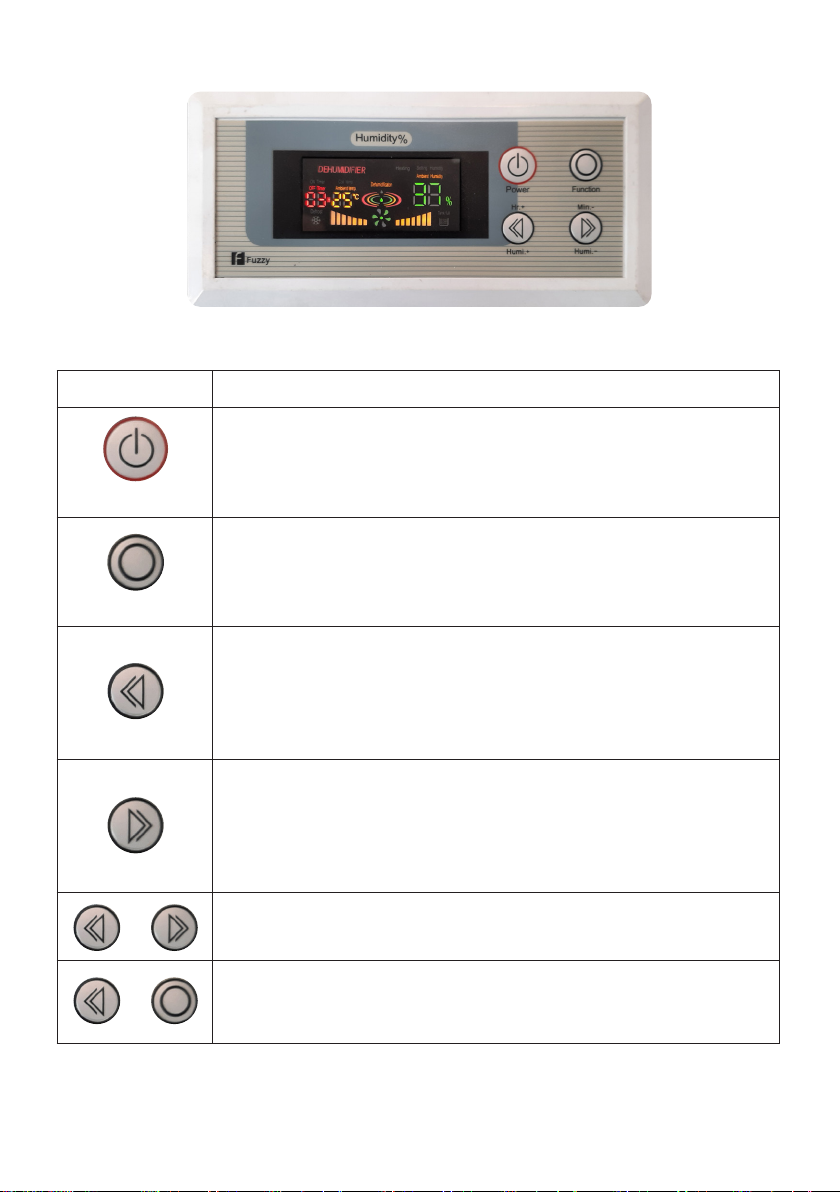

OPERATING INSTRUCTIONS

1. Attach the clear discharge tube (5 metres supplied) to the outlet by

removing the nut and sliding it back over the tubing. Then push nut and

tube over the tting and tighten,

2. Tubing should then be piped to a drain or container.

3. Plug dehumidier into the wall and turn on at switch.

If the unit has not been used recently it will start operating within a few

seconds. Screen will show ambient (current) room temperature and

humidity.

4. Set desired humidity using the plus and minus buttons. Humidity

percentage will ash for a few seconds then set. The panel will then

revert to current room humidity.

5. If the unit has recently been used it will not start up until the Power button

is pressed. There is then a 3 minute delay before fan starts. This is to

protect the compressor.

The desired humidity must be less than the current room humidity,

otherwise the dehumidier will register as reaching optimum and not

operate.

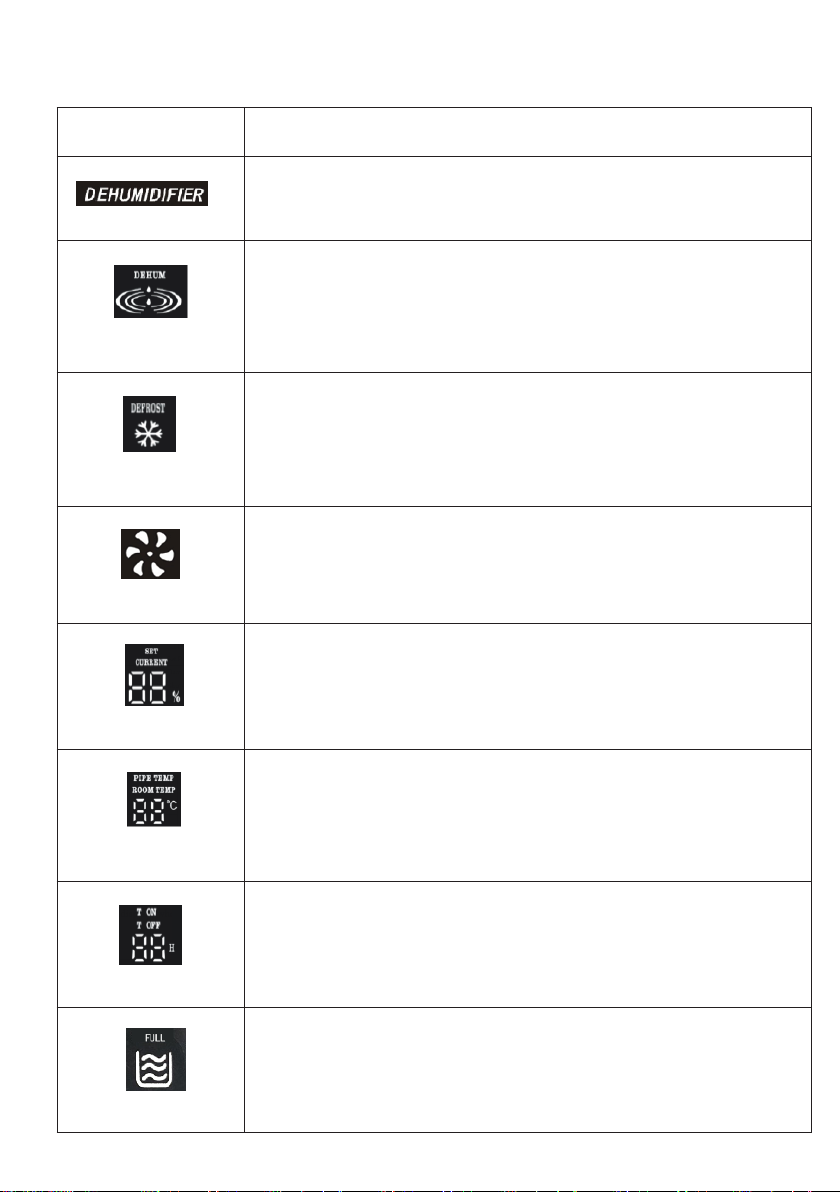

6. When the dehumidier is operating, the orange dehumidication light will

be showing, fan symbol spinning and the water droplet symbol pulsing.

(Dynamic display)

7. If required, you can set a timer to turn the dehumidier o after a set

number of hours. This can be done while the unit is operating. Press the

Function button once and then the plus or minus button to set the run

time in hours. The display will show TIMER OFF and number of hours

remaining until unit will automatically turn o.

8. There is a small holding tank in the dehumidier – once this is full the

pump sensors will register it as being full and discharge the water through

the clear tubing.

9. To turn the unit o, press Power button. There is a time delay for 60

seconds, during which time fan will run to allow machine to cool down.

10. Once the fan has stopped you can then turn it o at the wall.

11. When machine is not being used, cover with supplied dust cover to

prevent dust and overspray entering machine.