6

Series AE1L, AE.E, AE.N, AE.H, AE.V, AED1E, AED2N

Design ID, ZD

The set concrete foundations must be straight, even

and clean. Any traces of oil must be removed from

the foundations. The recessed anchor holes for the

foundation bolts must be cleaned and removed and

cleaned out with air. Prior to the installation of the

pump aggregate the surface of the concrete founda-

tions must be roughened and cleaned to ensure a

good bonding between the foundation block and the

mortar compound.

5.2.5 Pouring of base plate

After alignment on the concrete foundations , a low-

shrinkage mortar compound must be poured over the

entire length of the base plate, covering also the an-

chor holes with the connected foundation bolts.

Once the mortar compound has set on the base plate

and in the anchor holes, the foundation bolts must be

diagonally and evenly tightened.

Note: When pouring or adding the mortar compound

it must be observed that the base plate makes full

contact. Tap the plate to ensure that no cavities have

formed underneath.

5.3 Base plate

The base plate must be fixed on the foundation, ten-

sion-free.

5.4 Coupling

A pump aggregate supplied complete was carefully

mounted at the factory. As the pump and the drive are

fixed on the base plate, re-alignment of the coupling is

not required.

5.5 Assembling of pump and drive

If the aggregate is first completed on site, you need to

assemble the clutch as follows:

1. Thinly coat the pump and drive shafts with molyb-

denum sulfite (e.g. Molykote) and insert the

feather keys.

2. Wind up the pump and the motor-side clutch half

with the aid of a windup device so far until the

shaft end is aligned with the clutch hub. If no

windup device is available, heating the clutch

halves to approx. 100°C (without rubber buffers)

eases sliding on.

3. Fixate the clutch halves axially with a grub screw

(DIN 916).

4. When assembling the pump and the motor, the

drive motor respectively variable speed gear,

make sure that the clutch halves are exactly

aligned and that the distance between the cou-

pling halves is observed (see our aggregate draw-

ings and the details by the clutch manufacturers).

5. Install a contact protection in acc. with DIN EN

809.

5.6 Drive by V-belt drive

In case of a V-belt reduction from drive to pump,

make sure that two V-belt pulleys are aligned in paral-

lel.

The V-belt pulleys must be pushed onto the shaft

ends as far as possible. It must be possible to regu-

late the tension of the V-belts by means of a motor

rocker or by means of tensioning rails. They must be

slightly retightened after a short running-in period.

Excessive tensioning will destroy

the rolling bearings of the pump.

Our separate instructions “V-belt drive” (VM 706.0001

GB, Ident No. 133586) must be complied with.

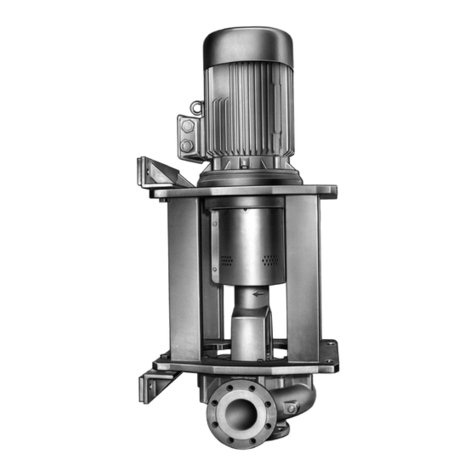

5.7 Space required for maintenance and servicing

The pump must be accessible from

all sides in order to be able to per-

form the required sight inspections.

There must be enough room for maintenance and

service work, especially for the exchange of the con-

veyor elements. The stator and rotor dismounting di-

mensions are listed in the pump respectively pump

aggregate dimension sheet. Also make sure that all

pipelines can be attached/detached without obsta-

cles.

5.8 Installing of pipelines

5.8.1 Nominal widths

The nominal widths of the suction and pressure pipes

should be designed according to the nominal widths

of the pipe connections. Gross deviations, especially

on the suction side, require consultation with the fac-

tory.

5.8.2 Supports and flange connections

The pipelines must be connected tension-free to the

pump via the flange connectors. They have to be

supported near the pipe and should be easy to screw

on in order to avoid strains. After loosening the

screws, the flanges may neither be slanted nor

springy and also not rest on each other under pres-

sure. Possible thermal stress on the pipelines has to

be kept away from the pump by means of suitable

measures, e.g. the installation of compensators.

5.8.3 Cleaning of pipelines prior to attachment

The pipelines, sliders and valves on the suction side

must be rinsed respectively cleaned under all circum-

stances before installing the pump.

Leftover assembly parts like screws, nuts, welding

beads, pieces of steel, etc. destroy the inside parts of

the pump. Any warranty claim is void when damages

are caused by such leftover materials. Flange seals

may not protrude to the inside. Blind flanges, stoppers

protective foils and/or lacquers on flanges and sealing

strips have to be completely removed.

5.9 Installing of auxiliary pipelines for additional fa-

cilities

All auxiliary pipelines for supplying the shaft seal and

the possible double jacket casing for heating and

cooling the pump have to be connected tension-free

and sealing.

The pipes for the quenching liquid with single-acting

mechanical seals with quench (design: G0Q and

G1Q) and the sealing liquid with double-acting me-

chanical seal (design: G0D/G1D) should be installed

with a large flowtrough profile. The quenching respec-

tively sealing liquid discharge takes place at the high-

est connection of the mechanical seal housing.

The flow direction of the flushing, sealing and quench-

ing liquid is indicated with arrows in the section draw-

ings.

In order to ensure self-deairing, the pipes must be in-

stalled continuously rising, short and favorable for the

flow.

The formation of air pockets and gas bubbles has to

be prevented, install deairing connections if required.

The heating/cooling liquid discharge must be con-

nected to the highest connection of the possible dou-

ble-jacket casing.