Amano AMERICAN SANDERS 07222A User manual

EZ-E Extension Edger

Operator’s Manual

For Models

07222A, 07223A, 07222C & 07223C

3

Contents

Operator Safety Instructions...................................................... 2-5

Introduction................................................................................... 6

Electrical Connection Instructions ................................................ 7

Machine Setup.............................................................................. 8

Operating Instructions. ................................................................. 9

Adjustment Procedures .............................................................. 10

Maintenance................................................................................11

Wiring Diagram........................................................................... 32

Parts Manual .............................................................................. 33

Upper Assembly .................................................................... 33-34

Lower Assembly.......................................................................... 35

Warranty ..................................................................................... 36

READ THIS BOOK

This book has important information for the use and safe operation of this machine. Failure to read this book prior to

operating or attempting any service or maintenance procedure to your American Sanders machine could result in injury

to you or to other personnel; damage to the machine or to other property could occur as well. You must have training in

the operation of this machine before using it. If your operator(s) cannot read this manual, have it explained fully before

attempting to operate this machine.

All directions given in this book are as seen from the operator’s position at the rear of the machine.

***This product is intended for commercial use only***

WARNING!

The Products sold with this Manual contain or may contain chemicals that are known to certain governments (such as the State of

California, as identied in its Proposition 65 Regulatory Warning Law) to cause cancer, birth defects or other reproductive harm. In

certain locations (including the State of California) purchasers of these Products that place them in service at an employment job site

or a publicly accessible space are required by regulation to make certain notices, warnings or disclosures regarding the chemicals that

are or may be contained in the Products at or about such work sites. It is the purchaser’s responsibility to know the content of, and to

comply with, any laws and regulations relating to the use of these Products in such environments. The Manufacturer disclaims any

responsibility to advise purchasers of any specic requirements that may be applicable to the use of the Products in such environments.

In this Operation Manual you will find three statements that you must read and observe to ensure safe operation of this

machine.

DANGER means: Severe bodily injury or death can occur to you or other personnel if the DANGER

statements found on this machine or in this Operation Manual are ignored or are not adhered to. Read

and observe all DANGER statements found in this Operation Manual and on your machine.

WARNING means: Injury can occur to you or to other personnel if the WARNING statements found on your

machine or in the Operation Manual are ignored or are not adhered to. Read and observe all WARNING

statements found in this Operation Manual and on your machine.

CAUTION means: Damage can occur to the machine or to other property if the CAUTION statements found

on your machine or in this Operation Manual are ignored or are not adhered to. Read and observe all

CAUTION statements found in this Operation Manual and on your machine.

Operator Safety Instructions

EN

DANGER: Failure to read the Owner’s Manual prior to operating or servicing your American Sanders machine could result in injury to

you or to other personnel; damage to the machine or to other property could occur as well. You must have training in the

operation of this machine before using it. If you or your operator(s) cannot read English, have this manual explained fully

before attempting to operate this machine.

DANGER: A. Sanding/nishing wood oors can create an explosive or combustible environment. Do not operate this machine around

solvents, thinners, alcohol, fuels, oor nishes, wood dust or any other ammable materials. Cigarette lighters, pilot lights,

electrical sparks and all other sources of ignition should be extinguished or avoided. Keep work area well ventilated.

B. Dust generated from sanding wood oors can spontaneously ignite or explode. Promptly dispose of any sanding dust in a

metal container clear of any combustibles. Do not dispose in a re.

DANGER: A. Electrocution could occur if the machine is being serviced while the machine is connected to a power source. Disconnect

the power supply before servicing.

B. Electrocution or re could occur if the machine is being operated with a damaged power cord. Keep the power cord clear

of the pad. Always lift the cord over the machine. Do not move the machine by the power cord.

C.Shock hazard. Do not use the machine if it has been rained on or sprayed with water.

DANGER: To avoid injury keep hands, feet, and loose clothing away from all moving parts on the machine. Disconnect the power cord

before replacing the pad, changing the abrasive, or when servicing. Do not operate the machine unless all guards are in place.

Never leave the machine unattended while connected to a power source.

WARNING: Injury can occur if protective clothing or equipment is not used while sanding. Always wear safety goggles, protective clothing,

and dust mask while sanding.

WARNING: This sander is not to be used on pressure treated wood. Some pressure treated woods contain arsenic and sanding pressure

treated wood produces hazardous dust. Inhaling hazardous dust from pressure treated wood can cause serious injury or

death. Sanding pressure treated wood decks or uneven surfaces can damage the sander which is not covered under warranty

or damage waiver.

WARNING: Any alterations or modications of this machine could result in damage to the machine or injury to the operator or other

bystanders. Alterations or modications not authorized by the manufacturer voids any and all warranties and liabilities.

WARNING: Risk of explosion. Floor sanding can result in an explosive mixture of ne dust and air. Use oor sanding machine only in a

well-ventilated area free from any ame or match.

General Power Tool Safety Warnings

WARNING: Read all safety warnings and instructions. Failure to follow warnings and instructions may result in electric shock, re and or

serious injury.

Save all warnings and instructions for future use.

The term “power tool” in the warnings refers to your main-operated (corded) power tool or battery operated (cordless) power tool.

1) Work Area Safety

a) Keep work area clean and well lit. Clutter or dark areas invite accidents.

b) Do not operate power tools in explosive atmospheres, such as in the presence of ammable liquids, gasses, or dust. Power tools create

sparks which may ignite the dust or fumes.

c) Keep children and bystanders away while operating a power tool. Distractions can cause you to lose control.

2) Electrical Safety

a) Power tool plugs must match the outlet. Never modify the plug in any way. Do not use any adapter plugs with earthed (grounded) power

tools. Unmodied plugs and matching outlets will reduce risk of electric shock.

b) Avoid body contact with earthed or grounded surfaces such as pipes, radiators, ranges, and refrigerators. There is an increased risk of

electric shock if your body is earthed or grounded.

c) Do not expose power tools to rain or wet conditions. Water entering a power tool will increase the risk of electric shock.

d) Do not abuse the cord. Never use the cord for carrying, pulling or unplugging the power tool. Keep cord away from heat, oil, sharp edges or

moving parts. Damaged or entangled cords increase the risk of electric shock.

e) When operating a power tool outdoors, use an extension cord suitable for outdoor use. Use of cord suitable for outdoor use reduces the risk

of electric shock.

EN

4 5

EN EN

f) If operating a power tool in a damp location is unavoidable, use a residual current device (RCD) or ground fault circuit interrupter (GFCI )

protected supply. Use of a RCD or GFCI reduces the risk of electric shock.

3) Personal Safety

a) Stay alert, watch what you are doing and use common sense when operating a power tool. Do not use a power tool while you are tired or under

the inuence of drugs, alcohol, or medication. A moment of inattention while operating power tools may result in serious personal injury.

b) Use personal protective equipment. Always wear eye protection. Protective equipment such as dust mask, non-skid safety shoes, hard hat, or

hearing protection used for appropriate conditions will reduce personal injury.

c) Prevent unintentional starting. Ensure switch is in off-position before connecting to power source and/or battery pack, picking up, or carrying

the tool. Carrying power tools with your nger on the switch or energizing power tools that have the switch on invites accidents.

d) Remove any adjustment wrench or key before turning the power tool on. Awrench or key left attached to a rotating part of the power tool may

result in personal injury.

e) Do not overreach. Keep proper footing and balance at all times. This enables better control of the power tool in unexpected situations.

f) Dress properly. Do not wear loose clothing or jewelry. Keep your hair, clothing and gloves away from moving parts.

g) Loose clothes, jewelry, or long hair can be caught in moving parts.If devices are provided for the connection of dust extraction and collection

facilities, ensure these are connected and properly used. Use of dust collection can reduce dust related hazards. It is recommendation that the

tool always be supplied via a residual current device with a rated residual current of 30mA or less.

4) Power Tool Use and Care

a) Do not force the power tool. Use the correct power tool for your application. The correct power tool will do the job better and safer at the rate

for which it was designed.

b) Do not use the power tool if the switch does not turn it on and off. Any power tool that cannot be controlled with the switch is dangerous and

must be repaired.

c) Disconnect the plug from the power source and/or the battery pack from the power tool before making any adjustments, changing accessories

or storing power tools. Such preventative safety measures reduce the risk of starting the power tool accidently.

d) Store idle power tools out of the reach of children and do not allow persons unfamiliar with the power tool or these instructions to operate the

power tool. Power tools are dangerous in the hands of untrained users.

e) Maintain power tools. Check for misalignment or binding of moving parts, breakage of parts and any other condition that may affect the power

tool’s operation. If damaged, have the power tool repaired before use. Many accidents are caused by poorly maintained power tools.

f) Keep cutting tools sharp and clean. Properly maintained cutting tools with sharp cutting edges are less likely to bind and are easier to control.

g) Use the power tool and accessories in accordance with these instructions, taking into account the working conditions and the work to be

performed. Use of the power tool for operations different from those intended could result in a hazardous situation.

h) Operating a tool that is not completely of fully assembled could result in injury or property damage. Do not operate this tool until it is

completely assembled. Keep all fasteners tight. Keep adjustments per tool’s specications.

5) Service

a) Have the power tool serviced by a qualied repair person using only identical replacement parts. This will ensure that the safety of the power

tool is maintained. If the supply cord is damaged, it must be replaced by the manufacturer, its service agent or similarly qualied persons in

order to avoid a hazard.

Safety Warnings for Sanding Operations

a) This power tool is intended to function as a sander. Read all safety warnings, instructions and specications provided with this power tool.

Failure to follow all instructions listed below may result in electric shock, re, or personal injury.

b) Operations such as grinding, wire brushing, polishing or cutting-off, are not recommended to be performed with this power tool. Operations for

which the tool was not designed may create a hazard and cause personal injury.

c) Do not use accessories which are not specically designed and recommended by the tool manufacturer. Just because the accessory can be

attached to your power tool, it does not assure safe operation.

d) The rated speed of the accessory must be at least equal to the maximum speed marked on the power tool. Accessories running faster than

their rated speed can break and y apart.

e) The outside diameter and thickness of your accessory must be within the capacity rating of your power tool. Incorrectly sized accessories

cannot be adequately guard or controlled.

f) The arbor size of wheels, anges, backing pads or any other accessory must t the spindle of the power tool. Accessories with arbor holes that

do not match the mounting hardware of the power tool will run out of balance, vibrate excessively and may cause loss of control.

g) Do not use damaged accessory. Before each use inspect the accessory such as abrasive wheel for chips or cracks, backing pad for cracks,

tear or excess wear, wire brush for loose or cracked wires. If power tool or accessory is dropped, inspect for damage or install an undamaged

accessory. After inspecting or installing an accessory, position yourself or bystanders away from the plane of the rotating accessory and run

the power tool at maximum no-load speed for one minute. Damaged accessories will normally break apart during this time.

h) Wear personal protective equipment. Depending on application, use face shield, safety goggles or safety glasses. As appropriate, wear dust

mask, hearing protectors, gloves and workshop apron capable of stopping ying debris generated by various operations. The eye protection

must be capable of stopping ying debris generated by various operations. The dust mask or respirator must be capable of ltering particles

generated by your operations. Prolonged exposure to high intensity noise may cause hearing loss.

i) Keep bystanders a safe distance away from work area. Anyone entering the work area must wear personal protective equipment. Fragments

of work piece or a broken accessory mayy away and cause injury beyond immediate area of operation.

j) Hold power tool by gripping insulated surfaces (handle) only, when performing an operation where the cutting accessory may contact hidden

wiring or its own cord. Cutting accessory contacting a “live” wire may make exposed metal parts of the power tool “live” and shock the operator.

k) Position the cord clear of the spinning accessory. If you loose control, the cord may be cut or snagged and your arm or hand may be pulled into

the spinning accessory.

l) Never lay the power tool down until the accessory has come to a complete stop. The spinning accessory may grab the surface and pull the

power tool out of your control.

m) Do not run the power tool while carrying it at your side. Accidental contact with the spinning accessory could snag your clothing, pulling the

accessory into your body.

n) Regularly clean the power tools air vents. The motor’s fan will draw the dust inside the housing and excessive accumulation may cause

electrical hazards.

o) Do not operate the power tool near ammable materials. Sparks could ignite these materials.

p) Do not use excessively oversized sanding disc paper. Follow manufacturer’s recommendations when selecting sanding paper. Larger sanding

paper extending beyond the sanding pad presents a laceration hazard and may cause snagging, tearing of the disc or kickback.

q) Risk of explosion. Floor sanding can result in an explosive mixture of ne dust and air. Use oor sanding machine only in a well-ventilated area

free from any ame or match.

Kickback and Related Warnings

Kickback is a sudden reaction to a pinched or snagged rotating wheel, backing pad, brush or any other accessory. Pinching or snagging causes

rapid stalling of the rotating backing pad which in turn causes uncontrolled power tool to be forced in the opposite direction of the backing pad’s

rotation at the point of the binding.

For example, if an abrasive wheel is snagged or pinched by the work piece, the edge of the wheel that is entering into the pinch point can dig into

the surface of the material causing the wheel to climb out or kick out. The wheel may either jump toward or away from the operator, depending on

direction of the wheel’s movement at the point of pinching. Abrasive wheels may also break under these conditions.

Kickback is the result of power tool misuse and incorrect operating procedures or conditions and can be avoided by taking proper precautions as

given below.

a) Maintain a rm grip on the power tool and position your body and arms to allow you to resist kickback forces. Always use auxiliary handles, if

provided for maximum control over kickback or torque reactions during start up. The operator can control torque reactions or kickback forces,

if proper precautions are taken.

b) Never place your hand near the rotating accessory. Accessory may kickback over your hand.

c) Do not position your body in the area where power tool will move if kickback occurs. Kickback will propel the tool in the direction opposite to

the wheel’s movement at the point of the snagging.

d) Use special care when working corners, sharp edges etc. Avoid bouncing and snagging the accessory. Corners, sharp edges or bouncing have

a tendency to snag the rotating accessory and cause loss of control or kickback.

Additional Rules for Safe Operation

a) Empty the dust bag or dust collection receiver frequently. Do not leave residue in dust bag or dust collection receiver unattended. Always empty

in a non-combustible metal container. Sanding wood or varnish produces dust that can self ignite and cause injury or damage. Follow this

precaution for storage.

b) Setall exposed nails. Sweep loose abrasive away from work area. Do not strike metal pipes, ect., with sanding paper. Striking metal or abrasive

particles with sanding paper produces sparks that could ignite the sanding dust which can cause injury or damage.

c) Do not operate a partially assemble power tool. Keep all adjustments within manufacturer’s specications. Keep all fasteners tight. Operating

a partially assembled power tool could result in injury to the operator or bystander and could cause damage to the equipment or surroundings.

d) Do not attempt to change the sanding paper while the power tool is running. The sanding pad can snag clothing and cause injury to limbs and

moving sanding paper can cause abrasions.

e) The power tool should only be used on an electrical system (mains) that is rated for the electrical requirements of the power tool as shown on

the nameplate. Use only on an earthing (grounded) system. Do not service the power tool if it is energized or connected to an electrical circuit.

Improper use could cause re or electric shock.

6 7

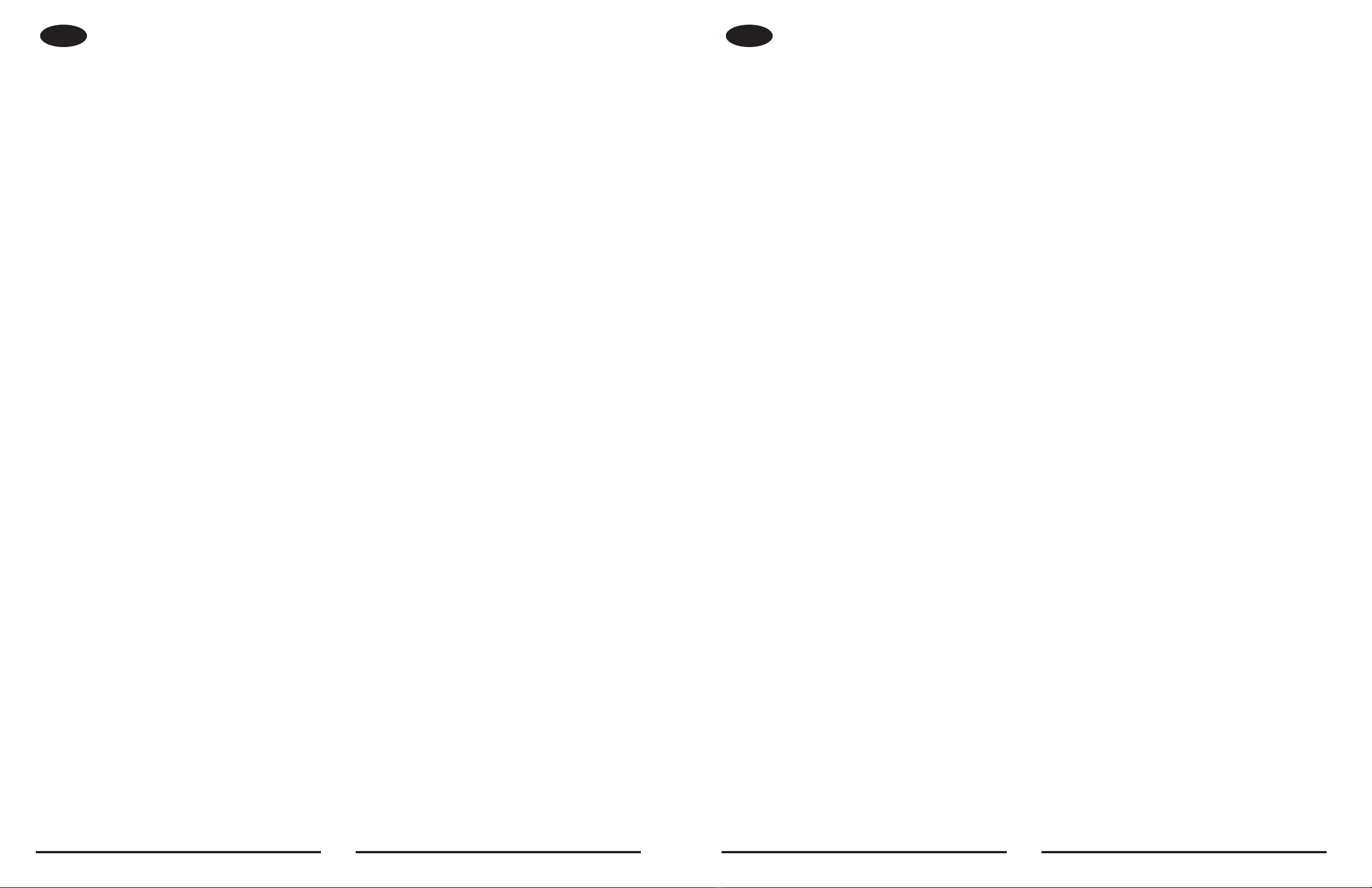

Parts List

DESCRIPTION

PART

NUMBER

QTY

ITEM

SWITCH DPST 16A/125V

SUPER

47394A11

BAG, EDGER

53544B12

COVER, MOTOR, BLACKAS017701

13

GUARD, LAMP, BLACKAS031100

1

7

PIN, ROLL, 1/8 X 1 1/8

NB0744002

4

EXTENSION, 8", EZ-EAS030100

1

5

GUARD DISC SUPER 7E

34109A16

1

2

7

6

4

5

3

Introduction Electrical Connection Instructions

EN EN

KNOW YOUR MACHINE

1 Control Switch

2 Dust Collection Bag

3 Operating Handles

4 Adjustable Casters

5 Removable Head

6 Wall Guard

7 Work Light

Model 07222A 07223A 07222C 07223C

Electrical Rating 115 V, 12.0 A,

60 Hz

115 V, 12.0 A,

60 Hz

115 V, 12.0 A,

60 Hz

115 V, 12.0 A,

60 Hz

Storage Case Standard Standard Standard Standard

Motor 1 Hp 1 Hp 1 Hp 1 Hp

Abrasive Size 7" x 7/8"

Dia. Disc

5"

Dia. Disc

7" x 7/8"

Dia. Disc

5"

Dia. Disc

Disc Rate 2800 rpm 3200 rpm 2800 rpm 3200 rpm

Disc Driver System Belt Driven Belt Driven Belt Driven Belt Driven

Power Cable 12-3 Gray Rubber 12-3 Gray

Rubber 12-3 Gray Rubber 12-3 Gray

Rubber

Dust Collection Standard Standard Standard Standard

Dust Control Rate 110 CFM 110 CFM 110 CFM 110 CFM

Extension Cords (120V)

Use only an approved extension cord with three conductors, a plug with three terminals, and a connector body with three holes.

WARNING:

If you use an extension cord, use an extension cord with minimum wire size 12 AWG. Do not use an extension cord longer than

50 feet. Do not join two extension cords.

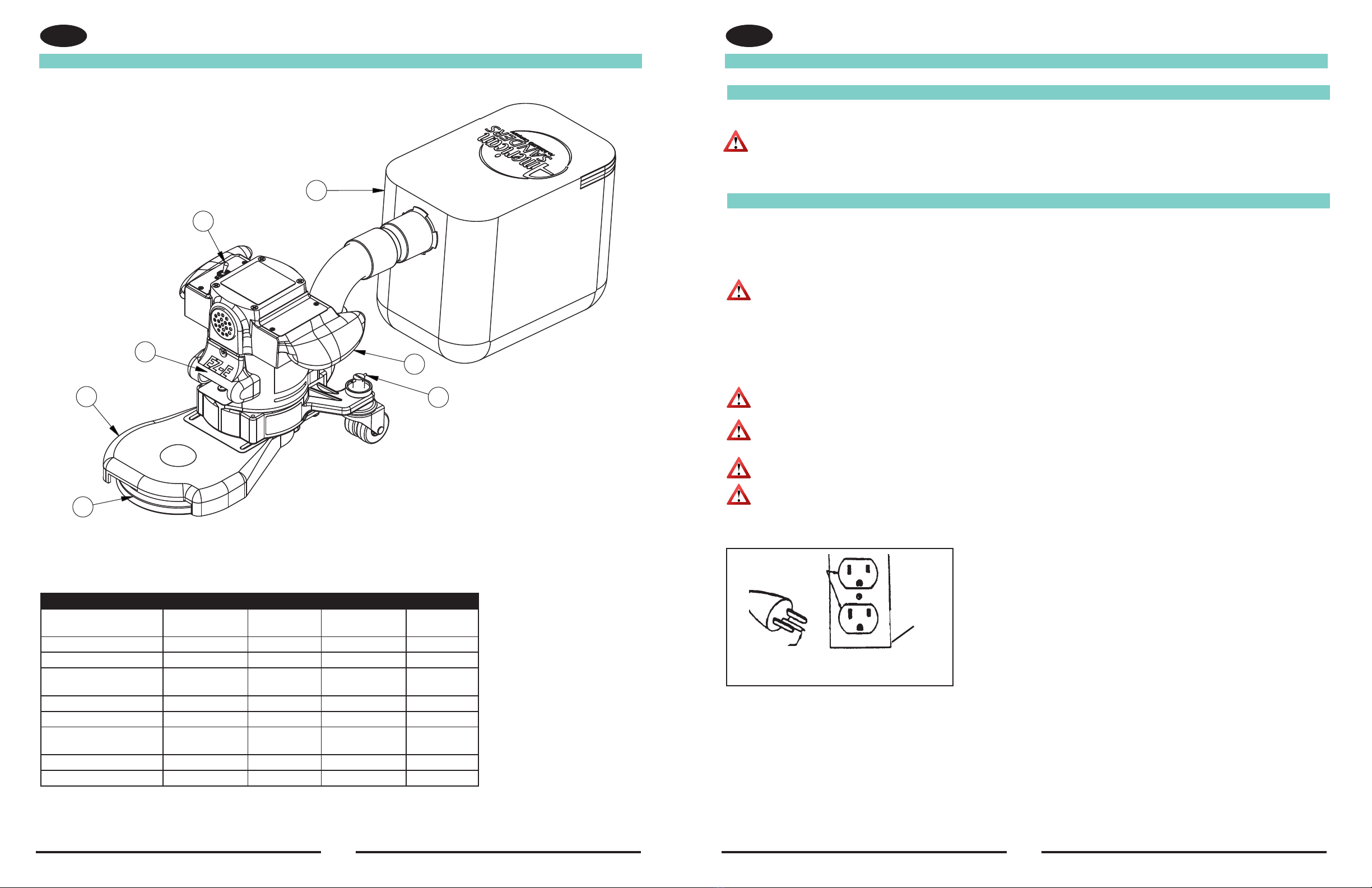

Instructions for connection to the power supply and the electrical ground.

This product must be grounded. If it should malfunction or breakdown, grounding provides a path of least resistance for electric current to reduce

the risk of electrical shock. This product is equipped with a cord having an equipment-grounding conductor and grounding plug. The plug must be

inserted into an appropriate oulet that is properly installed and grounded in accordance with all local codes and ordinances.

WARNING: Improper connection of the equipment-grounding conductor can result in a risk of electric shock. Check with qualied electri-

cian or service person if you are in doubt as to whether the outlet is properly grounded. Do not

modify the plug provided with

the product – if it will not t the outlet, have a proper outlet installed by a

qualied electrician.

This product is for use on a nominal 120 volt circuit and has a grounding attachment plug that looks like the plug illustrated in

gure 12. Make sure that the product is connected to an outlet having the same conguration as the plug. No adapter should

be used with this product. Always connect the machine to a dedicated 20 amp electrical line to prevent nuisance breaker trip-

ping and line overload due to other devices.

WARNING: To prevent possible electric shock, protect the machine from rain. Keep the machine in a dry building.

WARNING: To prevent possible electric shock, always use a 3-wire electrical system connected to the electrical ground. For maximum protection

against electrical shock, use a circuit that is protected by a ground fault circuit interupter. Consult your electrical contractor.

WARNING: Do not cut, remove or break the ground pin. If the outlet does not t the plug, consult your electrical contractor.

WARNING: Have worn, cut or damaged cords replaced by an authorized service person.

Electrical Connection Instructions (120V)

Figure 12

Grounded

Outlet

Grounding

Pin

(United States, Mexico and Canada)

Grounded

Outlet

Box

8 9

Installing the Sanding Head

1. Place the head on the machine, making sure the belt is placed around the motor pulley. Position the belt in the lower-most grooves, (closest to

the motor), for the 8” extension. Position the belt in the upper-most grooves, (furthest away from the motor), for the 13” extension. (Figure 4)

2. Start all four nuts “B” by hand, but do not tighten.

3. Rotate pad driver “C” to make sure belt is in the appropriate grooves.

CAUTION: Rapid belt wear will occur if belt is not properly aligned.

4. Tension belt and tighten nuts “B” with a 7/16” socket.

NOTE: The tension should be great enough so that the belt does not slip during use. Excessive tension will lessen bearing and belt life.

5. Secure belt guard with screws “A”.

WARNING: Bodily injury could occur if power is applied to the machine with the power switch already in the “ON” position. Always check

to assure that the power switch is in the “OFF” position before applying power to the power cable.

1. Move machine to the location of your work. Set any exposed nails with hammer and punch to avoid

encounter with abrasive.

2. Make sure the control switch is in the “OFF” position then connect the supply cable to an

appropriately grounded fused circuit. Connect the supply cable to the motor pigtail. (Figure 6)

3. With the machine in the reclined position rmly grasp both handles and ip the control switch to the

“ON” position. (Figure 5.)

4. Gradually lower pad to surface intended for sanding. Make sure the machine is in motion while

the pad is engaged with the surface to be sanded. You may use broad circular motion as you sand

along the length of the surface or your may use a combination of forward and sideward motions. In

time you will develop your own technique to optimize coverage and dust recovery. It is advisable to

not add effort to the pad as this may lead to “nosing in” or “tipping” which produces grooves or lines

on the surface.

5. When replacing abrasive, emptying the contents of the dust bag, or sanding operation is completed,

return machine to reclined position, ip control switch to “OFF” then

disconnect the motor pigtail from the supply cable.

6. Empty dust bag whenever it becomes 1/3 full

DANGER: Failure to disconnect the supply cable from machine whenever

servicing, replacing abrasive, or emptying the dust bag could

result in electrocution or severe injury. Never leave machine

unattended while the supply cable is connected.

DANGER: Never leave dust bag unattended with sanding dust in it.

Sanding dust can spontaneously ignite and cause a re or

explosion. Empty dust bag into a metal container, clear of any

combustibles. Do not empty content into a re. Do not overll

dust bag.

Machine Setup

EN EN

This sanding machine is designed to be operated with a remote vacuum dust

collection system or with the included dust bag.

Preparing Remote Vacuum Dust Collection Systems

To prepare the machine for remote vacuum dust collection systems that have a 2”

hose end, follow this procedure:

1. Install 2” hose end (gure 1, A) directly over the exhaust tube (gure 1, B).

2. The exhaust tube can be rotated for optimum convenience.

To prepare the machine for remote vacuum dust collection systems that have a 1

½” hose end, follow this procedure:

1.

Install the 2” x 1½” hose end adaptor (Part No. 30563A) (gure 1, C)

over the

exhaust tube (gure 1, B).

2. Insert 1½” hose end (gure 1, D) into the adaptor (gure 1, C).

NOTE: Start the remote vacuum collection system before operation.

Preparing to use the included dust bag

To prepare the machine for use with the included dust bag (Part No. 53544B),

follow this procedure:

1. Install the dust bag by pressing the end onto the exhaust tube until the ring

locks into the groove (gure 2). This is best done by pressing on the back of

the bag opening with the palm of your hand.

2. The exhaust tube can be rotated for optimum convenience.

3. To remove the dust bag from the exhaust tube, pry up the end of the bag

opening to partially release the internal rib from the groove, then pull.

4. To empty the dust bag, unzip the disposal ap and force contents out by

inverting the bag.

NOTE: For best results, empty frequently. Follow all warnings posted in this

manual and on the dust bag.

Preparing the Machine for Operation

1. Familiarize yourself with the machine. Read all danger, warning,

and caution

statements and the Owner’s Manual before operating

this machine.

2. The machine will accept either hook and loop or center-hole abrasive disc.

The tool is equipped with a retaining screw and washer for use with the

center-hole abrasive. When installing abrasive disc, take care to center disc

on driver. (Figure 3)

3.

NOTE: To avoid injuring the hook surface on the driver when sanding thick

paint, varnish, or wax, it is recommended you stack two discs on the driver

using a course, open coat abrasive.

EN ENGLISH

-8- American Sanders Operator’s Manual (EN) - Super 7R

Install the dust bag by

pressing the end onto the

exhaust tube until the ring

locks into the groove.

A

2” Hose from

vacuum system

(not included)

1.5” Hose from

vacuum system

(not included)

D

B

C

Exhaust Tube

(30563A) 2” Tube x 1.5” hose adaptor

Figure 1

Figure 2

MACHINE SET-UP

This sanding machine is designed to be operated with a remote vacuum

dust collection system or with the included dust bag.

Preparing Remote Vacuum Dust Collection Systems

To prepare the machine for remote vacuum dust collection systems that

have a 2” hose end, follow this procedure:

1. Install 2” hose end (gure 1, A) directly over the exhaust tube (gure 1,

B).

2. The exhaust tube can be rotated for optimum convenience.

To prepare the machine for remote vacuum dust collection systems that

have a 1 ½” hose end, follow this procedure:

1. Install the 2” x 1½” hose end adaptor (Part No. 30563A) (gure 1, C)

over the exhaust tube (gure 1, B).

2. Insert 1 ½” hose end (gure 1, D) into the adaptor (gure 1, C).

NOTE: Start the remote vacuum collection system before operation.

Preparing to use the included dust bag

To prepare the machine for use with the included dust bag (Part No.

53544B), follow this procedure:

1. Install the dust bag by pressing the end onto the exhaust tube until the

ring locks into the groove (gure 2). This is best done by pressing on

the back of the bag opening with the palm of your hand.

2. The exhaust tube can be rotated for optimum convenience.

3. To remove the dust bag from the exhaust tube, pry up the end of the

bag opening to partially release the internal rib from the groove, then

pull.

4. To empty the dust bag, unzip the disposal ap and force contents out

by inverting the bag.

NOTE: For best results, empty frequently. Follow all warnings posted

in this manual and on the dust bag.

Figure 1

EN ENGLISH

-8- American Sanders Operator’s Manual (EN) - Super 7R

Install the dust bag by

pressing the end onto the

exhaust tube until the ring

locks into the groove.

A

2” Hose from

vacuum system

(not included)

1.5” Hose from

vacuum system

(not included)

D

B

C

Exhaust Tube

(30563A) 2” Tube x 1.5” hose adaptor

Figure 1

Figure 2

MACHINE SET-UP

This sanding machine is designed to be operated with a remote vacuum

dust collection system or with the included dust bag.

Preparing Remote Vacuum Dust Collection Systems

To prepare the machine for remote vacuum dust collection systems that

have a 2” hose end, follow this procedure:

1. Install 2” hose end (gure 1, A) directly over the exhaust tube (gure 1,

B).

2. The exhaust tube can be rotated for optimum convenience.

To prepare the machine for remote vacuum dust collection systems that

have a 1 ½” hose end, follow this procedure:

1. Install the 2” x 1½” hose end adaptor (Part No. 30563A) (gure 1, C)

over the exhaust tube (gure 1, B).

2. Insert 1 ½” hose end (gure 1, D) into the adaptor (gure 1, C).

NOTE: Start the remote vacuum collection system before operation.

Preparing to use the included dust bag

To prepare the machine for use with the included dust bag (Part No.

53544B), follow this procedure:

1. Install the dust bag by pressing the end onto the exhaust tube until the

ring locks into the groove (gure 2). This is best done by pressing on

the back of the bag opening with the palm of your hand.

2. The exhaust tube can be rotated for optimum convenience.

3. To remove the dust bag from the exhaust tube, pry up the end of the

bag opening to partially release the internal rib from the groove, then

pull.

4. To empty the dust bag, unzip the disposal ap and force contents out

by inverting the bag.

NOTE: For best results, empty frequently. Follow all warnings posted

in this manual and on the dust bag.

Figure 2

Figure 3

Head Conversion

Removing the Sanding Head

1. Make sure the control switch is in the “OFF” position and disconnect the

motor pigtail from the supply cable. (Figure 6)

2. With a Phillips screwdriver, remove the two screws “A” securing the belt

guard. Remove the belt guard. (Figure 4)

3. With a 7/16” socket, remove the four nuts “B” securing the head attachment.

(Figure 4)

4. Lift the head off of the machine, making sure the belt slips over the motor pulley.

A

B

Figure 4

VIEW35

SCALE .3

SECTION A-A SCALE .3

A A

B

13" Belt

8" Belt

C

Operating Instructions

EN

ENGLISH

American Sanders Operator’s Manual (EN) - Super 7R - 9 -

Figure 3

Figure 4

Figure 5

MACHINE SET-UP

Preparing the Machine for Operation

1. Familiarize yourself with the machine. Read all danger, warning, and caution

statements and the Owner’s Manual before operating this machine. If you or

your operator cannot read English, have this manual explained fully before

attempting to operate this machine.

2. Remove screw and abrasive retainer. Center abrasive on pad and secure with

abrasive retainer and screw. (Figure 3)

3. Return machine to upright position and tilt machine back on casters until it

comes to rest on the exhaust bracket. Machine will be in a reclined position.

Do not allow machine to rest on pad especially after use, or compression set

may take place within elastomer on pad. This will create a at spot and bounce

during use. (Figure 4)

OPERATING INSTRUCTIONS

1. Move machine to the location of your work. Set any exposed nails with ham-

mer and punch to avoid encounter with abrasive.

WARNING: Bodily injury could occur if power is applied to

the machine with the power switch already in the “ON” position. Always

check to assure that the power switch is in the “OFF” position before

applying power to the power cable.

2. Make sure the control switch is in the “Off” position then connect the supply

cable to an appropriately grounded fused circuit. Connect the supply cable to

the motor pigtail. (Figure 5)

3. With the machine in the reclined position rmly grasp both handles and ip the

control switch to the “ON” position. (Figure 4.)

4. Gradually lower pad to surface intended for sanding. Make sure the ma-

chine is in motion while the pad is engaged with the surface to be sanded.

You may use broad circular motion as you sand along the length of the

surface or your may use a combination of forward and sideward motions.

In time you will develop your own technique to optimize coverage and dust

recovery. It is advisable to not add effort to the pad as this may lead to “nos-

ing in” or “tipping” which produces grooves or lines on the surface.

5. When replacing abrasive, emptying the contents of the dust bag, or sanding

operation is completed, return machine to reclined position, ip control

switch to “Off” then disconnect the motor pigtail from the supply cable.

6. Empty dust bag whenever it becomes 1/3 full.

Figure 6

Figure 5

This manual suits for next models

3

Table of contents

Languages:

Other Amano Edger manuals

Amano

Amano American Sanders Super 7R Australia User manual

Amano

Amano American Sanders EZ-E User manual

Amano

Amano 07125A User manual

Amano

Amano American Sanders 07246A User manual

Amano

Amano American Sanders COMPASS HDTR User manual

Amano

Amano American Sanders Compass User manual

Amano

Amano American Sanders Super 7R 240V User manual

Amano

Amano 07208A User manual