CLARKE TECHNOLOGY Operator's Manual PS-27 Page 9

CLARKE TECHNOLOGY

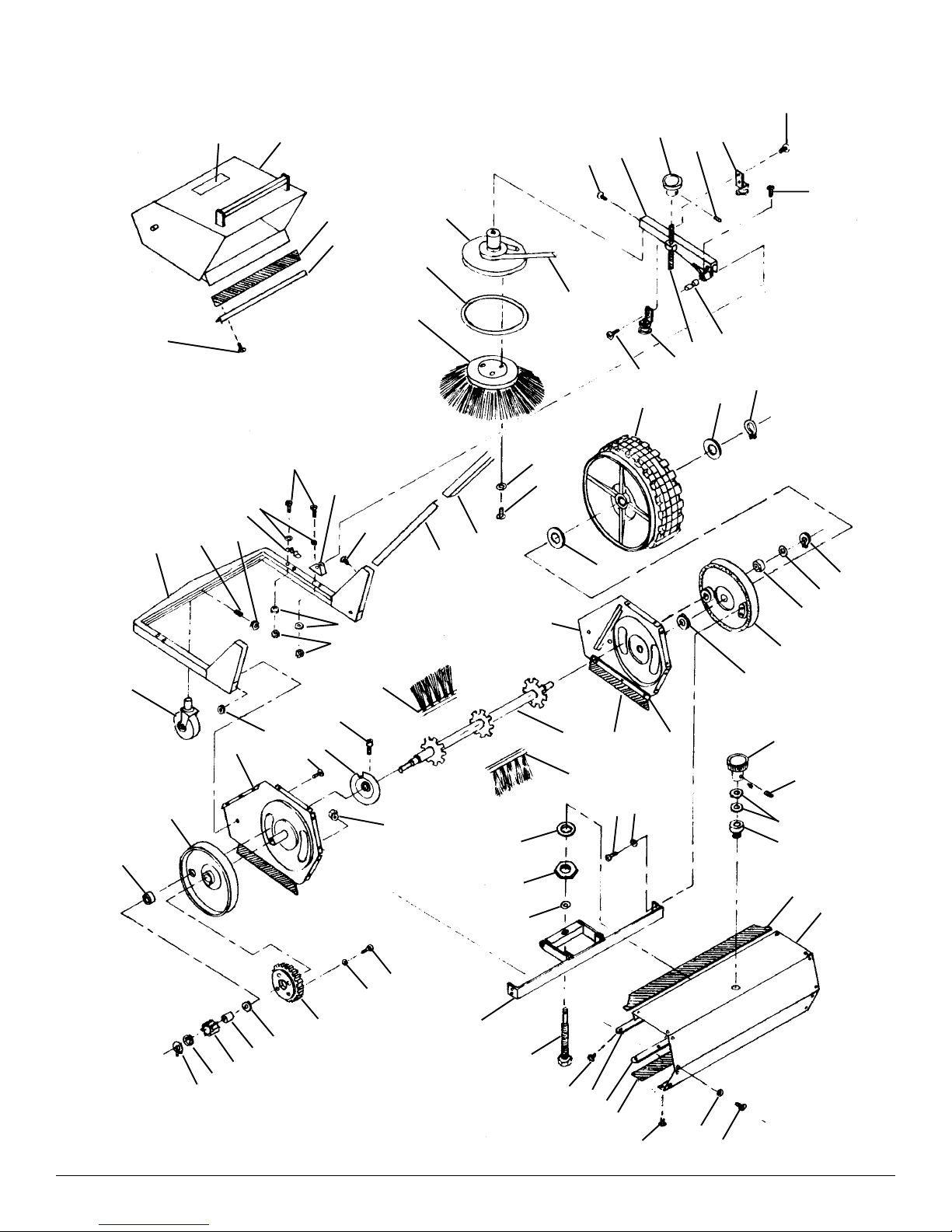

Model PS-27 Sweeper

Parts List - 12/98

Ref. Part No. Description Qty.

154867A Hopper Assembly 1

2 77371A Decal 1

3 56430A Skirt Hopper 1

4 57359A Retainer, Skirt 1

5 964046 Screw, M4 x 0.7 x 10 30

6 57237A Pulley Assembly 1

7 51608A Bumper, Side Broom 1

8 50504A Broom, Side 1

9 50911A "V" Belt 1

10 59854A M6 Spring Washer 13

11 964007 Screw M6 x 16 15

12 50130A Arm, Weldment 1

13 55522A Knob, Side Broom 1

14 964053 Screw, M6 x 12 16

15 54718A Idler Assembly 2

16 58804A Stud Adjustment 1

17 50419A Pin,Arm 1

18 964005 Screw, M5 x 0.8 x 10 5

19 962241 Socket Set, 10-24 x ½ 2

20 54911A Handle 1

21 56431A Angle Handle 2

22 53968A FrameWeldment 1

23 50505A Bracket, Side Broom 1

24 54230A Guide, Hopper 2

25 962337 Sockt Set, ¼-20 x ½ 1

26 52115A Caster 3" Assembly 1

27 50420A Panel, Left 1

28 56432A Shroud 2

29 92400A Nut, M6 x 1.0 7

30 980646 Flat Washer M6 6

31 902550 Bearing, 620322 ZZ 3

32 57839A Ring S-12 1

33 980648 Washer, 1.5 x 13.1 x 23 1

34 57000A Pinion 1

35 51820A Clutch 1

36 980679 Washer 2.0 x 17.6 x 32 3

37 54412A Gear, Nylon 1

38 980442 M5 Spring Washer 4

39 964004 Screw 5 x 16 4

40 56433A Brush Support 1

41 964012 M6 Socket Cap Screw 1

42 56434A Brush Rails 0.15 MM 5

43 56435A Brush Rails 0.25 MM 5

44 58315A Shaft 1

45 50421A Panel,Right 1

46 56436A Skirt, Side 2

47 57360A Retainer, Skirt 2

48 980630 Washer, 2.0 x 21, 1 x 40.1 3

49 57840A Ring S-17 1

50 980644 Washer, 2.0 x 16.4 x 32 4

51 59927A Tire 12" 2

52 57841A Ring S-16 2

53 55523A Knob, Main Broom 1

54 980615 Washer, 1.2 x 10.5 x 25.4 3

55 50422A Pivot Assembly 1

56 920334 Nut, ½ PT. 1

57 58805A Stud, Adjustment 1

58 50506A Bracket 1

59 50423A Panel, Cover 1

60 56438A Skirt, Hopper Upper 1

61 57361A Skirt, Retainer Upper 1

62 56437A Skirt, Retainer Lower 1

63 56437A Skirt, Lower 1

64 964047 Screw, M4 x 0.7 12

65 980257 Washer, Hopper 12

67 924002 Nut,M4

68 924004 Nut,M5 2