4

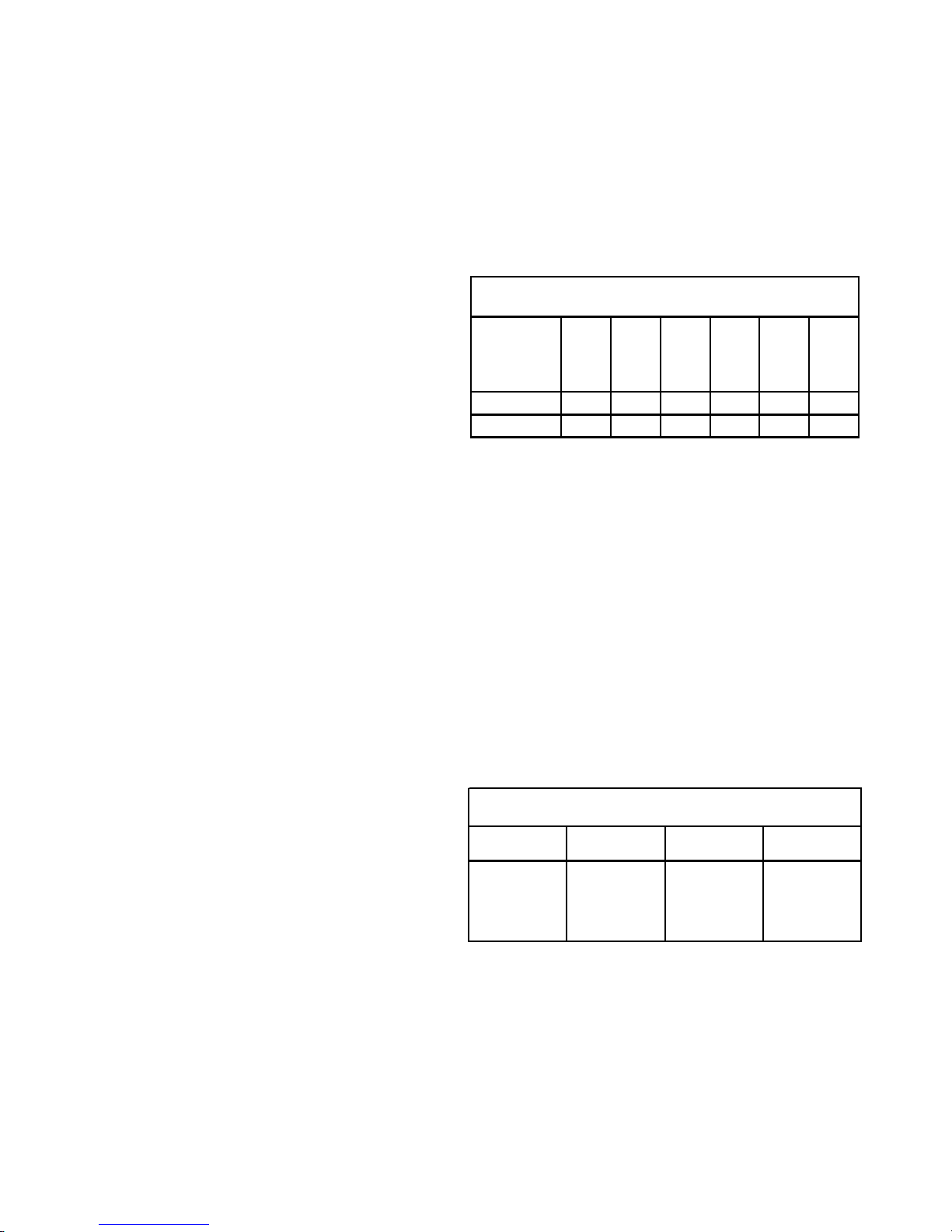

PRODUCT DESIGN 3. Conversionkits for high altitude natural orpropanegas

operation are available. See High Altitude Derate chart

fordetails.

4. Installer must supply the following gas line fittings, de-

pendingon which entrance isused:

Left -- Two 90º Elbows, one close nipple, straight pipe.

Right --Straight pipe toreach gas valve.

Accessibility Clearances (Minimum)

POSITION*

FRONT

SIDES

REAR

TOP

FLUE

FLOOR

Upflow30010C

Horizontal36060C

*= All positioning is determined as installed unit is viewed from the front.

C= If placed on combustible floor, floor MUST be wood only.

MINIMUM CLEARANCES TO COMBUSTIBLE MATERIALS

(INCHES)

NC= For instalaltion on non-combustible floors only. A non-combustible

subbase must be used for installations on combustible flooring.

24"at front isrequired for servicing orcleaning.

Note: Inall cases accessibility clearanceshall take prece-

denceoverclearancesfrom theenclosurewhere accessibil-

ityclearancesaregreater. Alldimensionsaregivenininches.

High Altitude Derate

Whenthis furnace is installedat high altitude, theappropri-

ate High Altitude orifice kit must be installed. This is re-

quireddue tothe natural reductionin thedensity of boththe

gas fuel and combustion air as altitude increases. The kit

will provide the proper design certified input rate within the

specifiedaltitude range.

0 to

7,000 ft. 7,001 to

9,000 ft. 9,001 to

11,000 ft. 7,001 to

11,000 ft.

LPM-05

LPM-06

2

Propane

Conversion Kit

rifi

HANG11

High Altitude

Natural Gas Kit

(#44 Orifices)

HANG12

High Altitude

Natural Gas Kit

(#45 Orifices)

HALP 10

High Altitude

LP Gas Kit

(#56 Orifices)

PROPANE AND HIGH ALTITUDE KITS

FOR *MH95*****XA* MODELS

1

LPM-05* supports White-Rodgers 2-stage valves only

2

LPM-06* supports Honeywell and White-Rodgers 2-stage valves

High altitude kits are purchased according to the installa-

tionaltitudeandusageofeithernaturalorpropanegas.Refer

tothe chartabove fora tabular listingof appropriatealtitude

rangesandcorrespondingmanufacturer’shighaltitudeNatu-

ralGas andPropane Gaskits. For atabular listingof appro-

priatealtituderangesandcorrespondingmanufacturer'sHigh

Altitude Pressure Switch kits, refer to either the Pressure

Switch Trip Points & Usage Chart in this manual or the Ac-

cessoryCharts in Service Instructions.

GeneralOperation

The*MH95furnacesare equippedwithanelectronic ignition

deviceused tolighttheburnersand aninduced draftblower

to exhaust combustion products.

Aninterlock switchpreventsfurnace operationif the blower

door is not in place. Keep the blower access door in place

exceptfor inspection andmaintenance.

This furnace is also equipped with a self-diagnosing elec-

tronic control module. In the event a furnace component is

notoperatingproperly, thecontrol moduleLED will flashon

and off in a factory-programmed sequence, depending on

theproblem encountered. Thislight can beviewed through

theobservation windowinthe bloweraccess door. Referto

theTroubleshooting Chartforfurther explanationof theLED

codesandAbnormal Operation-Integrated IgnitionControl

section in the Service Instructions for an explanation of the

possibleproblem.

Therated heatingcapacity of thefurnace shouldbe greater

thanor equal to thetotal heat loss of thearea to be heated.

The total heat loss should be calculated by an approved

methodor inaccordance with “ASHRAEGuide” or “Manual

J-LoadCalculations”published bytheAir ConditioningCon-

tractors of America.

*Obtain from: American National Standards Institute 1430

BroadwayNew York,NY 10018

LocationConsiderations

• The furnace should be as centralized as is practical

with respect to the air distribution system.

• Donot installthe furnacedirectlyon carpeting,tile, or

combustiblematerial otherthan wood flooring.

• When suspending the furnace from rafters or joists,

use 3/8" threaded rod and 2” x 2” x 3/8” angle as

shownintheInstallation andServiceInstructions.The

length of the rod will depend on the application and

clearancenecessary.

• When installed in a residential garage, the furnace

mustbepositioned sothe burnersandignition source

are located not less than 18 inches (457 mm) above

the floor and protected from physical damage by ve-

hicles.

Notes:

1. Installermustsupply oneortwoPVC pipes:onefor com-

bustionair(optional)andonefortheflueoutlet(required).

Ventpipe mustbe either2” or3” in diameter,depending

uponfurnace input,number ofelbows, lengthof runand

installation (1 or 2 pipes). The optional Combustion Air

Pipeisdependenton installation/coderequirementsand

must be 2” or 3” diameter PVC.

2. Linevoltagewiring canenterthrough therightor leftside

ofthe furnace.Low voltage wiringcan enterthrough the

rightor left side offurnace.