Encoder with Profibus interface

2

Contents

1 Preliminary note � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 4

1�1 Symbols used� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 4

1�2 Warning signs used � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 4

1�3 Notes on this document � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 4

2 Safety instructions � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 4

3 General information � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 5

3�1 1�2 Profibus technology � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 5

4 Functions and features � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 5

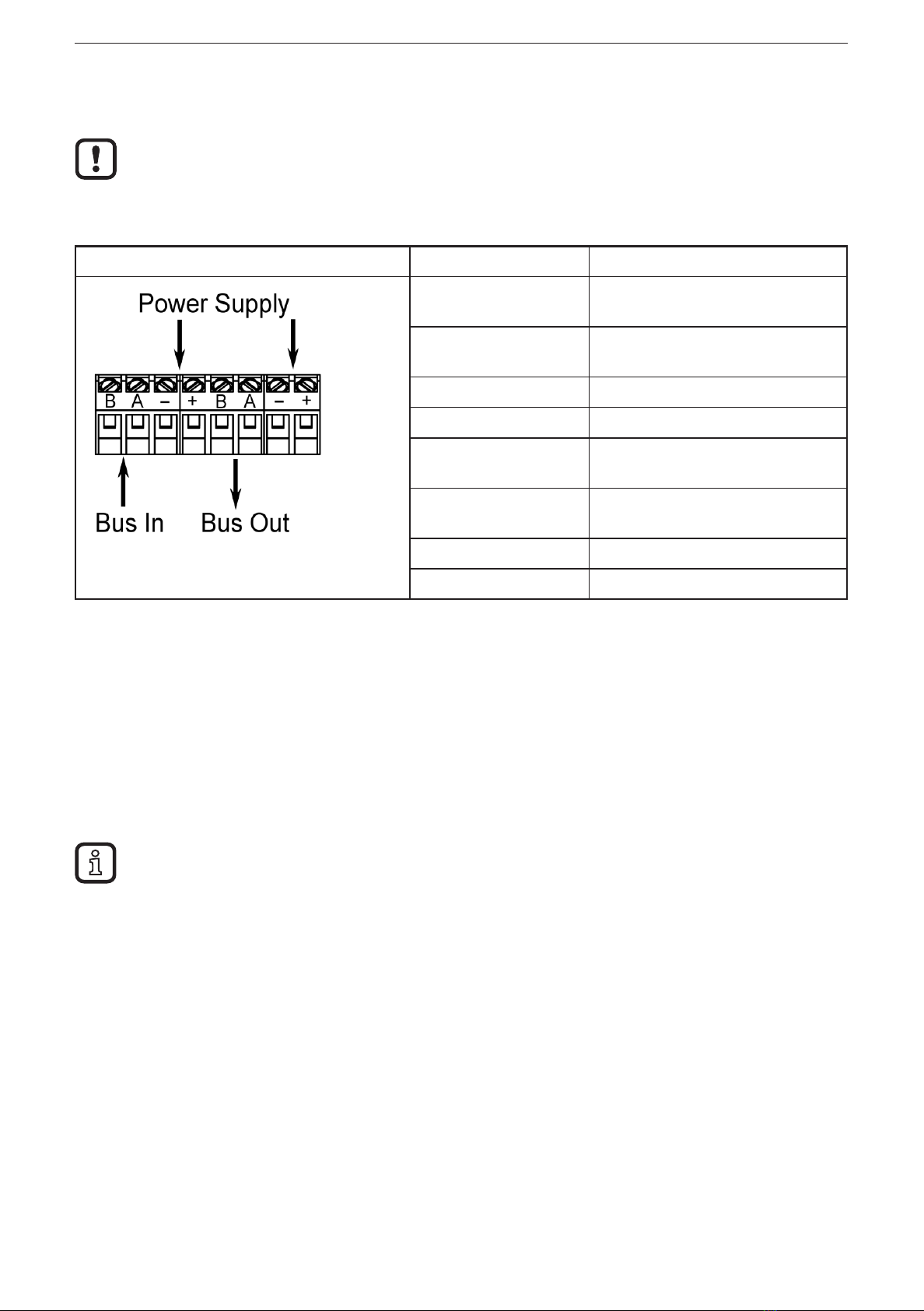

5 Electrical connection� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 6

5�1 Connection of the signal and supply cables � � � � � � � � � � � � � � � � � � � � � � � � 6

6 Installation� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 6

7 Installation� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 7

7�1 Settings in the terminal cap � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 7

7�1�1 Participant address � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 7

7�1�2 Bus termination � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 7

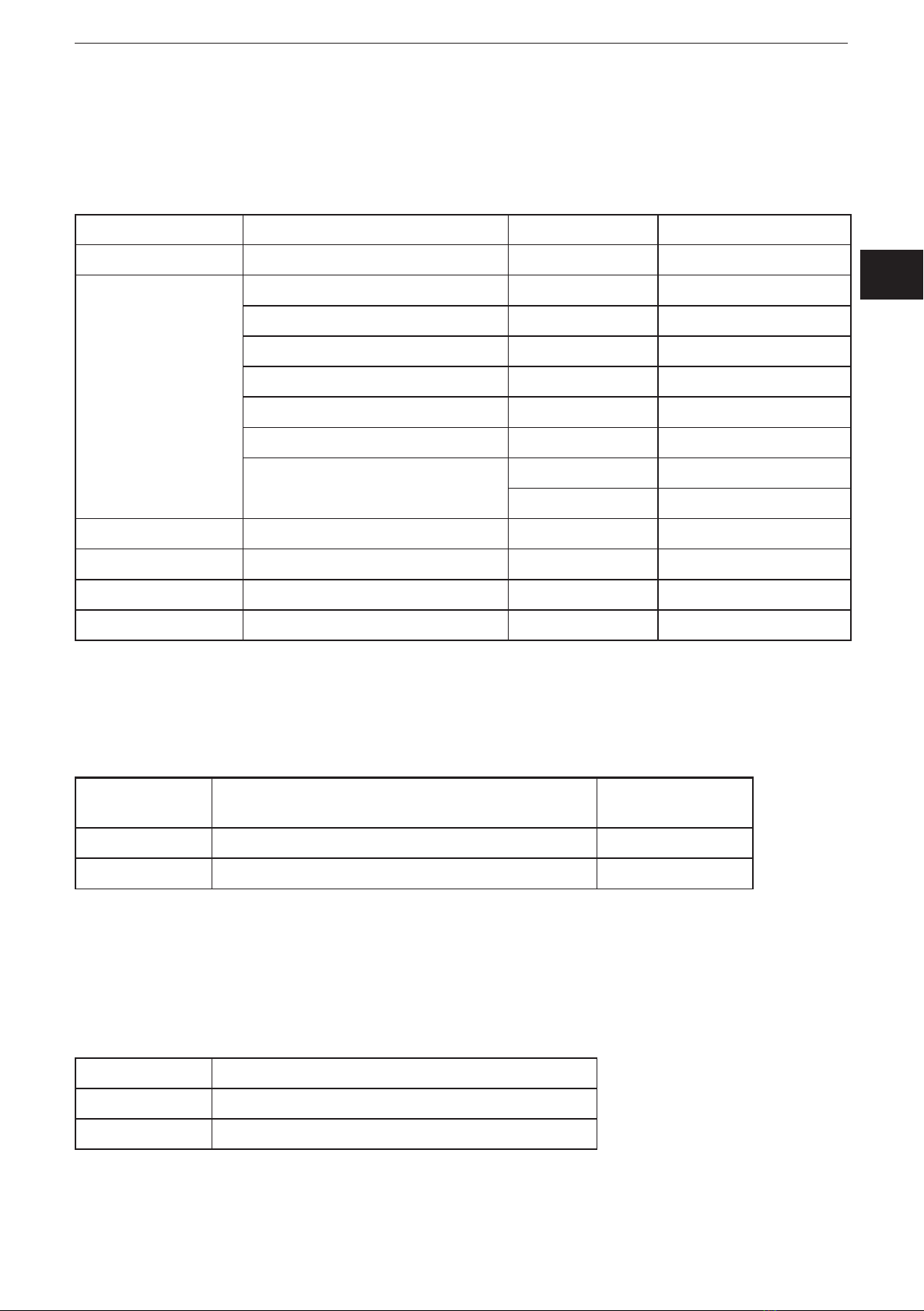

8 Device configuration � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 8

9 Encoder classes � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 8

9�1 Class 1 and Class 2 � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 8

9�2 Parameter setting � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 9

9�2�1 Class 2 functionality � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 9

9�2�2 Commissioning diagnostics � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 9

9�2�3 Scaling function � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 10

9�2�4 Measuring steps per revolution � � � � � � � � � � � � � � � � � � � � � � � � � � � � 10

9�2�5 Total resolution � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 10

9�3 Data exchange during normal operation � � � � � � � � � � � � � � � � � � � � � � � � � �11

9�3�1 Transfer of the process actual value � � � � � � � � � � � � � � � � � � � � � � � � �11

9�3�2 Preset function � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 12

10 Profibus encoder profile Class 2� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 13

10�1 Parameters� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 14

10�1�1 Activation of the manufacturer-specific parameters � � � � � � � � � � � � 14

10�1�2 Requested measuring steps � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 14

10�1�3 Required resolution � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 15

10�1�4 Activate set-up mode � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 16

10�1�5 Reduced diagnosis � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 17

10�1�6 Software limit switch� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 17

10�1�7 Physical measuring steps � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 18

10�1�8 Encoder type � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 18

10�1�9 Unit of measurement velocity� � � � � � � � � � � � � � � � � � � � � � � � � � � � � 19

10�2 Data exchange during normal operation � � � � � � � � � � � � � � � � � � � � � � � � 19

10�3 Set-up mode� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 20