Models i285O.SER|ES

12860-SERIES

.. Description .._

Nitrilelmp€ller

Nitrielmpeller

Shaft:

SELF.PRTMING

PI'MPS

DESIGN

FEATUFES

3l6StainlessSteel

3

11,

Shaft

Seal: Cabon-CeramichceType,Nitrile

Bearings: Carbon

Model12850-Se.ies-

% NPT

Modelr2860-Series

- 1"NPT

Model

r2850-Series

- 3%lbs11,7

ks)

Mod€l

12860-Series

- 57,lbs

{2,5

kg

)

12850-0001

12850-0003

12860-0001

12860-0003

NOTE:

Carbon/Carpenier20sealavailable

asa

spare

parr,

APPLICATIONS

Deslgn€dasalowcosl

p!mpfol|tfansfers,circulation,spil

retufns,filtrationandfillingline

use.Easilyhandles

pure

soutions,foaming

liquids,emulsions,suspended

solids,

gels

andferments.Becausethe p aslicpump is resistantto

corrosionandmetallic

contanination,itiswidelyusedfor

pumpingphoto

chemicals,

plating

compounds,labsolutions,

pharmaceutic6ls,

cosmetics,weakacids,alkalies,liquid

fertilizers,inseciicides,

dyes,detergenis,waxesand many

SeetheJabsco

ChemicaIResistance

Table

(availabte

upon

requestfrom ITT

Jabsco).lt hasbeenprepared

to hetp

you

selectthemosts!irable

impellerand

pump

materlal.

OPERATINGINSTRUCTIONS

1. INSTALLATION

Pumpmaybemountedinanyposil

on.

Theroiaiionofihe pump

shaftdeterminesthelocalionol

the

p!mp s intakeanddischarqe

portsFefertodimen.

sonaidrawl.g.Before

staning,turnthe

pump

shafl

nthe

directionof the operatingrotaiion.

2. DRIVE

- Beltor Directwith flexiblecoupln9

NOTICE:Donot

press

apllleyorcouplinsontheshaft

withoutsupportlngthe

shaftto

prevent

itsmovementrnto

theimpeler

bore.

BELTDRIVE-Overrightber oadw,ll

reduce

pump

bearing

life.

DIAECTDBIVE Clearance

shoud be leftbetweendrive

shaftand

pump

shaftwheninstaltins

couplingAways

Jnounl

pump

andaigndrive

shafrbeforeiighteningthe

couplrng

setscrew.

3. SPEEDS

- 100nPM

tothemaximum

shownrnrne

pedorm€ncetable.

For

longerpump

life,

operate

al

lowest

possible

speeds.

4 SELF^PRIMING-Prirnes

atloworhighspeeds.Forvertical

dry

suctof lftof l0 feel,

a minimum

of800RPM

is

rcqured.Pump

wil produce

suctionlifts

upto 22feet

wh€n

we(e.l BE

SURESUCTIONLINESABE

AIRTIGHT

ORPUMP

WLL NOTSELF.PN

ME.

5. RUNNINGDBY

- Unitdependson liquid

p!mped

for

lubrication.oO NOTRUNDRYFOR

MORETl.lAN30

SECONDS.Lackofliquidwilldamagetheimpeller

and

othercomponents.

6. CAUTION-Donot pumppetroleum

derivatives,solvents,

thinners.

highlyconcentrated

ororganicacids.lfcorosive

lluidsarehandled,

pump

lifewill be

prolonged

iffiushed

with wateraftereach

useoraftere.chwork day.Consult

Jabsco

ChemicalResistance

Tablein Industrial

Caralog.

Forlurther inlormation contact factory.

7. PRESSUBES

Forcontinuous

operation,

pressu

re

snou

ro

not exceed20 PSIfor 12850-Series

and30 PSIfor

12860'5eries.

8. TEMPERATURESRecom

mendedtem

peratu

rerangewith

neoprene!mpeller45"io180"F

(7'to82<C),

andwithnitile

impeller50'to 180"F

{10"

to 82'C)-

9. SPAREPARTS A JabscoServiceKitshould be kepton

handto maintain

all but ihe most badlyworn pumps.

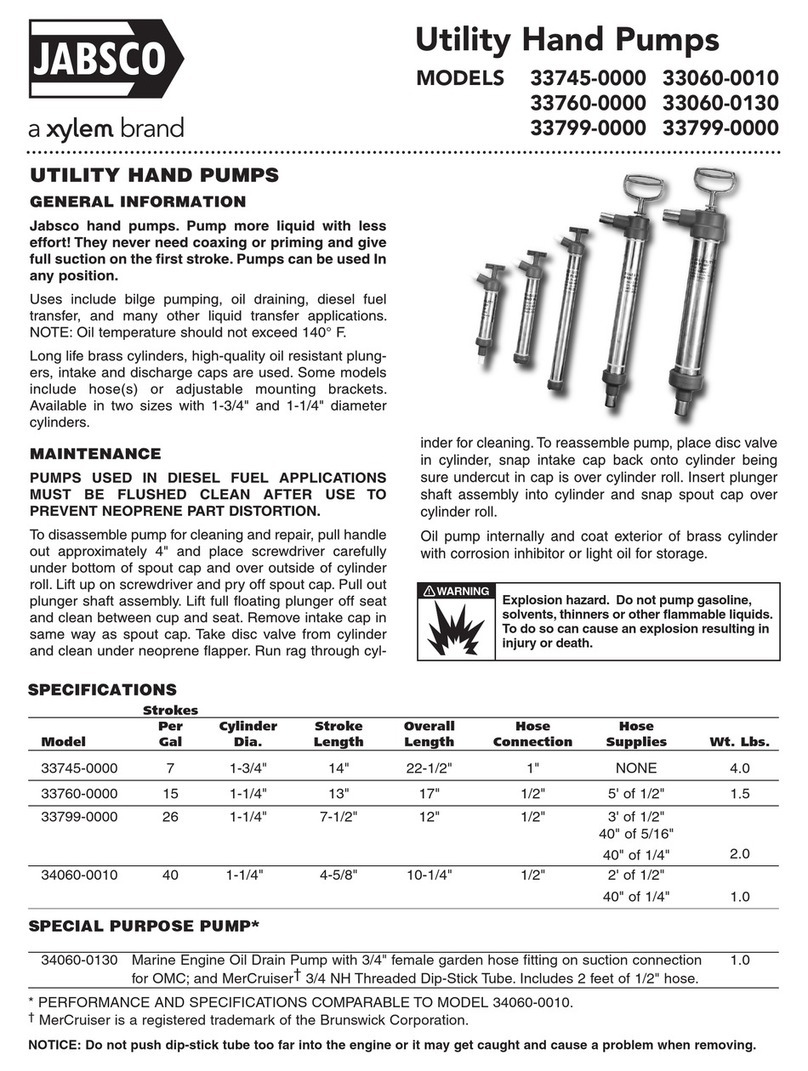

SELF·PRIMING PUMPS

DESIGN FEATURES

Models 12850·SERIES

12860·SERIES

Desc

ription

NeopreneImpeller

NitrileImpeller

Neoprenelmpeller

Nitrile

Impeller

Neoprene

or

Nitrile

PhenolicPla

stic

Model

12850-0001

12850-0003

12860-0001

12860-0003

Shaft: 316 Stai

nl

essSteel

ShaftSeal: Carbon-Ceramic

Face

Type,

Nitrile

Be

armgs: Carbon

Ports:

Model

1

2850-Series-

'h

~

NPT

ModeI12860-Series

-

1 ~

NPT

WeIght:

Model

128S0-Series-

3¥.lbs

(1,7 kg)

Model

12860-Series-

5'h

Ibs(2,5 kg)

Body

:

Impeller:

NO

T

E:

Carbon/Carpenter

spare parI. 20

seal

avai

labl

eas a

APPLICATIONS

Designed

asa

low

cost

pump

for

:transfers, circulation, spill

returns, filtration

and

filling line use. Easily handles pure

solutions,

foaming

liquids,emulsions, suspended solids, gels

and ferments. Because the plastic

pump

is resistant

to

corrosion

and metallic contamination, it is

widely

used

for

pumping

photo

chemicals, plating

compounds,

labsolutions,

pharmaceuticals, cosmetics, weak acids,alkalie

s,

liquid

fe

rtilizers, insecticides, dyes, detergent

s,

waxes and

many

more.

SeetheJabsco ChemicalResistanceTable (available

upon

request

from

In

Jabsco). It has been prepared tohelp you

selecl the

most

suitable

impeller

and

pump

material.

OPERATING INSTRUCTIONS

1.

INSTALLATION-Pump

may

be

mounted

in any position.

The rotation

of

the

pump

shaft determinesthe location

of

lhe

pump's

intake and discharge ports. Refer

10

dimen·

sional

drawing.

Before starting, turnthe

pump

shaft in the

direction

of

the operating rotation.

2.

DRIVE

-Bell

or

Direct With flexible coupling.

NOTICE

Do

not

press apulley

or

couplmg

on the shaft

WIthout

supponmgthe

shaft10prevent its

movement

into

the

impeller

bore.

BELT

DRIVE

-

Ovcnight

beltloadWill reduce

pump

bearing

life.

DIRECT DRIVE -Clearance shou

ld

be left between

drive

shaft

and

pump

shaft

when

installing coupling.

Always

mOunt

pump

and align

drive

shaft before tightening the

coupling

set screw.

3.SPEeDS -

100

RPM

to

the

maximum

shown

in the

performancelable.

For

longer

pump

life, operClleallowest

possible speeds.

4,

SE

LF

-PRIMIN

G-

Primes at

low

orhigh

speeds. Forverti

cal

dry

suction lift of 10feet. a

mmimum

of 800

RP

M

is

required. Pump

wi

ll

produce suction lifts

up

to

22

feet

when

welted

.

BE

SURE

SUC

TI

ON

LI

NE

S

ARE

AIRT!GHT

OR

PUMP WILL NOT SELF-PRIME.

5.

RUNNING

DRY

-Unit depends

on

liq

uid

pumped

for

lubrication.

DO

NOT RUN DRY

FOR

MORE THAN 30

SECONDS. Lack of liquid

will

damage

the

impeller

and

other

components.

6.

CAUTION-

Do

not

pump

petroleum

derivatives

,solvents,

thinners,

highly

concentrated

or

orga

ni

cacids. Ifcorrosive

fluids

are handled,

pump

life

will

be

prolonged

if

flushed

w

ith

wa

ter

after

eachuse

or

after

each

work

day

.

Consult

Jab

sco Chemical Resistance Table

in

Industri

al Catalog.

For

further

information

contact

factory

.

7.

PRESSURES-

Forcontinuousoperation,

pressure should

nOI

exceed 20

PSI

for

12850-Series and 30

PSI

for

1286().Serle

s.

8. TEMPERATURES-Recommendedtemperature range

with

neoprene

Impeller45

Q

to

180'F

(Tt082

Cj, and

with

nitrile

impeller

50°

to

18O"F

(10"

to

82'C).

9.

SPARE

PARTS -A

Jabsco

Service Kit

should

be kept on

hand

to

maintain

all

but

the

most

badly

worn

pumps.