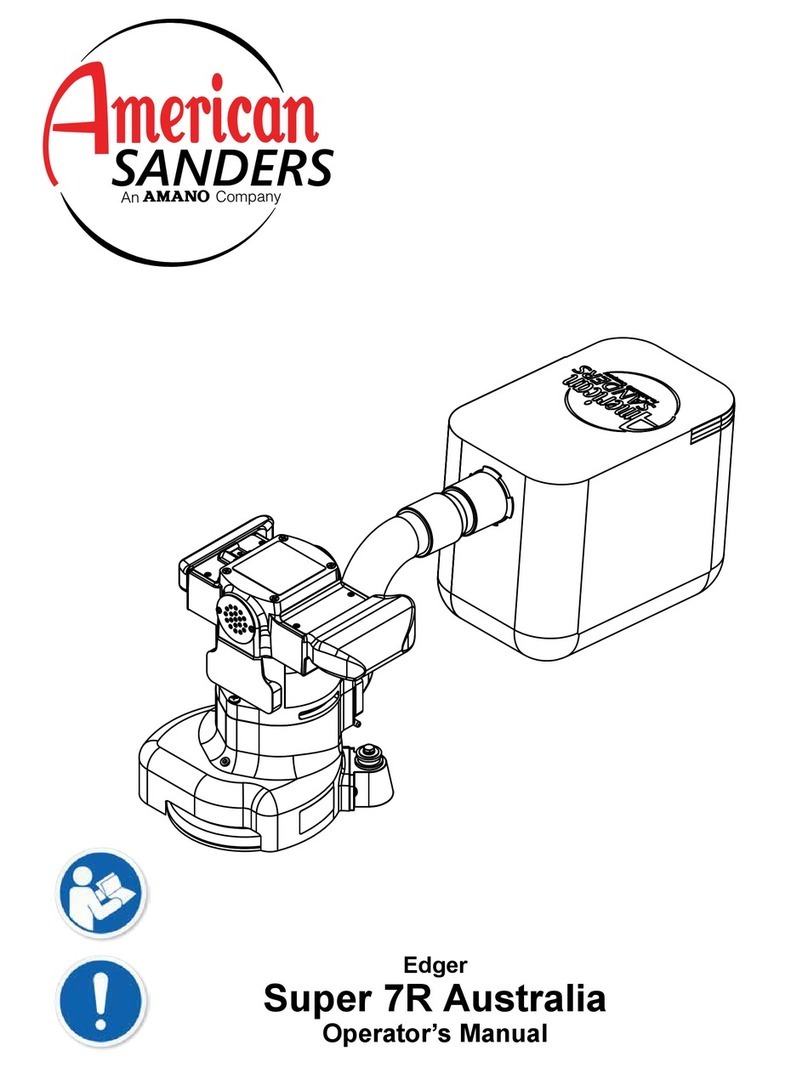

Amano 07208A User manual

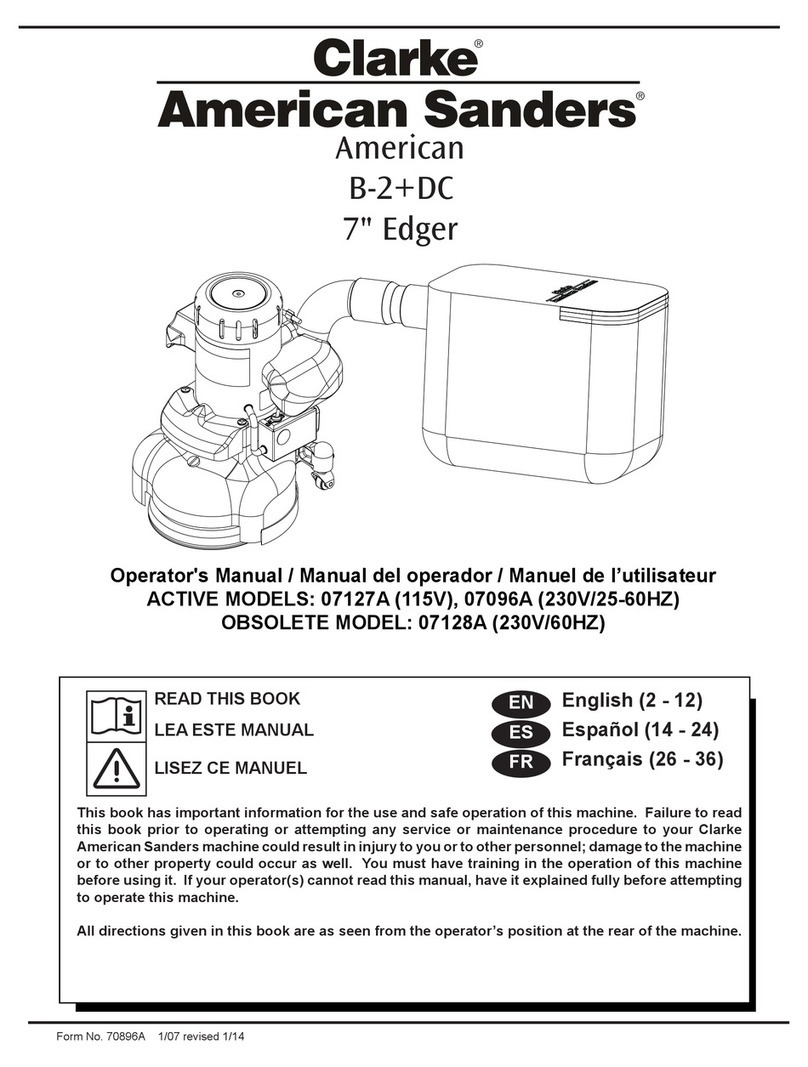

7” Edger

Super 7R

Operator’s Manual

For Models

07208A, 07208B, 07209A, 07209B

Contents

Operator Safety Instructions..................................................... 4-7

Introduction...................................................................................8

Machine Specifications.................................................................8

Electrical Connection Instructions ..............................................9

Machine Setup............................................................................10

Operating Instructions ................................................................11

Adjustment Procedures ..............................................................12

Maintenance......................................................................... 12-13

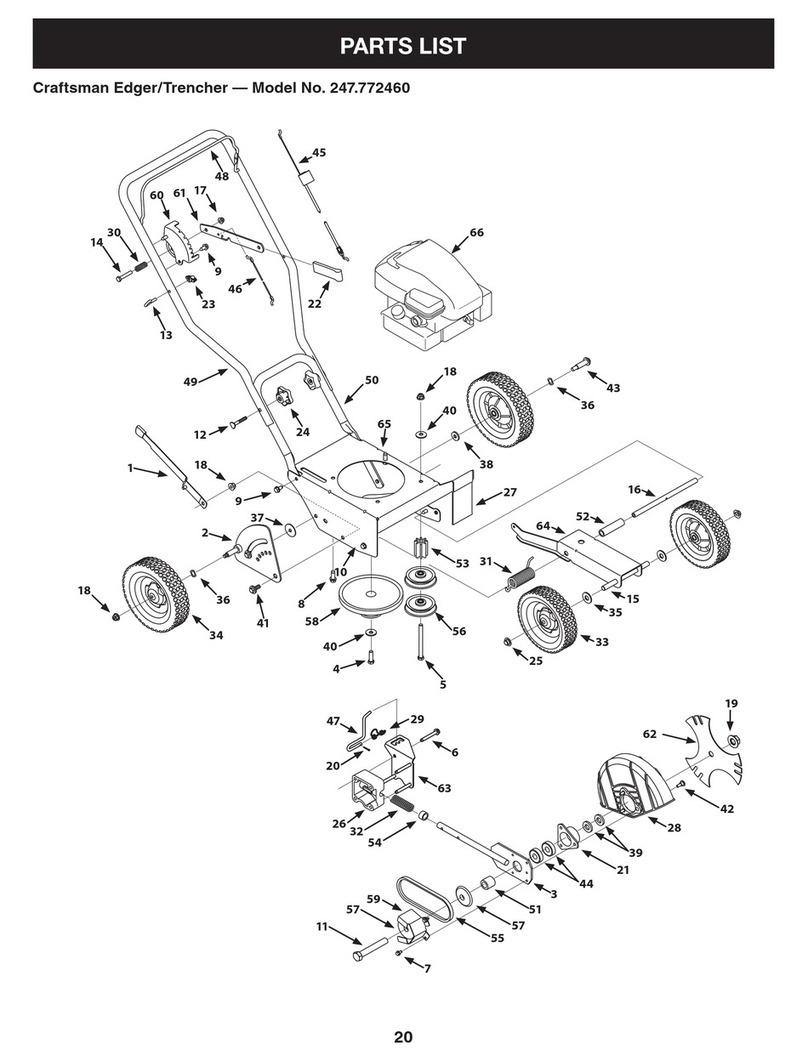

Parts Manual ..............................................................................32

Wiring Diagram...........................................................................33

Lower Assembly .........................................................................34

Upper Assembly .........................................................................36

Warranty .....................................................................................38

READ THIS BOOK

This book has important information for the use and safe operation of this machine. Failure to read this book prior to

operating or attempting any service or maintenance procedure to your American Sanders machine could result in injury

to you or to other personnel; damage to the machine or to other property could occur as well. You must have training in

the operation of this machine before using it. If your operator(s) cannot read this manual, have it explained fully before

attempting to operate this machine.

All directions given in this book are as seen from the operator’s position at the rear of the machine.

***This product is intended for commercial use only***

WARNING!

The Products sold with this Manual contain or may contain chemicals that are known to certain governments (such as the State of

California, as identied in its Proposition 65 Regulatory Warning Law) to cause cancer, birth defects or other reproductive harm. In

certain locations (including the State of California) purchasers of these Products that place them in service at an employment job site

or a publicly accessible space are required by regulation to make certain notices, warnings or disclosures regarding the chemicals that

are or may be contained in the Products at or about such work sites. It is the purchaser’s responsibility to know the content of, and

to comply with, any laws and regulations relating to the use of these Products in such environments. The Manufacturer disclaims any

responsibility to advise purchasers of any specic requirements that may be applicable to the use of the Products in such environments.

In this Operation Manual you will find three statements that you must read and observe to ensure safe operation of this

machine.

DANGER means: Severe bodily injury or death can occur to you or other personnel if the DANGER

statements found on this machine or in this Operation Manual are ignored or are not adhered to. Read

and observe all DANGER statements found in this Operation Manual and on your machine.

WARNING means: Injury can occur to you or to other personnel if the WARNING statements found on

your machine or in the Operation Manual are ignored or are not adhered to. Read and observe all

WARNING statements found in this Operation Manual and on your machine.

CAUTION means: Damage can occur to the machine or to other property if the CAUTION statements found

on your machine or in this Operation Manual are ignored or are not adhered to. Read and observe all

CAUTION statements found in this Operation Manual and on your machine.

Operator Safety Instructions

EN

EN

DANGER: Failure to read the Owner’s Manual prior to operating or servicing your American Sanders machine could result in injury to

you or to other personnel; damage to the machine or to other property could occur as well. You must have training in the

operation of this machine before using it. If you or your operator(s) cannot read English, have this manual explained fully

before attempting to operate this machine.

DANGER: A. Sanding/nishing wood oors can create an explosive or combustible environment. Do not operate this machine around

solvents, thinners, alcohol, fuels, oor nishes, wood dust or any other ammable materials. Cigarette lighters, pilot lights,

electrical sparks and all other sources of ignition should be extinguished or avoided. Keep work area well ventilated.

B. Dust generated from sanding wood oors can spontaneously ignite or explode. Promptly dispose of any sanding dust in

a metal container clear of any combustibles. Do not dispose in a re.

DANGER: A. Electrocution could occur if the machine is being serviced while the machine is connected to a power source. Disconnect

the power supply before servicing.

B. Electrocution or re could occur if the machine is being operated with a damaged power cord. Keep the power cord clear

of the pad. Always lift the cord over the machine. Do not move the machine by the power cord.

C.Shock hazard. Do not use the machine if it has been rained on or sprayed with water.

DANGER: To avoid injury keep hands, feet, and loose clothing away from all moving parts on the machine. Disconnect the power cord

before replacing the pad, changing the abrasive, or when servicing. Do not operate the machine unless all guards are in

place. Never leave the machine unattended while connected to a power source.

WARNING: Injury can occur if protective clothing or equipment is not used while sanding. Always wear safety goggles, protective

clothing, and dust mask while sanding.

WARNING: This sander is not to be used on pressure treated wood. Some pressure treated woods contain arsenic and sanding

pressure treated wood produces hazardous dust. Inhaling hazardous dust from pressure treated wood can cause serious

injury or death. Sanding pressure treated wood decks or uneven surfaces can damage the sander which is not covered

under warranty or damage waiver.

WARNING: Any alterations or modications of this machine could result in damage to the machine or injury to the operator or other

bystanders. Alterations or modications not authorized by the manufacturer voids any and all warranties and liabilities.

WARNING: Risk of explosion. Floor sanding can result in an explosive mixture of ne dust and air. Use oor sanding machine only in a

well-ventilated area free from any ame or match.

A SPECIAL WARNING ABOUT BAG FIRES

Dust generated from sanding raw or previously nished wood oors CAN SPONTANEOUSLY IGNITE OR EXPLODE!

The sanding machine’s DUST CONTAINMENT BAG MUST BE EMPTIED FREQUENTLY and before any work stoppage.

NEVER STORE SANDING DUST IN OR AROUND STRUCTURES OR OTHER COMBUSTIBLE MATERIALS.

Promptly dispose of any sanding dust outside in accordance with local regulations. Do not dispose in a re.

5

WARNING: Read all safety warnings and

instructions. Failure to follow warnings and

instructions may result in electric shock, re and

or serious injury.

Save all warnings and instructions for future use.

The term “power tool” in the warnings refers to your

main-operated (corded) power tool or battery operated

(cordless) power tool.

1) Work area safety

a) Keep work area clean and well lit. Clutter or dark

areas invite accidents.

b) Do not operate power tools in explosive

atmospheres, such as in the presence of

ammable liquids, gases, or dust. Power tools

create sparks which may ignite the dust or fumes.

c) Keep children and bystanders away while

operating a power tool. Distractions can cause

you to lose control.

2) Electrical safety

a) Power tool plugs must match the outlet. Never modify the

plug in any way. Do not use any adapter plugs with earthed

(grounded) power tools. Unmodied plugs and matching

outlets will reduce risk of electric shock.

b) Avoid body contact with earthed or grounded surfaces such

as pipes, radiators, ranges, and refrigerators. There is an

increased risk of electric shock if your body is earthed or

grounded.

c) Do not expose power tools to rain or wet conditions. Water

entering a power tool will increase the risk of electric shock.

d) Do not abuse the cord. Never use the cord for carrying,

pulling or unplugging the power tool. Keep cord away

from heat, oil, sharp edges or moving parts. Damaged or

entangled cords increase the risk of electric shock.

e) When operating a power tool outdoors, use an extension

cord suitable for outdoor use. Use of cord suitable for

outdoor use reduces the risk of electric shock.

f) If operating a power tool in a damp location is unavoidable,

use a residual current device (RCD) or ground fault circuit

interrupter (GFCI ) protected supply. Use of a RCD or GFCI

reduces the risk of electric shock.

3) Personal safety

a) Stay alert, watch what you are doing and use common

sense when operating a power tool. Do not use a power

tool while you are tired or under the inuence of drugs,

alcohol, or medication. A moment of inattention while

operating power tools may result in serious personal injury.

b) Use personal protective equipment. Always wear eye

protection. Protective equipment such as dust mask, non-

skid safety shoes, hard hat, or hearing protection used for

appropriate conditions will reduce personal injury.

c) Prevent unintentional starting. Ensure switch is in

o-position before connecting to power source and/or

battery pack, picking up, or carrying the tool. Carrying

power tools with your nger on the switch or energizing

power tools that have the switch on invites accidents.

d) Remove any adjustment wrench or key before turning

the power tool on. A wrench or key left attached to a

rotating part of the power tool may result in personal injury.

e) Do not overreach. Keep proper footing and balance at

all times. This enables better control of the power tool in

unexpected situations.

f) Dress properly. Do not wear loose clothing or jewelry.

Keep your hair, clothing and gloves away from moving

parts. Loose clothes, jewelry, or long hair can be caught in

moving parts.

g) If devices are provided for the connection of dust

extraction and collection facilities, ensure these are

connected and properly used. Use of dust collection can

reduce dust related hazards. It is recommendation that the

tool always be supplied via a residual current device with a

rated residual current of 30mA or less.

4) Power tool use and care

a) Do not force the power tool. Use the correct power tool

for your application. The correct power tool will do the job

better and safer at the rate for which it was designed.

b) Do not use the power tool if the switch does not turn it

on and o. Any power tool that cannot be controlled with

the switch is dangerous and must be repaired.

c) Disconnect the plug from the power source and/or the

battery pack from the power tool before making any

adjustments, changing accessories or storing power

tools. Such preventative safety measures reduce the risk of

starting the power tool accidentally.

d) Store idle power tools out of the reach of children and

do not allow persons unfamiliar with the power tool or

these instructions to operate the power tool. Power

tools are dangerous in the hands of untrained users.

e) Maintain power tools. Check for misalignment or

binding of moving parts, breakage of parts and any

other condition that may aect the power tool’s

operation. If damaged, have the power tool repaired

before use. Many accidents are caused by poorly

maintained power tools.

f) Keep cutting tools sharp and clean. Properly maintained

cutting tools with sharp cutting edges are less likely to bind

and are easier to control.

g) Use the power tool, accessories and tool bits etc. in

accordance with these instructions, taking into account

the working conditions and the work to be performed.

Use of the power tool for operations dierent from those

intended could result in a hazardous situation.

5) Service

a) Have the power tool serviced by a qualied repair

person using only identical replacement parts. This

will ensure that the safety of the power tool is maintained.

If the supply cord is damaged, it must be replaced by the

manufacturer, its service agent or similarly qualified persons

in order to avoid a hazard.

General Power Tool Safety Warnings

6

EN

1. This power tool is intended to function as a

sander. Read all safety warnings, instructions and

specications provided with this power tool. Failure

to follow all instructions listed below may result in

electric shock, re, or personal injury.

2. Operations such as grinding, wire brushing,

polishing or cutting-o, are not recommended to

be performed with this power tool. Operations

for which the tool was not designed may create a

hazard and cause personal injury.

3. Do not use accessories which are not specically

designed and recommended by the tool

manufacturer. Just because the accessory can be

attached to your power tool, it does not assure safe

operation.

4. The rated speed of the accessory must be at least

equal to the maximum speed marked on the power

tool. Accessories running faster than their rated

speed can break and y apart.

5. The outside diameter and thickness of your

accessory must be within the capacity rating of

your power tool. Incorrectly sized accessories

cannot be adequately guard or controlled.

6. The arbor size of wheels, anges, backing pads

or any other accessory must t the spindle of the

power tool. Accessories with arbor holes that do

not match the mounting hardware of the power tool

will run out of balance, vibrate excessively and may

cause loss of control.

7. Do not use damaged accessory. Before each use

inspect the accessory such as abrasive wheel for

chips or cracks, backing pad for cracks, tear or

excess wear, wire brush for loose or cracked wires.

If power tool or accessory is dropped, inspect for

damage or install an undamaged accessory. After

inspecting or installing an accessory, position

yourself or bystanders away from the plane of

the rotating accessory and run the power tool at

maximum no-load speed for one minute. Damaged

accessories will normally break apart during this

time.

8. Wear personal protective equipment. Depending

on application, use face shield, safety goggles or

safety glasses. As appropriate, wear dust mask,

hearing protectors, gloves and workshop apron

capable of stopping ying debris generated by

various operations. The eye protection must be

capable of stopping ying debris generated by

various operations. The dust mask or respirator

must be capable of ltering particles generated

by your operations. Prolonged exposure to high

intensity noise may cause hearing loss.

9. Keep bystanders a safe distance away from work

area. Anyone entering the work area must wear

personal protective equipment. Fragments of work

piece or a broken accessory mayy away and

cause injury beyond immediate area of operation.

10. Hold power tool by gripping insulated surfaces

(handle) only, when performing an operation where

the cutting accessory may contact hidden wiring or

its own cord. Cutting accessory contacting a “live”

wire may make exposed metal parts of the power

tool “live” and shock the operator.

11. Position the cord clear of the spinning accessory. If

you loose control, the cord may be cut or snagged

and your arm or hand may be pulled into the

spinning accessory.

12. Never lay the power tool down until the accessory

has come to a complete stop. The spinning

accessory may grab the surface and pull the power

tool out of your control.

13. Do not run the power tool while carrying it at

your side. Accidental contact with the spinning

accessory could snag your clothing, pulling the

accessory into your body.

14. Regularly clean the power tools air vents. The

motor’s fan will draw the dust inside the housing

and excessive accumulation may cause electrical

hazards.

15. Do not operate the power tool near ammable

materials. Sparks could ignite these materials.

16. Do not use excessively oversized sanding disc

paper. Follow manufacturer’s recommendations

when selecting sanding paper. Larger sanding

paper extending beyond the sanding pad presents

a laceration hazard and may cause snagging,

tearing of the disc or kickback.

17. Risk of explosion. Floor sanding can result in an

explosive mixture of ne dust and air. Use oor

sanding machine only in a well-ventilated area free

from any ame or match.

Safety Warnings for Sanding Operations

7

EN

Kickback and Related Warnings

Kickback is a sudden reaction to a pinched or

snagged rotating wheel, backing pad, brush or any

other accessory. Pinching or snagging causes rapid

stalling of the rotating backing pad which in turn causes

uncontrolled power tool to be forced in the opposite

direction of the backing pad’s rotation at the point of the

binding.

For example, if an abrasive wheel is snagged or

pinched by the work piece, the edge of the wheel that

is entering into the pinch point can dig into the surface

of the material causing the wheel to climb out or kick

out. The wheel may either jump toward or away from

the operator, depending on direction of the wheel’s

movement at the point of pinching. Abrasive wheels

may also break under these conditions.

Kickback is the result of power tool misuse and

incorrect operating procedures or conditions and can

be avoided by taking proper precautions as given

below.

1. Maintain a rm grip on the power tool and position

your body and arms to allow you to resist kickback

forces. Always use auxiliary handles, if provided

for maximum control over kickback or torque

reactions during start up. The operator can control

torque reactions or kickback forces, if proper

precautions are taken.

2. Never place your hand near the rotating accessory.

Accessory may kickback over your hand.

3. Do not position your body in the area where power

tool will move if kickback occurs. Kickback will

propel the tool in the direction opposite to the

wheel’s movement at the point of the snagging.

4. Use special care when working corners, sharp

edges etc. Avoid bouncing and snagging the

accessory. Corners, sharp edges or bouncing

have a tendency to snag the rotating accessory

and cause loss of control or kickback.

1. Empty the dust bag or dust collection receiver

frequently. Do not leave residue in dust bag or dust

collection receiver unattended. Always empty in a

non-combustible metal container. Sanding wood

or varnish produces dust that can self ignite and

cause injury or damage. Follow this precaution for

storage.

2. Set all exposed nails. Sweep loose abrasive away

from work area. Do not strike metal pipes, etc.,

with sanding paper. Striking metal or abrasive

particles with sanding paper produces sparks that

could ignite the sanding dust which can cause

injury or damage.

3. Do not operate a partially assemble power tool.

Keep all adjustments within manufacturer’s

specications. Keep all fasteners tight. Operating

a partially assembled power tool could result in

injury to the operator or bystander and could cause

damage to the equipment or surroundings.

4. Do not attempt to change the sanding paper while

the power tool is running. The sanding pad can

snag clothing and cause injury to limbs and moving

sanding paper can cause abrasions.

5. The power tool should only be used on an electrical

system (mains) that is rated for the electrical

requirements of the power tool as shown on the

nameplate. Use only on an earthing (grounded)

system. Do not service the power tool if it is

energized or connected to an electrical circuit.

Improper use could cause re or electric shock.

Additional Rules For Safe Operation

8

Introduction

EN

KNOW YOUR MACHINE

1 Control Switch

2 Dust Collection Bag

3 Operating Handles

4 Abrasive Wrench

5 Steel Reinforced Molded Rubber Sanding Pad

6 Wall Guard

7 Work Light

8 Circuit Breaker (on select models) 2

1

7

6

5

4

38

Model 07209A 07208A 07208B 07209B

Electrical Rating 115 V, 12.0 A, 60 Hz 115 V, 12.0 A, 60 Hz 115 V, 12.0 A, 60 Hz 115 V, 12.0 A, 60 Hz

Storage Case Standard Standard NA NA

Motor 1 Hp 1 Hp 1 Hp 1 Hp

Abrasive Size 7" x 7 7/8" Dia. Disc 7" x 7 7/8" Dia. Disc 7" x 7 7/8" Dia. Disc 7" x 7 7/8" Dia. Disc

Disc Rate 2800 rpm 2800 rpm 2800 rpm 2800 rpm

Disc Driver System Gear Driven Gear Driven Gear Driven Gear Driven

Power Cable 12-3 Gray Rubber 14-3 Gray Rubber 14-3 Gray Rubber 12-3 Gray Rubber

Dust Collection Standard Standard Standard Standard

Dust Control Rate 110 CFM 110 CFM 110 CFM 110 CFM

9

Electrical Connection Instructions

EN

SAFETY INSTRUCTIONS

This oor-nishing machine shall be grounded while in use to protect the operator from electrical shock. The machine

is provided with a three-conductor cord and a three contact grounding attachment plug to t the proper grounding type

receptacle. The green (or green and yellow) conductor in the cord is the grounding wire. Never connect this wire to other than

the grounding pin of the attachment plug.

This machine is for use on a nominal 120 volt or 240 volt circuit and has a grounding plug that resembles the plug illustarted

as (A) in the sketch. Make sure that the machine is connected to an outlet having the same conguration as the plug. No

adapter should be used with this machine.

10

Machine Setup

EN

This sanding machine is designed to be operated with a remote vacuum

dust collection system or with the included dust bag.

Preparing Remote Vacuum Dust Collection Systems

To prepare the machine for remote vacuum dust collection systems that

have a 2” hose end, follow this procedure:

1. Install 2” hose end (gure 1, A) directly over the exhaust tube

(gure 1, B).

2. The exhaust tube can be rotated for optimum convenience.

To prepare the machine for remote vacuum dust collection systems that

have a 1 ½” hose end, follow this procedure:

1.

Install the 2” x 1½” hose end adaptor (Part No. 30563A) (gure 1, C)

over the exhaust tube (gure 1, B).

2. Insert 1 ½” hose end (gure 1, D) into the adaptor (gure 1, C).

NOTE: Start the remote vacuum collection system before operation.

Preparing to use the included dust bag

To prepare the machine for use with the included dust bag (Part No.

53544B), follow this procedure:

1. Install the dust bag by pressing the end onto the exhaust tube

until the ring locks into the groove (gure 2). This is best done

by pressing on the back of the bag opening with the palm of your

hand.

2. The exhaust tube can be rotated for optimum convenience.

3. To remove the dust bag from the exhaust tube, pry up the end

of the bag opening to partially release the internal rib from the

groove, then pull.

4. To empty the dust bag, unzip the disposal ap and force contents

out by inverting the bag.

NOTE: For best results, empty frequently. Follow all warnings

posted in this manual and on the dust bag.

Preparing the Machine for Operation

1. Familiarize yourself with the machine. Read all danger, warning,

and caution statements and the Owner’s Manual before operating

this machine. If you or your operator cannot read English,

have this manual explained fully before attempting to operate this

machine.

2. Remove screw and abrasive retainer. Center abrasive on pad

and secure with abrasive retainer and screw. (Figure 3)

3.

Return machine to upright position and tilt machine back on casters

until

it comes to rest on the exhaust bracket. Machine will be in a

reclined position.

Do not allow machine to rest on pad especially

after use, or compression set may take place within elastomer on

pad. This will create a at spot and bounce during use. (Figure 4)

EN ENGLISH

-8- American Sanders Operator’s Manual (EN) - Super 7R

Install the dust bag by

pressing the end onto the

exhaust tube until the ring

locks into the groove.

A

2” Hose from

vacuum system

(not included)

1.5” Hose from

vacuum system

(not included)

D

B

C

Exhaust Tube

(30563A) 2” Tube x 1.5” hose adaptor

Figure 1

Figure 2

MACHINE SET-UP

This sanding machine is designed to be operated with a remote vacuum

dust collection system or with the included dust bag.

Preparing Remote Vacuum Dust Collection Systems

To prepare the machine for remote vacuum dust collection systems that

have a 2” hose end, follow this procedure:

1. Install 2” hose end (gure 1, A) directly over the exhaust tube (gure 1,

B).

2. The exhaust tube can be rotated for optimum convenience.

To prepare the machine for remote vacuum dust collection systems that

have a 1 ½” hose end, follow this procedure:

1. Install the 2” x 1½” hose end adaptor (Part No. 30563A) (gure 1, C)

over the exhaust tube (gure 1, B).

2. Insert 1 ½” hose end (gure 1, D) into the adaptor (gure 1, C).

NOTE: Start the remote vacuum collection system before operation.

Preparing to use the included dust bag

To prepare the machine for use with the included dust bag (Part No.

53544B), follow this procedure:

1. Install the dust bag by pressing the end onto the exhaust tube until the

ring locks into the groove (gure 2). This is best done by pressing on

the back of the bag opening with the palm of your hand.

2. The exhaust tube can be rotated for optimum convenience.

3. To remove the dust bag from the exhaust tube, pry up the end of the

bag opening to partially release the internal rib from the groove, then

pull.

4. To empty the dust bag, unzip the disposal ap and force contents out

by inverting the bag.

NOTE: For best results, empty frequently. Follow all warnings posted

in this manual and on the dust bag.

Figure 1

EN ENGLISH

-8- American Sanders Operator’s Manual (EN) - Super 7R

Install the dust bag by

pressing the end onto the

exhaust tube until the ring

locks into the groove.

A

2” Hose from

vacuum system

(not included)

1.5” Hose from

vacuum system

(not included)

D

B

C

Exhaust Tube

(30563A) 2” Tube x 1.5” hose adaptor

Figure 1

Figure 2

MACHINE SET-UP

This sanding machine is designed to be operated with a remote vacuum

dust collection system or with the included dust bag.

Preparing Remote Vacuum Dust Collection Systems

To prepare the machine for remote vacuum dust collection systems that

have a 2” hose end, follow this procedure:

1. Install 2” hose end (gure 1, A) directly over the exhaust tube (gure 1,

B).

2. The exhaust tube can be rotated for optimum convenience.

To prepare the machine for remote vacuum dust collection systems that

have a 1 ½” hose end, follow this procedure:

1. Install the 2” x 1½” hose end adaptor (Part No. 30563A) (gure 1, C)

over the exhaust tube (gure 1, B).

2. Insert 1 ½” hose end (gure 1, D) into the adaptor (gure 1, C).

NOTE: Start the remote vacuum collection system before operation.

Preparing to use the included dust bag

To prepare the machine for use with the included dust bag (Part No.

53544B), follow this procedure:

1. Install the dust bag by pressing the end onto the exhaust tube until the

ring locks into the groove (gure 2). This is best done by pressing on

the back of the bag opening with the palm of your hand.

2. The exhaust tube can be rotated for optimum convenience.

3. To remove the dust bag from the exhaust tube, pry up the end of the

bag opening to partially release the internal rib from the groove, then

pull.

4. To empty the dust bag, unzip the disposal ap and force contents out

by inverting the bag.

NOTE: For best results, empty frequently. Follow all warnings posted

in this manual and on the dust bag.

Figure 2

EN

ENGLISH

American Sanders Operator’s Manual (EN) - Super 7R - 9 -

Figure 3

Figure 4

Figure 5

MACHINE SET-UP

Preparing the Machine for Operation

1. Familiarize yourself with the machine. Read all danger, warning, and caution

statements and the Owner’s Manual before operating this machine. If you or

your operator cannot read English, have this manual explained fully before

attempting to operate this machine.

2. Remove screw and abrasive retainer. Center abrasive on pad and secure with

abrasive retainer and screw. (Figure 3)

3. Return machine to upright position and tilt machine back on casters until it

comes to rest on the exhaust bracket. Machine will be in a reclined position.

Do not allow machine to rest on pad especially after use, or compression set

may take place within elastomer on pad. This will create a at spot and bounce

during use. (Figure 4)

OPERATING INSTRUCTIONS

1. Move machine to the location of your work. Set any exposed nails with ham-

mer and punch to avoid encounter with abrasive.

WARNING: Bodily injury could occur if power is applied to

the machine with the power switch already in the “ON” position. Always

check to assure that the power switch is in the “OFF” position before

applying power to the power cable.

2. Make sure the control switch is in the “Off” position then connect the supply

cable to an appropriately grounded fused circuit. Connect the supply cable to

the motor pigtail. (Figure 5)

3. With the machine in the reclined position rmly grasp both handles and ip the

control switch to the “ON” position. (Figure 4.)

4. Gradually lower pad to surface intended for sanding. Make sure the ma-

chine is in motion while the pad is engaged with the surface to be sanded.

You may use broad circular motion as you sand along the length of the

surface or your may use a combination of forward and sideward motions.

In time you will develop your own technique to optimize coverage and dust

recovery. It is advisable to not add effort to the pad as this may lead to “nos-

ing in” or “tipping” which produces grooves or lines on the surface.

5. When replacing abrasive, emptying the contents of the dust bag, or sanding

operation is completed, return machine to reclined position, ip control

switch to “Off” then disconnect the motor pigtail from the supply cable.

6. Empty dust bag whenever it becomes 1/3 full.

Figure 3

Figure 4

11

Operating Instructions

EN

1. Move machine to the location of your work. Set any exposed nails

with hammer and punch to avoid encounter with abrasive.

WARNING: Bodily injury could occur if power is applied to the

machine with the power switch already in the “ON” position. Always check

to assure that the power switch is in the “OFF” position before applying

power to the power cable.

2. Make sure the control switch is in the “Off” position then connect the

supply cable to an appropriately grounded fused circuit. Connect

the supply cable to the motor pigtail. (Figure 5)

3. With the machine in the reclined position rmly grasp both handles

and ip the control switch to the “ON” position. (Figure 4.)

4. Gradually lower pad to surface intended for sanding. Make sure the

machine is in motion while the pad is engaged with the surface to

be sanded. You may use broad circular motion as you sand along

the length of the surface or your may use a combination of forward

and sideward motions. In time you will develop your own technique

to optimize coverage and dust recovery. It is advisable to not add

effort to the pad as this may lead to “nosing in” or “tipping” which

produces grooves or lines on the surface.

5. When replacing abrasive, emptying the contents of the dust bag, or

sanding operation is completed, return machine to reclined position,

ip control switch to “Off” then disconnect the motor pigtail from the

supply cable.

6. Empty dust bag whenever it becomes 1/3 full.

.

DANGER: Failure to disconnect the supply cable from machine

whenever servicing, replacing abrasive, or emptying the dust bag could

result in electrocution or severe injury. Never leave machine unattended

while the supply cable is connected.

DANGER: Never leave dust bag unattended with sanding dust

in it. Sanding dust can spontaneously ignite and cause a re or explosion.

Empty dust bag into a metal container, clear of any combustibles. Do not

empty content into a re. Do not overll dust bag.

EN

ENGLISH

American Sanders Operator’s Manual (EN) - Super 7R - 9 -

Figure 3

Figure 4

Figure 5

MACHINE SET-UP

Preparing the Machine for Operation

1. Familiarize yourself with the machine. Read all danger, warning, and caution

statements and the Owner’s Manual before operating this machine. If you or

your operator cannot read English, have this manual explained fully before

attempting to operate this machine.

2. Remove screw and abrasive retainer. Center abrasive on pad and secure with

abrasive retainer and screw. (Figure 3)

3. Return machine to upright position and tilt machine back on casters until it

comes to rest on the exhaust bracket. Machine will be in a reclined position.

Do not allow machine to rest on pad especially after use, or compression set

may take place within elastomer on pad. This will create a at spot and bounce

during use. (Figure 4)

OPERATING INSTRUCTIONS

1. Move machine to the location of your work. Set any exposed nails with ham-

mer and punch to avoid encounter with abrasive.

WARNING: Bodily injury could occur if power is applied to

the machine with the power switch already in the “ON” position. Always

check to assure that the power switch is in the “OFF” position before

applying power to the power cable.

2. Make sure the control switch is in the “Off” position then connect the supply

cable to an appropriately grounded fused circuit. Connect the supply cable to

the motor pigtail. (Figure 5)

3. With the machine in the reclined position rmly grasp both handles and ip the

control switch to the “ON” position. (Figure 4.)

4. Gradually lower pad to surface intended for sanding. Make sure the ma-

chine is in motion while the pad is engaged with the surface to be sanded.

You may use broad circular motion as you sand along the length of the

surface or your may use a combination of forward and sideward motions.

In time you will develop your own technique to optimize coverage and dust

recovery. It is advisable to not add effort to the pad as this may lead to “nos-

ing in” or “tipping” which produces grooves or lines on the surface.

5. When replacing abrasive, emptying the contents of the dust bag, or sanding

operation is completed, return machine to reclined position, ip control

switch to “Off” then disconnect the motor pigtail from the supply cable.

6. Empty dust bag whenever it becomes 1/3 full.

12

Adjustment Procedures

Routine Maintenance

EN

Leveling

To level machine: Grasp caster adjusting screw “A” with an appropriate

tool (pliers ect.). Using a similar tool, loosen locknut “B” with a counter

clockwise motion. (Figure 6).

Condition - Pad creates ridges on both edges or a “hop” is experi-

enced: Rotate both adjusting screws equal amounts clockwise. Tighten

locknuts and test on a piece of plywood. Repeat procedure until condi-

tion is corrected. We recommend you not exceed 1/8” rotation for each

attempt.

Condition - Pad creates a ridge on the tip of the pad: Rotate both

adjusting screws counter clockwise, tighten locknuts and test. Repeat

procedure until condition is corrected. Use only 1/8 rotation for each

attempt.

Condition - Pad creates a ridge on only one side of the pad: Either

rotate the adjusting screw of the side effected clockwise or rotate the

adjusting screw opposite counterclockwise, depending on whether the

ridge terminates beyond the tip of the pad or prior to it. If it is prior to

the tip, adjust the side effected, otherwise adjust the opposite side.

EN ENGLISH

-10- American Sanders Operator’s Manual (EN) - Super 7R

Figure 6

OPERATING INSTRUCTIONS cont.

DANGER: Failure to disconnect the supply cable from

machine whenever servicing, replacing abrasive, or emptying the

dust bag could result in electrocution or severe injury. Never leave

machine unattended while the supply cable is connected.

DANGER: Never leave dust bag unattended with

sanding dust in it. Sanding dust can spontaneously ignite and cause

a re or explosion. Empty dust bag into a metal container, clear of

any combustibles. Do not empty content into a re. Do not overll

dust bag.

ADJUSTMENT PROCEDURES

Leveling

To level machine: Grasp caster adjusting screw “A” with an appropriate

tool (pliers ect.). Using a similar tool, loosen locknut “B” with a counter

clockwise motion. (Figure 6).

Condition - Pad creates ridges on both edges or a “hop” is experienced:

Rotate both adjusting screws equal amounts clockwise. Tighten locknuts

and test on a piece of plywood. Repeat procedure until condition is cor-

rected. We recommend you not exceed 1/8” rotation for each attempt.

Condition - Pad creates a ridge on the tip of the pad: Rotate both

adjusting screws counter clockwise, tighten locknuts and test. Repeat

procedure until condition is corrected. Use only 1/8 rotation for each

attempt.

Condition - Pad creates a ridge on only one side of the pad: Either rotate

the adjusting screw of the side effected clockwise or rotate the adjusting

screw opposite counterclockwise, depending on whether the ridge

terminates beyond the tip of the pad or prior to it. If it is prior to the tip,

adjust the side effected, otherwise adjust the opposite side.

ROUTINE MAINTENANCE

CAUTION: Failure to perform maintenance at

recommended intervals may void warranty.

Carbon Brushes

Have the carbon brushes replaced at least every 500 hours and more

frequently under heavy use.

Dust Bag

Periodically the dust bag should be turned inside out, shaken vigor-

ously and machine washed in cold water

to prevent pore blockage and loss of dust control.

Bearings

To insure reliable performance, have armature and pad driver

bearings inspected for wear or damage after every 1500

hours. If used heavily, have the bearings replaced seasonally.

Lubrication

The machine comes fully lubricated. The gears in the gear

box have enough lubrication for approximately six months of

normal operation. Have the lubricant changed at least every

6 months or more frequently under heavy use.

A

B

CAUTION: Failure to perform maintenance at recommended intervals may void warranty.

Carbon Brushes

Have the carbon brushes replaced at least every 500 hours and more frequently under heavy use.

Dust Bag

Periodically the dust bag should be turned inside out, shaken vigorously and machine washed in cold water

to prevent pore blockage and loss of dust control.

Bearings

To insure reliable performance, have armature and pad driver bearings inspected for wear or damage after every 1500 hours. If used heavily, have

the bearings replaced seasonally.

Lubrication

The machine comes fully lubricated. The gears in the gear box have enough lubrication for approximately six months of normal operation. Have the

lubricant changed at least every 6 months or more frequently under heavy use.

CAUTION: Maintenance and repairs performed by unauthorized personnel could result in damage or injury. Maintenance and repairs

performed by unauthorized personnel will void your warranty. Failure to perform maintenance at recommended intervals may void warranty.

13

Maintenance

EN

To Change The Lubricant In The Gearbox

To change the lubricant in the gearbox, follow this procedure:

1. Put the machine upside down on a bench.

2. Align one of the two holes in the rubber pad with one of the three holes in the rotating wall guard.

3. Align both holes with one of the three screws in the gear housing cover. Remove the screw from the gear housing cover. (Figure 9)

4. Align the holes with each of the other two screws, then remove screws.

CAUTION: Make sure no dust enters the gear box. Damage will occur to the gear box.

5. Remove the cover from the gear housing.

6. Remove the old lubricant from the gearbox.

7. Add six ounces of American SandersTechnology lubricant to the gear box.

CAUTION: To prevent damage to the motor, do not add more than six ounces

of lubricant to the gearbox.

8. Using the three screws removed above, install the cover on the gear housing.

9. Start the machine and let it run for 15 minutes. A small amount of excess lubricant

should ow out the vent hole. If none appears it may be necessary to add

additional lubricant.

10. Wipe off excess lubricant and clear vent hole.

Carbon Brushes

Inspect all four brushes every 6 months or 250 hours. Access to the brushes is gained through the front and back motor vent plugs and under

both motor covers (gure 7). Press tab (A) on spring clip assembly in, rotate, then remove (gure 8).Use needlenose pliers to disconnect the

shunt wire. If any brush has worn to 3/8” in length or shorter, replace the entire set.

CAUTION: Use only motor brush PN 40818A or PN 40055A with shunt wire or motor failure will occur.

When replacing the brushes make sure that the brush seats against the commutator, the spring rest in the recess of the brush, and the brush

is free to travel. When returning the switch cover, keep any wires clear of the commutator and any pinch site.

EN

ENGLISH

American Sanders Operator’s Manual (EN) - Super 7R -11 -

Figure 9

Qty Part No.

1Qt. 16610A

1Gal. 16611A

Lubricants

Figure 7

Figure 8

MAINTENANCE

CAUTION: Maintenance and repairs performed by

unauthorized personnel could result in damage or injury. Maintenance

and repairs performed by unauthorized personnel will void your

warranty. Failure to perform maintenance at recommended intervals

may void warranty.

Carbon Brushes

Inspect all four brushes every 6 months or 250 hours. Access to the

brushes is gained through the front and back motor vent plugs and un-

der both motor covers (gure 7). Press tab (A) on spring clip assembly

in, rotate, then remove (gure 8).Use needlenose pliers to disconnect

the shunt wire. If any brush has worn to 3/8” in length or shorter,

replace the entire set.

CAUTION: Use only motor brush PN 40818A or PN

40055A with shunt wire or motor failure will occur.

When replacing the brushes make sure that the brush seats against the

commutator, the spring rest in the recess of the brush, and the brush is

free to travel. When returning the switch cover, keep any wires clear of

the commutator and any pinch site.

To Change The Lubricant In The Gearbox

To change the lubricant in the gearbox, follow this procedure:

1. Put the machine upside down on a bench.

2. Align one of the two holes in the rubber pad with one of the three

holes in the rotating wall guard.

3. Align both holes with one of the three screws in the gear housing

cover. Remove the screw from the gear housing cover. (Figure 9)

4. Align the holes with each of the other two screws, then remove

screws.

CAUTION: Make sure no dust enters the gear box.

Damage will occur to the gear box.

5. Remove the cover from the gear housing.

6. Remove the old lubricant from the gearbox.

7. Add six ounces of American SandersTechnology lubricant to the

gear box.

CAUTION: To prevent damage to the motor, do not add

more than six ounces of lubricant to the gearbox.

8. Using the three screws removed above, install the cover on the

gear housing.

9. Start the machine and let it run for 15 minutes. A small amount of

excess lubricant should ow out the vent hole. If none appears it

may be necessary to add additional lubricant.

10. Wipe off excess lubricant and clear vent hole.

A

Figure 8

EN

ENGLISH

American Sanders Operator’s Manual (EN) - Super 7R -11 -

Figure 9

Qty Part No.

1Qt. 16610A

1Gal. 16611A

Lubricants

Figure 7

Figure 8

MAINTENANCE

CAUTION: Maintenance and repairs performed by

unauthorized personnel could result in damage or injury. Maintenance

and repairs performed by unauthorized personnel will void your

warranty. Failure to perform maintenance at recommended intervals

may void warranty.

Carbon Brushes

Inspect all four brushes every 6 months or 250 hours. Access to the

brushes is gained through the front and back motor vent plugs and un-

der both motor covers (gure 7). Press tab (A) on spring clip assembly

in, rotate, then remove (gure 8).Use needlenose pliers to disconnect

the shunt wire. If any brush has worn to 3/8” in length or shorter,

replace the entire set.

CAUTION: Use only motor brush PN 40818A or PN

40055A with shunt wire or motor failure will occur.

When replacing the brushes make sure that the brush seats against the

commutator, the spring rest in the recess of the brush, and the brush is

free to travel. When returning the switch cover, keep any wires clear of

the commutator and any pinch site.

To Change The Lubricant In The Gearbox

To change the lubricant in the gearbox, follow this procedure:

1. Put the machine upside down on a bench.

2. Align one of the two holes in the rubber pad with one of the three

holes in the rotating wall guard.

3. Align both holes with one of the three screws in the gear housing

cover. Remove the screw from the gear housing cover. (Figure 9)

4. Align the holes with each of the other two screws, then remove

screws.

CAUTION: Make sure no dust enters the gear box.

Damage will occur to the gear box.

5. Remove the cover from the gear housing.

6. Remove the old lubricant from the gearbox.

7. Add six ounces of American SandersTechnology lubricant to the

gear box.

CAUTION: To prevent damage to the motor, do not add

more than six ounces of lubricant to the gearbox.

8. Using the three screws removed above, install the cover on the

gear housing.

9. Start the machine and let it run for 15 minutes. A small amount of

excess lubricant should ow out the vent hole. If none appears it

may be necessary to add additional lubricant.

10. Wipe off excess lubricant and clear vent hole.

A

Figure 9

Contents

Instrucciones de seguridad para el operador.............................15

Introducción................................................................17

Machine Specifications................................................................17

Instrucciones de conexión eléctrica .............................................18

Instalación de la máquina............................................................19

Operación de la máquina.......................................................20-21

Procedimientos de ajuste de la lijadora.......................................21

Mantenimiento de rutina...............................................................22

Parts Manual...............................................................................32

Wiring Diagram............................................................................33

Lower Assembly..........................................................................34

Upper Assembly..........................................................................36

Warranty.....................................................................................38

LEA ESTE MANUAL

Este manual contiene información importante acerca del uso y la seguridad de la máquina. Si no lee el manual antes de utilizar su

máquina American Sanders o de intentar realizar los procedimientos de reparación o mantenimiento de la misma, usted o el resto

del personal podrían sufrir lesiones; asimismo, podrían producirse daños a la máquina o a otras propiedades. Antes de utilizar la

máquina, es necesario recibir la capacitación adecuada en la operación de la misma. Si el operador de la máquina no sabe leer en

español, explíquele el manual exhaustivamente antes de que intente utilizarla.

Todas las indicaciones incluidas en este manual se ofrecen desde la posición del operador en la parte posterior de la máquina.

ADVERTENCIA!

Los Productos a la venta en este Manual contienen, o pueden contener, productos químicos reconocidos por algunos gobiernos (como el Estado

de California, según lo indica en su Proposición 65, Ley de Advertencia Regulatoria) como causantes de cáncer, defectos de nacimiento u otros

daños reproductivos. En algunas jurisdicciones (incluido el Estado de California), los compradores de estos Productos que los coloquen en servicio

en un emplazamiento laboral o en un espacio de acceso público tienen la obligación regulatoria de realizar determinados avisos, advertencias o

divulgaciones respecto de los productos químicos contenidos o posiblemente contenidos en los Productos utilizados en tal lugar. Es la responsabilidad

del comprador conocer y cumplir con todas las leyes y reglamentaciones relacionadas con el uso de estos Productos en tales entornos. El Fabricante

niega toda responsabilidad de informar a los compradores sobre requisitos especícos que pueden regir el uso de los Productos en tales entornos.

ES

PELIGRO signica: Usted u otras personas pueden estar expuestos a sufrir lesiones personales, inclusive la

muerte si las indicaciones de PELIGRO que se encuentran en esta máquina o en el manual

de instrucciones se ignoran o no se tienen en cuenta. Lea y respete todas las indicaciones

de PELIGRO que se encuentran en el manual de instrucciones y en la máquina.

ADVERTENCIA signica: Usted u otras personas pueden estar expuestos a sufrir lesiones personales, si las

indicaciones de ADVERTENCIA que se encuentran en esta máquina o en el manual de

instrucciones se ignoran o no se tienen en cuenta. Lea y respete todas las indicaciones de

ADVERTENCIA que se encuentran en el manual de instrucciones y en su máquina.

PRECAUCIÓN signica:

La máquina u otros bienes pueden sufrir daños materiales si las indicaciones de PRECAUCIÓN

que se encuentran en la máquina o en el manual de instrucciones se ignoran o no se

tienen en cuenta. Lea y respete todas las indicaciones de PRECAUCIÓN que se

encuentran en el manual de instrucciones y en la máquina.

Instrucciones De Seguridad Para El Operador

***Este producto está destinado exclusivamente para uso comercial***

ES

15

ES

16

UNA ADVERTENCIA ESPECIAL SOBRE LOS INCENDIOS DE LAS BOLSAS

El polvo que se genera al lijar pisos de madera en bruto o previamente acabados PUEDE ENCENDERSE O EXPLOTAR DE

FORMA ESPONTÁNEA! Las BOLSAS CONTENEDORAS DE POLVO de la lijadora DEBEN VACIARSE CON FRECUENCIA

y antes de cualquier interrupción de trabajo. NUNCA ALMACENE POLVO DE LIJADO EN ESTRUCTURAS U OTROS

MATERIALES COMBUSTIBLES NI ALREDEDOR DE ELLOS. Elimine de inmediato el polvo de lijado en exteriores de

acuerdo con la normativa local. No lo arroje al fuego.

17

Introducción

ES

CONOZCA SU MÁQUINA

1 Interruptor de control

2 Bolsa colectora de polvo

3 Manijas de funcionamiento

4 Llave del abrasivo

5 Almohadilla de lijado de goma moldeada y reforzada con acero

6 Protección de pared

7 Luz de funcionamiento

8 Cortacircuitos (en modelos selectos)

2

1

7

6

5

4

38

Modelo 07209A 07208A 07208B 07209B

Requerimientos eléctricos 115 V, 12.0 A, 60 Hz 115 V, 12.0 A, 60 Hz 115 V, 12.0 A, 60 Hz 115 V, 12.0 A, 60 Hz

Caja de almacenamiento Standard Standard NA NA

Motor 1 Hp, 756 vatios 1 Hp, 756 vatios 1 Hp, 756 vatios 1 Hp, 756 vatios

Tamaño del abrasivo 7" x 7 7/8" Dia. Disc 7" x 7 7/8" Dia. Disc 7" x 7 7/8" Dia. Disc 7" x 7 7/8" Dia. Disc

Velocidad de disco 2800 rpm 2800 rpm 2800 rpm 2800 rpm

Sistema del impulsor de disco Gear Driven Gear Driven Gear Driven Gear Driven

Cable de alimentación 12-3 Gray Rubber 14-3 Gray Rubber 14-3 Gray Rubber 12-3 Gray Rubber

Colector de polvo Standard Standard Standard Standard

Tasa de control de polvo 110 CFM 110 CFM 110 CFM 110 CFM

ES

18

Instrucciones de conexión eléctrica

Esta máquina para pisos de acabado deberá estar conectado a tierra mientras esté en uso para proteger al operador de una descarga eléctrica.

La máquina está provista de un cable de tres conductores y un accesorio de conexión a tierra de tres contactos de enchufe para adaptarse al

receptáculo de conexión a tierra adecuada. El conductor verde (o verde y amarillo) en el cable es el cable a tierra. Nunca conecte este cable a

otro que el pasador de puesta a tierra del enchufe.

Esta máquina es para uso en un circuito nominal de 120 voltios y tiene un enchufe de conexión a tierra que se parece al enchufe illustarted

como (A) en el boceto. Asegúrese de que la máquina está conectada a un tomacorriente que tenga la misma configuración que el enchufe. Sin

adaptador se debe utilizar con esta máquina.

Instalación de la máquina

ES

Esta lijadora está diseñada para utilizarse con un sistema colector de

polvo remoto mediante vacío o con la bolsa de polvo incluida.

Preparación de los sistemas colectores de polvo remotos

mediante vacío

Si desea preparar la máquina para sistemas colectores de polvo remotos

mediante vacío que tengan un extremo de manguera de 2”, siga este

procedimiento:

1. Instale e extremo de manguera de 2” (gura 1, A) directamante

sobre el tubo de escape (gura 1, B).

2. El tubo de escape puede girarse para mayor comodidad.

Si desea preparar la máquina para sistemas colectores de polvo remotos

mediante vacío que tengan un extremo de manguera de 1 ½”, siga este

procedimiento:

1. Instale el adaptador del extremo de manguera de 2” x 1½” (Node

pieza 30563A) (gura 1, C) sobre el tubo de escape (gura 1, B).

2. Inserte el extremo de manguera de 1½” (gura 1, D) en el adaptador

(gura 1, C).

NOTA: Ponga en marche el sistema colector remoto mediante vacío

antes de encender la máquina.

Preparación para usar la bolsa de polvo incluida

Si desea preparar la máquina para su uso con la bolsa de polvo incluida

(No de pieza 53544B), siga este procedimiento.

1. Instale la bolsa de recolección de polvo presionando el extremo del

tubo de escape hasta que el anillo encaje dentro de la ranura (gura

2). El mejor modo de hacer esto es presionando la parte posterior

de la abertura de la bolsa con la palma de su mano.

2. El tubo de escape puede girarse para mayor comodidad.

3. Para retirar la bolsa de polvo del tubo de escape, haga palanca

hacia arriba en el extremo de la abertura de la bolsa para liberar

parcialmente el saliente interno de la ranura, y después tire.

4. Para vaciar la bolsa de polvo, abra la aleta de vaciado y saque sus

contenidos dando la vuelta a la bolsa.

NOTA: Para lograr los mejores resultados, vacíe frecuentemente.

Siga todas las advertencias incluidas en el manual y en la bolsa de

polvo.

ES ESPAÑOL

-18- American Sanders Manual del operador (ES) - Super 7R

A

MANGUERA DE 2”

DEL SISTEMA DE

ASPIRACIÓN (NO

INCLUIDO)

MANGUERA DE

1.50” DEL SISTEMA

DE ASPIRACIÓN

(NO INCLUIDO)

D

B

C

TUBO DE ESCAPE

Figura 1

Figura 2

INSTALE LA BOLSA DE

RECOLECCIÓN DE POLVO

PRESIONANDO EL EXTREMO DEL

TUBO DE ESCAPE HASTA QUE EL

ANILLO ENCAJE DENTRO DE LA

RANURA.

Instalación de la máquina

Esta lijadora está diseñada para utilizarse con un sistema colector de

polvo remoto mediante vacío o con la bolsa de polvo incluida.

Preparación de los sistemas colectores de polvo remotos mediante

vacío

Si desea preparar la máquina para sistemas colectores de polvo remo-

tos mediante vacío que tengan un extremo de manguera de 2”, siga

este procedimiento:

1. Instale e extremo de manguera de 2” (gura 1, A) directamante

sobre el tubo de escape (gura 1, B).

2. El tubo de escape puede girarse para mayor comodidad.

Si desea preparar la máquina para sistemas colectores de polvo remo-

tos mediante vacío que tengan un extremo de manguera de 1 ½”, siga

este procedimiento:

1. Instale el adaptador del extremo de manguera de 2” x 1½” (Node

pieza 30563A) (gura 1, C) sobre el tubo de escape (gura 1, B).

2. Inserte el extremo de manguera de 1½” (gura 1, D) en el adaptador

(gura 1, C).

NOTA: Ponga en marche el sistema colector remoto mediante vacío

antes de encender la máquina.

Preparación para usar la bolsa de polvo incluida

Si desea preparar la máquina para su uso con la bolsa de polvo inclu-

ida (No de pieza 53544B), siga este procedimiento.

1. Instale la bolsa de recolección de polvo presionando el extremo del

tubo de escape hasta que el anillo encaje dentro de la ranura (gura

2). El mejor modo de hacer esto es presionando la parte posterior

de la abertura de la bolsa con la palma de su mano.

2. El tubo de escape puede girarse para mayor comodidad.

3. Para retirar la bolsa de polvo del tubo de escape, haga palanca

hacia arriba en el extremo de la abertura de la bolsa para liberar

parcialmente el saliente interno de la ranura, y después tire.

4. Para vaciar la bolsa de polvo, abra la aleta de vaciado y saque sus

contenidos dando la vuelta a la bolsa.

NOTA: Para lograr los mejores resultados, vacíe frecuentemente.

Siga todas las advertencias incluidas en el manual y en la bolsa de

polvo.

19

Instalación de la máquina

ES

20

Preparando la máquina para la operación

1. Veillez prendre connaissance de l’appareil et lisez toutes les notices de danger,

d’avertissements et de mises en garde. Assurez-vous que tous les opérateurs de cet

appareil ont bien lu le Manuel de l’utilisateur. S’ils ne sont pas en mesure de lire ce

Manuel, ils devront se le faire expliquer entièrement avant d’utiliser la ponceuse.

2. Saque el tornillo y el retenedor del abrasivo. Centre el abrasivo sobre la almohadilla y

asegúrelo con el retenedor y el tornillo del abrasivo. (Figura 3)

3. Vuelva a colocar la máquina en posición vertical e inclínela hacia atrás sobre las

roldanas pivotantes hasta que se apoye sobre la abrazadera de escape. La máquina

estará en posición reclinada. No deje que la máquina permanezca apoyada sobre la

almohadilla, especialmente después del uso, ya que de lo contrario se podrá producir

el endurecimiento por compresión dentro del elastómero de la almohadilla. Esto creará

una parte plana y rebotes durante el uso. (Figura 4)

ES

ESPAÑOL

American Sanders Manual del operador (ES) - Super 7R - 19 -

Figura 3

Figura 4

Figura 5

Instalación de la máquina

Preparando la máquina para la operación

1. Veillez prendre connaissance de l’appareil et lisez toutes les notices de

danger, d’avertissements et de mises en garde. Assurez-vous que tous les

opérateurs de cet appareil ont bien lu le Manuel de l’utilisateur. S’ils ne sont

pas en mesure de lire ce Manuel, ils devront se le faire expliquer entièrement

avant d’utiliser la ponceuse.

2. Saque el tornillo y el retenedor del abrasivo. Centre el abrasivo sobre la

almohadilla y asegúrelo con el retenedor y el tornillo del abrasivo. (Figura 3)

3. Vuelva a colocar la máquina en posición vertical e inclínela hacia atrás sobre

las roldanas pivotantes hasta que se apoye sobre la abrazadera de escape.

La máquina estará en posición reclinada. No deje que la máquina permanez-

ca apoyada sobre la almohadilla, especialmente después del uso, ya que de

lo contrario se podrá producir el endurecimiento por compresión dentro del

elastómero de la almohadilla. Esto creará una parte plana y rebotes durante

el uso. (Figura 4)

Operación de la máquina

1. Desplace la máquina al lugar de trabajo. Fije cualquier anillo expuesto con

martillo y embutidor para evitar que se tope con el abrasivo. Conecte el cable

de alimentación a un circuito adecuadamente provisto de toma de tierra y

fusibles.

ADVERTENCIA: Pueden producirse lesiones corporales

si se aplica potencia a la máquina con el interruptor de control colocado

en la posición “ON” (Encendido). Verique siempre que el interruptor de

control se encuentre en posición “OFF” (Apagado) antes de enchufar el

cable de alimentación.

2. Asegúrese de que el interruptor de control esté ajustado en “OFF” (Apagado).

Para la posición “OFF” (Apagado), el interruptor se mueve hacia el lado del

operador. Vea la marca en el interruptor. Conecte el cable de alimentación al

cable eléctrico del motor. (Figura 5)

3. Con la máquina en posición recli nada, tome rmemente las dos manijas y

mueva el interruptor de control a la posición “ON” (Encendido). (Figura 4)

4. Baje gradualmente la almohadilla a la supercie destinada a ser lijada.

Asegúrese de que la máquina esté en movimiento mientras la almohadilla

está engranada con la supercie a lijar. Puede usar un movimiento circu-

lar amplio mientras lija a lo largo de la supercie o una combinación de

movimientos hacia adelante y hacia los costados. Con el tiempo desarrollará

su propia técnica, lo cual le permitirá optimizar la cobertura y la recolección

de polvo. Es aconsejable no agregar esfuerzo a la almohadilla ya que esto

podría conducir a la “elevación de la parte delantera” o a la “inclinación” y

como resultado quedarían ranuras o líneas en la supercie.

5. Al cambiar el abrasivo, vacíe el contenido de la bolsa de polvo o, al terminar

el lijado, vuelva a dejar la máquina en la posición reclinada, desactive el inter-

ruptor de control en la posición “OFF” (Apagado), luego desconecte el cable

eléctrico del motor del cable de alimentación.

6. Vacíe la bolsa de polvo cada vez que se llene hasta 1/3 de su capacidad.

Operación de la máquina

1. Desplace la máquina al lugar de trabajo. Fije cualquier anillo expuesto con martillo y

embutidor para evitar que se tope con el abrasivo. Conecte el cable de alimentación a

un circuito adecuadamente provisto de toma de tierra y fusibles.

ADVERTENCIA: Pueden producirse lesiones corporales si se aplica potencia a

la

máquina con el interruptor de control colocado en la posición “ON” (Encendido).

Verique siempre que el interruptor de control se encuentre en posición “OFF”

(Apagado) antes de enchufar el cable de alimentación.

2. Asegúrese de que el interruptor de control esté ajustado en “OFF” (Apagado). Para la

posición “OFF” (Apagado), el interruptor se mueve hacia el lado del operador. Vea la

marca en el interruptor. Conecte el cable de alimentación al cable eléctrico del motor.

(Figura 5)

3. Con la máquina en posición recli nada, tome rmemente las dos manijas y mueva el

interruptor de control a la posición “ON” (Encendido). (Figura 4)

4. Baje gradualmente la almohadilla a la supercie destinada a ser lijada. Asegúrese de

que la máquina esté en movimiento mientras la almohadilla está engranada con la

supercie a lijar. Puede usar un movimiento circular amplio mientras lija a lo largo de

la supercie o una combinación de movimientos hacia adelante y hacia los costados.

Con el tiempo desarrollará su propia técnica, lo cual le permitirá optimizar la cobertura

y la recolección de polvo. Es aconsejable no agregar esfuerzo a la almohadilla ya que

esto podría conducir a la “elevación de la parte delantera” o a la “inclinación” y como

resultado quedarían ranuras o líneas en la supercie.

EN

ENGLISH

American Sanders Operator’s Manual (EN) - Super 7R - 9 -

Figure 3

Figure 4

Figure 5

MACHINE SET-UP

Preparing the Machine for Operation

1. Familiarize yourself with the machine. Read all danger, warning, and caution

statements and the Owner’s Manual before operating this machine. If you or

your operator cannot read English, have this manual explained fully before

attempting to operate this machine.

2. Remove screw and abrasive retainer. Center abrasive on pad and secure with

abrasive retainer and screw. (Figure 3)

3. Return machine to upright position and tilt machine back on casters until it

comes to rest on the exhaust bracket. Machine will be in a reclined position.

Do not allow machine to rest on pad especially after use, or compression set

may take place within elastomer on pad. This will create a at spot and bounce

during use. (Figure 4)

OPERATING INSTRUCTIONS

1. Move machine to the location of your work. Set any exposed nails with ham-

mer and punch to avoid encounter with abrasive.

WARNING: Bodily injury could occur if power is applied to

the machine with the power switch already in the “ON” position. Always

check to assure that the power switch is in the “OFF” position before

applying power to the power cable.

2. Make sure the control switch is in the “Off” position then connect the supply

cable to an appropriately grounded fused circuit. Connect the supply cable to

the motor pigtail. (Figure 5)

3. With the machine in the reclined position rmly grasp both handles and ip the

control switch to the “ON” position. (Figure 4.)

4. Gradually lower pad to surface intended for sanding. Make sure the ma-

chine is in motion while the pad is engaged with the surface to be sanded.

You may use broad circular motion as you sand along the length of the

surface or your may use a combination of forward and sideward motions.

In time you will develop your own technique to optimize coverage and dust

recovery. It is advisable to not add effort to the pad as this may lead to “nos-

ing in” or “tipping” which produces grooves or lines on the surface.

5. When replacing abrasive, emptying the contents of the dust bag, or sanding

operation is completed, return machine to reclined position, ip control

switch to “Off” then disconnect the motor pigtail from the supply cable.

6. Empty dust bag whenever it becomes 1/3 full.

Figura 3

Figura 4

This manual suits for next models

4

Table of contents

Languages:

Other Amano Edger manuals

Amano

Amano American Sanders COMPASS HDTR User manual

Amano

Amano American Sanders Super 7R Australia User manual

Amano

Amano American Sanders Compass User manual

Amano

Amano 07125A User manual

Amano

Amano American Sanders 07246A User manual

Amano

Amano American Sanders Super 7R 240V User manual

Amano

Amano American Sanders EZ-E User manual

Amano

Amano AMERICAN SANDERS 07222A User manual