830133GB/151111 - Subject to Technical Modifications - 3

General

Operating Range

The heat pump is designed exclusively for the heating of

heating circuit water and domestic hot water. Considering

the application limits (see technical details), the heat pump

can be installed on new or existing heating installations.

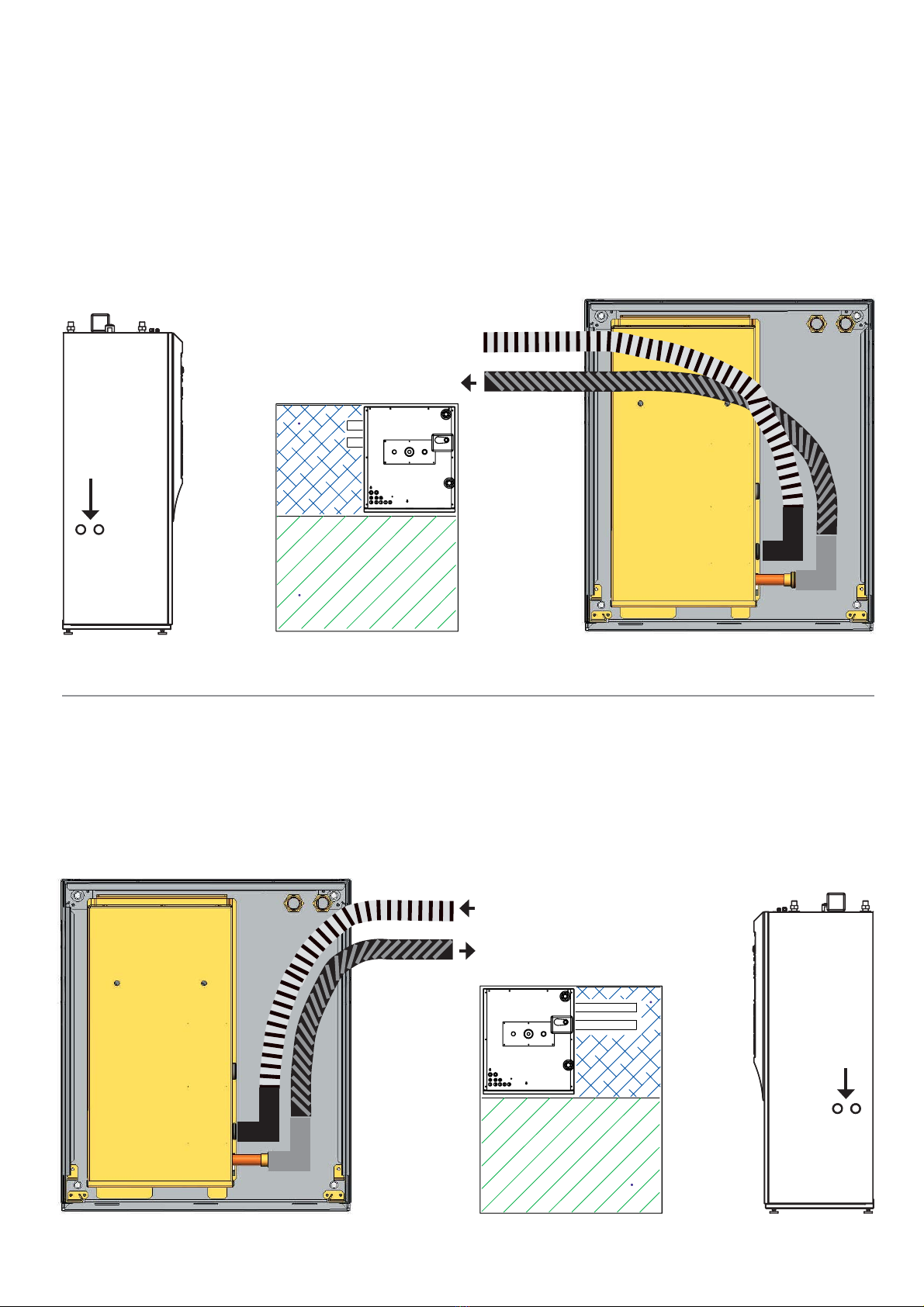

Functioning of the brine / water heat pump

The heat pump converts the low temperature heat of

the ground to a higher temperature. Brine (a mixture of

water and antifreeze agent) is pumped through coils in

the ground and conducted to the evaporator of the heat

pump. The evaporator contains the liquid agent which

boils and vaporizes at low temperatures and low pressure.

The vaporizing heat is transferred from the brine. The

compressor sucks in the vaporized agent and compresses

it to achieve a higher pressure. The compressed gaseous

agent enters the condenser, where it condenses at high

pressure and high temperature. The condensation heat

is transferred to the heating circuit water with resultant

increase in temperature.

The energy transmitted to the heating circuit water

corresponds to the energy transmitted from the brine plus

the small amount of electric energy for the compressor.

Energy-saving use of the heat pump heating

installation

By choosing a heat pump heating installation, you have

acknowledged the need for environmental protection

by lower emissions and less consumption of energy. To

ensure your new heating system works as efficiently as

possible, please note the following:

The heat pump heating installation must be correctly

sized and installed.

Avoid unnecessarily high flow temperatures. The

lower the flow temperature at the heating circuit water

side is, the more efficiently the heat pump works.

The controller must be set correctly!!

Preferably open the window totally to renew the air.

Compared to constantly pivot-hung windows opening

outward, this kind of ventilation reduces the energy

consumption and saves money!

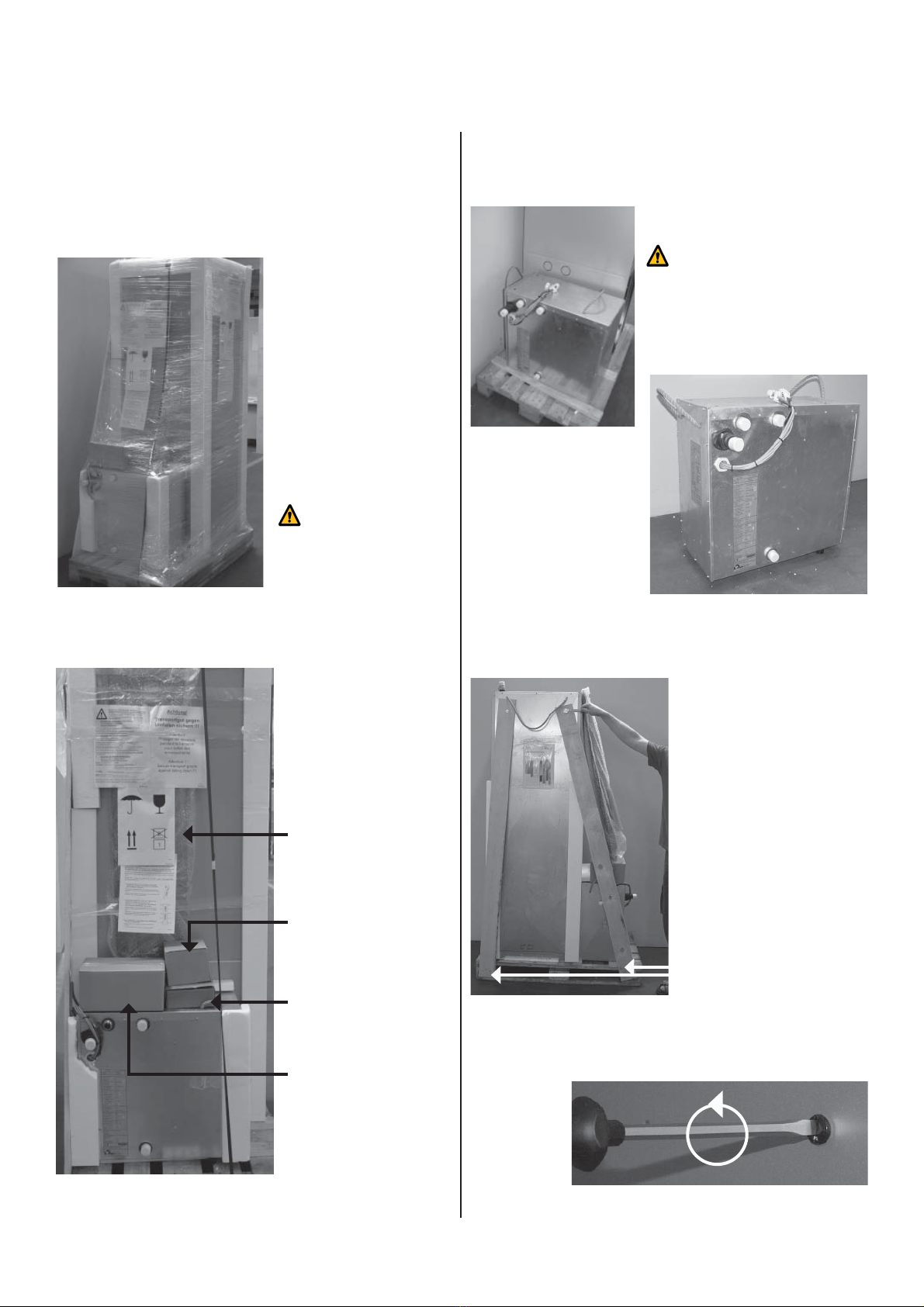

Scope of Supply

• Compact device with module box

• Integrated heat pump and heating installation controller

(during the transport, the outdoor temperature sensor is

stored inside the device)

• Electric switch box with power contactor.

• Integrated brine circuit circulating pump and heating circuit

circulating pump (Note: free pressing - see Technical

Data Sheets)

•

Integrated domestic hot water storage with external current

anode

• Safety components for the heating circuit

• Pressure differential valve for heating circuit

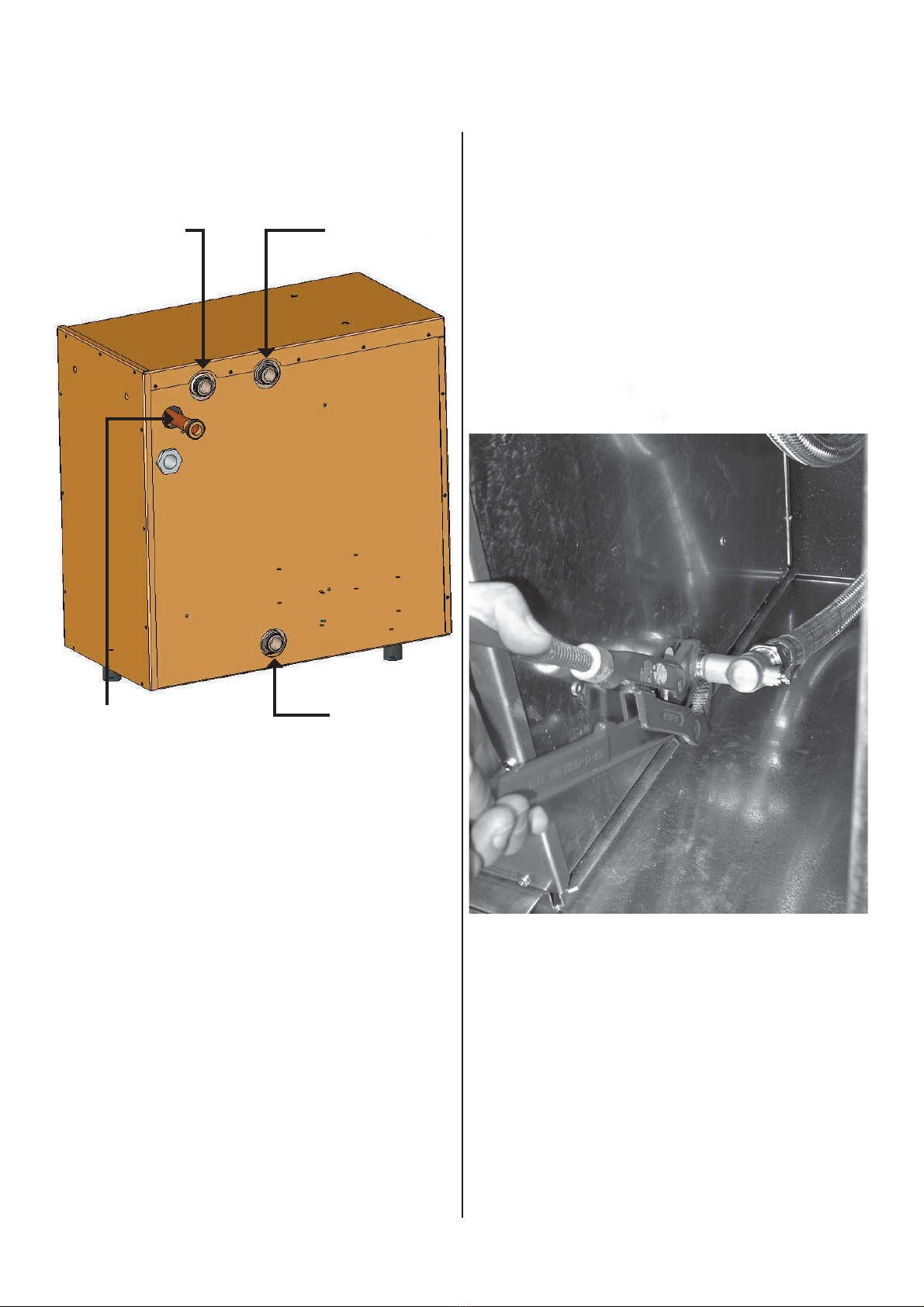

• Adjustable stands

• 3-way reversing valve for domestic hot water heating

• Electrical heating element: 6kW (reversible to 4kW or

2kW))

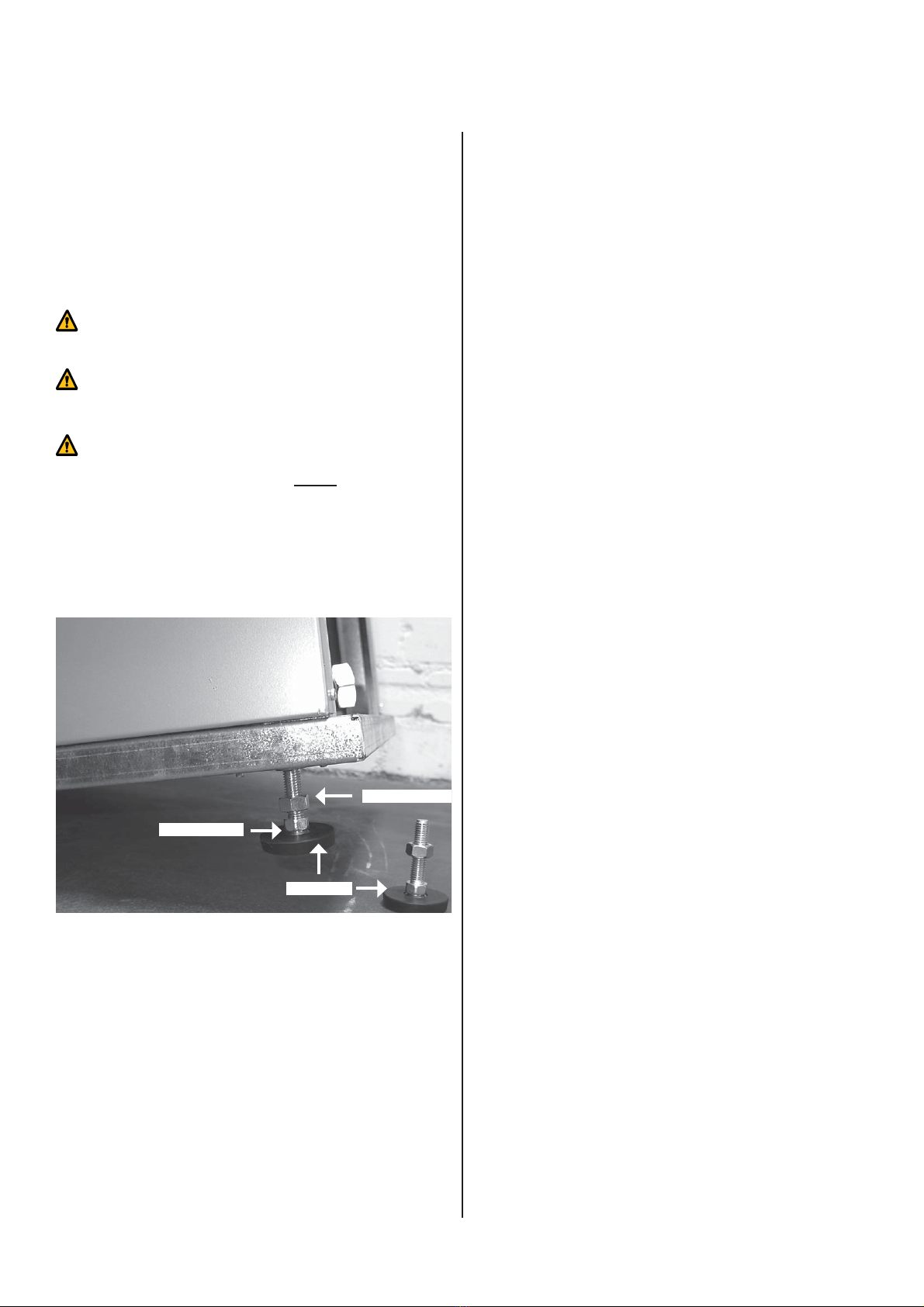

• Connection-set brine:

2 flexible reinforced tubes (stainless steel), pre-insulated

+ insulating material + small parts

• Operating element for heat pump controller

Expansion vessel and safety components for the

brine circuit are not delivered with the unit.

Expansion vessel for the heating circuit is not

delivered with the unit.

Further features:

Sensors inside the device for sensing the hot gas temperature

and heating-circuit water flow and return temperature.

Sensors for monitoring of the heat source temperature and the

hot gas temperature of the refrigeration circuit.

i

SCOPE OF SUPPLY / GENERAL