7

We suggest a minimum of 5 HP air compressor with a holding tank of 50

cubic feet (1,400 l) capacity for one tool.

Air hose fitting is 1/4” BSPP

The use of heavy duty 3/8” (10mm) hose is suggested for all lines.

LUBRICATION (Lube Oil is used to protect the tool from rusting when not in use)

PROPER CAREAND LUBRICATIONARE IMPORTANT FACTORS IN THE USEFUL

LIFE OF THIS TOOL.

At the end of each workday, 2-3 drops of lubricant oil, solvent free oil (included with

each polisher) should be placed in the air inlet at the base of the tool. Rotate the

spindle counter clockwise, by hand 3-4 revolutions. Reinstall the air hose and run

the tool for a minute or two. (Replacement containers of oil may be purchased from

Alpha Professional Tools®Part # AIR-008.)

Maintenance and Usage Tip

Automatic oilers are not recommended: the volume, grade, and composition of oil

used may cause premature failure. In-line air dryers are recommended to extend

the life of the tool. Old or worn compressors, which emit oil through the air lines,

can dramatically shorten the life of the tool.

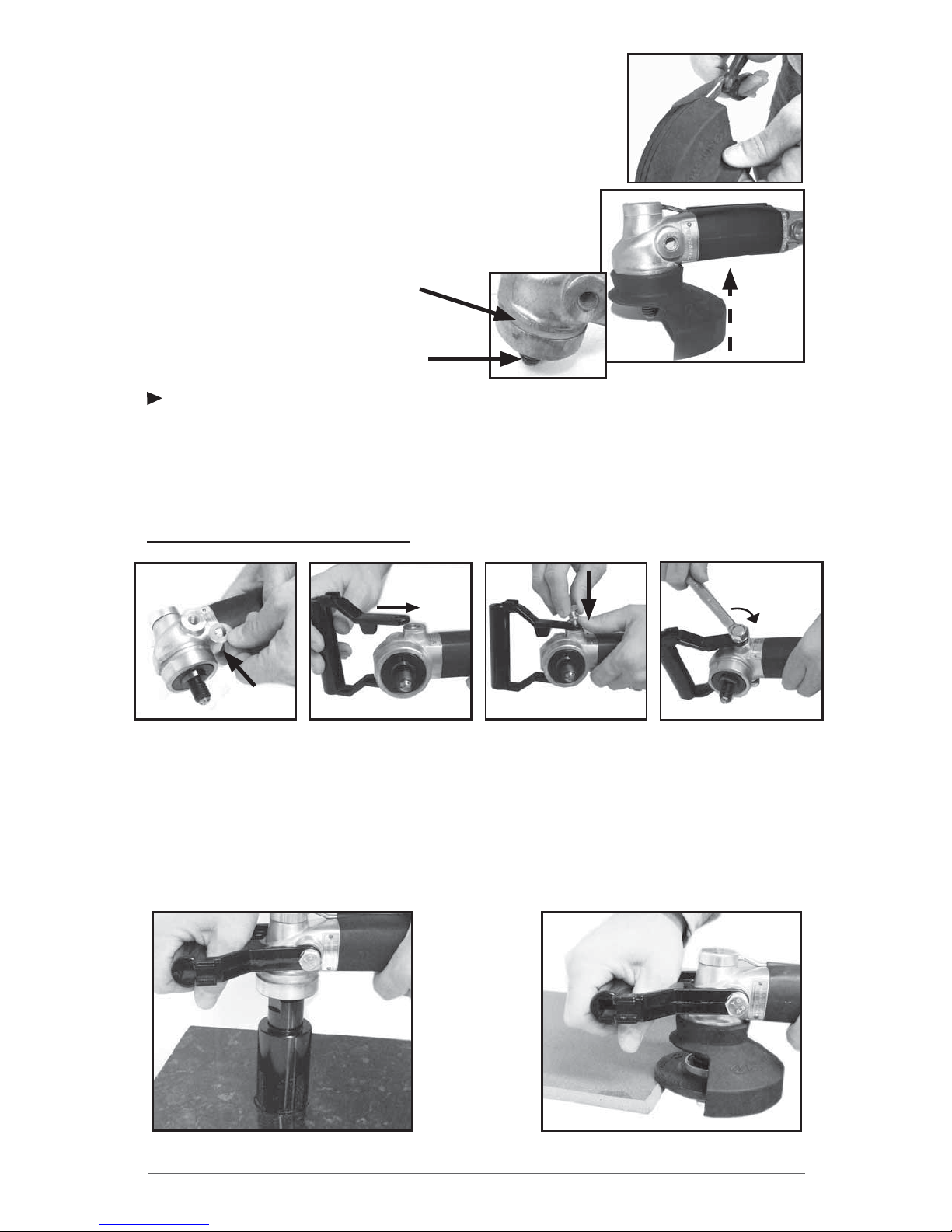

SPINDLE SIZE

The Alpha® AIR-658 air polisher features a 5/8”-11 size spindle. This tool has

been designed for portable/shop production and uses all modern accessories.

It is very important that you do not run anything heavier than the recommended

accessories on this machine. A drop of oil should be applied to the outside

threads whenever attachments are changed to facilitate removal and prevent

rust. A 22mm Spindle Wrench is provided to assist in changing accessories.

Maintenance and Usage Tip

Do not leave the tool submersed in water. This could expose the inner

moving parts to moisture, which will shorten the life of the tool.

Do not leave threaded accessories (backer pads, core drill bits, profilers) on

the spindle of tool for extended periods of time; this may result in making it

difficult to remove these accessories.

Excessive force or impact to the spindle may result in premature failure of

gears and/or bearings, which may not be immediately evident.

AIR VALVE LEVER

The valve lever controls the flow of air through the tool. It has two positions- ON or

OFF. Run the tool at the recommended range of 85-90 PSI, with the lever pointing

•

•

•

•

•

•