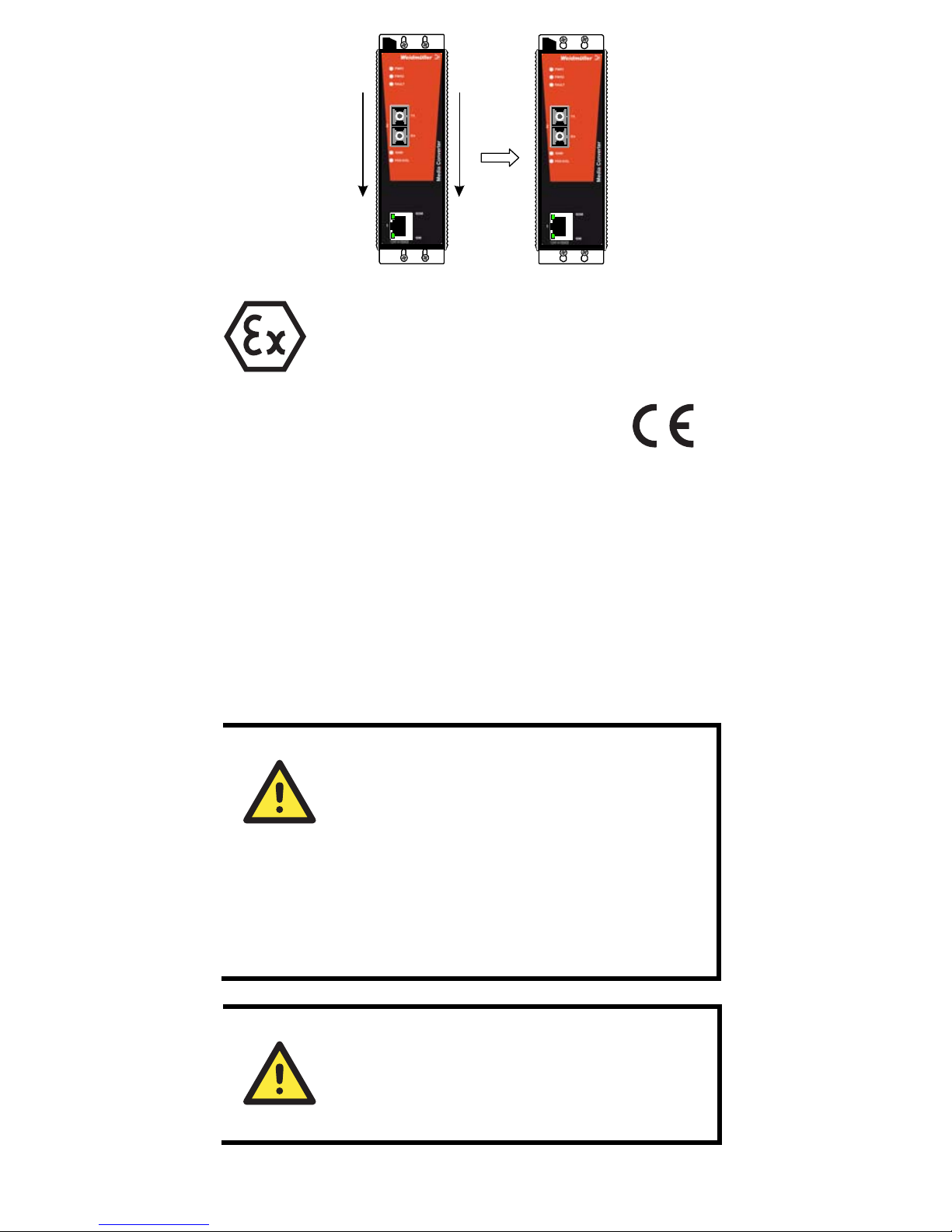

WARNING

This equipment has been evaluated as EEx nC

IIC T4 equipment under DEMKO Certificate No.

03 ATEX 0324537U. Each module is marked

with II 3G and is suitable for use in Zone 2

Explosive Atmospheres. Devices must be

installed in a minimum IP 54 enclosure as

defined in IEC 60529 and EN 60529.

ATTENTION

This unit is a built-in type. During installation into

certain end equipment, it must comply with fire

enclosure stipulations of IEC 60950/EN60950, or

similar statements.

ATTENTION

Safety First!

Be sure to disconnect the power cord before

installing and/or wiring your Weidmüller Media

Converter.

ATTENTION

Safety First!

Calculate the maximum possible current in each

power wire and common wire. Observe all electrical

codes dictating the maximum current allowable for

each wire size.

If the current goes above the maximum ratings, the

wiring could overheat, causing serious damage to

your equipment.

You should also pay attention to the following points:

yUse separate paths to route wiring for power and devices. If power

wiring and device wiring paths must cross, make sure the wires are

perpendicular at the intersection point.

NOTE: Do not run signal or communications wiring and power

wiring in the same wire conduit. To avoid interference, wires with

different signal characteristics should be routed separately.

yYou can use the type of signal transmitted through a wire to

determine which wires should be kept separate. The rule of thumb

is that wiring that shares similar electrical characteristics can be

bundled together.

yKeep input wiring and output wiring separated.

yIt is strongly advised that you label wiring to all devices in the

system when necessary.

Grounding the Media Converter

Grounding and wire routing help limit the effects of noise due to

electromagnetic interference (EMI). Run the ground connection from

the ground screw to the grounding surface prior to connecting devices.

- 7 -