The Classic Teat Spray System is designed exclusively for use in

milking installations. Any application outside the use described

in this operating manual will be taken to be not in accordance

with the intended purpose. The manufacturer/supplier will not

be held responsible for any losses arising as a result of such use.

The user will take full responsibility for use. USE IN

ACCORDANCE WITH THE INTENDED PURPOSE ALSO

INCLUDES COMPLYING WITH THE OPERATING MANUAL AND

THE CONDITIONS FOR INSPECTION AND MAINTENANCE.

A

AT

TT

TE

EN

NT

TI

IO

ON

N!

!Whilst in operation the installation is under an

operating pressure of 3 to 4 bar!

Do not spray dip into your eyes! If you do, rinse with copious

amounts of water and seek medical attention!

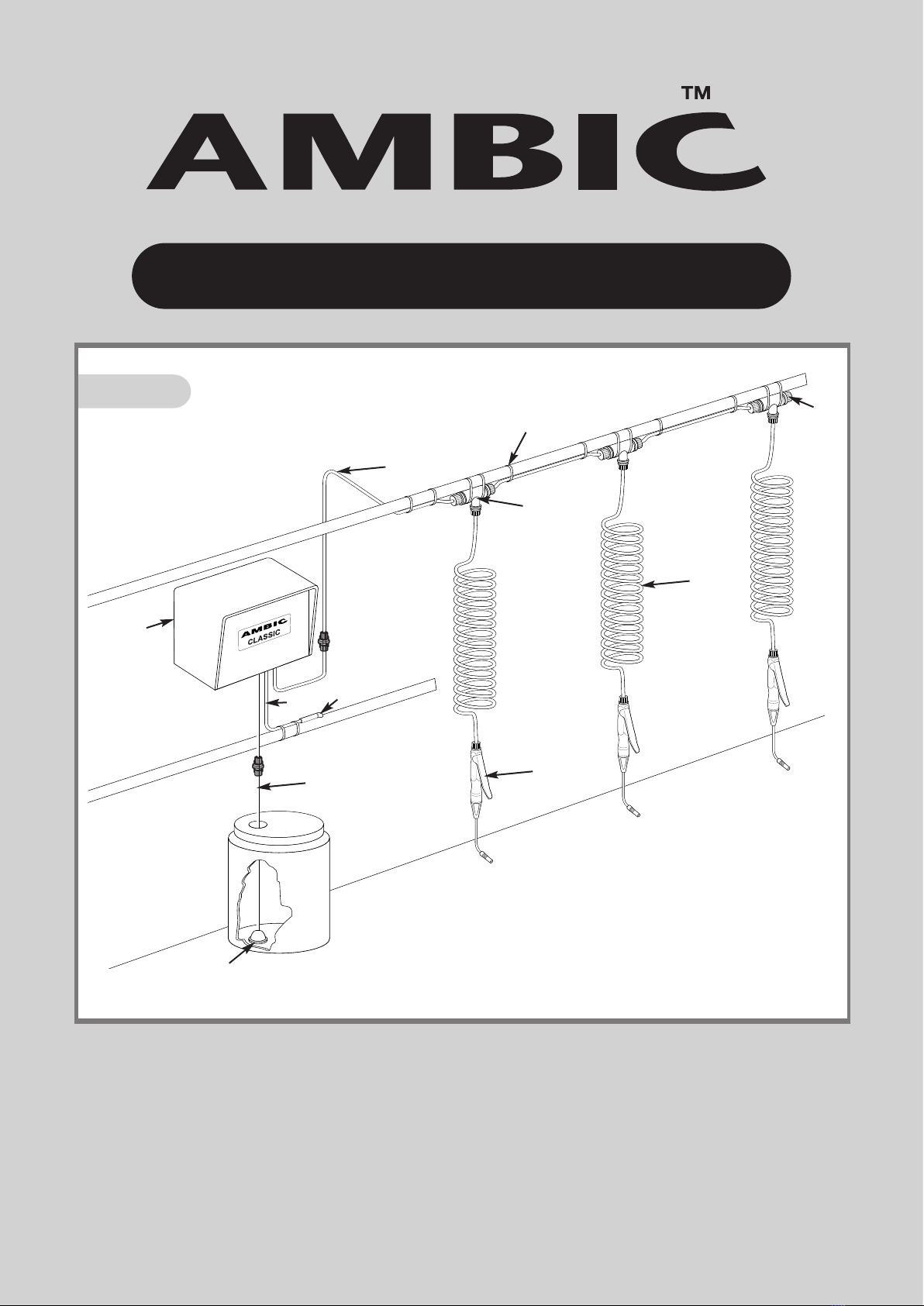

For general parlour layout refer to Fig. 1.

Position Power Unit (A) not more than 2 metres (6ft) above the

base of the Chemical Container, preferably in a dust free

environment, close to a regulated Vacuum Line.

Screw white bracket to wall securely using 3 x screws and wall

plugs supplied. Attach the Power Unit (A) ensuring that the

hooks properly engage the rectangular holes in the back plate.

V

VA

AC

CU

UU

UM

MS

SU

UP

PP

PL

LY

YDrill a 10mm Ø (3/8”Ø) hole in the top of

a regulated main vacuum line (FIG. 3). Remove burrs, lubricate

Pipe Adapter (B) and twist into hole.

Secure Tube (E) with Cable Ties (K). Do not over-tighten and

avoid sharp bends. Cut tube to correct length or leave loosely

coiled.

C

CH

HE

EM

MI

IC

CA

AL

LI

IN

NT

TA

AK

KE

ERemove the nut and end of line plug

from the straight connector on the liquid intake tubing

(FIG. 2 C). Place container of chemical in position and insert

tube fitted with the filter so that the filter (D) rests on the

bottom of the Chemical Container.

Insert tube through nut, warm end of tube to ease assembly

and push fully onto inlet straight connector (Fig2 C). Tighten

nut firmly with fingers. Do not use pliers or other tools. This

method (FIG. 5) should be used when connecting all such

fittings on Classic.

P

PR

RE

ES

SS

SU

UR

RE

EL

LI

IN

NE

ERemove the end of line plug from the straight

connector (FIG. 2 F) on the pressure line and attach one end of

the coil of transparent tubing. Retain plug to seal last ‘T’

connector. Determine position of ‘T’s (G) and strap loosely to a

suitable support (FIG. 4). Cut suitable lengths of Tubing (F)

strapping and connecting to ‘T’s (G) and outlet straight

connector. Attach Coils (I) and Guns (H) (FIG. 6). Seal open

end of last ‘T’ with Blanking Plug (J) and Nut.

Finally, once positions are correct, fully tighten Cable Ties. Do

not over-tighten on tubing and avoid sharp bends.

When installation is complete, turn on Vacuum Pump. Power

Unit will automatically start, reaching full pressure within 1

minute.

There will be some air in the system. To expend this, hold each

gun vertically above the Delivery Line at arms length pointing

away from face. Press gun lever until air bubbles are no longer

apparent.

Classic is suitable for use with any recognised Teat Disinfectant

Spray except Sodium Hypochlorite and Peroxyacetic Acid.

When using concentrates, ensure that the manufacturers

instructions are followed. Agitation may, periodically, be

required.

Important: Replenish disinfectant supply before it runs out to

prevent air entering the system.

S

SP

PR

RA

AY

YI

IN

NG

GFor effective Mastitis Pathogen control the teats

must be completely covered with disinfectant. On adjustable

nozzle guns rotate nozzle to achieve correct spray pattern

(FIG. 11). Fixed cone nozzles (as on AJS/502) do not require

adjustment.

The nozzle should ideally be positioned approximately 15cm

(6”) below the teats. Optimum and economical coverage is

achieved by employing a circular movement (FIG. 12 & 13).

Application time will differ between cows; however, on average

should be approximately 1 second per cow.

E

EN

ND

DO

OF

FM

MI

IL

LK

KI

IN

NG

Gwhen the main Vacuum Supply is turned off,

the Power Unit automatically returns pressurised disinfectant to

the Chemical Container. This ensures immediate safety and

also flushes any debris from the Intake Filter (D).

W

Wo

or

rk

ki

in

ng

go

on

nt

th

he

eP

Po

ow

we

er

rU

Un

ni

it

tTurn off and disconnect vacuum

supply and ensure that unit is depressurized BEFORE

disconnecting any tubing, by opening/disconnecting one or

more guns. Remove the Power Unit to a safe and convenient

working surface. Remove the case by undoing the four

retaining screws.

D

DI

IR

RE

EC

CT

TI

IO

ON

NA

AL

LV

VA

AL

LV

VE

EA

AT

TS

S/

/4

42

25

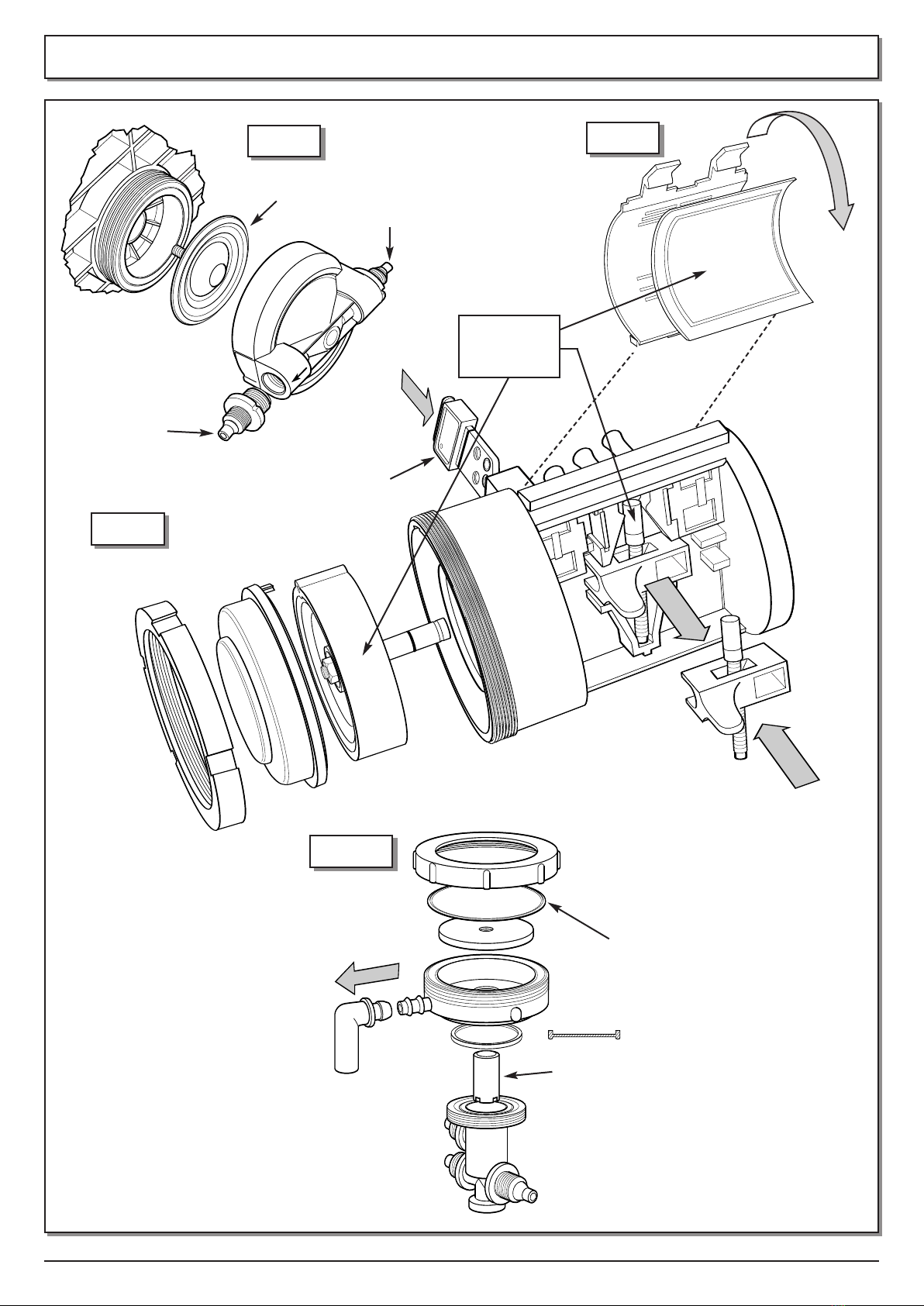

5The Directional Valve (FIG. 2

ATS/425) is mounted at the top right hand side of the Power

Unit: this directs vacuum to the Diaphragm Pump. Spare parts

are contained in Service Kit ATS/448.

Complete Replacement

Unscrew the two retaining screws from the back plate and

carefully remove the three vacuum tubes. Warming and noting

their order will assist removal and fitting. Refitting is a reversal

of removal.

V

VA

AL

LV

VE

EF

FI

IL

LT

TE

ER

R(ATS/444) Replace every 1000 hours or sooner

if heavily contaminated. Manually release Filter Cover Clips by

levering with fingers (FIG. 8). Carefully remove Filter taking

care not to drop dust into the working parts. Fit new Filter by

reversing the process.

B

BL

LE

EE

ED

DI

IN

NS

SE

ER

RT

TA

AT

TS

S/

/4

44

47

7Pull out of main body taking care not

to dislodge the 4 ‘O’ Rings. Inspect two small holes near the

end (FIG. 9) and clean every 1000 hours, or sooner if heavily

contaminated, using strand of wire attached to bleed insert.

D

DI

IA

AP

PH

HR

RA

AG

GM

MA

AS

SS

SE

EM

MB

BL

LY

Y(ATS/443) Replace, using ATS/448,

every 3000 hours. First remove Valve Filter (see above). Pull

Drive Box in direction of Arrow (FIG 9) using pliers on Lug.

Remove Spring (ATS/442). Unscrew large black ring nut, gently

prise off red cap, using a screwdriver in slot provided. Pull out

rubber Diaphragm by grasping outer rim. Replace Spring at

same time as Diaphragm replaced.

Fit new Diaphragm Assembly ATS/443 by reversing the

operation, taking care not to remove the pre-lubrication on the

shaft and ensuring that the semi circular location engages in

the recess on the main body. When replacing the Drive Box

push hard until a click is heard indicating proper engagement.

Prior to fitting the Filter and Cover, push Drive Box from end to

end. An audible click should be heard, indicating proper

operation.

D

DI

IA

AP

PH

HR

RA

AG

GM

MP

PU

UM

MP

PA

AT

TS

S/

/4

42

26

6The pump is located on the left

of the Power Unit ATS/426 (FIG. 2). It needs no maintenance

but, in the rare event of failure, it is easily removed by gently

pulling the pump from the two plastic retaining clips on the

base. Unscrew 4 Nuts, on the Pump Head, ATS/445 and

ATS/446 (FIG. 7), warm tube ends and pull off gently, noting

their positions. Replacement of the small pump diaphragms

4

9. OPERATION

6. SAFETY

10. MAINTENANCE

8. INITIAL START UP

7. INSTALLATION