Delivery......................................1

Unpacking ....................................1

Safety Procedures and Precautions . . . . . . . . . . . . . . . . . 2

Installation

SiteInstallation..............................3

ClearanceRequirements.......................3

Installation Requirements . . . . . . . . . . . . . . . . . . . . . . 4

WaterDrainage..............................4

rolley Guide Installation. . . . . . . . . . . . . . . . . . . . . . . 5

Dimension Drawings, weights & capacities. . . . . . . 6-10

Options and Accessories . . . . . . . . . . . . . . . . . . . . . . 11

Electrical Specifications . . . . . . . . . . . . . . . . . . . . . . 12

Operation

OperatingIntroduction........................13

Chill Processing Cycles. . . . . . . . . . . . . . . . . . . . . . . 14

Quickchiller Operation Modes . . . . . . . . . . . . . . . . . . 14

Initial Quickchiller Operation . . . . . . . . . . . . . . . . . . . 14

AdditionalInformation........................15

Control Panel Identification . . . . . . . . . . . . . . . . . . . . 16

BasicOperation ............................17

Advanced Operation - Hold emp . . . . . . . . . . . . . . . 18

Advanced Operation - Chill Modes . . . . . . . . . . . . . . 19

Factory Default Set Points. . . . . . . . . . . . . . . . . . . . . 19

Advanced Operation - Programming . . . . . . . . . . . . . 20

Advanced Operation - User Settings . . . . . . . . . . . . . 21

FoodProbeUse............................22

ime & emperature Guidelines . . . . . . . . . . . . . . . . 22

AutomaticDefrost...........................22

Food Handling Guidelines . . . . . . . . . . . . . . . . . . . . . 23

ProductCovering ...........................23

Portioning&Packaging.......................23

Quickchiller Pan Capacity . . . . . . . . . . . . . . . . . . . . . 24

Product Capacity Per Pan . . . . . . . . . . . . . . . . . . . . . 24

Portion Sizes and Pan Capacities . . . . . . . . . . . . . . . 25

Care and Cleaning

Cleaning and Preventative Maintenance . . . . . . . . . . 26

Protecting Stainless Steel Surfaces. . . . . . . . . . . . . . 26

CleaningAgents............................26

CleaningMaterials ..........................26

InteriorCleaning............................27

ExteriorCleaning ...........................27

Probe Cleaning Procedures. . . . . . . . . . . . . . . . . . . . 27

Food rolleyCleaning........................27

Monthly Compressor & Condenser Maintenance . . . . 27

Service

ControlErrorDisplays........................28

Service Views

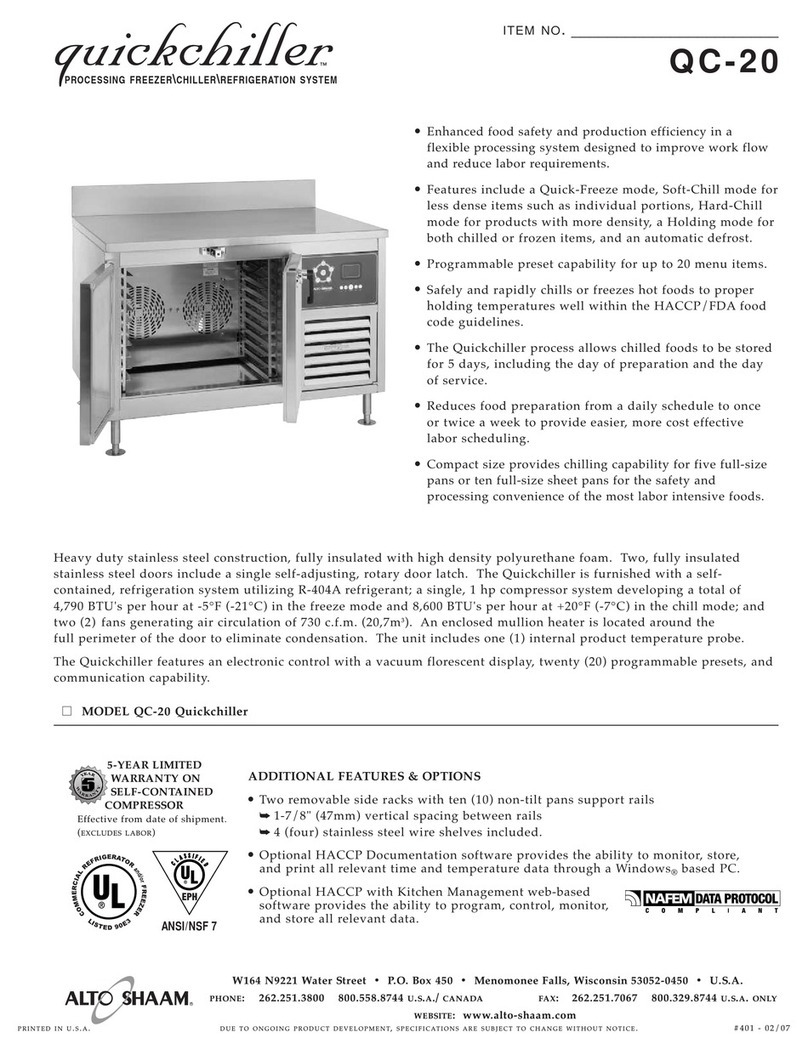

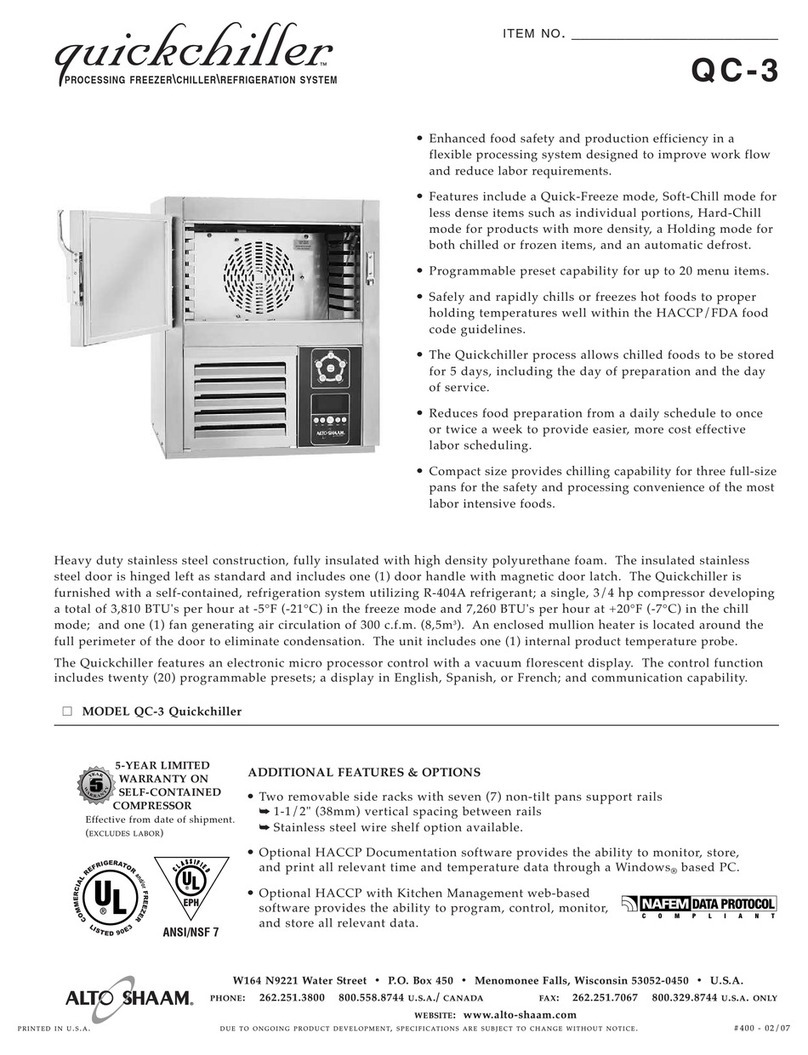

QC-3Control .............................29

QC-3Coil................................30

QC-20Control ............................31

QC-20Coil...............................32

QC-20Condenser..........................33

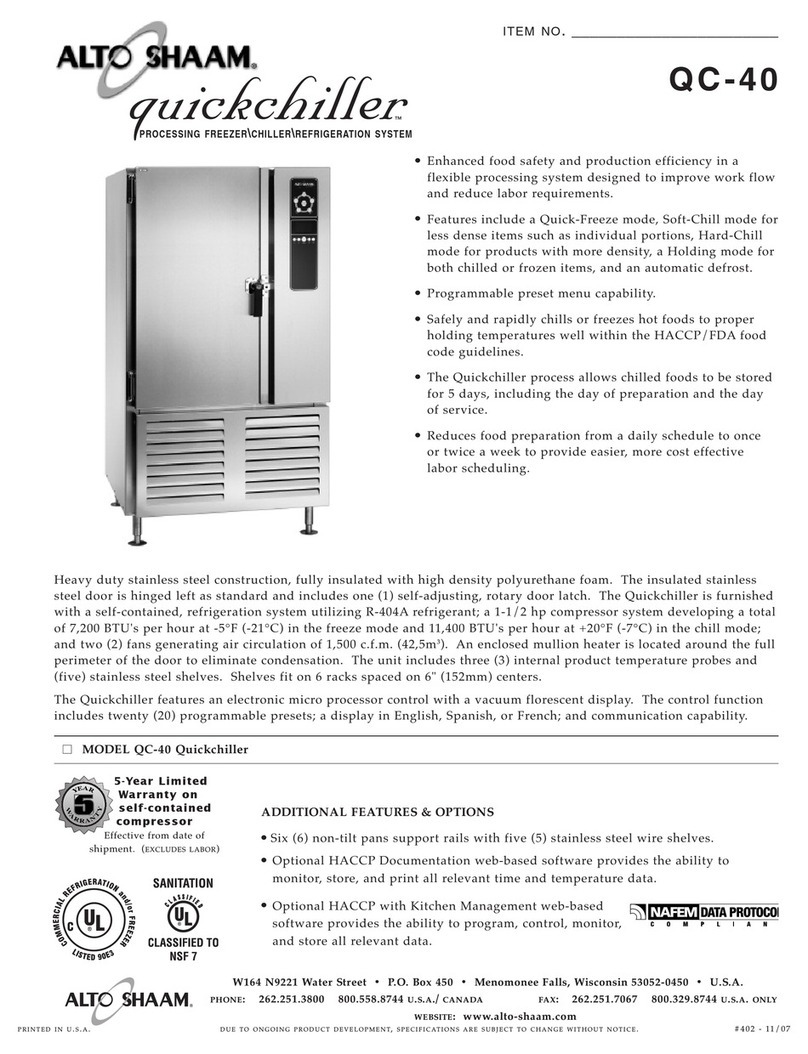

QC-40 ..................................34

QC-40Control ............................35

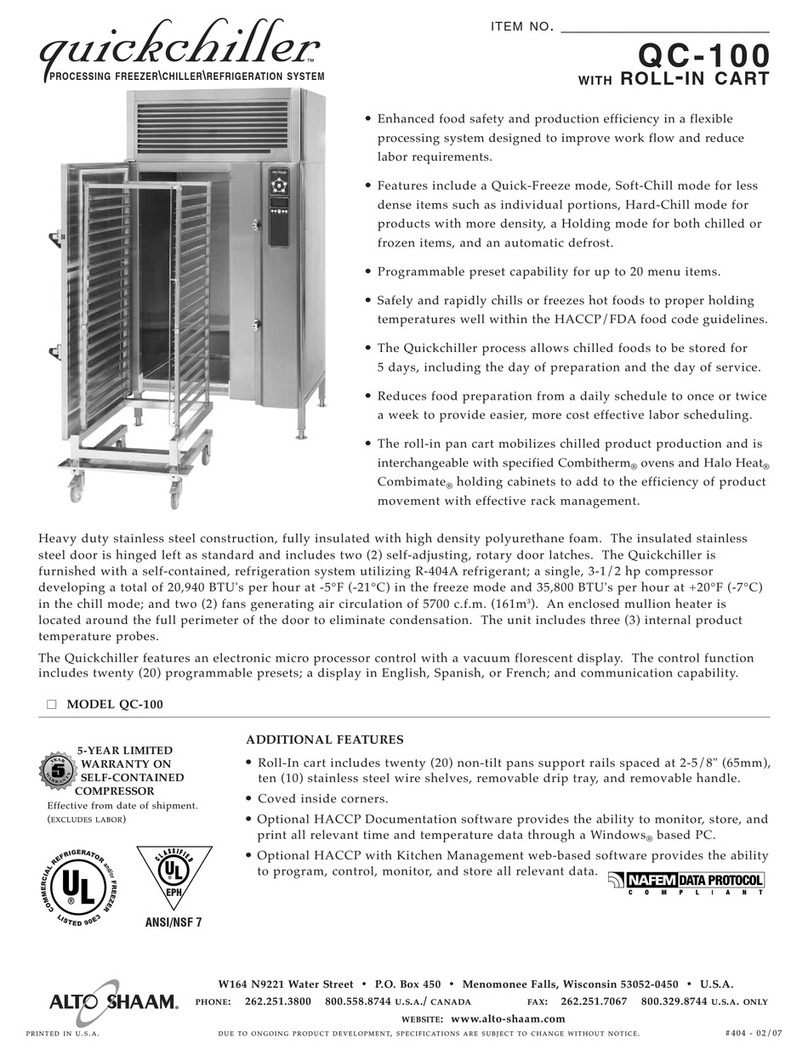

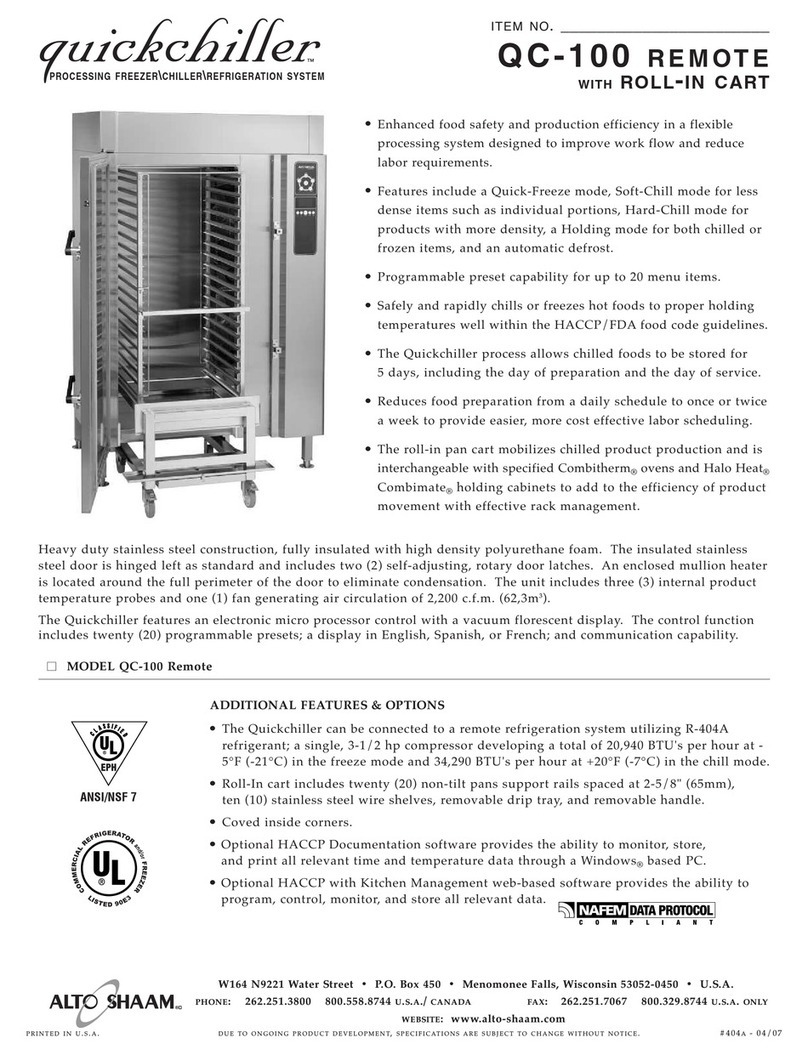

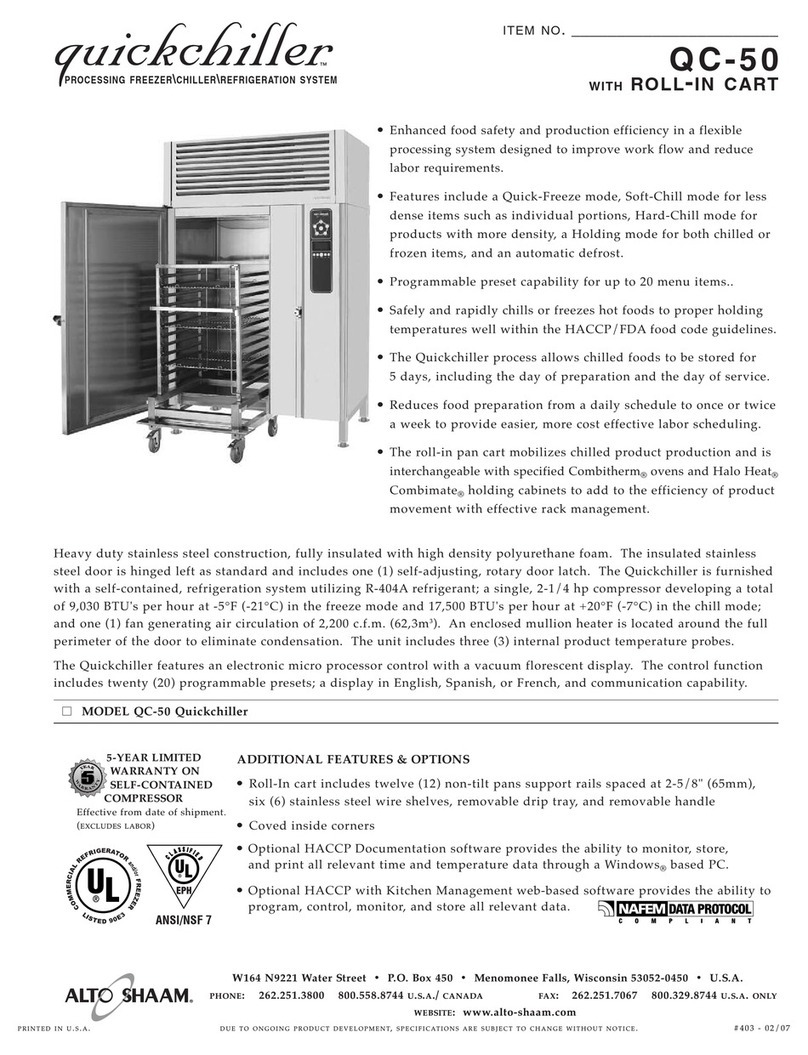

QC-50, QC-100 Control . . . . . . . . . . . . . . . . . . . . . 36

QC-100Coil..............................37

QC-50, QC-100 Breaker . . . . . . . . . . . . . . . . . . . . . 38

QC-50,QC-100Fan........................38

QC-50Remote............................39

QC-50, QC-100 Remote Condenser Connection. . . 40

Wire Diagrams

Wiring

QC-3 ...................................41

QC-20 ..................................41

QC-40 ..................................42

QC-50 ..................................43

QC-100..................................44

Wire Schematics

QC-3,208-240V,1PH.......................45

QC-20,208-240V,1PH......................46

QC-40,208-240V,1PH......................47

QC-40,208-240V,3PH......................48

QC-40,380-415V,3PH......................49

QC-40B, 208-240V, 1PH . . . . . . . . . . . . . . . . . . . . . 50

QC-50,208-240V,1PH......................51

QC-50 Remote, 208-240V, 1PH . . . . . . . . . . . . . . . 52

QC-50,208-240V,3PH......................53

QC-100, 208-240V, 1PH . . . . . . . . . . . . . . . . . . . . . 54

QC-100 Remote, 208-240V, 1PH . . . . . . . . . . . . . . 55

QC-100,380-415,3PH......................56

QC-100, 208-240V, 3PH . . . . . . . . . . . . . . . . . . . . . 57

Warranty

ransportation Damage and Claims . . . . . . Back Cover

Limited Warranty . . . . . . . . . . . . . . . . . . . . . Back Cover