Amano American SANDERS 07242A User manual

Concrete Vacuum

07242A

Operator’s Manual

READ THIS BOOK

This book has important information for the use and safe operation of this machine. Failure to

read this book prior to operating or attempting any service or maintenance procedure to your

American Sanders machine could result in injury to you or to other personnel; damage to the

machine or to other property could occur as well. You must have training in the operation of

this machine before using it. If your operator(s) cannot read this manual, have it explained fully

before attempting to operate this machine.

All directions given in this book are as seen from

the operator’s position at the rear of the machine.

WARNING!

To reduce the risk of fire, electric shock, or injury:

lDo not use where explosive vapors, such as gas, solvents, alcohol, fuels, or combustible materials

such as grain, wood dust, are present in the air. Keep the work area well ventilated.

lDust produced from sanding wood or varnish could self ignite causing injury or damage. If this

material has been picked up, empty it immediately after use in a metal container.

lDo not use unless machine is fully assembled. Do not modify the machine. Read all instructional

labels on the machine. Replace damaged labels.

lDo not allow to be used as a toy. Close attention is necessary when used around children.

lUse extra care when cleaning on stairs.

lConnect to properly grounded outlet. See “grounding Instructions”.

lDo not use unless all filtering elements are present. Clean filtering elements frequently.

SAVE THESE INSTRUCTIONS

***This product is intended for commercial use only***

WARNING!

The Products sold with this Manual contain or may contain chemicals that are known to certain

governments (such as the State of California, as identied in its Proposition 65 Regulatory Warning Law)

to cause cancer, birth defects or other reproductive harm. In certain locations (including the State of

California) purchasers of these Products that place them in service at an employment job site or a publicly

accessible space are required by regulation to make certain notices, warnings or disclosures regarding the

chemicals that are or may be contained in the Products at or about such work sites. It is the purchaser’s

responsibility to know the content of, and to comply with, any laws and regulations relating to the use of

these Products in such environments. The Manufacturer disclaims any responsibility to advise purchasers

of any specic requirements that may be applicable to the use of the Products in such environments.

Contents

Safety Instructions.............................................................................. 4

Functional Description........................................................................ 5

Technical Data.................................................................................... 6

Operation.........................................................................................7-8

Warranty ........................................................................................... 10

Troubleshooting................................................................................ 10

Filter..................................................................................................13

Vacuum Motor Assembly.................................................................. 14

Tank Assembly ................................................................................. 16

Cover Assembly ............................................................................... 18

Warranty ........................................................................................... 20

The descriptions contained in this document are not binding. The company therefore reserves the right to make any

modications at any time to elements, details, or accessory supply, as considered necessary for reasons of improvement

or manufacturing/commercial requirements. The reproduction, even partial, of the text and drawings contained in this

document is prohibited by law.

American Sanders reserves the right to make any technical and/or supply modications. The images are

shown as a reference only, and are not binding as to the actual design and/or equipment.

4

Safety Instructions

Read the following safety instructions before starting the machine. Save the User Guide for future reference. Failure

to comply with the safety instructions voids the warranty and may result in personal injury and damage to the product.

American Sanders is not responsible for damage to the equipment caused by improper installation or improper

operation of the equipment.

Warning

This machine is intended for professional use only.

Only use accessories and replacement parts included in the American Sanders product line.

WARNING

Use the machine for its intended purpose. Follow the instructions for the material to be extracted.

WARNING

This machine is only intended for extraction of dry material.

WARNING

When using electrical devices, basic safety instructions must be followed to reduce the risk of fire, electric

shock or personal injury.

WARNING

If incorrect or non-OEM parts are used (especially filters, hoses and plastic bags), the machine can leak

hazardous dust which may result in personal injury.

Environmental protection

Packaging materials can be recycled. Do not dispose of the packaging in household waste. Instead it should be

returned for recycling. Discarded units contain recyclable materials that should be recycled. Batteries, oil and similar

items must not get into the environment. Dispose of scrapped units in an appropriate recycling system.

Discarded filters contain recyclable material that should be recycled.

Transfer used filters to a suitable recycling system.

For more information, please contact your nearest recycling center.

Work area environment

Do not expose the machine to moisture. Do not use it in damp or wet areas or close to flammable liquids or gases.

CAUTION

This machine must only be used and stored in a dry environment.

CAUTION

Do not rinse the machine with water.

Overload

Do not expose the machine to moisture. Do not use it in damp or wet areas or close to flammable liquids or gases.

Bodily injuries

CAUTION

Never try to change electrical connections yourself. An error can be fatal!

Never allow the extraction point to make contact with any part of the body. The strong negative pressure can damage

blood vessels in the skin.

WARNING

This machine is only intended for extraction of dry material.

5

Power cord

Never pull the machine by the power cord. Keep the power cord away from heat and sharp objects. Regularly inspect

the power cord.

If using an extension cord, it must be waterproof.

The machine must not be used if the power cords or contacts are damaged.

If the power cord is damaged, it must be replaced by American Sanders or a American Sanders authorized service

center.

Care and maintenance

Keep the machine clean and free from dust deposits. Ensure that the suction hose and all seals are intact and

undamaged. Keep the carrying handles dry and free from oil and grease.

Inspection

Regularly check the device for damage and wear. Any damage must be rectified by a American Sanders authorized

service center.

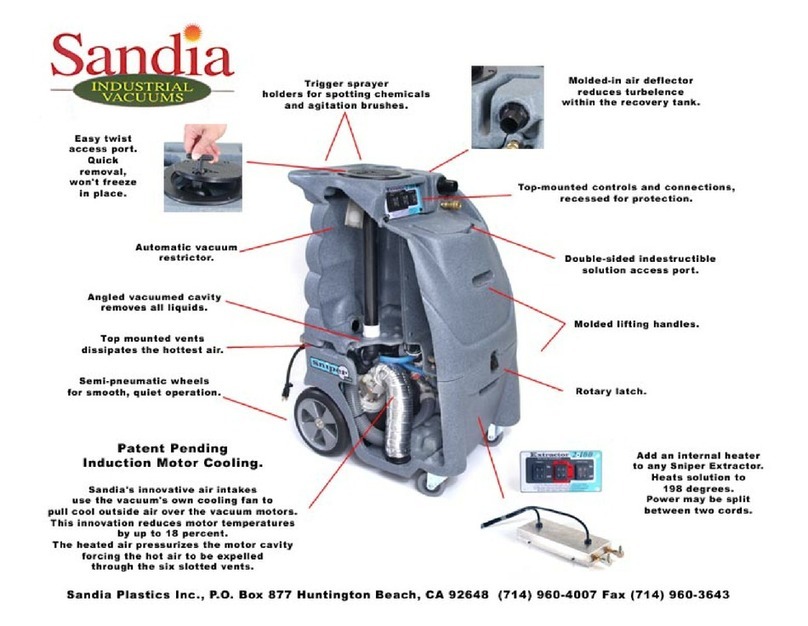

Functional description

The dust extractor uses negative pressure (suction) to force the air through a suction cover/nozzle, hose system,

pre-separator and dust separator. Coarse separation is carried out in the machine’s cyclone, providing very effective

separation of any coarse dust. Fine dust is separated in the units filter. Reverse-pulse filter cleaning ensures extended

filter life. The machine is fitted with a HEPA filter.

The dust extractor is durable and reliable. It is particularly well suited to the suction and removal of dry, harmful, non-

combustible dust in filter class H.

DC400L is used for spot extraction (with maximum throttling Ø 15 mm) in many contexts e.g. when grinding, welding,

personal clean-up and cleaning. The DC400L is powered by two 1-phase, 2-stage fans.

The dust extractor has the following discharge

options:

L – Longopac: The machine is equipped with

a flexible bag system, in which the dust is

collected in a closed system.

The dust extractor has the following discharge options:

c – Plastic bag: The extracted and separated material is collected in a plastic bag that can be detached in one simple operation.

The material can easily be recycled or disposed of.

a - Container: A cylindrical container for collection of separated material.

L – Longopac: The machine is equipped with a flexible bag system, in which the dust is collected in a closed system.

Technical data

DC Tromb 400c DC Tromb 400a DC Tromb 400L

HxWxL [mm] 1360 x 600 x 780 1360 x 600 x 780 1360 x 600 x 780

Weight [kg] 46 51 50

Inlet [mm] Ø76 Ø76 Ø76

Hose length Ø 50 [m] 555

Collecting container [l] 20 40 longopac

Flow max, open inlet [m³/h] 393 393 393

Flow max, fan [m³/h] 420 420 420

Negative pressure, max. [kPa] 22 22 22

Power [W] 3000 3000 3000

Fine filter, polyester, area [m2]1,85 1,85 1,85

Degree of separation, fine filter, EN 60335-2-69, Class

M [%]

99,9 99,9 99,9

Filter area, HEPA filter [m2]2,2 2,2 2,2

Degree of separation, machine, EN 60335-2-69,

Appendix A-A, Class H [%]

99,995 99,995 99,995

Filter classification, EN 1822-1 HEPA H13 HEPA H13 HEPA H13

Sound level [dB(A)] 70 70 70

DC Tromb, Art.nr. 9480-M 15

ENGLISH

6

Technical Data 07242A - DC 400L

HxWxL (in) 53.5 x 22 x 27

Weight (lb) 110

Inlet (in) 3

Hose length Ø 50 (ft) 16.4

Collecting container (l) longopac

Flow max, open Inlet (m³/h/CFM) 320/188

Flow Max fan (m³/h/CFM) 360/212

Negative pressure, max. (kPa) 20

Power (W) 2100

Fine lter, polyester, area (ft2)20

Degree of separation, ne lter, EN 60335-2-69,

ClassM (%) 99.9

Filter area, micro lter (ft2)23.7

Degree of separation, machine, EN 60335-2-69,

Appendix A-A, Class H (%) 99.995

Filter classication, EN 1822-1 HEPA H13

Sound level [dB(A)] 70

Technical data

Technical Data UK/USA/CAN DC Tromb 400c DC Tromb 400a DC Tromb 400L

HxWxL [in] 53,5 x 22 x 27 53,5 x 22 x 27 53,5 x 22 x 27

Weight [lb] 101 112 110

Inlet [in] 333

Hose length Ø 50 [ft] 16,4 16,4 16,4

Collecting container [l] 20 40 longopac

Flow max, open inlet, UK [m³/h / CFM] 330/194 330/194 330/194

Flow max, open Inlet, USA/CAN [m³/h / CFM] 320/188 320/188 320/188

Flow Max fan, UK, USA, CAN [m3/h / CFM] 360/212 360/212 360/212

Negative pressure max, UK [kPa] 21 21 21

Negative pressure max, USA/CAN [kPa] 20 20 20

Power, UK [W] 2680 2680 2680

Power, USA, CAN [W] 2100 2100 2100

Fine filter, polyester, area [ft2]20 20 20

Degree of separation, fine filter, EN 60335-2-69, Class M

[%]

99,9 99,9 99,9

Filter surface, microfilter [ft2]23,7 23,7 23,7

Degree of separation, machine, EN 60335-2-69, Appendix

A-A, Class H [%]

99,995 99,995 99,995

Filter classification, EN 1822-1 HEPA H13 HEPA H13 HEPA H13

Sound level [dB(A)] 70 70 70

Pressure generation and air flow

Operation

Connection

Connect the machine to an electrical outlet with a voltage as per the machine’s rating plate specifications.

16 DC Tromb, Art.nr. 9480-M

ENGLISH

Pressure generation and air flow

7

Operation

Connection

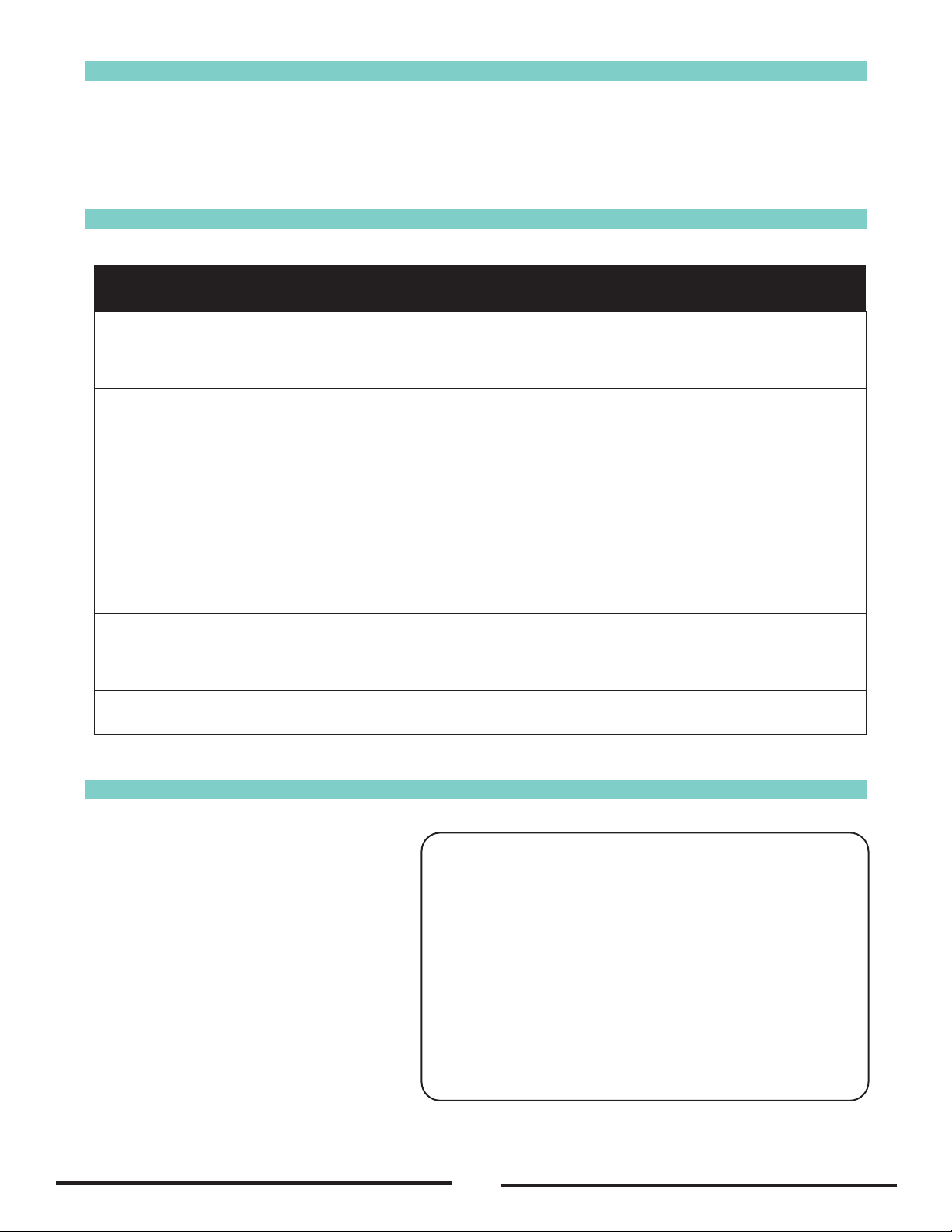

Connect the machine to an electrical outlet with a voltage as per the machine’s rating plate specifications.

Filter cleaning

The machine has a filter status indicator that lights up when the filter needs to be cleaned

or replaced. The filters must be cleaned 1-2 times a day with continuous use and when the

manometer needle is in the red field.

The filters should be cleaned when the manometer is in the red field.

1. Keep the machine switched on and close the throttle at the cyclone inlet. Reset the filter cleaner button.

2. Wait for 5-10 pulses.

3. Switch off the machine.

4. Open the throttle at the cyclone inlet and reset the filter cleaner button.

5. Switch on the machine.

6. Check that the pressure gauge indicates green or that the filter indication lamp is off. If not, repeat the procedure. If

the gauge indicates red or the light is on even after repetition, the fine filter needs to be replaced.

Filter cleaning

The machine has a filter status indicator that lights up when the filter needs to be cleaned or replaced. The filters must be cleaned

1-2 times a day with continuous use and when the manometer needle is in the red field.

The filters should be cleaned when the manometer is in the red field.

1. Keep the machine switched on and close the throttle at the cyclone inlet. Reset the filter cleaner button.

2. Wait for 5-10 pulses.

3. Switch off the machine.

4. Open the throttle at the cyclone inlet and reset the filter cleaner button.

5. Switch on the machine.

6. Check that the pressure gauge indicates green or that the filter indication lamp is off. If not, repeat the procedure. If the

gauge indicates red or the light is on even after repetition, the fine filter needs to be replaced.

Emptying

a – Container

The container underneath the cyclone should be emptied when about 2/3 full.

c – Plastic bag

You must clean the filters before replacing the plastic bag. It should be replaced when the dust level is about 5 cm below the

discharge flap.

Dust-free bag change

DC Tromb, Art.nr. 9480-M 17

ENGLISH

Filter cleaning

The machine has a filter status indicator that lights up when the filter needs to be cleaned or replaced. The filters must be cleaned

1-2 times a day with continuous use and when the manometer needle is in the red field.

The filters should be cleaned when the manometer is in the red field.

1. Keep the machine switched on and close the throttle at the cyclone inlet. Reset the filter cleaner button.

2. Wait for 5-10 pulses.

3. Switch off the machine.

4. Open the throttle at the cyclone inlet and reset the filter cleaner button.

5. Switch on the machine.

6. Check that the pressure gauge indicates green or that the filter indication lamp is off. If not, repeat the procedure. If the

gauge indicates red or the light is on even after repetition, the fine filter needs to be replaced.

Emptying

a – Container

The container underneath the cyclone should be emptied when about 2/3 full.

c – Plastic bag

You must clean the filters before replacing the plastic bag. It should be replaced when the dust level is about 5 cm below the

discharge flap.

Dust-free bag change

DC Tromb, Art.nr. 9480-M 17

ENGLISH

Filter cleaning

The machine has a filter status indicator that lights up when the filter needs to be cleaned or replaced. The filters must be cleaned

1-2 times a day with continuous use and when the manometer needle is in the red field.

The filters should be cleaned when the manometer is in the red field.

1. Keep the machine switched on and close the throttle at the cyclone inlet. Reset the filter cleaner button.

2. Wait for 5-10 pulses.

3. Switch off the machine.

4. Open the throttle at the cyclone inlet and reset the filter cleaner button.

5. Switch on the machine.

6. Check that the pressure gauge indicates green or that the filter indication lamp is off. If not, repeat the procedure. If the

gauge indicates red or the light is on even after repetition, the fine filter needs to be replaced.

Emptying

a – Container

The container underneath the cyclone should be emptied when about 2/3 full.

c – Plastic bag

You must clean the filters before replacing the plastic bag. It should be replaced when the dust level is about 5 cm below the

discharge flap.

Dust-free bag change

DC Tromb, Art.nr. 9480-M 17

ENGLISH

Filter cleaning

The machine has a filter status indicator that lights up when the filter needs to be cleaned or replaced. The filters must be cleaned

1-2 times a day with continuous use and when the manometer needle is in the red field.

The filters should be cleaned when the manometer is in the red field.

1. Keep the machine switched on and close the throttle at the cyclone inlet. Reset the filter cleaner button.

2. Wait for 5-10 pulses.

3. Switch off the machine.

4. Open the throttle at the cyclone inlet and reset the filter cleaner button.

5. Switch on the machine.

6. Check that the pressure gauge indicates green or that the filter indication lamp is off. If not, repeat the procedure. If the

gauge indicates red or the light is on even after repetition, the fine filter needs to be replaced.

Emptying

a – Container

The container underneath the cyclone should be emptied when about 2/3 full.

c – Plastic bag

You must clean the filters before replacing the plastic bag. It should be replaced when the dust level is about 5 cm below the

discharge flap.

Dust-free bag change

DC Tromb, Art.nr. 9480-M 17

ENGLISH

Filter cleaning

The machine has a filter status indicator that lights up when the filter needs to be cleaned or replaced. The filters must be cleaned

1-2 times a day with continuous use and when the manometer needle is in the red field.

The filters should be cleaned when the manometer is in the red field.

1. Keep the machine switched on and close the throttle at the cyclone inlet. Reset the filter cleaner button.

2. Wait for 5-10 pulses.

3. Switch off the machine.

4. Open the throttle at the cyclone inlet and reset the filter cleaner button.

5. Switch on the machine.

6. Check that the pressure gauge indicates green or that the filter indication lamp is off. If not, repeat the procedure. If the

gauge indicates red or the light is on even after repetition, the fine filter needs to be replaced.

Emptying

a – Container

The container underneath the cyclone should be emptied when about 2/3 full.

c – Plastic bag

You must clean the filters before replacing the plastic bag. It should be replaced when the dust level is about 5 cm below the

discharge flap.

Dust-free bag change

DC Tromb, Art.nr. 9480-M 17

ENGLISH

Filter cleaning

The machine has a filter status indicator that lights up when the filter needs to be cleaned or replaced. The filters must be cleaned

1-2 times a day with continuous use and when the manometer needle is in the red field.

The filters should be cleaned when the manometer is in the red field.

1. Keep the machine switched on and close the throttle at the cyclone inlet. Reset the filter cleaner button.

2. Wait for 5-10 pulses.

3. Switch off the machine.

4. Open the throttle at the cyclone inlet and reset the filter cleaner button.

5. Switch on the machine.

6. Check that the pressure gauge indicates green or that the filter indication lamp is off. If not, repeat the procedure. If the

gauge indicates red or the light is on even after repetition, the fine filter needs to be replaced.

Emptying

a – Container

The container underneath the cyclone should be emptied when about 2/3 full.

c – Plastic bag

You must clean the filters before replacing the plastic bag. It should be replaced when the dust level is about 5 cm below the

discharge flap.

Dust-free bag change

DC Tromb, Art.nr. 9480-M 17

ENGLISH

8

Operation

Emptying

L – Longopac

Close the bag using the supplied cable ties when you believe that it has been filled to a suitable level. Another cable

tie is used a little further up. This forms the bottom of the next bag. The filled bag is then cut off, and the machine is

ready to be used again.

Changing the bag magazine

1. Rotate the holder to the position in which it can be pulled down.

2. Insert a bag magazine into the holder and refit it.

3. Cut the four tapes that hold the bag magazine together and pull the inner end of the bag upwards over the rubber

strip. Then secure the bag with the strap. Pull the outer end over the holder, and tie a cable tie in place as a bottom

closure.

The machine should be switched for the duration of the bag change. Remove the bag. The bag must be sealed as soon as it is

removed from the machine. Only use Dustcontrol’s original bags.

Fit the new bag. Use the strap for dust-free work. Use the hooks for simple suspension of the bag.

Clean the filter and use the dust extractor.

L – Longopac

Close the bag using the supplied cable ties when you believe that it has been filled to a suitable level. Another cable tie is used a

little further up. This forms the bottom of the next bag. The filled bag is then cut off, and the machine is ready to be used again.

Changing the bag magazine

1. Rotate the holder to the position in which it can be pulled down.

2. Insert a bag magazine into the holder and refit it.

3. Cut the four tapes that hold the bag magazine together and pull the inner end of the bag upwards over the rubber strip. Then

secure the bag with the strap. Pull the outer end over the holder, and tie a cable tie in place as a bottom closure.

Service/Maintenance

Cleaning

The machine must be switched off and unplugged before cleaning and maintenance.

18 DC Tromb, Art.nr. 9480-M

ENGLISH

The machine should be switched for the duration of the bag change. Remove the bag. The bag must be sealed as soon as it is

removed from the machine. Only use Dustcontrol’s original bags.

Fit the new bag. Use the strap for dust-free work. Use the hooks for simple suspension of the bag.

Clean the filter and use the dust extractor.

L – Longopac

Close the bag using the supplied cable ties when you believe that it has been filled to a suitable level. Another cable tie is used a

little further up. This forms the bottom of the next bag. The filled bag is then cut off, and the machine is ready to be used again.

Changing the bag magazine

1. Rotate the holder to the position in which it can be pulled down.

2. Insert a bag magazine into the holder and refit it.

3. Cut the four tapes that hold the bag magazine together and pull the inner end of the bag upwards over the rubber strip. Then

secure the bag with the strap. Pull the outer end over the holder, and tie a cable tie in place as a bottom closure.

Service/Maintenance

Cleaning

The machine must be switched off and unplugged before cleaning and maintenance.

18 DC Tromb, Art.nr. 9480-M

ENGLISH

9

Safety Instructions

Filter replacement

The fine filter must be replaced at least once a year. Only original filters may be used. HEPA filters must be replaced

after 300 hours.

WARNING

Filter replacement may only be performed by trained personnel. Use a protective mask and suitable

equipment.

CAUTION

When replacing the filter, no tools/sharp objects can be used as these may damage the sealing surface of

the filter.

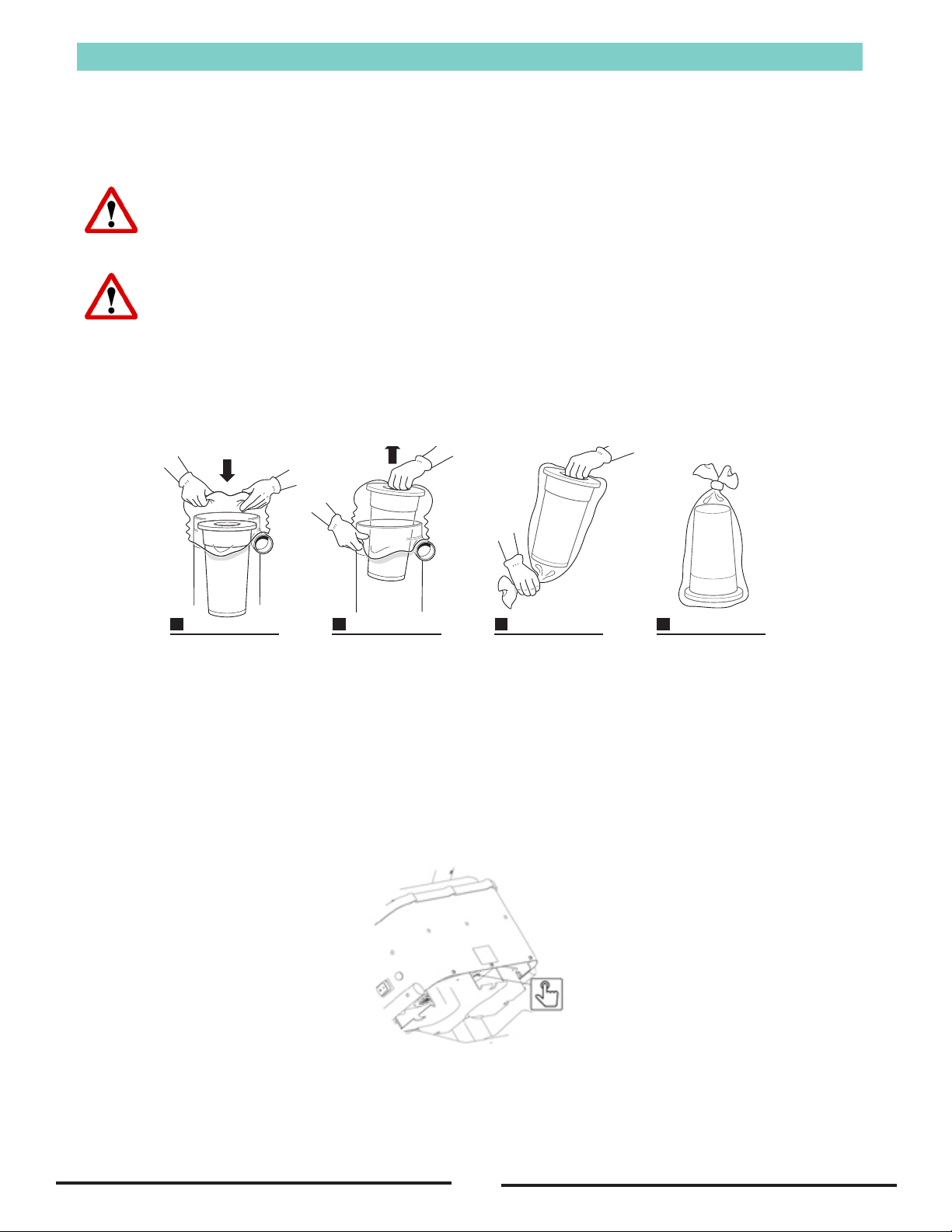

Release and lift off the upper part for free access to the filter. Lift the filter straight up. If appropriate, fit a plastic bag

over the cyclone to prevent the dust in the filter from spreading. Check the gasket when replacing the filter. A worn

gasket can allow hazardous dust to escape. Never use old gaskets or non-OEM parts. Place used filters in a plastic

bag and seal the bag. See instructions below.

Motor

The typical service life of a fan motor’s original brushes is 600-700 hours. The brush can be replaced. The service life

of the second brush set is approx. 400 hours, while that of the third set is approx. 300 hours. After this time, the motor

is considered worn out and should be replaced.

Overheating

If the machine is at risk of overheating (for example, as a result of powerful throttling), the temperature guard will trip

and the machine will stop. The operator must then press the power switch to the OFF position, unplug from the mains

and wait 3-5 minutes for the machine to cool down. Then reset the temperature guard by pressing the RESET button.

Reconnect the power cord to the electrical outlet and restart the machine by pressing the power switch to the ON

position.

Regular checks

Regularly check the power cord for damage.

The machine must be tested and inspected at least once a year due to its use with hazardous materials. Worn parts

must be replaced. Never risk functionality and service life. Only use genuine parts.

Filter replacement

The fine filter must be replaced at least once a year. Only original filters may be used. HEPA filters must be replaced after

300 hours.

WARNING

Filter replacement may only be performed by trained personnel. Use a protective mask and suitable

equipment.

CAUTION

When replacing the filter, no tools/sharp objects can be used as these may damage the sealing surface of the

filter.

Release and lift off the upper part for free access to the filter. Lift the filter straight up. If appropriate, fit a plastic bag over the

cyclone to prevent the dust in the filter from spreading. Check the gasket when replacing the filter. A worn gasket can allow

hazardous dust to escape. Never use old gaskets or non-OEM parts. Place used filters in a plastic bag and seal the bag. See

instructions below.

1 2 3 4

Motor

The typical service life of a fan motor's original brushes is 600-700 hours. The brush can be replaced. The service life of the

second brush set is approx. 400 hours, while that of the third set is approx. 300 hours. After this time, the motor is considered

worn out and should be replaced.

Overheating

If the machine is at risk of overheating (for example, as a result of powerful throttling), the temperature guard will trip and the

machine will stop. The operator must then press the power switch to the OFF position, unplug from the mains and wait 3-5

minutes for the machine to cool down. Then reset the temperature guard by pressing the RESET button. Reconnect the power

cord to the electrical outlet and restart the machine by pressing the power switch to the ON position.

Regular checks

Regularly check the power cord for damage.

The machine must be tested and inspected at least once a year due to its use with hazardous materials. Worn parts must be

replaced. Never risk functionality and service life. Only use genuine parts.

Consumables

For spare parts, see the Dustcontrol website.

DC Tromb, Art.nr. 9480-M 19

ENGLISH

Filter replacement

The fine filter must be replaced at least once a year. Only original filters may be used. HEPA filters must be replaced after

300 hours.

WARNING

Filter replacement may only be performed by trained personnel. Use a protective mask and suitable

equipment.

CAUTION

When replacing the filter, no tools/sharp objects can be used as these may damage the sealing surface of the

filter.

Release and lift off the upper part for free access to the filter. Lift the filter straight up. If appropriate, fit a plastic bag over the

cyclone to prevent the dust in the filter from spreading. Check the gasket when replacing the filter. A worn gasket can allow

hazardous dust to escape. Never use old gaskets or non-OEM parts. Place used filters in a plastic bag and seal the bag. See

instructions below.

1 2 3 4

Motor

The typical service life of a fan motor's original brushes is 600-700 hours. The brush can be replaced. The service life of the

second brush set is approx. 400 hours, while that of the third set is approx. 300 hours. After this time, the motor is considered

worn out and should be replaced.

Overheating

If the machine is at risk of overheating (for example, as a result of powerful throttling), the temperature guard will trip and the

machine will stop. The operator must then press the power switch to the OFF position, unplug from the mains and wait 3-5

minutes for the machine to cool down. Then reset the temperature guard by pressing the RESET button. Reconnect the power

cord to the electrical outlet and restart the machine by pressing the power switch to the ON position.

Regular checks

Regularly check the power cord for damage.

The machine must be tested and inspected at least once a year due to its use with hazardous materials. Worn parts must be

replaced. Never risk functionality and service life. Only use genuine parts.

Consumables

For spare parts, see the Dustcontrol website.

DC Tromb, Art.nr. 9480-M 19

ENGLISH

10

Warranty

The warranty period is two years and covers manufacturing defects. The warranty is valid on condition that the

machine is used in the normal way and receives the required service. Normal wear and tear is not covered. Repairs

must be carried out by American Sanders or personnnel authorized by American Sanders. Otherwise, the warranty is

void.

Troubleshooting

EC Declaration of Conformity

Problem Cause Action

Motor not running Power supply not connected Connect power supply

Motor stops immediately

after starting Incorrect fuse Replace with the correct fuse

Motor runs, but no suction

Suction hose not connected

Suction hose perforated

Blocked lter

Suction hose too long or narrow

Hose partially blocked

Top of machine poorly tted

Dust trapped in cyclone

The pump is rotating in the

wrong direction

Connect hose

Replace hose

Clean or replace

Replace hose

Reverse or clean hose

Adjust tting

Remove top and clean cyclone

Let an electrician change the phase

Motor stops during

operation

Motor overheated Make sure the machine is not throttled and

wait for it to cool down (about 30 min)

Machine blows dust Filter loose or damaged. Check and replace as necessary

Abnormal sound from

machine Book service

11

Notes:

_________________________________

___________________________________

_____________________________________

_____________________________________

_____________________________________

_____________________________________

_____________________________________

_____________________________________

_____________________________________

_____________________________________

_____________________________________

_____________________________________

_____________________________________

_____________________________________

_____________________________________

_____________________________________

_____________________________________

_____________________________________

_____________________________________

_____________________________________

Concrete Vacuum

07242A

Operator’s Manual

12

TO QUALIFY FOR THIS WARRANTY

(1) Machine must be registered at the time of

purchase on a form provided by American

Sanders. Your American Sanders Distributor is

responsible for the registration of your machine.

Please cooperate with your Distributor in supplying

necessary information on the card.

(2) The machine must have been purchased from

American Sanders or an authorized American

Sanders Distributor.

(3) This warranty extends to the original purchaser

only and is not transferable to subsequent owners.

TIME PERIODS

(1) ONE (1) YEAR WARRANTY - For the

DC400L - 07242A.

Warranted to be free from defects in material and

workmanship for a period of one (1) year from

the date of purchase by the original owners. (See

Exclusions)

EXCLUSIONS (Not Covered by Warranty)

(1) Parts that fail through normal wear by reason of

their characteristics (cords, hoses, & etc.).

(2) This warranty does not extend to parts affected by

misuse, neglect, abuse or improper maintenance.

All defective parts must be returned to the

distributor for credit.

THE OBLIGATION OF AMERICAN SANDERS

(1) The obligation of American Sanders under this

warranty is limited to repairing or replacing, at its

option, any part which is proven to be defective in

material or workmanship under normal use for the

applicable period stated above.

(2) Warranty repairs will be made by your American

Sanders Distributor without charge for parts and

labor. They will be compensated with a warranty

labor rate of $45.00 per hour, for the first year of

ownership.

(3) Parts repaired or replaced under this warranty are

warranted only during the balance of the original

warranty period. All defective parts replaced under

these warranties become the property of American

Sanders.

WARRANTY SERVICE

To obtain warranty service, take your machine and

proof of purchase to any authorized American Sanders

Distributor. American Sanders will not reimburse

expenses for service calls or travel. For the Distributor

in your area, call American Sanders Customer Service

Department at 800-367-3550 or 336-372-8080. If you

are dissatisfied with the service that you receive, call or

write American Sanders Customer Service Department

for further assistance.

INSTRUCTIONS AND CONDITIONS FOR WARRANTY

REIMBURSEMENT

l Order replacement part: Orders will be processed

and charged, as normal procedure.

l Call American Sanders for R/A number.

l You will need the Engine Serial Number, Machine

Serial Number, and the Machine Model Number.

l Parts must be returned, accompanied with the

R/A number to be eligible for warranty credit.

l All Warranty Parts will be shipped prepaid

UPS Ground, any other method will be at the

recipients expense.

l Freight on any Warranty Part after 30 days must

be paid for by the Purchaser.

l Warranty labor rate is $45.00 per hour.

l Credit will be issued upon completion of the

above steps, at the above rates.

DISCLAIMER OF CONSEQUENTIAL

AMERICAN SANDERS DISCLAIMS ANY

RESPONSIBILITY FOR LOSS OF USER TIME

OF THE AMERICAN SANDERS MACHINE OR

ANY OTHER INCIDENTAL OR CONSEQUENTIAL

DAMAGE EXCEPT AS STATED IN THE WARRANTY

APPLICABLE TO EACH MACHINE. EXCEPT AS

STATED IN SUCH WARRANTIES, THE COMPANY

DOES NOT OTHERWISE WARRANT ANY MACHINE

AND NO WARRANTY, EXPRESS, IMPLIED OR

STATUTORY IS MADE BY THE COMPANY.

© 2021 American Sanders

Limited Warranty

DC400L - 07242A

LT073900_H; 081419

13

PARA CALIFICAR PARA ESTA GARANTÍA

(1) El equipo debe registrarse en el momento de

la compra en un formulario proporcionado por

American Sanders. Su distribuidor American

Sanders es responsable del registro de su

equipo. Coopere con su distribuidor brindando la

información necesaria en la tarjeta.

(2) El equipo debe haberse comprado en American

Sanders o con un distribuidor autorizado de

American Sanders.

(3) Esta garantía se extiende al comprador original

solamente y no se puede transferir a otros

propietarios.

PERÍODOS DE TIEMPO

(1) GARANTÍA DE UN (1) AÑO: Para el

DC400L - 07242A.

Garantizado por estar libres de defectos en

material y mano de obra por un período de un (1)

año a partir de la fecha de compra por parte de los

propietarios originales. (Consulte Exclusiones)

EXCLUSIONES (No cubiertas por la garantía)

(1) Piezas que fallan debido al desgaste normal por

sus características (cordones, mangueras, etc.).

(2) Esta garantía no se extiende a partes afectadas

por mal uso, negligencia, abuso o mantenimiento

incorrecto. Todas las partes defectuosas se deben

devolver al distribuidor para recibir un crédito.

LA OBLIGACIÓN DE AMERICAN SANDERS

(1) La obligación de American Sanders bajo esta

garantía se limita a la reparación o reemplazo, a

su elección, de cualquier parte que se compruebe

tiene defectos de material o mano de obra durante

el uso normal por el período aplicable antes

mencionado.

(2) El distribuidor de American Sanders realizará las

reparaciones de garantía sin cargo por piezas y

mano de obra. Ellos recibirán una compensación

con una tarifa de mano de obra de garantía de

$45.00 por hora, por el primer año de propiedad.

(3) Las partes reparadas o reemplazadas bajo esta

garantía están cubiertas por la garantía solo

durante el resto del período de la garantía original.

Todas las partes defectuosas reemplazadas bajo

estas garantías se convierten en propiedad de

American Sanders.

SERVICIOS DE GARANTÍA

Para obtener servicio de garantía, lleve su equipo y

prueba de compra a cualquier distribuidor autorizado

de American Sanders. American Sanders no

reembolsará los gastos por las llamadas o viajes para

el servicio. Para el Distribuidor en su área, llame al

Departamento de Servicio al Cliente de American

Sanders al 800-367-3550 o al 336-372-8080. Si no

está satisfecho con el servicio que recibe, llame o

escriba al Departamento de Servicio al Cliente de

American Sanders para recibir más ayuda.

INSTRUCCIONES Y CONDICIONES PARA EL

REEMBOLSO DE GARANTÍA

l Pida la pieza de reemplazo: Los pedidos se

procesarán y cobrarán, como un procedimiento

normal.

l Llame a American Sanders para obtener el

número de R/A.

l Necesitará el número de serie del motor, número

de serie del equipo y número de modelo del

equipo.

l Las piezas se deben devolver, acompañadas

con el número de R/A para ser elegible para el

crédito por la garantía.

l Todas las piezas de garantía se deberán

enviar prepagadas por servicio terrestre de

UPS, cualquier otro método será a costa del

beneficiario.

l El Comprador debe pagar el flete para cualquier

pieza de la garantía después de 30 días.

l La tarifa de mano de obra de la garantía es de

$45.00 por hora.

l El crédito se emitirá al completar los pasos

anteriores, en las tarifas anteriores.

DESCARGO DE RESPONSABILIDAD DE DAÑOS

Y PERJUICIOS

AMERICAN SANDERS SE LIBERA DE

RESPONSABILIDAD POR LA PÉRDIDA DEL

TIEMPO DEL USUARIO DEL EQUIPO AMERICAN

SANDERS O POR CUALQUIER OTRO DAÑO

INCIDENTAL O CONSECUENCIAL, EXCEPTO POR

LO ESTABLECIDO EN LA GARANTÍA APLICABLE

A CADA EQUIPO. EXCEPTO COMO SE INDICA EN

TALES GARANTÍAS, LA COMPAÑÍA NO GARANTIZA

DE OTRA MANERA CUALQUIER EQUIPO Y LA

COMPAÑÍA NO OTORGA NINGUNA GARANTÍA,

EXPRESA, IMPLÍCITA O LEGAL.

© 2021 American Sanders

Garantía limitada

DC400L - 07242A

LT073900_H; 081419

14

POUR ÊTRE ADMISSIBLE À LA PRÉSENTE

GARANTIE

(1) L’appareil doit être inscrit au moment de l’achat à

l’aide de la fiche fournie par American Sanders.

L’enregistrement de votre appareil s’effectue

auprès de votre distributeur American Sanders.

Veuillez lui fournir tous les renseignements exigés

sur la fiche.

(2) L’appareil doit avoir été acheté auprès d’American

Sanders ou d’un distributeur American Sanders

autorisé.

(3) La présente garantie n’est offerte qu’à l’acheteur

initial et n’est pas transférable aux propriétaires

subséquents.

PÉRIODES

(1) GARANTIE D’UN (1) AN — Pour le modèle

DC400L - 07242A.

Garanti contre tout défaut de matériaux et de main-

d’œuvre pour une période d’un (1) an à compter

de la date d’achat par le propriétaire initial. (Se

reporter aux exclusions.)

EXCLUSIONS (non couvertes par la garantie)

(1) Les pièces qui font défaut par suite d’une usure

normale en raison de leurs caractéristiques

(cordons, tuyaux, etc.).

(2) Cette garantie ne couvre pas les pièces affectées

par une mauvaise utilisation, des abus, de la

négligence et un entretien inadéquat. Vous devez

retourner les pièces défectueuses au distributeur

pour vous les faire créditer.

LES OBLIGATIONS D’AMERICAN SANDERS

(1) Les obligations d’American Sanders en vertu de

cette garantie se limitent à la réparation ou au

remplacement, à sa discrétion, de toute pièce

présentant un défaut avéré de matériaux ou de

main-d’œuvre dans le cadre d’une utilisation

normale pour la période applicable énoncée

plus haut.

(2) Les réparations sous garantie seront effectuées

par votre distributeur American Sanders sans frais

pour les pièces et la main-d’œuvre. Ce dernier

sera rémunéré au taux de main-d’œuvre de

45,00 $/h pour la première année de possession.

(3) Les pièces réparées ou remplacées en vertu de

cette garantie sont garanties seulement durant

la période restante de la période de garantie

originale. Toutes les pièces défectueuses

remplacées en vertu de ces garanties deviennent

la propriété d’American Sanders.

SERVICE SOUS GARANTIE

Pour obtenir du service sous garantie, apportez votre

appareil et une preuve d’achat chez un distributeur

American Sanders autorisé. American Sanders ne

remboursera pas de frais engagés en lien avec

des appels de service ou des déplacements. Pour

connaître le distributeur de votre région, communiquez

avec le service à la clientèle d’American Sanders au

800 367-3550 ou au 336 372-8080. Si vous n’êtes pas

satisfait du service reçu, communiquez avec le service

à la clientèle d’American Sanders pour obtenir de

l’aide.

INSTRUCTIONS ET CONDITIONS POUR

L’OBTENTION D’UN REMBOURSEMENT SOUS

GARANTIE

l Commande de pièce de rechange : Les

commandes sont traitées et facturées comme

toute procédure normale.

l Communiquez avec American Sanders pour

obtenir un numéro d’autorisation de renvoi.

l Vous aurez besoin du numéro de série du

moteur, du numéro de série de la machine et du

numéro de modèle de la machine.

l Vous devez joindre le numéro d’autorisation de

renvoi aux pièces renvoyées pour être admissible

au crédit en vertu de la garantie.

l Toutes les pièces sous garantie sont expédiées

UPS Ground prépayé; tout autre moyen

d’expédition est au frais du destinataire.

l Le transport de toute pièce sous garantie après

30 jours doit être payé par l’acheteur.

l Le taux de main-d’œuvre sous garantie est de

45,00 $/h.

l Le crédit est émis une fois toutes les étapes

précédentes terminées, aux tarifs précités.

AVIS DE NON-RESPONSABILITÉ POUR LES

DOMMAGES INDIRECTS

AMERICAN SANDERS SE DÉGAGE DE TOUTE

RESPONSABILITÉ À L’ÉGARD DU TEMPS

D’UTILISATION DE L’APPAREIL AMERICAN

SANDERS PERDU ET DE TOUT AUTRE DOMMAGE

ACCESSOIRE OU CONSÉCUTIF, À L’EXCEPTION

DE CE QUI EST ÉNONCÉ DANS LA GARANTIE

QUI S’APPLIQUE À LA MACHINE. À L’EXCEPTION

DE CE QUI EST ÉNONCÉ DANS DE TELLES

GARANTIES, L’ENTREPRISE NE GARANTIT PAS

AUTREMENT TOUTE MACHINE ET AUCUNE

GARANTIE EXPRESSE, IMPLICITE OU STATUTAIRE

N’EST DÉLIVRÉE PAR L’ENTREPRISE.

© 2021 American Sanders

Garantie limitée

DC400L - 07242A

LT073900_H; 081419

American Sanders

an AMANO Company

1 Eclipse Rd lPO Box 909

Sparta, North Carolina 28675 lUSA

www.pioneereclipse.com

www.americansanders.com

+1-336-372-8080

1-800-367-3550

Fax 1-336-372-2913

© 2021 American Sanders

LT07242A

080321_A

Table of contents

Other Amano Vacuum Cleaner manuals

Popular Vacuum Cleaner manuals by other brands

Hoover

Hoover 7011PH Allergy manual

Sandia Plastics

Sandia Plastics Sniper 2-100 Specifications

Tacony

Tacony TRUVOX INTERNATIONAL Valet Single Motor... user manual

Montgomery Ward

Montgomery Ward 772975 instruction manual

DS Produkte

DS Produkte PC-P003WH instruction manual

Panasonic

Panasonic Quickdraw MC-V7312 operating instructions