, STOP! Immediately call your gas

supplier from a neighbor’s phone. Follow the gas

supplier’s instructions. If you do not smell gas, go to

the next step.

8. Move gas valve switch to ON. See Figure 3.

9. Replace the unit access panel.

10. Turn on all electrical power to the unit.

11. Set the thermostat to desired setting.

12. If the furnace will not operate, see the section “Turning

Gas Off to the Unit” and call your the gas supplier.

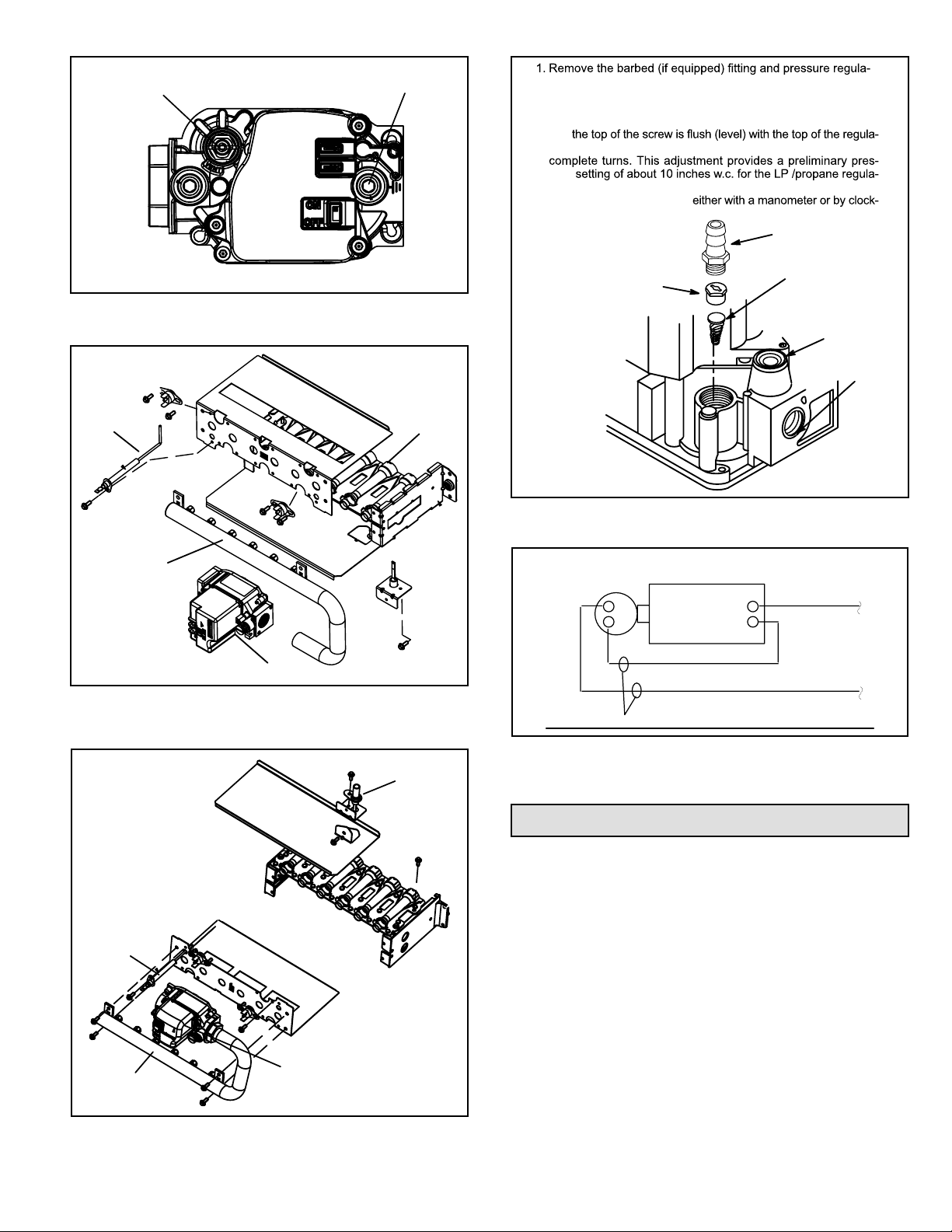

Gas Pressure Measurement

Gas Flow (Approximate)

Capacity

Seconds for One Revolution

Natural LP

1 cu ft

Dial

2 cu ft

Dial

1 cu ft

Dial

2 cu ft

Dial

-045 80 160 200 400

-070 55 110 136 272

-090 41 82 102 204

-110 33 66 82 164

-135 27 54 68 136

Natural - 1000 btu/cu ft LP - 2500 btu/cu ft

Table 1. Gas Meter Clocking Chart

Furnace should operate at least 5 minutes before checking

gas ow. Determine time in seconds for two revolutions of

gas through the meter. (Two revolutions assures a more

accurate time.) Divide by two and compare to time in

Table 1. If manifold pressure matches Table 2 and rate is

incorrect, check gas orices for proper size and restriction.

Remove temporary gas meter if installed.

Supply Pressure Measurement

When testing supply gas pressure, use the 1/8” N.P.T.

supply line tap located on the gas valve to facilitate test

gauge connection. See Figure 2. Check gas line pressure

with unit ring at maximum rate. Low pressure may result

in erratic operation or underre. High pressure can result in

permanent damage to gas valve or overre.

On multiple unit installations, each unit should be checked

separately, with and without units operating. Supply

pressure must fall within range listed in Table 2.

NOTE: To obtain accurate reading, shut off all other gas

appliances connected to meter.

Manifold Pressure Measurement

1. Connect test gauge to manifold pressure tap (Figure

2) on gas valve.

2. Start unit and allow 5 minutes for unit to reach steady

state.

3. After allowing unit to stabilize for 5 minutes, record

manifold pressure and compare to value given in

Table 2.

4. If necessary, make adjustments. Figure 2 shows

location of adjustment screw.

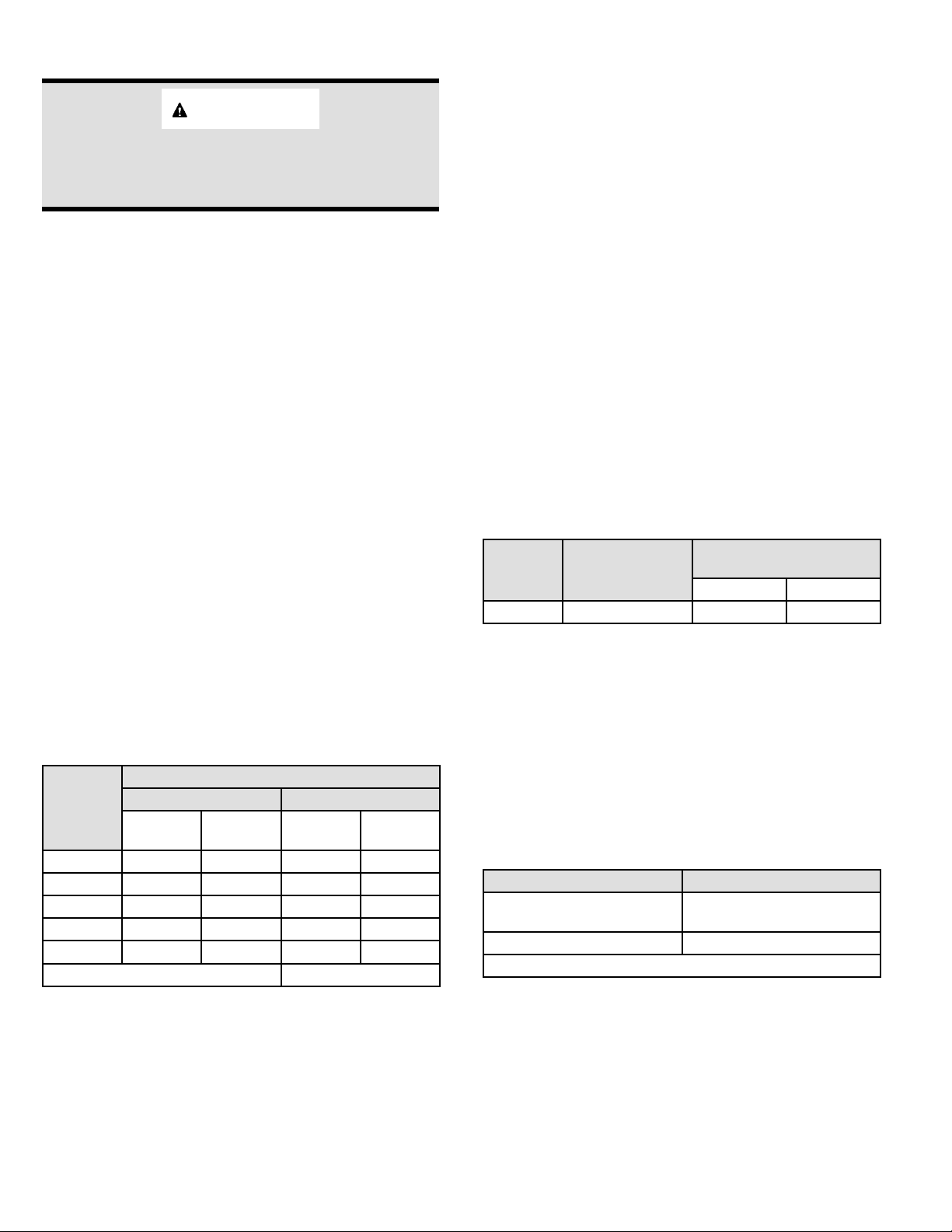

Capacity

Manifold

Pressure in. w.g.

0 - 7500 ft.

Supply Line Pressure

in. w.g.

Min Max

All Models 10.0 11.0 13.0

Table 2.

Proper Combustion

Furnace should operate minimum 15 minutes with correct

manifold pressure and gas ow rate before checking

combustion. Take combustion sample beyond the ue

outlet and compare to Table 3.

NOTE: Shut unit off and remove manometer as soon as

the supply pressure, manifold pressure and combustion

sample have been obtained. Take care to remove barbed

tting and replace threaded plug.

Model CO2% for LP

All A93, A95, 92G1, 95G1 &

96G1 Units 8.4 - 9.6

All A80 & 80G1 Units 7.5 - 9.0

The carbon monoxide reading should not exceed 100 ppm.

Table 3.

Turning Off Gas to the Unit

1. Set the thermostat to its lowest setting.

2. Turn off all the electrical power to the unit.

3. Remove the access panel.

4. Move the switch on the gas valve to OFF. Do not force

the switch.