American-Lincoln 1 - 1

91 WS

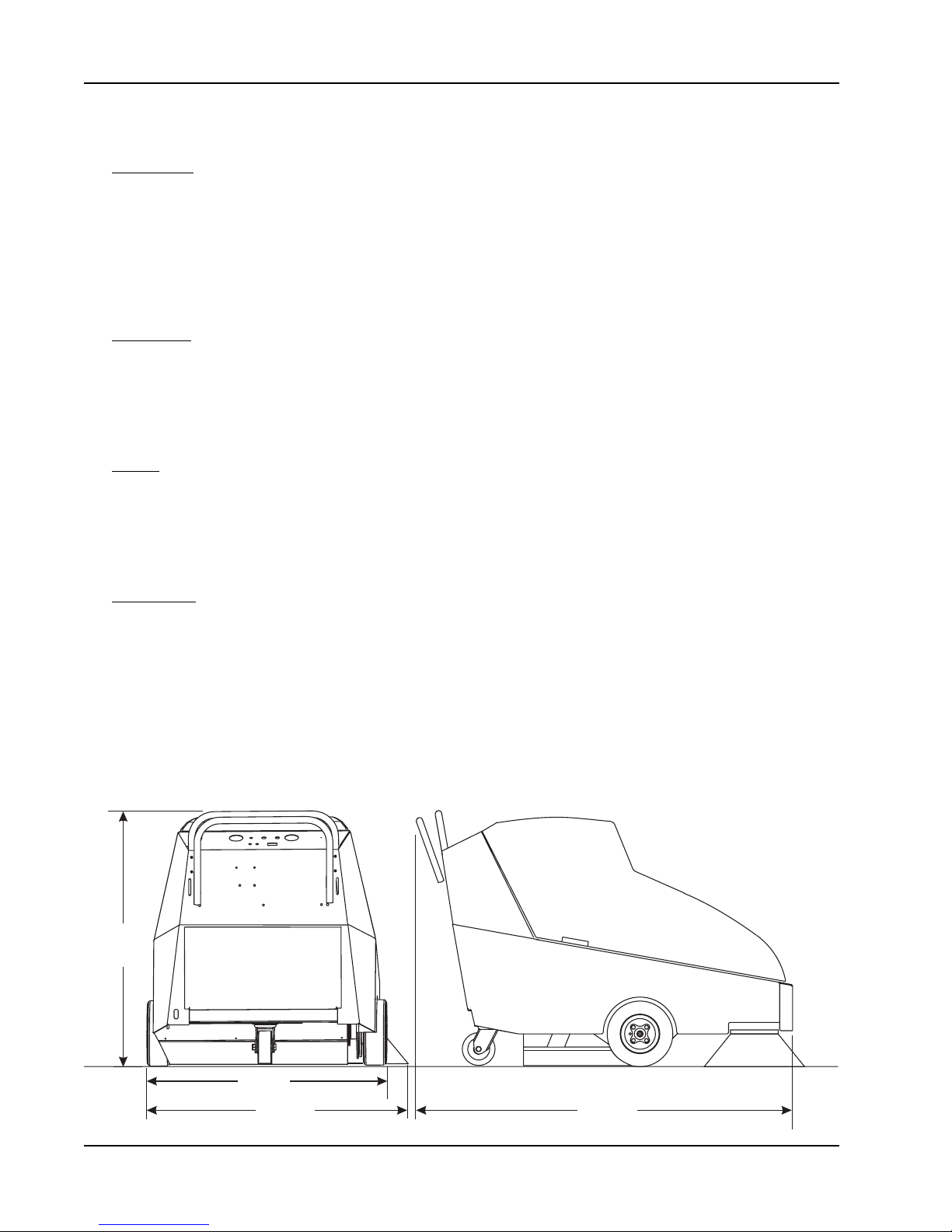

MACHINE SPECIFICATIONS........................................................................................................................ 1-3

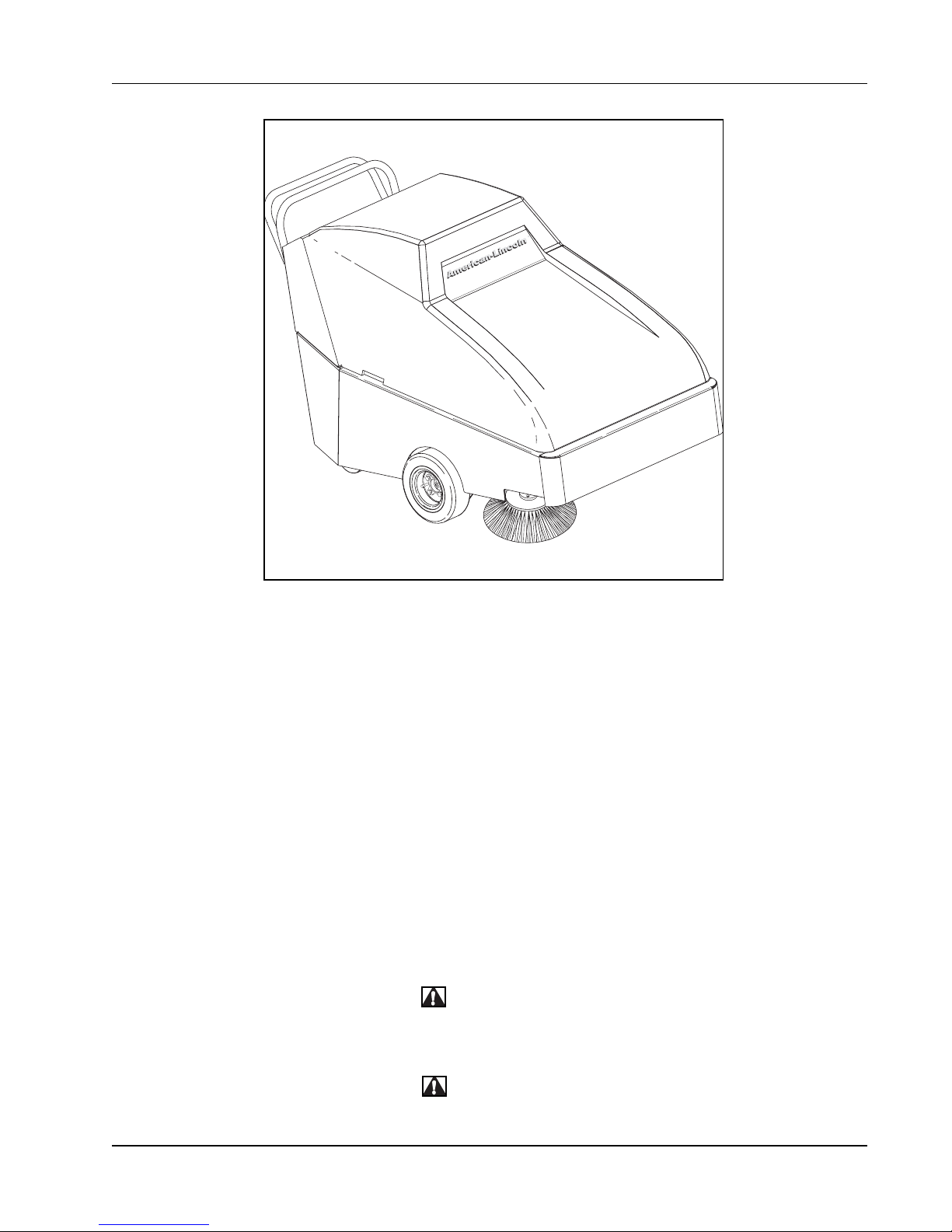

MACHINE PREPARATION............................................................................................................................. 1-5

GAS/LP POWERED MACHINES ........................................................................................................... 1-5

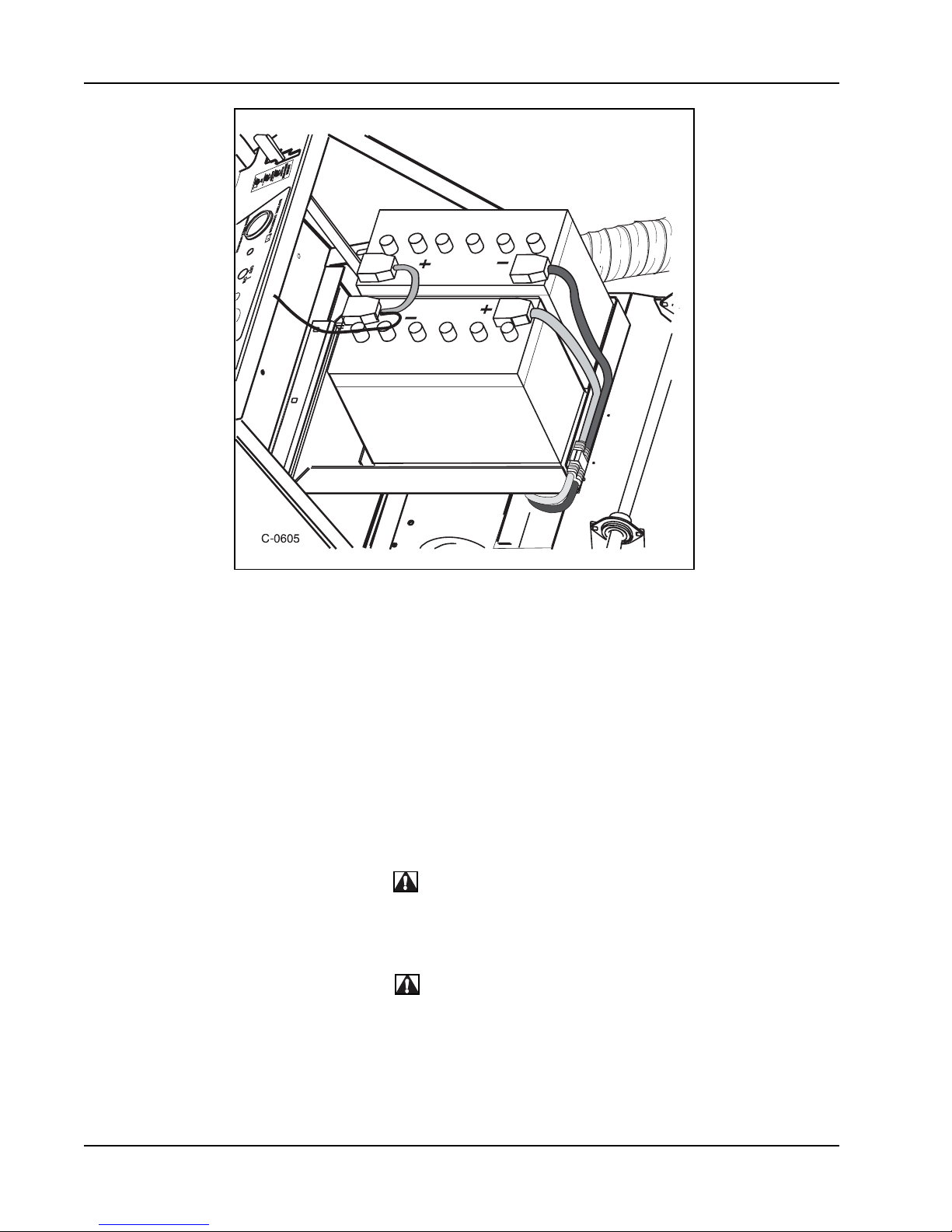

BATTERY POWERED MACHINES ........................................................................................................ 1-6

SAFETY PRECAUTIONS............................................................................................................................... 1-7

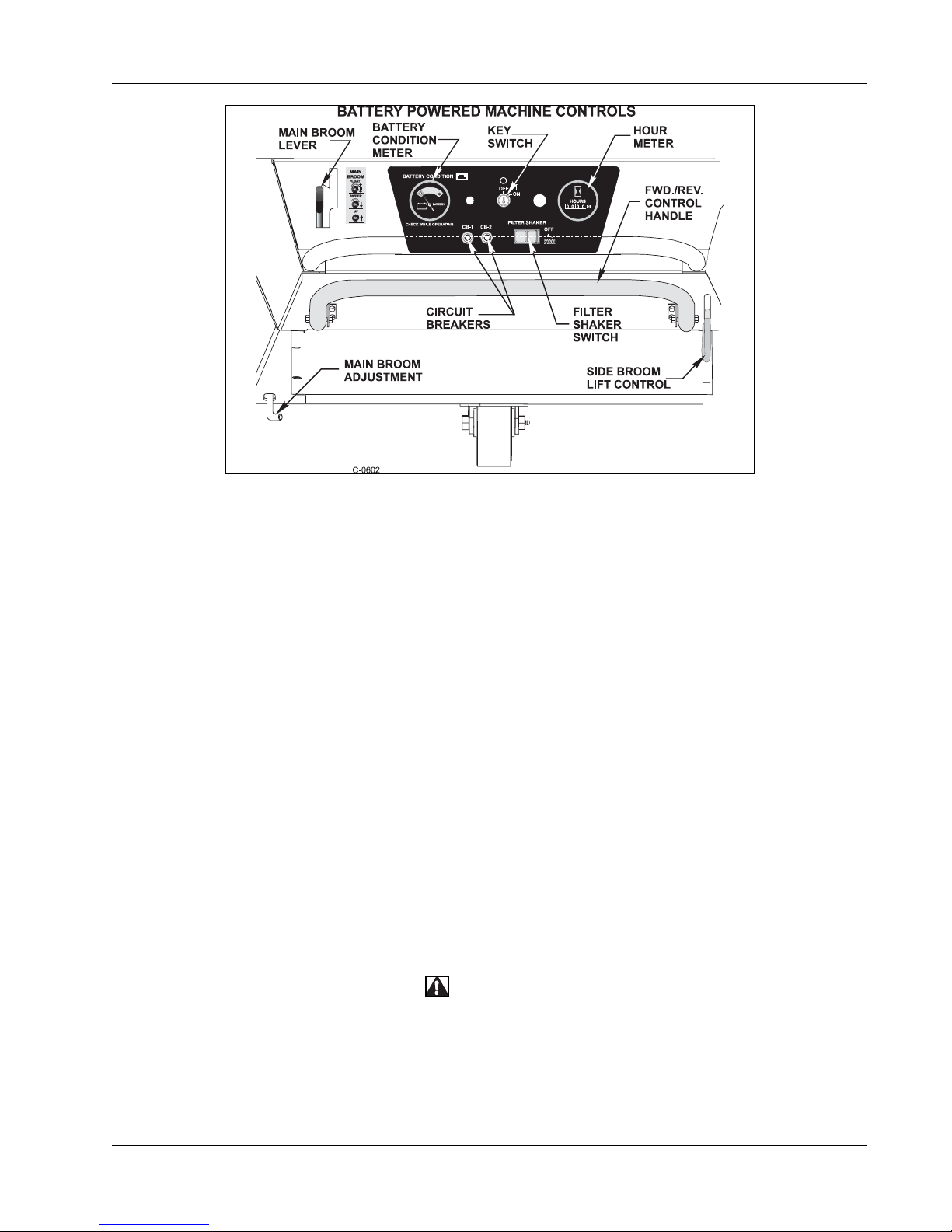

MACHINE CONTROLS .................................................................................................................................. 1-9

KEY SWITCH .......................................................................................................................................... 1-9

BATTERY CONDITION METER (BATTERY ONLY)................................................................................1-9

HOUR METER ......................................................................................................................................... 1-9

START BUTTON (GAS/LP ONLY)........................................................................................................... 1-10

BATTERY VOLT METER (GAS/LP ONLY) ............................................................................................. 1-10

CHOKE CONTROL (GAS/LP ONLY) ...................................................................................................... 1-10

LOW OIL LIGHT (GAS/LP ONLY) ........................................................................................................... 1-10

FILTER SHAKER SWITCH...................................................................................................................... 1-10

SIDE BROOM LIFT HANDLE.................................................................................................................. 1-11

MAIN BROOM LEVER ............................................................................................................................ 1-1

MAIN BROOM ADJUSTMENT ................................................................................................................ 1-11

FILTER MANIFOLD LATCH ..................................................................................................................... 1-12

HOPPER DUMP HANDLE ...................................................................................................................... 1-12

FORWARD/REVERSE CONTROL HANDLE ......................................................................................... 1-12

CIRCUIT BREAKERS .............................................................................................................................. 1-13

REWIND STARTER ................................................................................................................................. 1-13

OPERATING INSTRUCTIONS ...................................................................................................................... 1-14

BATTERY MACHINE OPERATION ......................................................................................................... 1-14

GAS/LP MACHINE OPERATION............................................................................................................ 1-14

PRE-START CHECKLIST ........................................................................................................................ 1-15

TO START THE BATTERY POWERED SWEEPER .............................................................................. 1-15

TO START THE GAS POWERED SWEEPER ......................................................................................1-15

TO START THE LP POWERED SWEEPER......................................................................................... 1-15

TO START THE ENGINE WITH THE REWIND STARTER ..................................................................... 1-16

TO DRIVE THE MACHINE FOR TRANSPORT ...................................................................................... 1-16

TO SWEEP WITH MACHINE ................................................................................................................. 1-16

TO EMPTY HOPPER .............................................................................................................................. 1-16

TO STOP SWEEPER ............................................................................................................................. 1-16

POST OPERATION CHECKLIST ............................................................................................................ 1-17

BATTERY CHARGING INSTRUCTIONS ................................................................................................. 1-17

TO CHARGE THE MOTIVE POWERED BATTERIES (BATTERY ONLY)............................................. 1-18

GASOLINE POWERED MACHINE FUELING INSTRUCTIONS ............................................................ 1-18

TO FILL THE GASOLINE POWERED MACHINE FUEL TANK ............................................................. 1-18

LP POWERED FUELING INSTRUCTIONS ............................................................................................ 1-18

TO CHANGE THE LP TANKS ................................................................................................................. 1-19

MACHINE STORAGE - GASOLINE POWERED MACHINES............................................................... 1-19

MACHINE STORAGE - BATTERY POWERED MACHINES ................................................................. 1-19

SERVICE CHART........................................................................................................................................... 1-20

HOW TO SWEEP .......................................................................................................................................... 1-22

SWEEPING GUIDELINES ...................................................................................................................... 1-22

SWEEPING VARIOUS TYPES OF DEBRIS.......................................................................................... 1-22

SERVICE INSTRUCTIONS............................................................................................................................ 1-23

MAIN BROOM ......................................................................................................................................... 1-23

TO CHECK THE MAIN BROOM SWEEP PATTERN .............................................................................1-23

TO ADJUST THE MAIN BROOM SWEEP HEIGHT ............................................................................... 1-23

TO REPLACE THE MAIN BROOM......................................................................................................... 1-24

SIDE BROOM .......................................................................................................................................... 1-25

TO CHECK THE SIDE BROOM SWEEP PATTERN.............................................................................. 1-25

TO ADJUST THE SIDE BROOM SWEEP HEIGHT................................................................................ 1-25

TO CHANGE THE SIDE BROOMS ........................................................................................................ 1-26

DUST CONTROL .................................................................................................................................... 1-26

TO CLEAN THE FILTER BAFFLE........................................................................................................... 1-26

TO CLEAN THE PANEL FILTER ............................................................................................................. 1-26

TABLE OF CONTENTS