2MK3001RP April 2023 R1

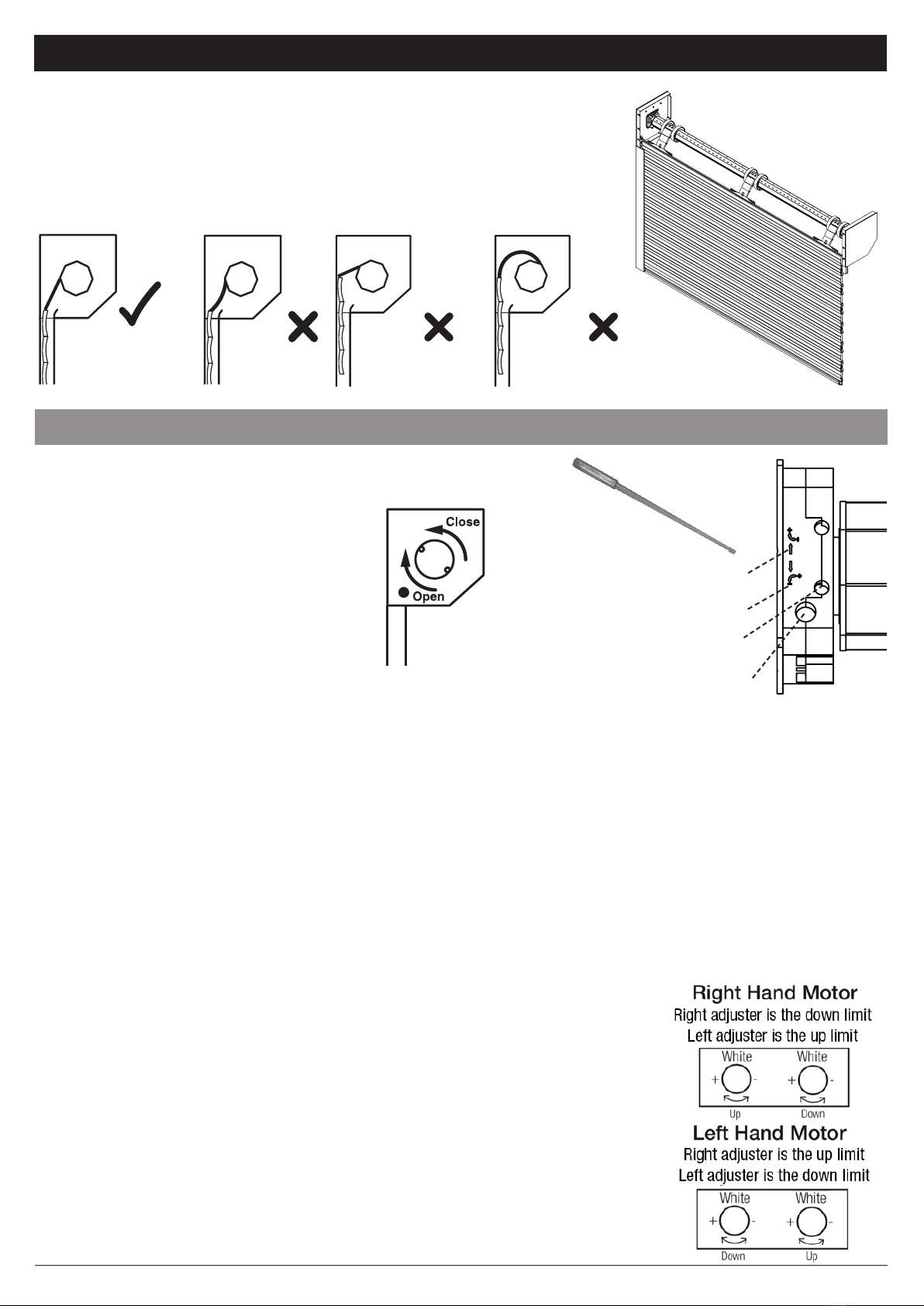

Check:

i. Delivery note

ii. Order sheet

iii. Door dimensions / colour

iv. Opening dimensions / clearances

v. Components

vi. Check for any damage to the guide rails

or the outside roll of the curtain

Do not proceed further with the

installation unless you are sure that

the door is the correct size, and all

components are present.

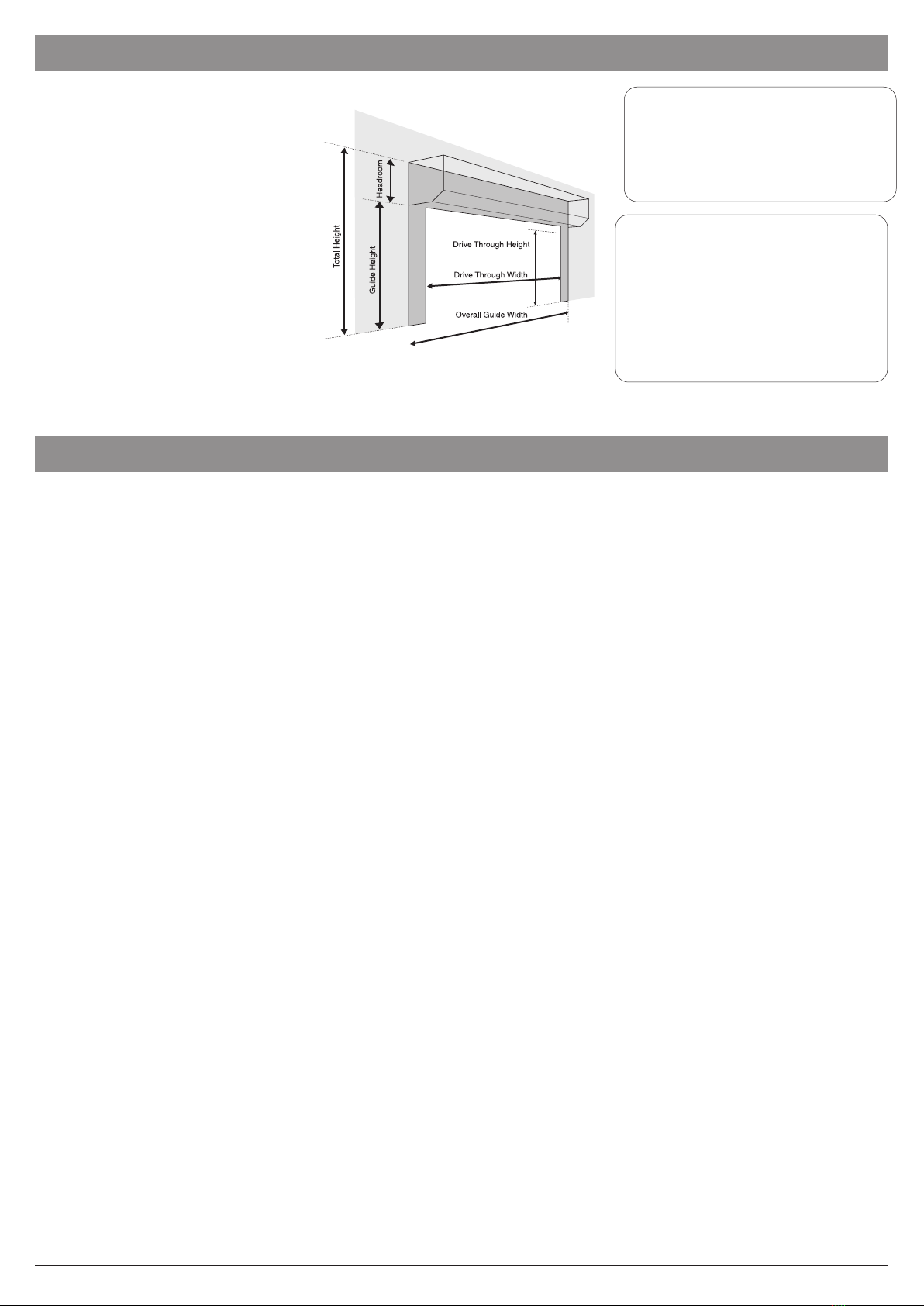

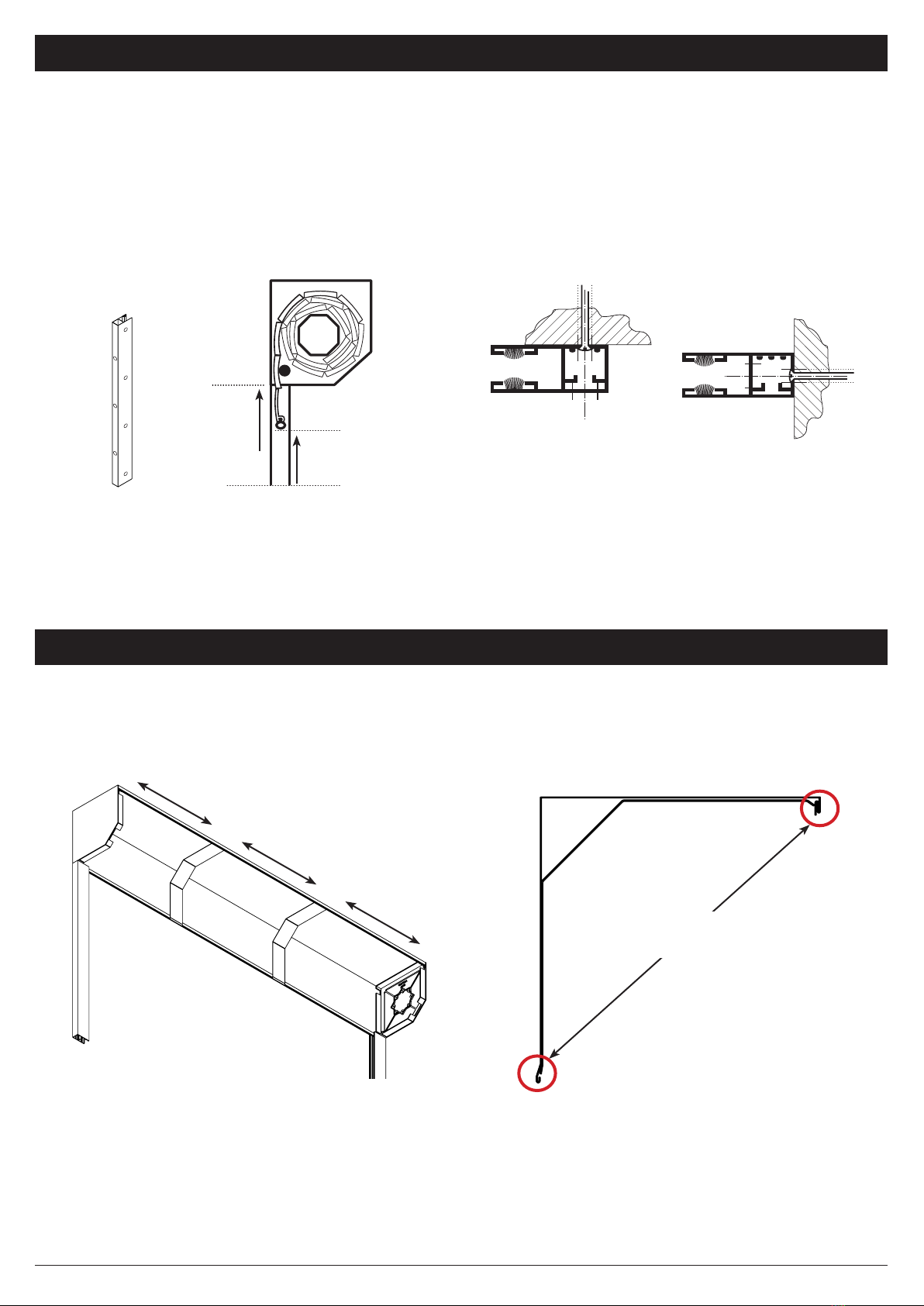

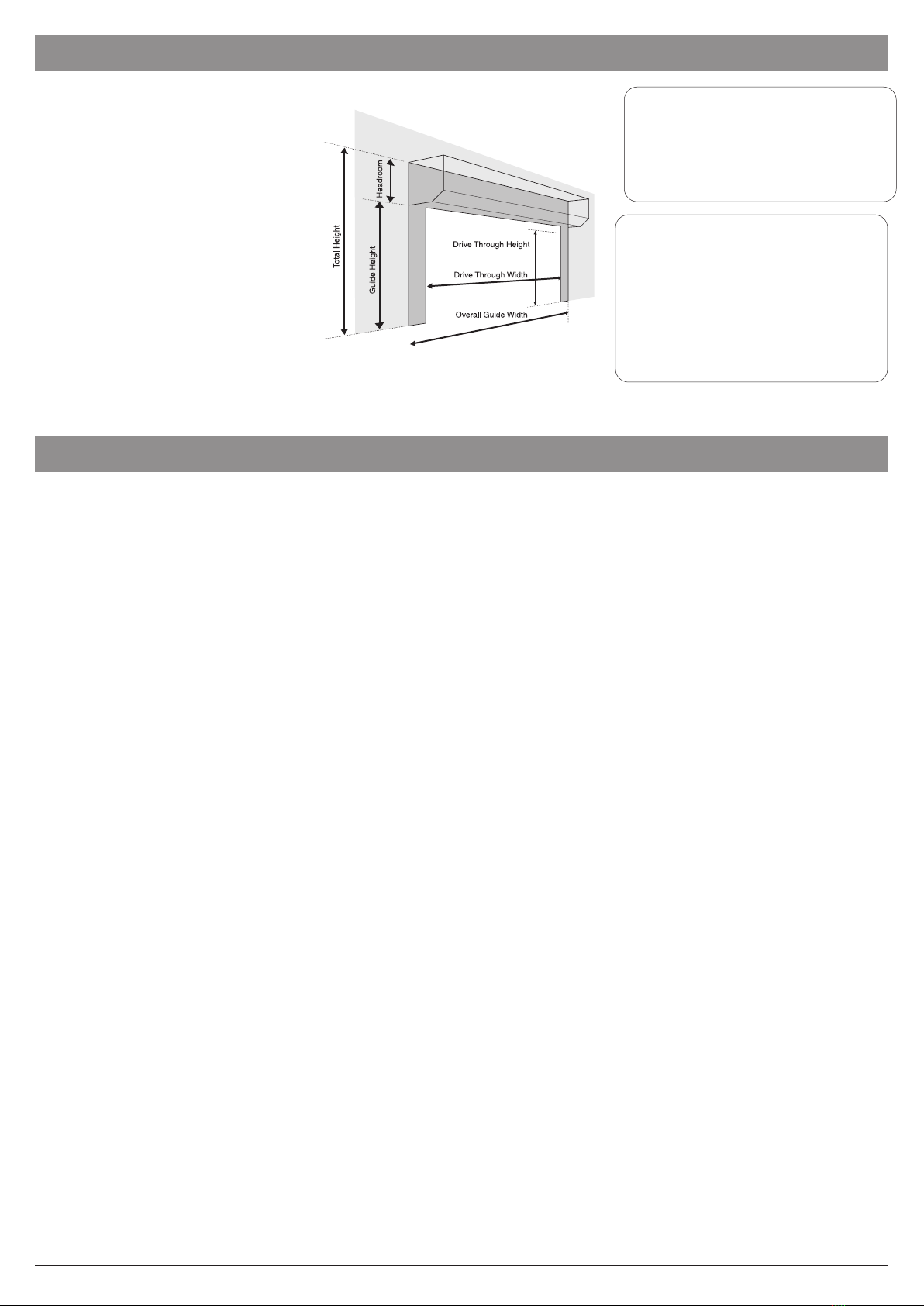

WIDTHS

Manufacturing Width = Over Guide Width

Drive Through Width = Over Guide Width less

150mm for 75mm guides

HEIGHTS

Manufacturing Height = Guide Height

Total Height = Guide Height + End Plate

Headroom/End Plate up to 2.5m Guide Height =

300mm

Drive Through Height = Guide Height less 100mm

Before removing the old door check that the door size and colour

correspond with that which was ordered.

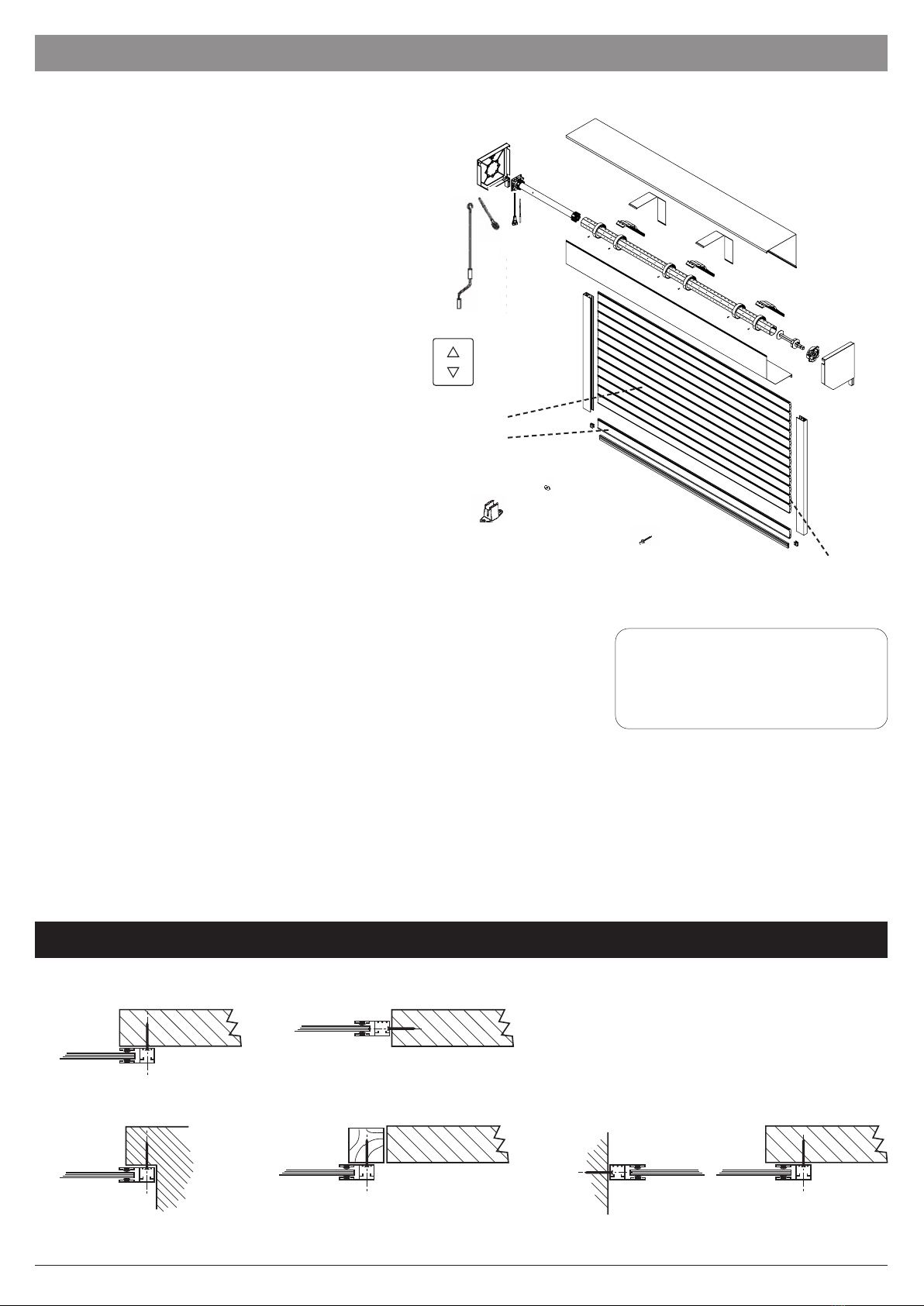

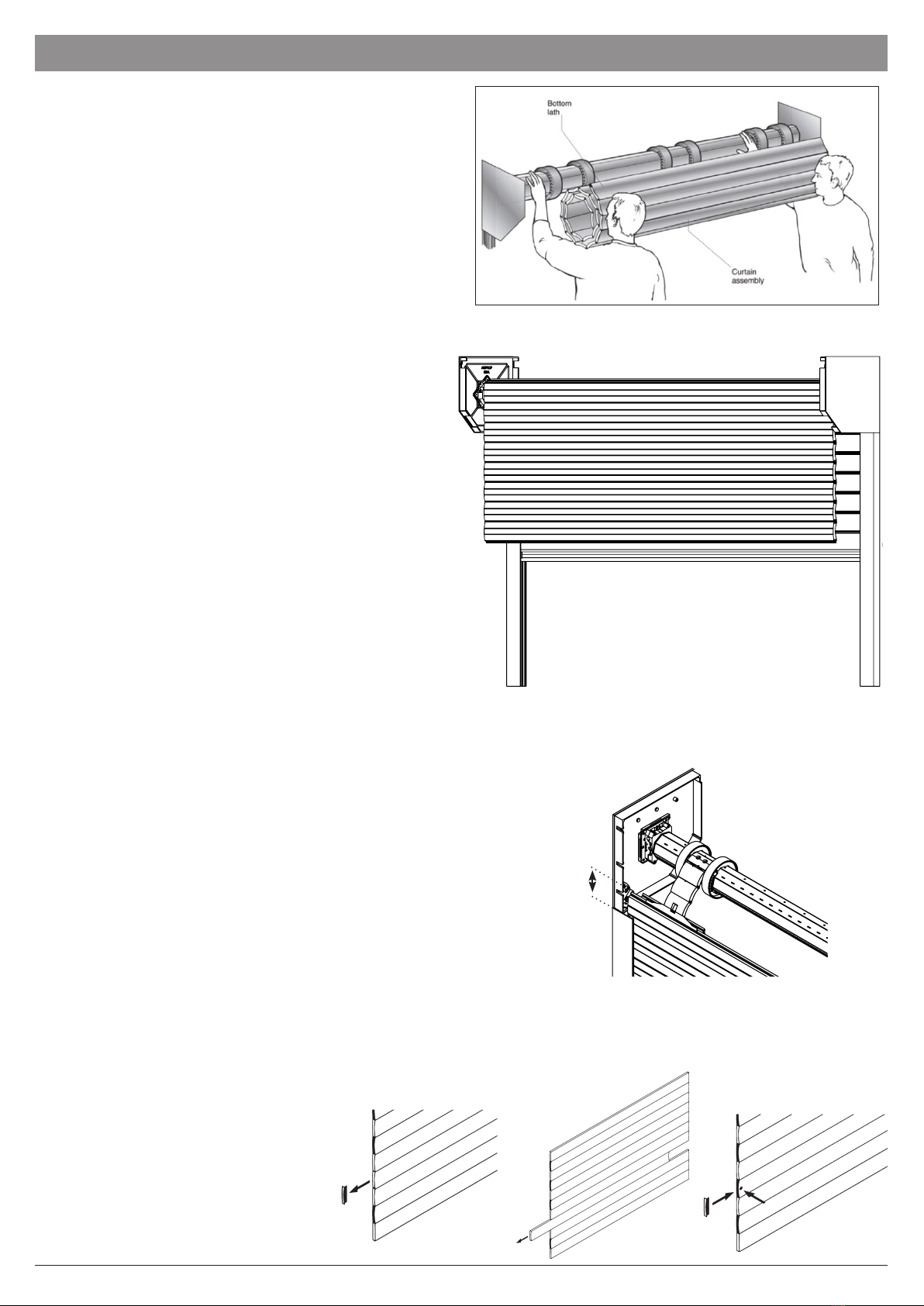

Structural condition of opening.

i. Ensure the area around the opening is strong enough to

support the weight of the door.

ii. The surface where the door is to be fitted must be flush and

reasonably smooth. Small irregularities in the brickwork will be

acceptable.

iii. No obstacles in fitting footprint eg. no sharp objects, pipes,

cables, bumps etc. sticking out from the pillars, lintel or header

to twist the guides, distort the fascia or catch on the curtain.

iv. The lintel must not protrude backwards or forwards from the

brick piers. Should the lintel protrude backwards or forwards

from the brick piers this will require special instructions, please

consult your supplier.

v. The floor must be flat/level. If necessary install a sub-frame to

ensure secure, flush and level fixing (recommended minimum

70 X 70 PAR). The lintel must not protrude backwards or

forwards from the brick piers. Should the lintel protrude

backwards or forwards from the brick piers this will require

special instructions, please consult your installer.

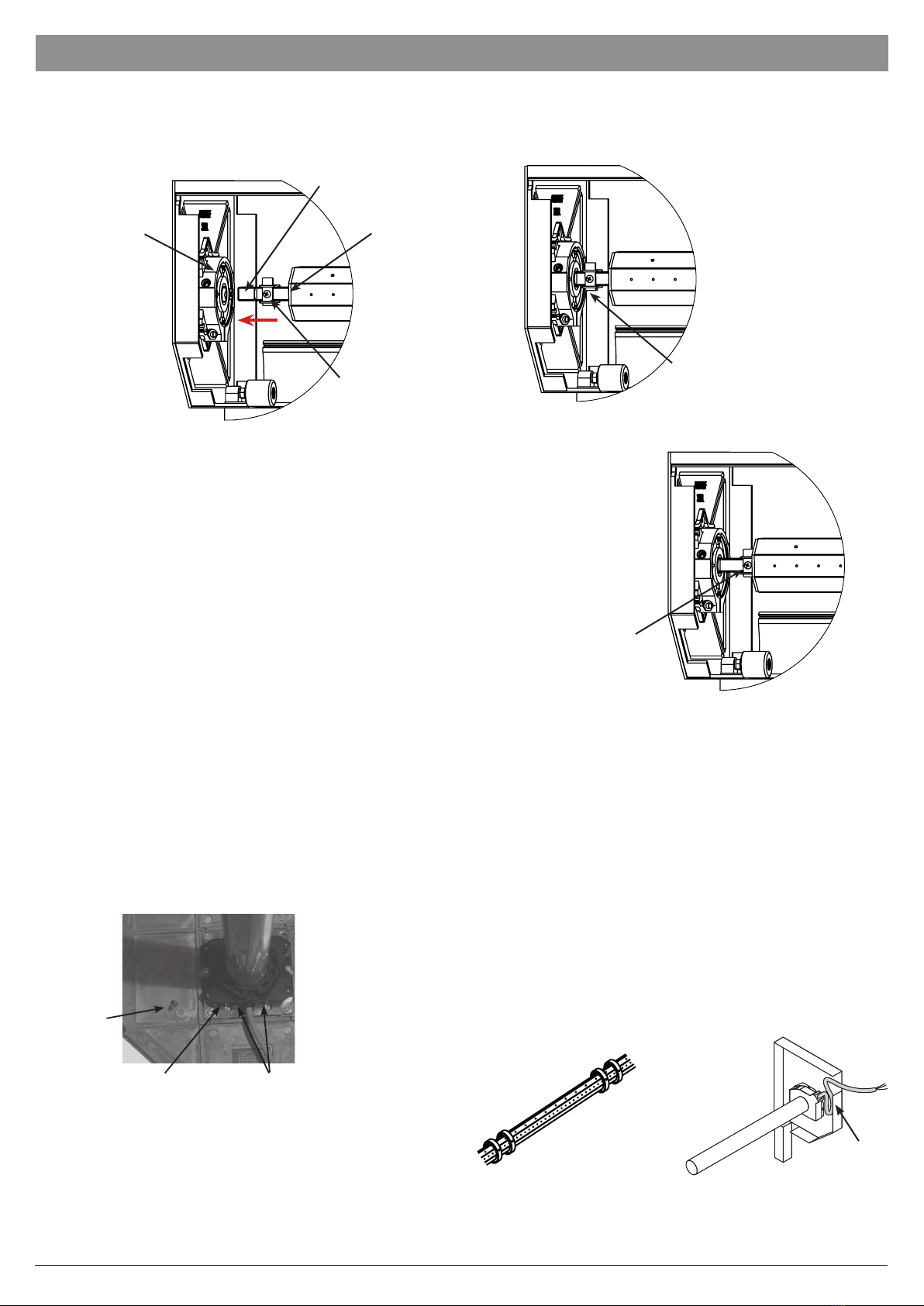

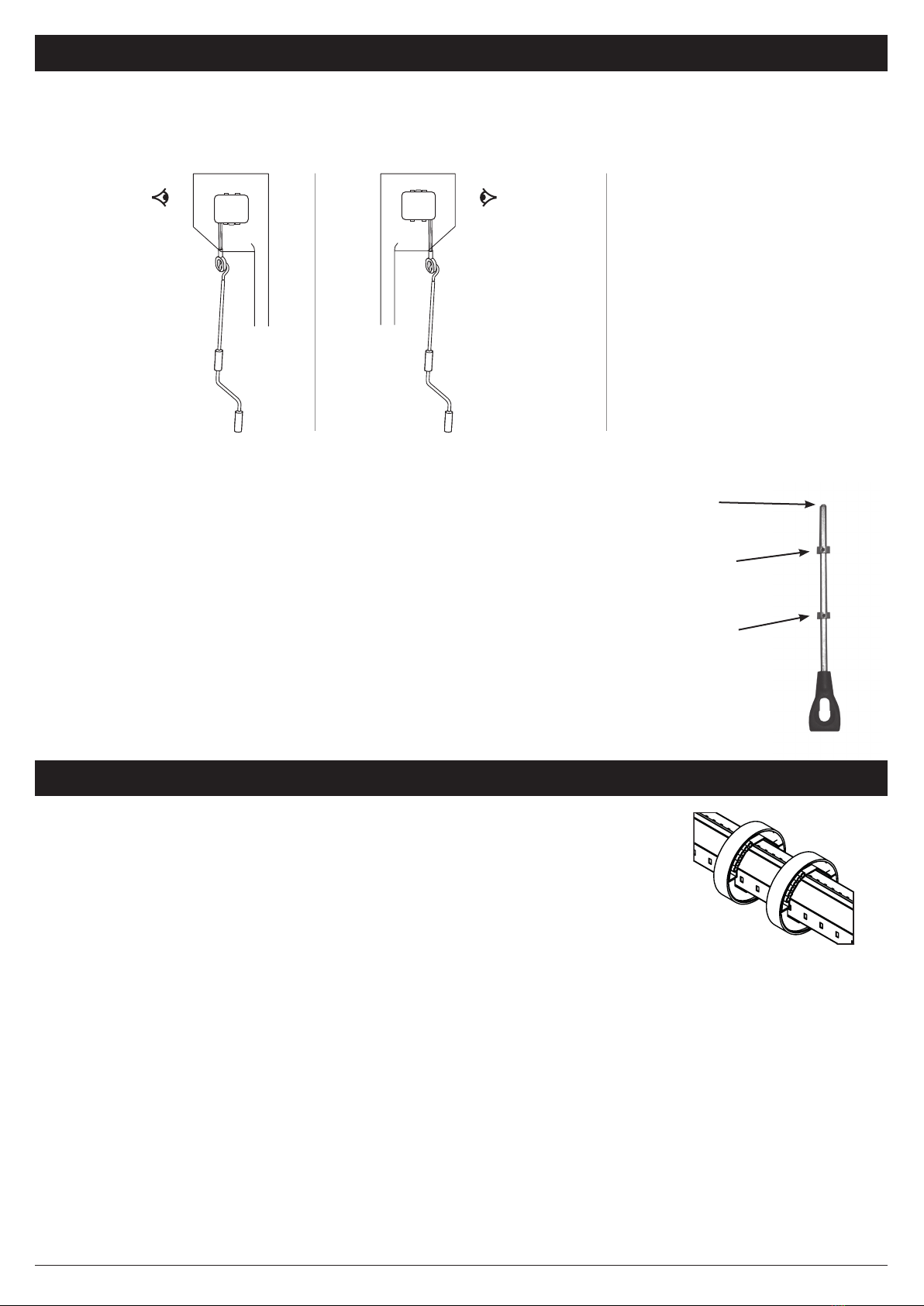

Fitting Notes

vi. It is recommended that 2 people are available for fitting all

door sizes.

vii. The door must be fitted square and level, irrespective

of the shape of the opening; on no account should any

compensation be made to suit an irregular opening.

viii. Ensure all necessary tools are to hand before starting.

ix. The door package and its contents should be checked for

obvious damage before removal of the wrapping.

IF THERE IS ANY DAMAGE YOUR SUPPLIER SHOULD BE

CONTACTED IMMEDIATELY.

x. Ensure there is a suitable 13amp 3 pin switched socket

adjacent to where the Remote Control Box is to be fitted.

xi. Ensure all tools and door components are gathered together

inside the garage prior to starting the installation.

Recommended Tools for Assembly:

• 2 stepladders

• Spirit/laser level

• Tape measure

• Power drill

• 10mm A/F spanner

• Slot screwdriver

• Pozidrive screwdriver

• 3.5mm drill bit

• 7.0mm drill bit

• 11.0mm drill bit

• 3mm A/F Allen key

• 4mm A/F Allen key

• Hacksaw

• Suitable wall plugs (not supplied)

• Suitable fixings (not supplied)

Note: In case of power failure a manual override system is fitted as standard but this can only be operated from inside the garage. If

the garage has no service entrance door then an exterior release kit must be fitted to allow manual operation of the garage door from

outside.

01. PRE-INSTALLATION AND COMPONENT CHECK (CONTINUED)

PRE-INSTALLATION CHECK