5

Optional Pedestal

Are you placing the dryer on a pedestal? You have the option of

purchasing pedestals of different heights separately for this dryer.

You may select a 10" (254 mm) pedestal or a 15.5" (394 mm)

pedestal with a storage drawer. The pedestal will add to the total

height of the dryer for a total height of approximately

46" (1168 mm) or 51.5" (1308 mm), respectively.

For a garage installation, you will need to place the 10" (254 mm)

pedestal at least 9" (229 mm) above the floor. You will need to

place the 15.5" (394 mm) pedestal at least 3" (76 mm) above the

floor.

Optional pedestal (15.5" [394 mm] model shown)

To order, call the dealer from whom you purchased your dryer or

refer to the “Assistance or Service” section.

Pedestal Height Color Part Number

10"(254 mm) White WHP1000SQ

15.5"(394 mm) White XHP1550VW

15.5"(394 mm) Burgundy XHP1550VM

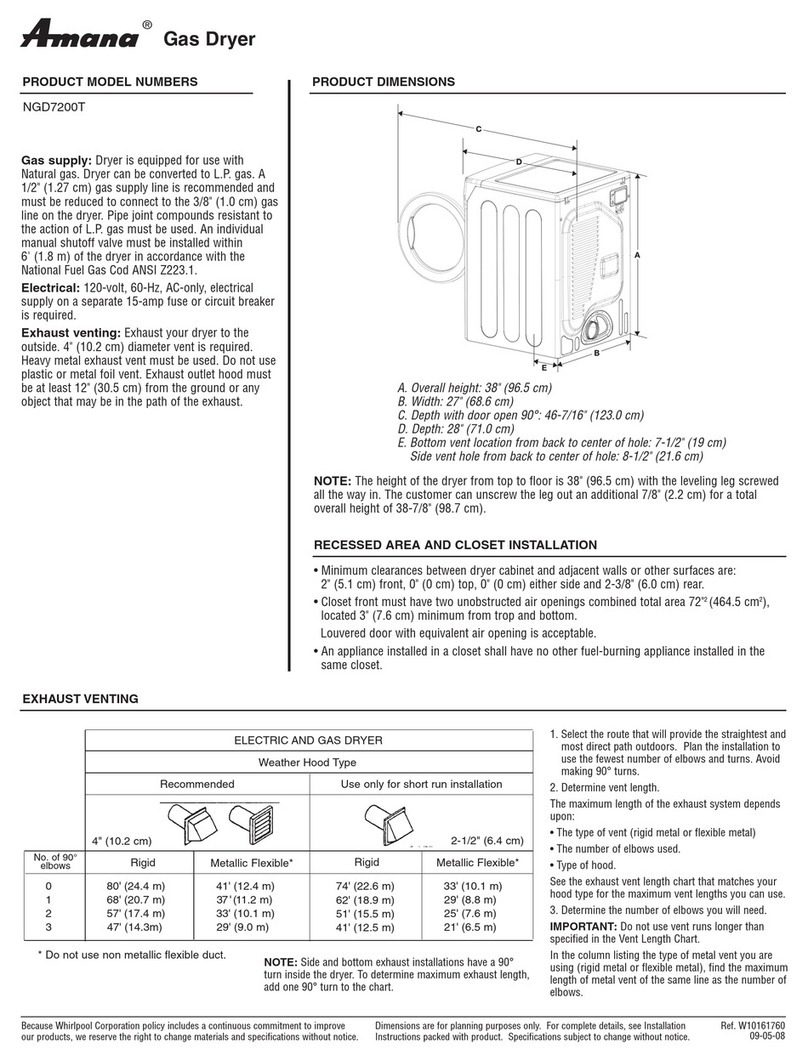

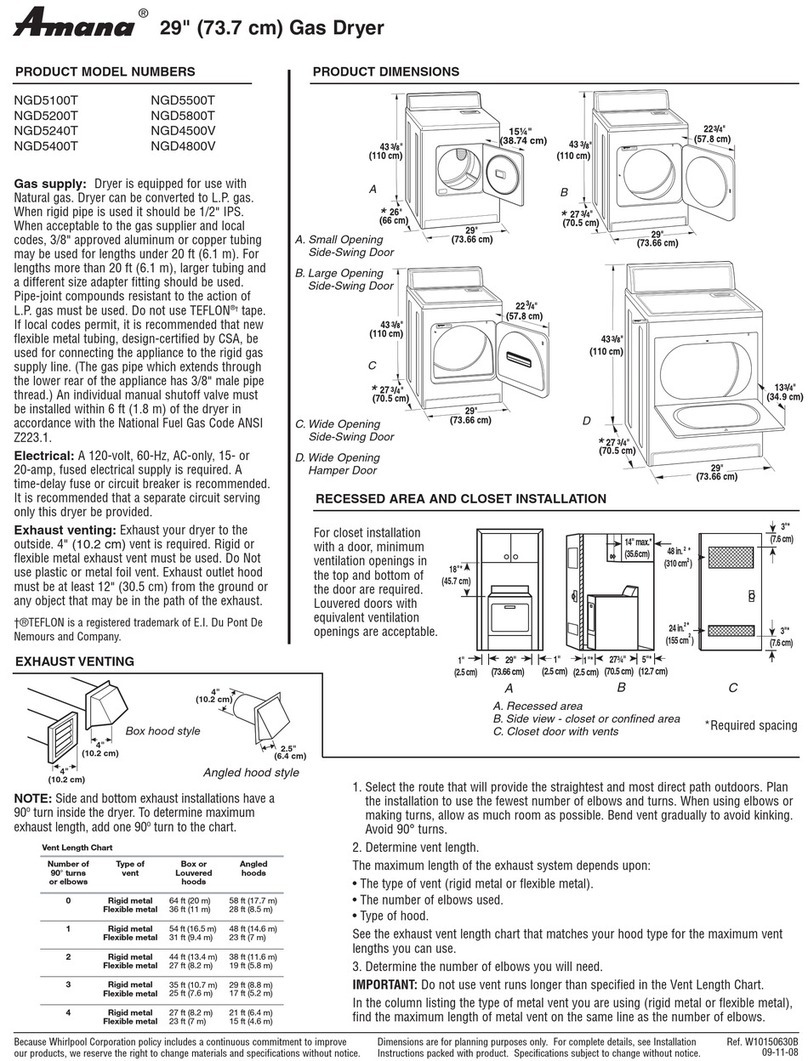

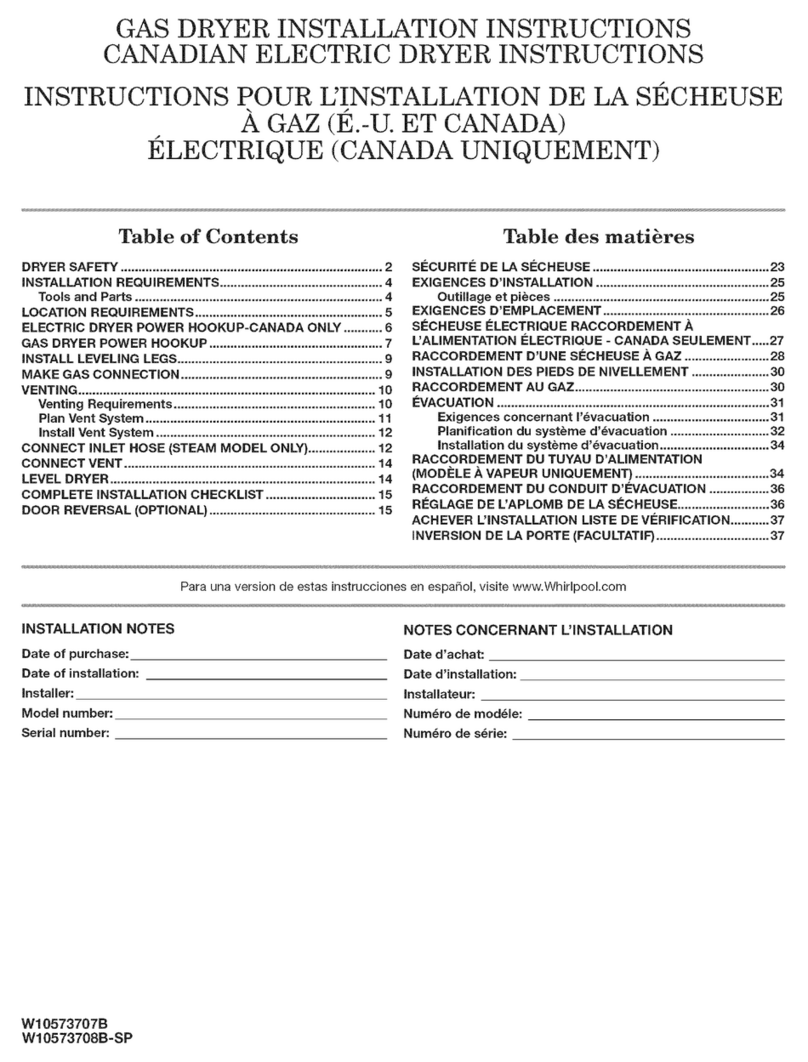

Location Requirements

You will need

■A location that allows for proper exhaust installation. A gas

dryer must be exhausted to the outdoors. See “Venting

Requirements.”

■A grounded electrical outlet located within 2 ft (610 mm) of

either side of the dryer. See “Electrical Requirements.”

■A sturdy floor to support the total dryer weight of 200 lbs

(90.7 kg). The combined weight of a companion appliance

should also be considered.

■A level floor with a maximum slope of 1" (25 mm) under entire

dryer. (If slope is greater than 1" [25 mm], install Extended

Dryer Feet Kit, Part No. 279810.) Clothes may not tumble

properly and automatic sensor cycles may not operate

correctly if dryer is not level.

■For a garage installation, you will need to place the dryer

at least 18" (460 mm) above the floor. If using a pedestal, you

will need 18" (460 mm) to the bottom of the dryer.

Do not operate your dryer at temperatures below 45ºF (7ºC).

At lower temperatures, the dryer might not shut off at the end of

an automatic cycle. Drying times can be extended.

The dryer must not be installed or stored in an area where it will

be exposed to water and/or weather.

Check code requirements. Some codes limit, or do not permit,

installation of the dryer in garages, closets, mobile homes, or

sleeping quarters. Contact your local building inspector.

NOTE: No other fuel-burning appliance can be installed in the

same closet as a dryer.

Installation clearances

The location must be large enough to allow the dryer door to

open fully.

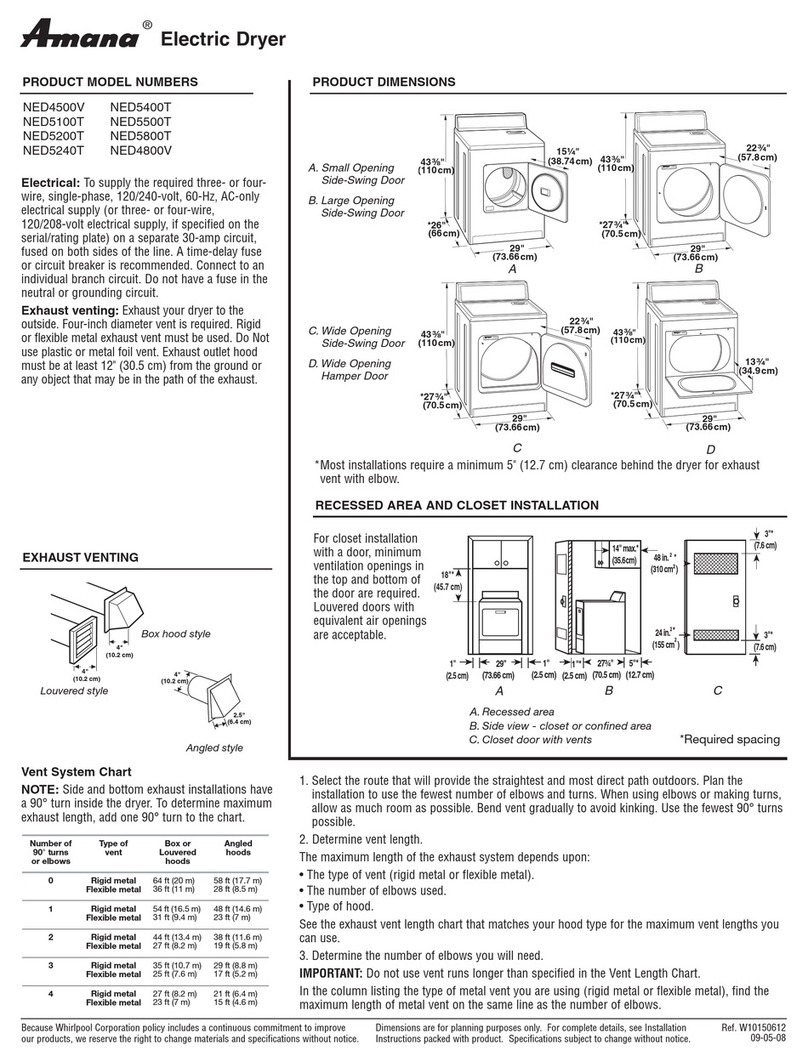

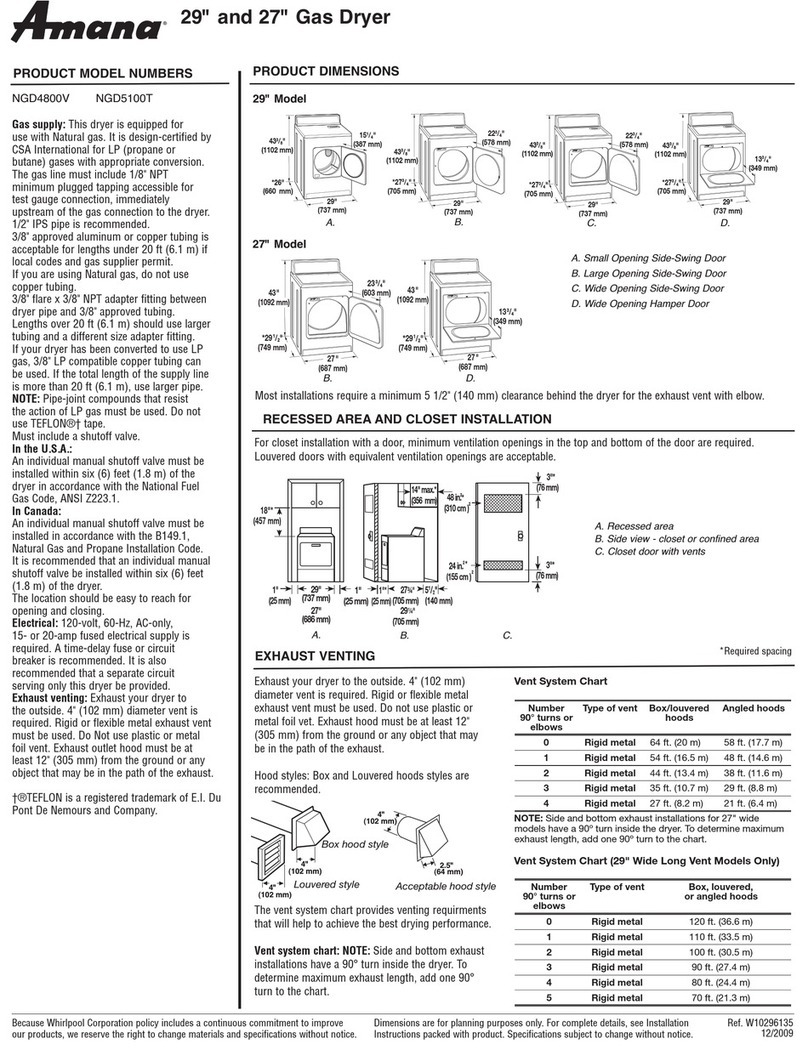

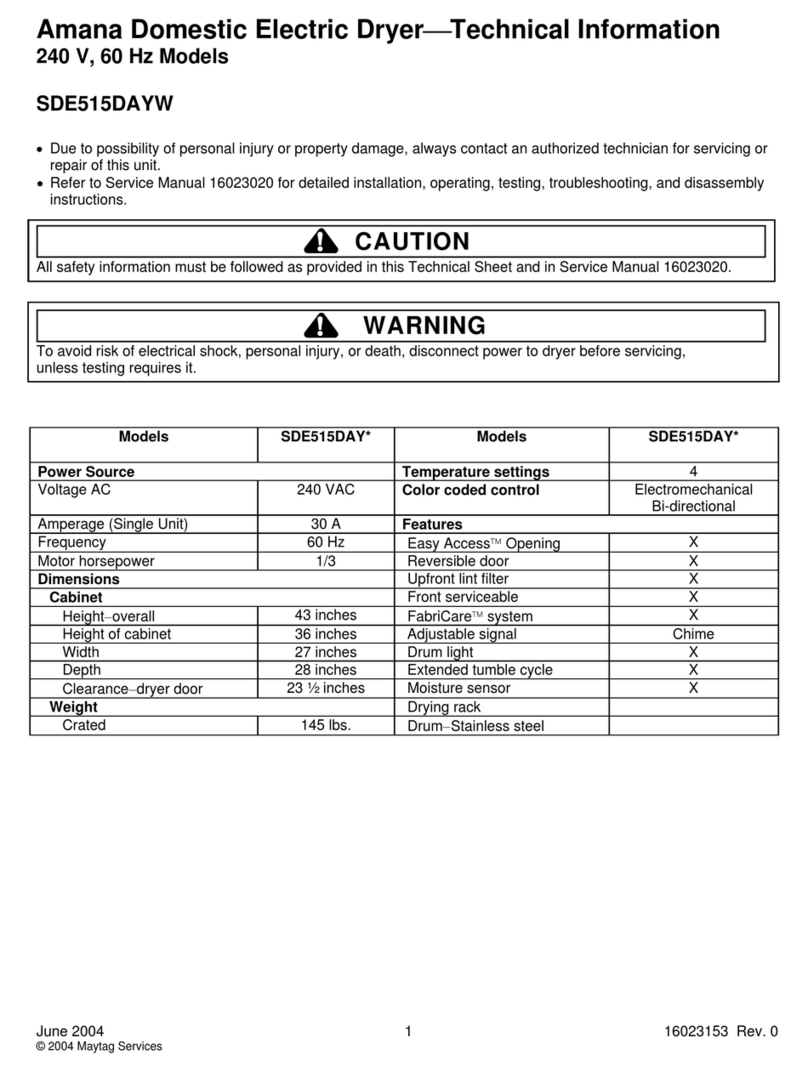

Dryer Dimensions

38"

(965.2 mm)

*31½"

(800.1 mm) 27"

(686 mm)

50½"

(1282.7 mm)

*Most installations require a minimum 5" (127 mm) clearance

behind the dryer for the exhaust vent with elbow. See “Venting

Requirements.”

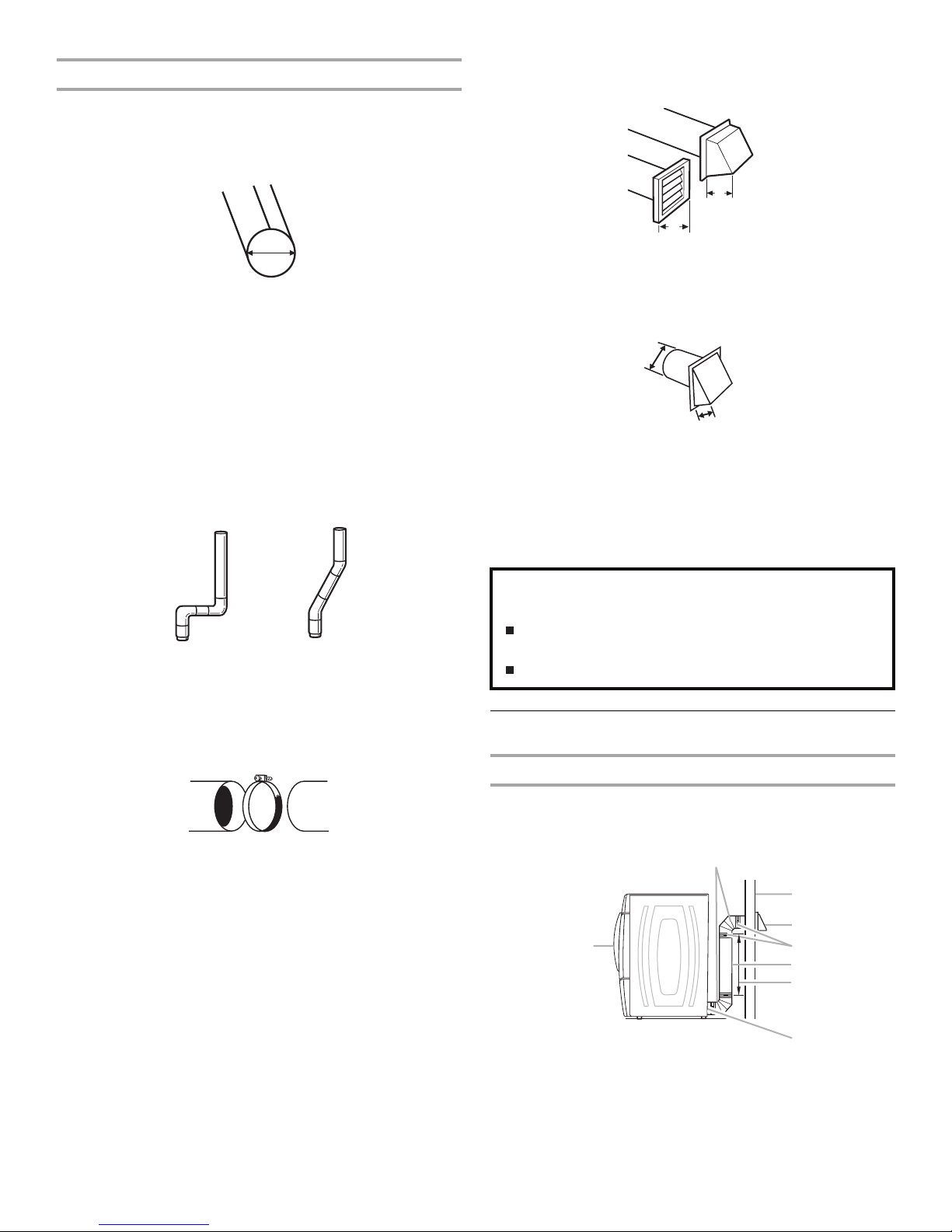

Installation spacing for recessedarea or closet installation

The following spacing dimensions are recommended for this

dryer. This dryer has been tested for spacing of 0" (0 mm)

clearance on the sides and rear. Recommended spacing should

be considered for the following reasons:

■Additional spacing should be considered for ease of

installation and servicing.

■Additional clearances might be required for wall, door, and

floor moldings.

■Additional spacing should be considered on all sides of the

dryer to reduce noise transfer.

■For closet installation, with a door, minimum ventilation

openings in the top and bottom of the door are required.

Louvered doors with equivalent ventilation openings are

acceptable.

■Companion appliance spacing should also be considered.

Custom undercounter installation - Dryer only

0"

(0 mm)

38" min.

(965.2 mm)

1"*

(25 mm)

1"*

(25 mm)

27"

(686 mm)

*Required spacing