Amada LP1173173 User manual

Y01OM1173243-10

OPERATION MANUAL

FIBER COOLING CHILLER UNIT (200-230V AC)

LP1173173

LP1173173

Thank you for purchasing our Fiber Cooling Chiller Unit (200-230V AC) LP1173173.

・This operation manual explains its method of operation and precautions for use.

・Before using, read this operation manual carefully; after reading, save it in a proper place

where you can easily access.

Contents

1. Configuration ............................................................................... 1

2. Name and Functions of Each Section........................................ 2

3. Installation and Preparation........................................................ 3

4. Maintenance

(1) Replacing the Replacement Cartridge of the DI Filter .............. 12

(2) Replacing the Filter Cartridge ................................................... 14

(3) Inspecting Water Leaks from the Pump.................................... 15

(4) Cleaning the Dust-proof Filter................................................... 16

(5) Cleaning or Replacing the Union-type Small Line Filter ........... 17

5. Alarm Code................................................................................... 18

LP1173173

1

CAUTION

For handling of thermo chiller and flow switch, refer to the attached operation

manual.

1. Configuration

Part Name Model No. Q’ty

Thermo chiller (HRS012-A-20-MT) PZ1173142 1

Alarm detecting cable (20 m) AS1172750 1

Different diameter coupling 8-6 for

stainless pipe SKUSDK8-6 4

Coupling for stainless pipe SKUTK8 2

Insert material SKITK8 10

SKITK6 4

Polyolefin tube (20 m) TPH0806W-20 2

Soft polyolefin tube (1 m) TPS0604W 1

NFH tightening spanner PA1173184 1

Power cable PZ1169303 1

DI filter cartridge HRS-DF001 1

Ferrule pack for reconnecting the

coupling SKFPK8 2

Option

Part Name Model No. Item No.

Alarm detecting cable (5 m) AS1172751 1172751

LP1173173

2

2. Name and Functions of Each Section

Thermo chiller Controls the water temperature.

The recommended setting temperature is 27°C (no

condensation).

Electrical resistivity sensor Monitors the resistance value of cooling water.

DI filter Controls the resistance value of cooling water.

Flow switch Monitors the cooling water flow rate.

Filter housing Housing for the filter cartridge.

Filter cartridge Removes impurities from the cooling water.

Valve Used when replacing the filter cartridge.

Flow regulator Adjusts the flow rate.

Pressure switch Monitors the pressure of cooling water.

LP1173173

3

3. Installation and Preparation

This chapter explains where to install the thermo chiller and cooling water.

Installation Place

Follow the attached operation manual for the thermo chiller.

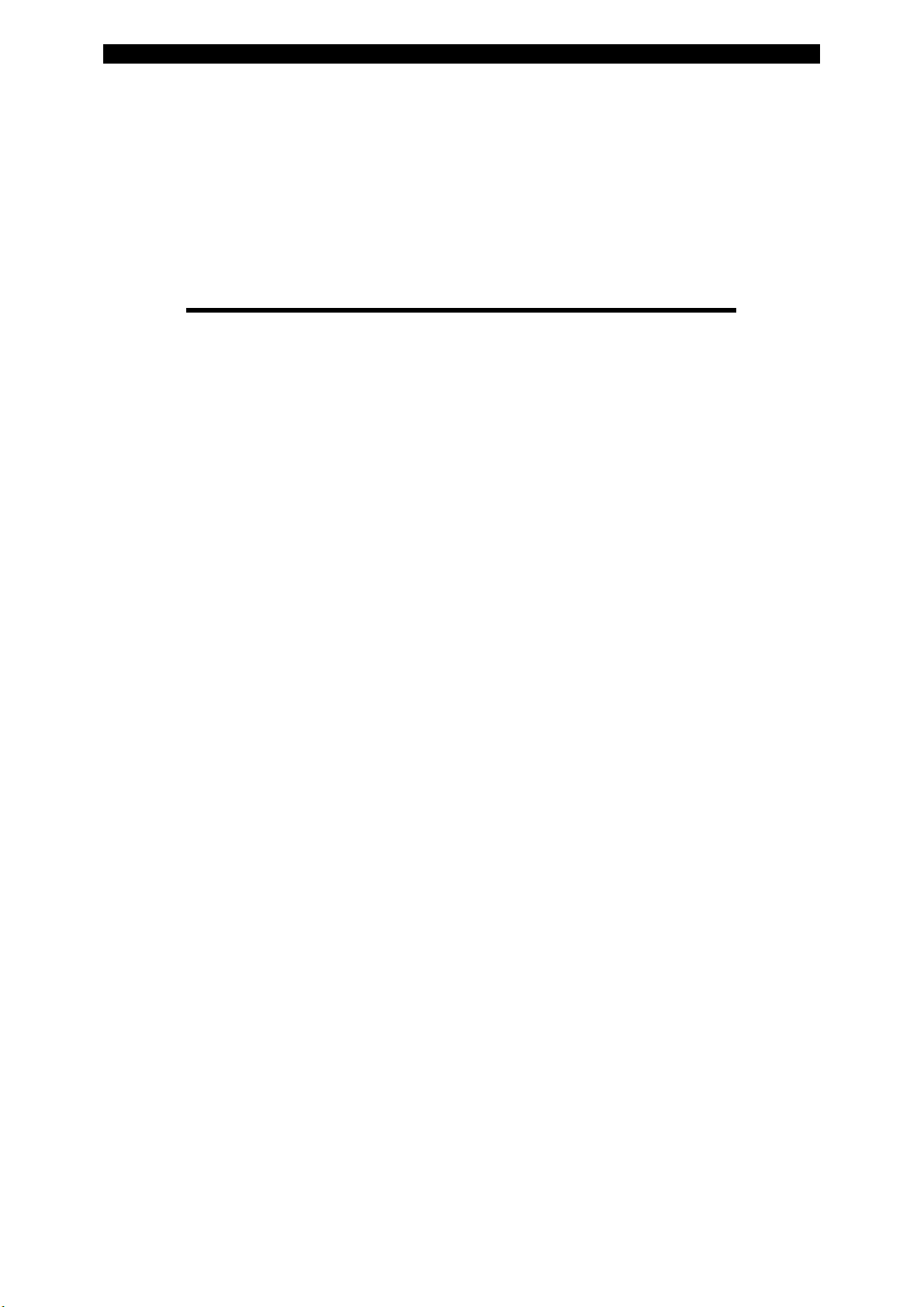

Mounting the DI Filter Replacement Cartridge

Since the DI cartridge deteriorates on contact with the air, it is packed separately.

Mount it before use.

1) Mount the a replacement cartridge with the seal part up. (See figure below.)

入口 出口

通気栓

ドレン栓

固定金具

緩む

入口 出口

通気栓

ドレン栓

固定金具

緩む

DIフィルター

交換用カートリッジ

シール部

DIフィルター

交換用カートリッジ

シール部

Seal part

DI filter

Replacement cartridge

Seal part

Drain plug

Ventilation plug

Loosen

Inlet OutletOutlet

Clamp

Cove

r

O-ring

Case

DI filter

cartridge

Air vent

V band

Drain

LP1173173

4

2) Mount the lower half of the DI filter with the reverse procedure to removing it.

3) Close the clamp.

4) Mount the drain plug.

5) Close the ventilation plug.

6) Start the thermo chiller with the valve of the DI filter closed.

7) Open the valve on the thermo chiller’s RETURN side only.

8) Open the ventilation plug to remove air, and close it again.

9) Open the valve on the thermo chiller’s OUTLET side.

⇒Check for leaks.

⇒When the cartridge is replaced, the water level of the cooling water tank will

drop. In that case, supply the cooling water.

Cooling Water

Use the cooling water meeting water quality standard established by Japan

Refrigeration and Air Conditioning Industry Association (JRA GL-02-1994 / cooling

water system - cyclic water - makeup water). (Cooling water supplied with the Laser

or distilled water is recommended.)

Tap water, water for industrial use, or ground water may cause corrosion or

clogging, resulting in fault of the equipment.

Connections and Preparations of Each Section

1) Connecting the power supply

When using the attached power cable (PZ1169303), use the terminal suitable for

the terminal block on the customer side.

For wiring, follow the attached operation manual for the thermo chiller.

200-230V AC

L

A

pprox.

3

m

A

pprox.

100

mm

Clr.: WHT

Clr.: BLK

Clr.: YEL/GRN

N

PE

LP1173173

5

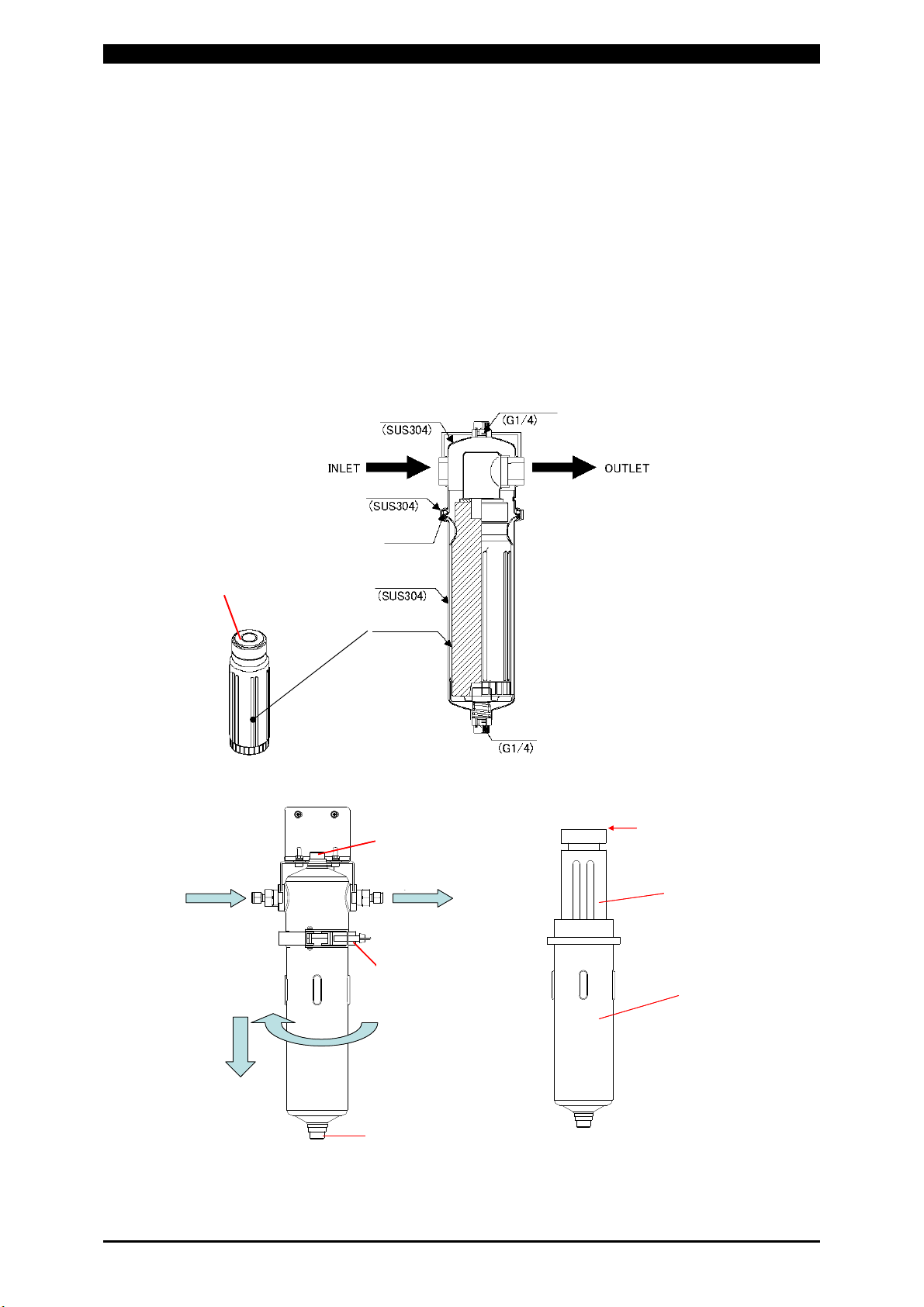

2) Connecting the tube

Note 1 Tube, TPH0806W-20

Cut the tube into any length in the range of 20 m on each side of IN/OUT.

(Since the required flow can not be secured with a tube over 20 m long, the flow

rate error will occur.)

Install the fiber connector 2.5 m or less from the floor.

Secure the minimum bending radius 100 mm.

Coupling,

SKUSDK8-6

(Note 2)

Tube,

TPH0806W-20

(Note 1)

Tube,

TPS0604W

(Note 3)

Fiber connector

(Note 4)

2.5 m max.

LP1173173

6

When cooling plural optical fibers:

・Up to two optical fibers can be cooled.

・Connect optical fibers in parallel as shown below.

・The maximum length of cooling tube should be 40 m in total. (+++++=

40 m max.)

Note 2 Coupling, SKUSDK8-6

Be sure to insert the insert material (SKITK8 or SKITK6) before connection.

Insert material (SKITK8 or SKITK6)

[Connection method]

a. Without removing the nut, insert the tube into

the coupling and push the end of the tube all

the way in.

b. Tighten the nut with a hand until it stops

moving. Put a mark in this position.

c. Rotate the nut 450 degrees clockwise with a

spanner, keeping the coupling body with

another spanner from moving.

SKUSDK8-6

SKUTK8

SKUTK8

SKUSDK8-6 SKUSDK8-6

SKUSDK8-6

LP1173173

7

[Reconnection method]

a. Before loosening the nut, check its

position. (This position is used as a

reference in the Step d.)

b. Remove the nut.

Check again that the front ferrule is

mounted at the proper position.

Check that no foreign matter is attached

to the body.

c. Insert the front ferrule until it attaches

firmly to the body and tighten the nut

with a hand.

Take care not to scratch the body with

the end of the tube.

d. Tighten the nut with a spanner until it

goes slightly over the position before

loosened (15 to 30 degrees).

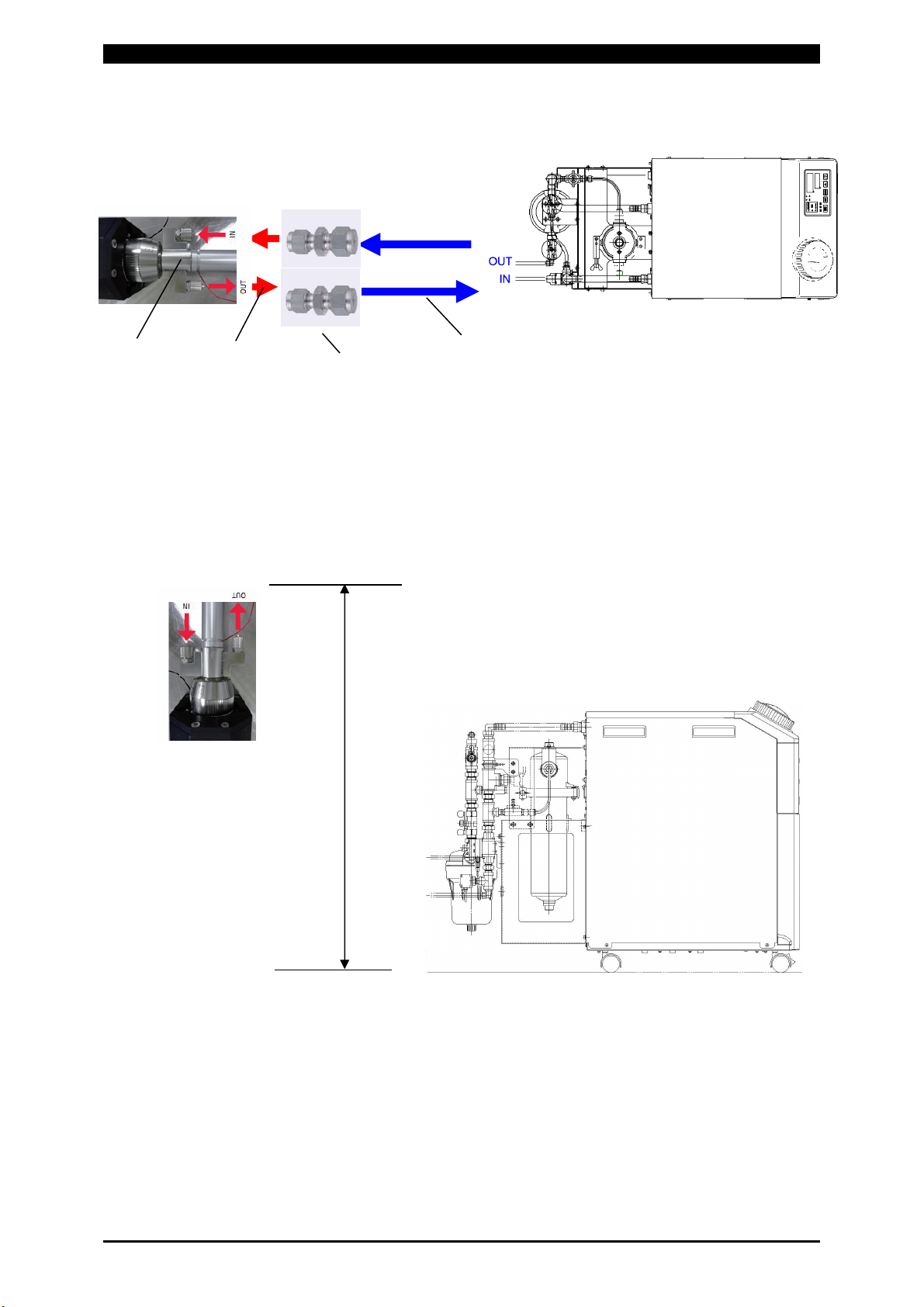

Note 3 Tube, TPS0604W

It is recommended that the length be 100 mm or shorter on each side of IN/OUT.

When the length is longer than 100 mm, the pressure loss becomes greater and

a flow rate error may occur.

Note 4 Fiber connector

・Confirm that the optical unit is connected before fitting pipe.

・Confirm that the Laser is turned off.

・Be careful about IN and OUT.

100 mm or shorter

recommended

Coupling,

SKUSDK8-6

SKFPK8

Ferrule pack for recon-

necting the coupling

LP1173173

8

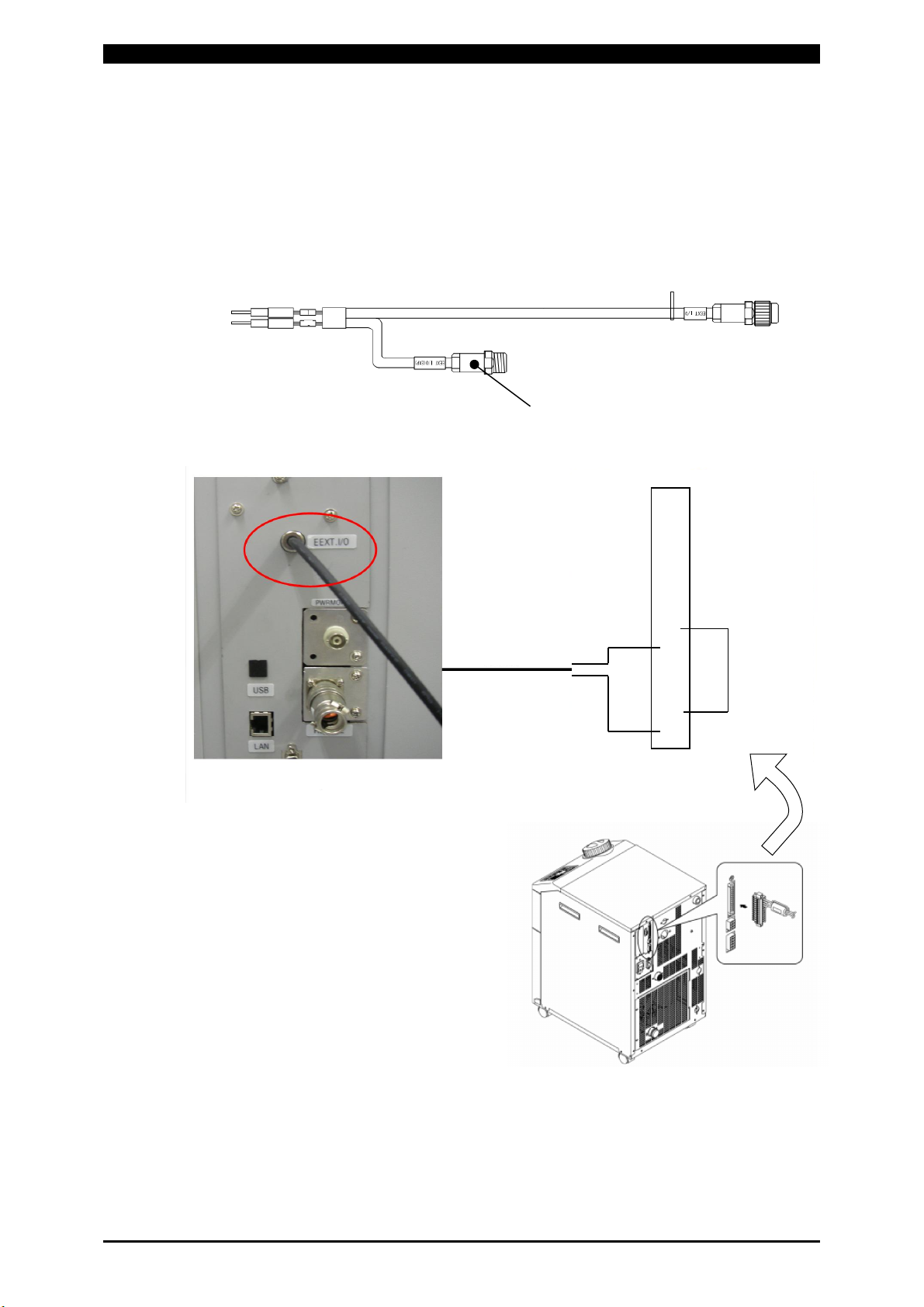

Wiring

・For the AC power cable connection, follow the attached operation manual for the

thermo chiller.

・Connect the alarm detecting cable (attached AS1172750 (20 m) or optional

AS1172751 (5 m)) to the Laser. Connect the EEXT. I/O (AS1172786)

disconnected from the Laser to the jack side of the alarm detecting cable.

To detect the alarm of the thermo chiller, connect the cable to Nos. 1 and 5.

Jack side

Alarm detecting cable

Connection

Laser rear Thermo chiller rear

5

12

11

10

9

8

7

6

5

4

3

2

1 AAS1185835

Alarm detecting cable

Table of contents

Popular Chiller manuals by other brands

Trane

Trane RTAA-70 Installation & maintenance guide

Carrier

Carrier Omnizone 50BVC Installation, Start-Up, Service and Controls Operation and Troubleshooting

York

York YGWH 115 Installation, commissioning & operation

Galletti

Galletti PERFORMA MPE Series Technical manual

SMC Networks

SMC Networks HRR Series manual

Daikin

Daikin EWAQ016CAW Installation and operation manual