AMC-210 Transmitter with external electrochemical sensor

1

TABLE OF CONTENTS

Section Title Page

1WARRANTY.............................................................................................................3

1.1 LIABILITY...........................................................................................................3

1.2 PRODUCT RETURN .........................................................................................3

1.3 MODIFICATIONS AND SUBSTITUTIONS.........................................................3

2PRODUCT INFORMATION......................................................................................4

2.1 SENSOR/TRANSMITTER..................................................................................4

2.2 FACTORY CALIBRATION.................................................................................4

3PRODUCT DESCRIPTION ......................................................................................5

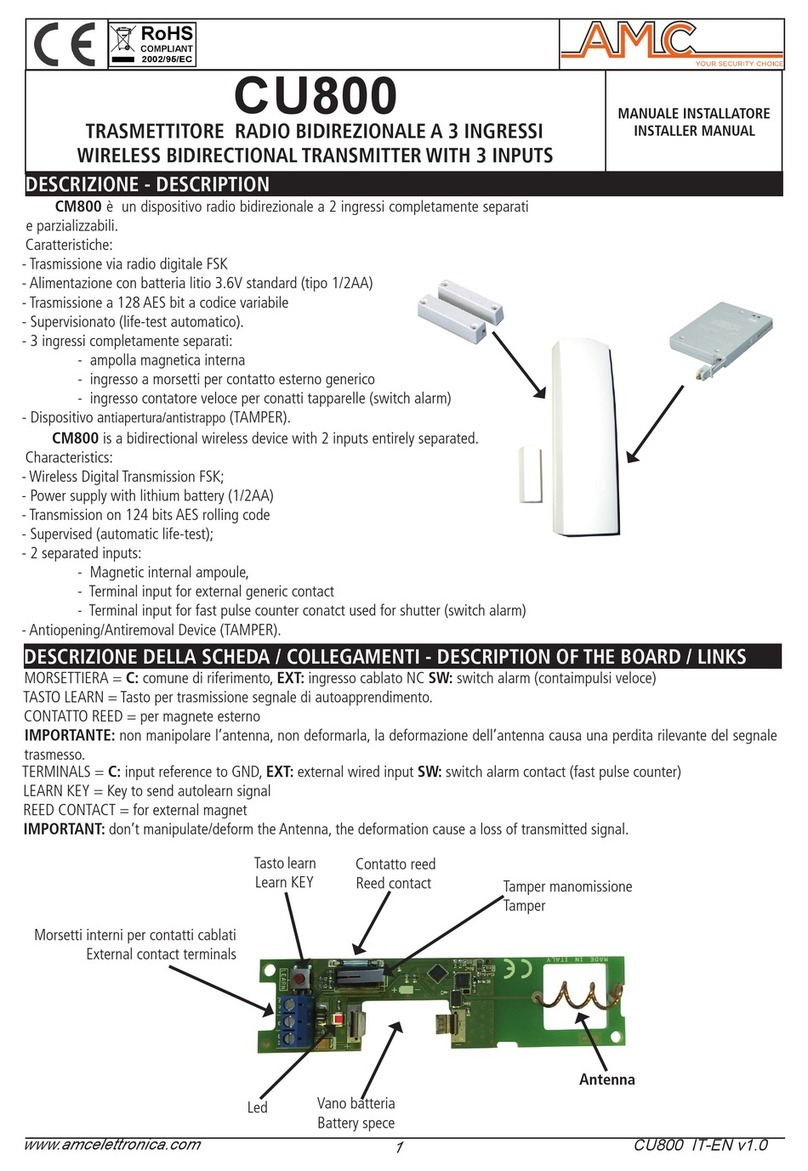

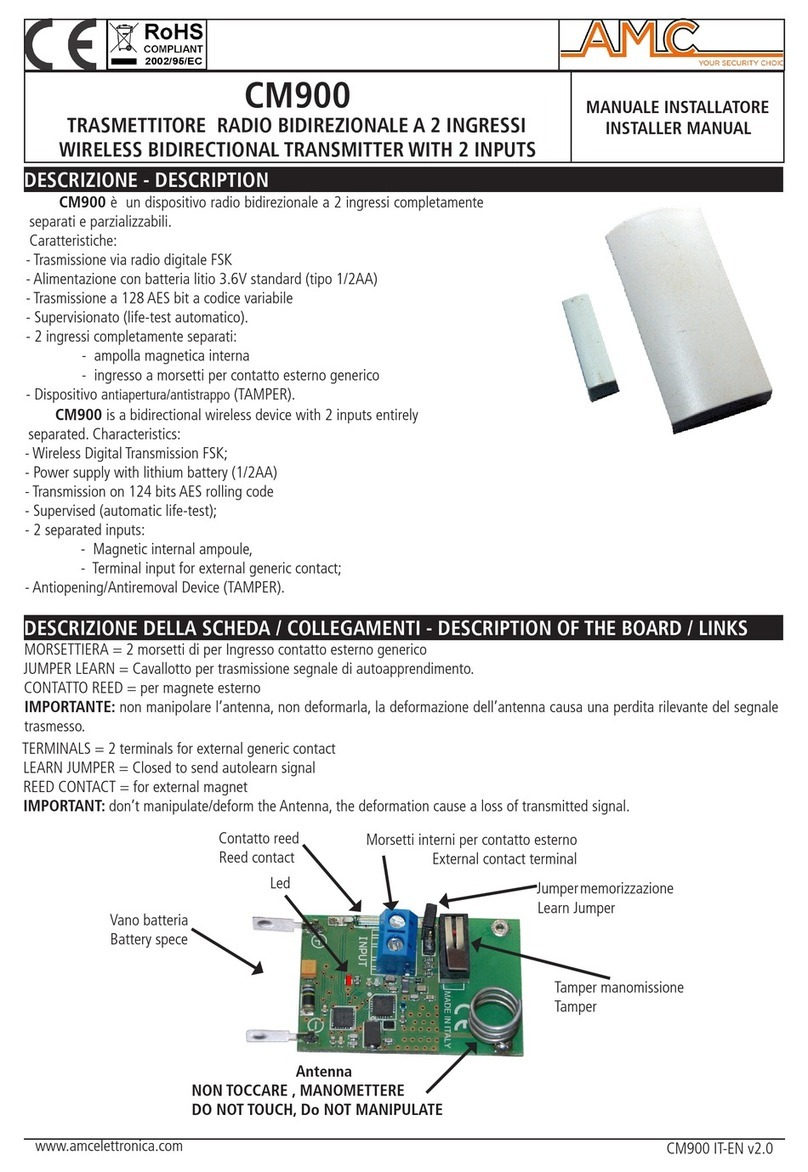

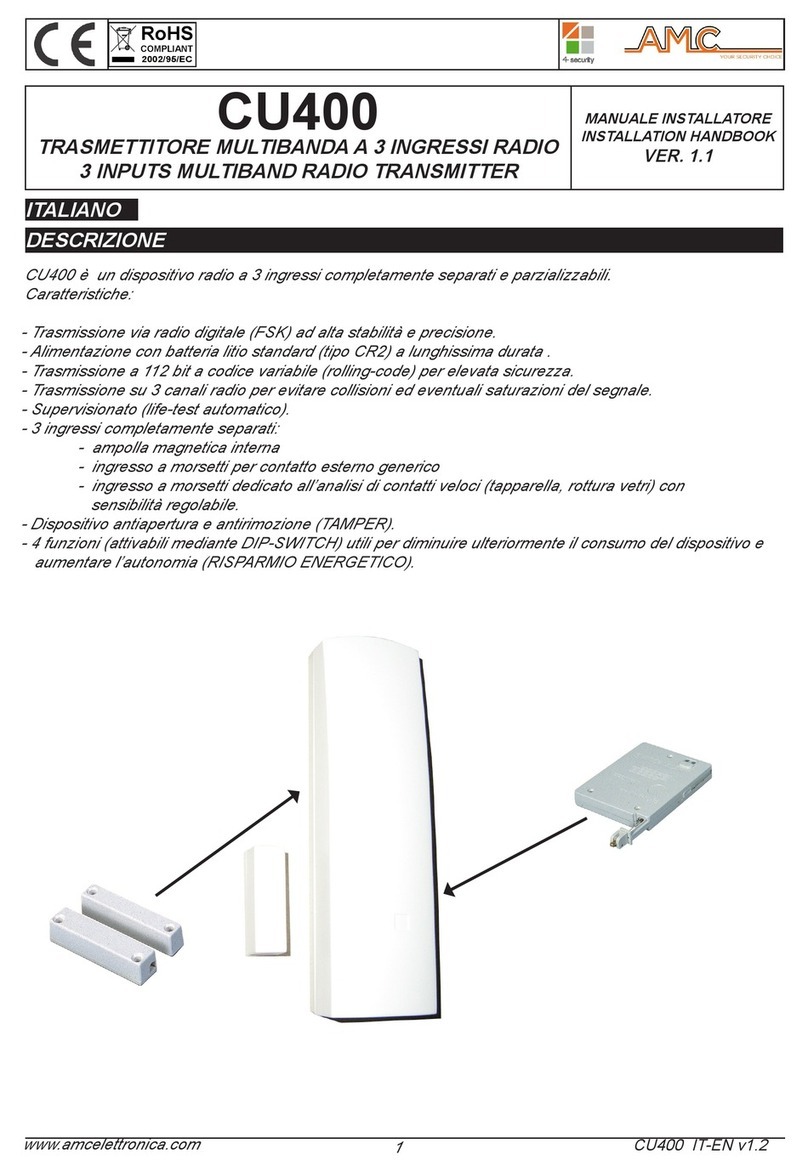

3.1 GENERAL DESCRIPTION.................................................................................5

3.1.1 SENSOR / TRANSMITTER SPECIFICATIONS......................................................5

3.2 HOUSING OPTIONS.........................................................................................6

4INSTALLATION .......................................................................................................7

4.1 LOCATION AND MOUNTING............................................................................7

4.2 CABLE SELECTION AND WIRING...................................................................8

4.2.1 TRANSMITTER TO MONITOR WIRING...............................................................10

4.2.2 INTERFACING TO COMPUTER, DATALOGGER, OR NON-AMC MONITOR....11

5OPERATION AND CALIBRATION........................................................................12

5.1 OPERATION....................................................................................................12

5.2 CALIBRATION.................................................................................................12

5.2.1 EQUIPMENT REQUIRED.....................................................................................13

5.2.2 TRANSMITTER CALIBRATION/VERIFICATION SET-UP PROCEDURE............13

5.2.3 RECALIBRATION .................................................................................................14

6PREVENTIVE MAINTENANCE..............................................................................15

6.1 GENERAL........................................................................................................15

6.2 VERIFICATION OF OPERATION....................................................................15

6.3 SENSOR REPLACEMENT..............................................................................15

7ADDENDUM (FOR OXYGEN ONLY).....................................................................17