Component Testing Information

!WARNING

To avoid risk of electrical shock, personal injury or death; disconnect power to washer before servicing, unless testing

requires power.

RT3220006 Rev. 3 October 20012

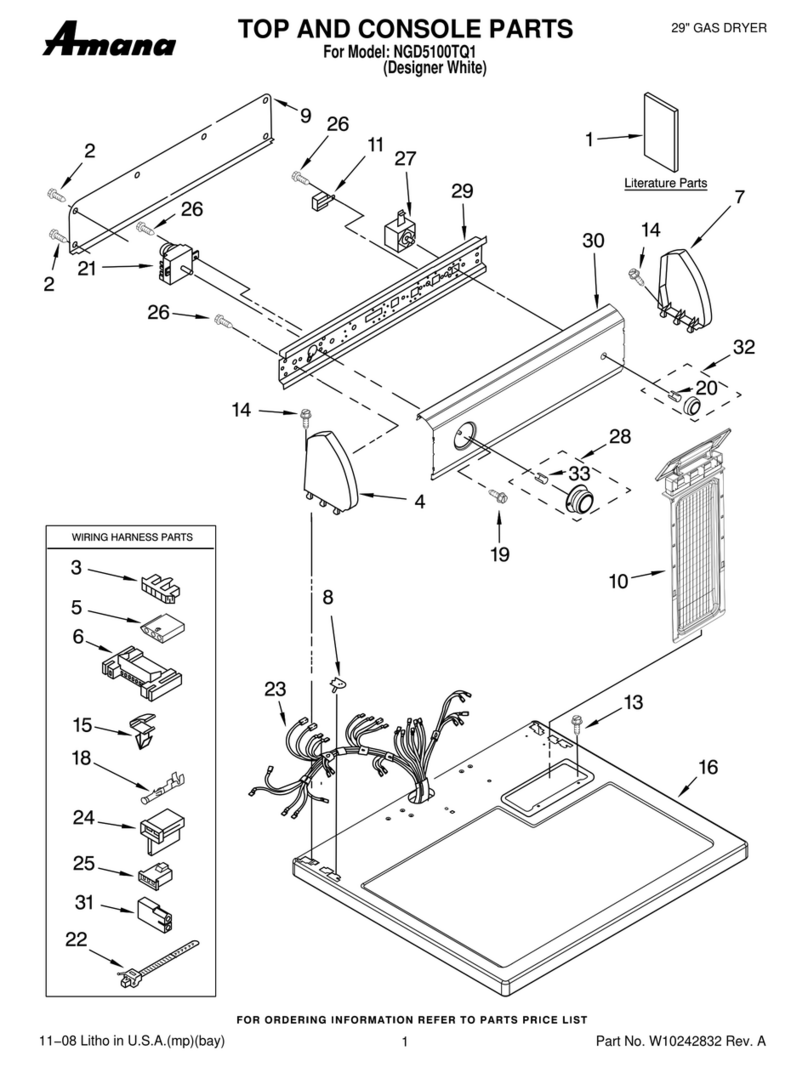

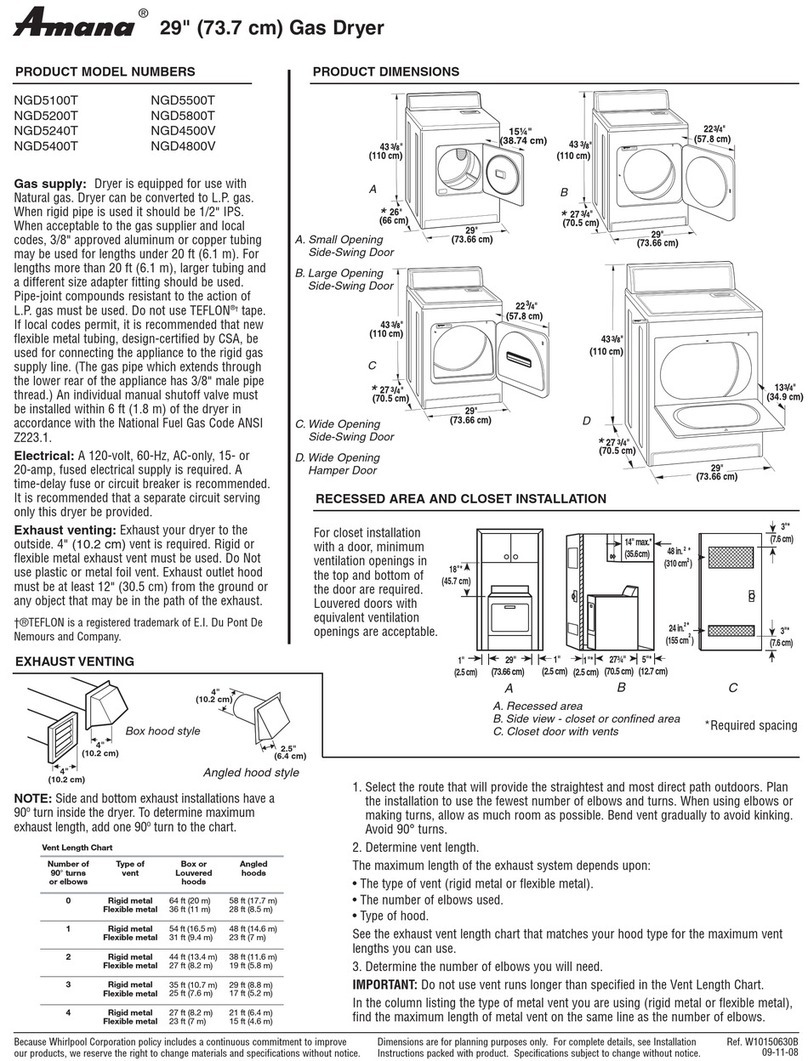

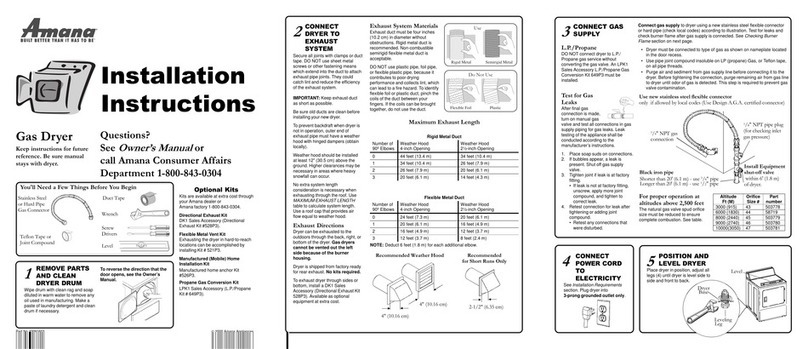

Illustration Component Test Procedure Results

40113801

Thermal fuse Measure resistance of thermal fuse from

terminal to terminal.

Open at 360°±12°F (182°±7°C) ........

Auto reset −31°F (−35°C)

If thermal fuse is open, both thermal fuse

and thermostat limit must be replaced.

Continuity < 1 Ω

Red −62641

Thermostat limit

S.P.S.T. −2 terminals

Measure resistance of the following

terminals:

Terminals 1 −2..................................

Open at 225°±7°F

Close at 185°±9°F

Continuity < 1 Ω

Pink / White −503979

Thermostat cycling

S.P.D.T. −3 terminals

Measure resistance of the following

terminals:

Terminals 1 −3..................................

Heat thermostat with a small flame until a

distinct click is heard.

Terminals 1 −2..................................

Open at 153°±5°F

Close at 138°±5°F

Continuity < 1 Ω

Continuity < 1 Ω

61623

Thermostat heater Disconnect wire terminals and measure

resistance of terminals.

Terminal to terminal...............................

2400 ±240 Ω

504570

Door switch

1 −COM

2 −N.C.

3 −N.O.

Measure resistance of the switch:

Door closed

Terminals 1 −3..................................

Door opened

Terminals 1 −2..................................

Continuity < 1 Ω

Continuity < 1 Ω

38424*

Rocker switch

(Extra Rinse)

* -Indicates color

Measure resistance of switch positions:

Closed (ON position).........................

Open (OFF position)........................

Continuity >1 Ω

Infinite 1 MΩ

40070501

Adjustable buzzer Measure resistance of the switch in the

following positions:

Off...................A −Open...................

Low .................A −1.........................

Medium.............A −2.........................

High..................A −1 −2...................

Infinite > 1 MΩ

Continuity < 1 Ω

Continuity < 1 Ω

Continuity < 1 Ω

40084201

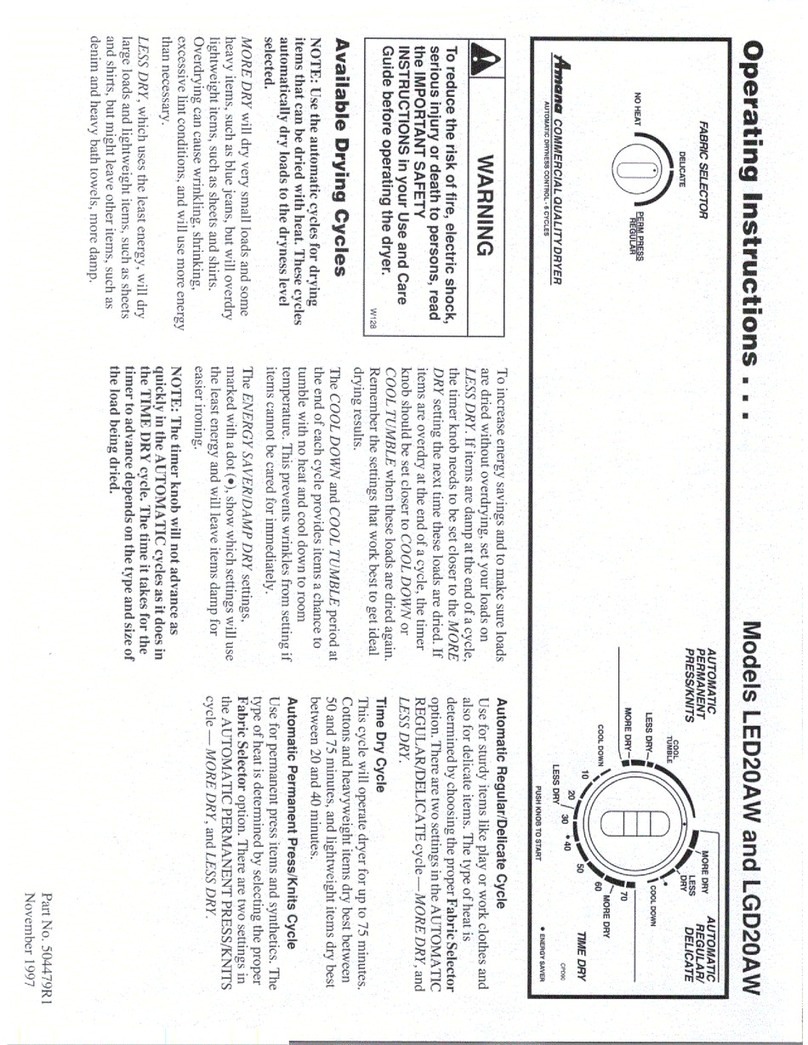

Fabric selector

4 position switch Place switch in the positions indicated in

the chart.

Measure resistance of the terminals

indicated.

X indicates continuity (< 1 Ω)

Fluff

Delicate

Perm

Press

Regular

L1-1

X

L1-2

X

X

X

L1-3

X

L1-4

X

40112701

Timer Verify input and output voltage is

present. See specific Wiring Diagram for timing

sequence chart.