6 7

Safety

Safety edge

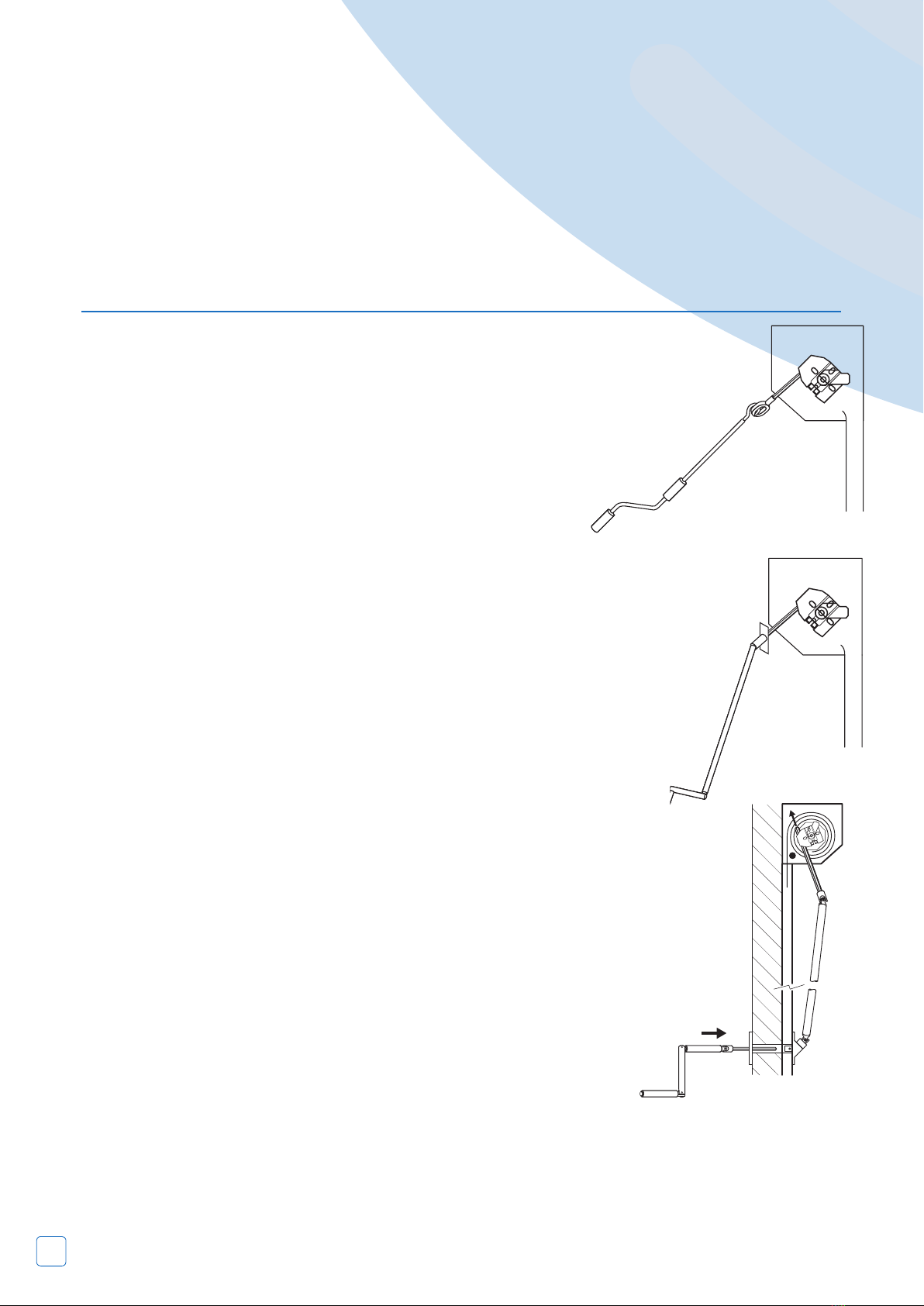

The Safety Edge is tted to the bottom of the

door and is activated when the door starts to

close. If it comes into contact with an object while

the door is closing, it transmits a signal to the wall

mounted control unit, the door will then stop and

reopen a short distance.

The safety edge also works as a weather seal,

designed to be pressed against the ground. The

bottom slat transmitter\cable has an IP rating

of IP54 and is protected against dust and water

splashing.

Safety Devices

The standard remote control receiver unit is

supplied with either an electrical wireless safety

edge or optical wired safety edge.

To operate:

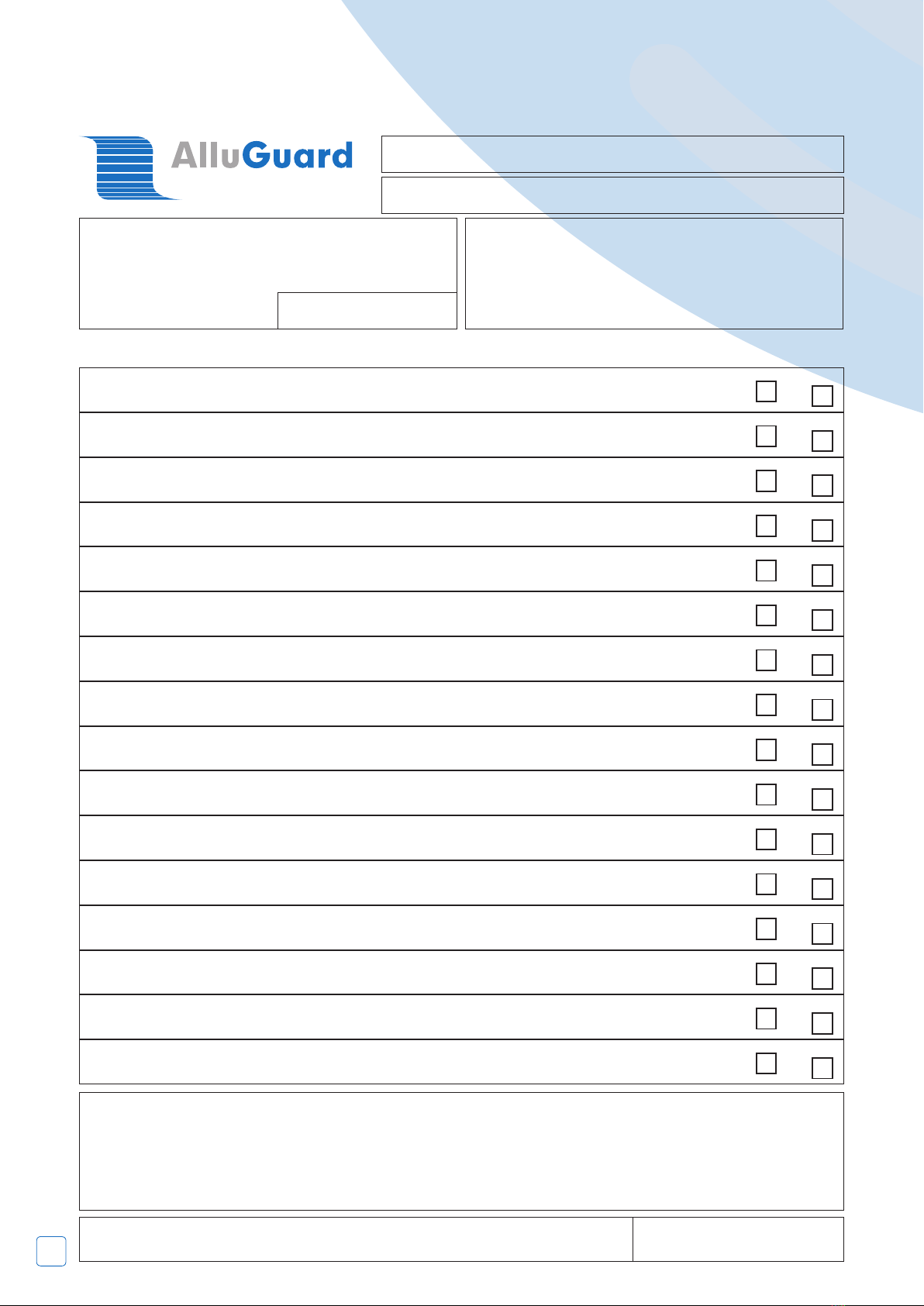

Hold crank handle in

line with eye and rotate

handle until the door

reaches the

open/closed

position.

To operate:

Externally tted doors will need

the cover cap or

override lock removing

and the crank handle inserting.

Rotate

handle until the

door reaches

the open/closed

position.

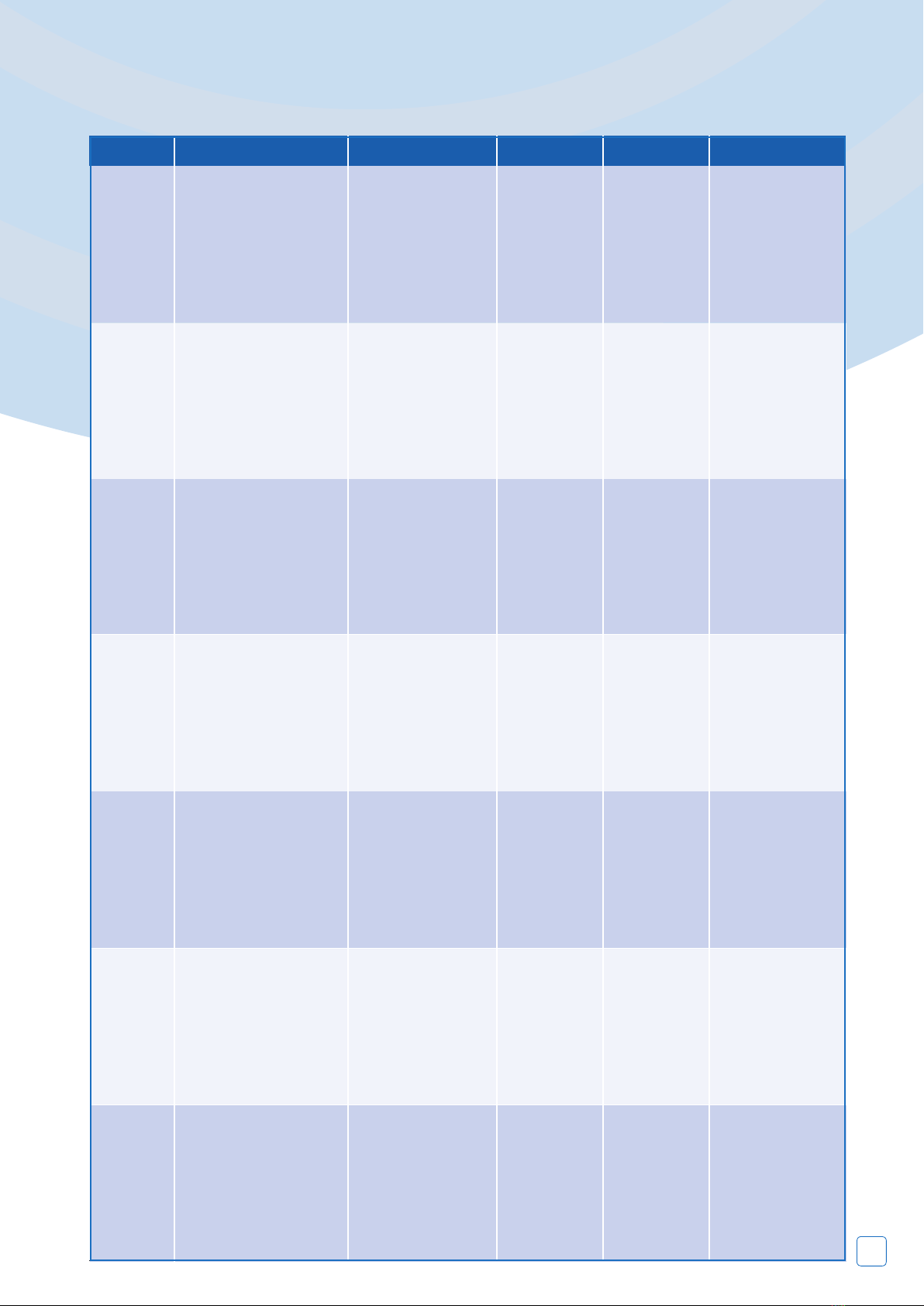

To operate:

Remove lock and insert crank

handle and rotate until door

reaches the open/close position.

DO NOT OVERWIND

When the main power is reinstalled, ensure

that the power isolator is switched back on.

If applicable secure the handle back onto the

wall. Remember to keep the crank handle in a

convenient place.

Power Failure

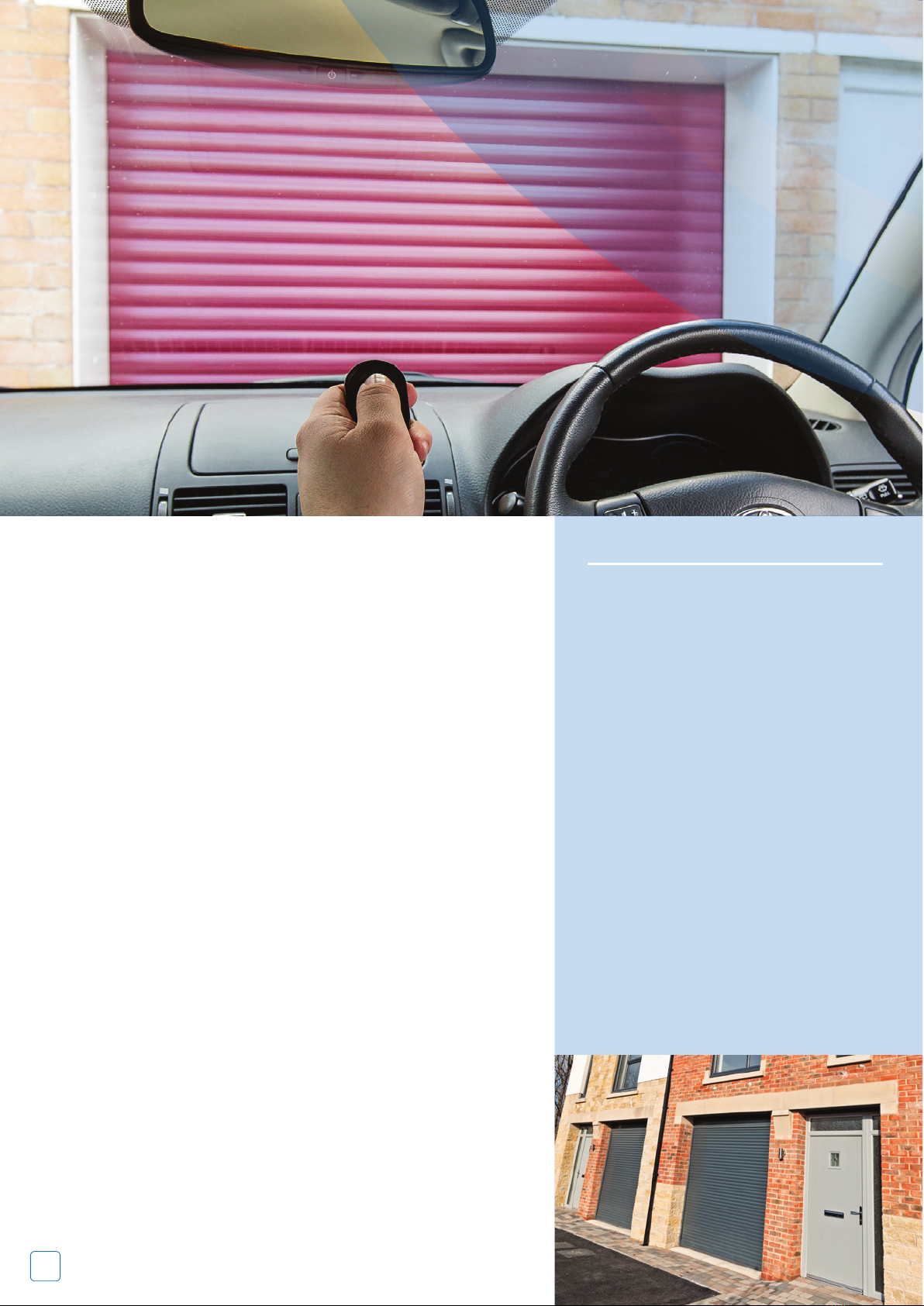

Electrically Operated Products

If your roller garage door is not working

correctly please contact your installer for

assistance. N.B: Always isolate the power before

attempting to make an adjustment or repair.

Untrained operators are advised to contact an

approved installer.

Power failure

In the event of disruption to the power supply,

or the motor temporarily over heating (the

motor is protected by a thermal cut out), the

door can be operated manually. Isolate power

supply before using the manual override.

To operate: Hold crank handle in line with eye

and rotate handle until the door reaches the

open/closed position.

If the door is not used during the power

failure then no action has to be taken as

the unit will reset itself when the power is

restored.

Important

If the garage has no service door then an

exterior release kit should have been tted

to allow emergency opening from outside.

Follow instructions supplied with that kit.

Note

When closing the door manually ensure that the

locking joints are set in the fully closed position to

ensure security.

Insert the hooked end of the winding handle into

the override eye; this is projecting downwards from

the drive motor at one end of the curtain roll, rotate

the handle to operate the door to open or close.