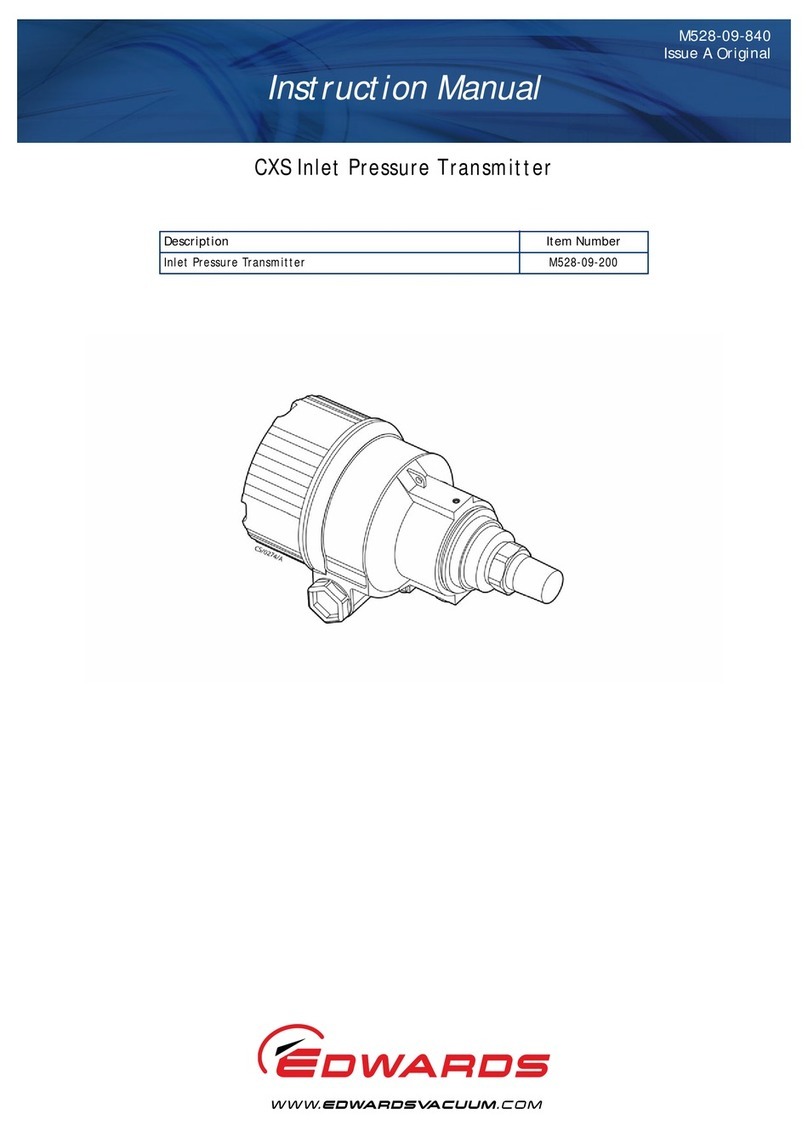

Edwards CXS User manual

M528-00-840

Issue A Original

Instruction Manual

CXS Exhaust Temperature Transmitter

Description Item Number

CXS Exhaust Temperature Transmitter M528-09-280

This page has been intentionally left blank.

© Edwards Limited 2013. All rights reserved. Page i

Edwards and the Edwards logo are trademarks of Edwards Limited.

Contents

M528-00-840 Issue A

Contents

Section Page

1 Introduction ....................................................................................... 1

1.1 Scope and definitions ................................................................................................... 1

1.2 Description ................................................................................................................ 1

1.2.1 Operational information ................................................................................................ 1

2 Installation ......................................................................................... 3

2.1 Installation safety ....................................................................................................... 3

2.2 Exhaust temperature transmitter installation ....................................................................... 3

2.3 Exhaust temperature transmitter set-up ............................................................................. 6

3 Operation .......................................................................................... 7

3.1 Exhaust temperature display .......................................................................................... 7

4 Maintenance ....................................................................................... 8

For return of equipment, complete the HS Forms at the end of this manual.

Illustrations

Figure Page

1 Assembly .................................................................................................................. 2

2 Pump underside showing temperature transmitter, cable routing and tie wrap positions ................... 2

3 Exhaust and plug location .............................................................................................. 4

4 Temperature transmitter electrical connection showing terminals 1 and 2 .................................... 5

5 Connector bulkhead connections 2 and 8 ............................................................................ 5

6 Pump Display Terminal (PDT) .......................................................................................... 6

Associated Publications

CXS Dry Pumps Instruction Manual M528-00-880

Technical Information (Endress+Hauser Instruments International) Omnigrad M TR10

TI00256ten_0111

CXS_EH Combination Systems Instruction Manual M518-00-880

cg/09/13

This page has been intentionally left blank.

M528-00-840 Issue A

Page ii © Edwards Limited 2013. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

© Edwards Limited 2013. All rights reserved. Page 1

Edwards and the Edwards logo are trademarks of Edwards Limited.

Introduction

M528-00-840 Issue A

1Introduction

1.1 Scope and definitions

This manual provides installation, operation and maintenance instructions for the Edwards exhaust temperature

transmitter accessory. The temperature transmitter must be used as specified in this manual. Read this manual

before installing and operating the temperature transmitter.

Important safety information is highlighted as WARNING and CAUTION instructions; these instructions must be

obeyed. The use of WARNINGS and CAUTIONS is defined below.

CAUTION

Cautions are given where failure to observe the instruction could result in damage to the equipment, associated

equipment and process.

1.2 Description

1.2.1 Operational information

The CXS Exhaust temperature transmitter accessory comprises an Endress and Hauser Ex ia temperature transmitter

and a kit of parts to enable connection to the CXS dry pump. Once connected and set-up, it is possible to display

exhaust gas temperatures on a Pump Display Terminal (PDT). Alternatively, the temperature transmitter can be

connected directly to an independent control system using suitable wiring and intrinsic safety barriers (not supplied)

suitable for the instrument and environment.

The PDT (part number D372-80-700) is available as an accessory and must be used for installation configuration.

Pack contents:

Temperature transmitter TR10-GBA8CDR2H200E

Cable M52809281

Gland RS 444-2931 REF 5311 1510

Gland locknut LAPP 53119013

Tie wraps (not shown) KAT. C. 460194

Edwards instruction manual M52800840

Endress and Hauser TR10 instruction manual

WARNING

Warnings are given where failure to observe the instruction could result in injury or death to

people.

M528-00-840 Issue A

Page 2 © Edwards Limited 2013. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Introduction

Figure 1 - Assembly

Figure 2 - Pump underside showing temperature transmitter, cable routing and tie wrap positions

The cable connects the temperature transmitter to the interface connector on the connector bulkhead.

The transmitter is an intrinsically safe instrument and complies with the wiring requirements of EN60069-11 and -14.

1 Temperature transmitter and cable

Note: Front bulkhead removed for clarity.

1 Temperature transmitter

2Cablegland

3 Cable gland locknut

4 Cable assembly

© Edwards Limited 2013. All rights reserved. Page 3

Edwards and the Edwards logo are trademarks of Edwards Limited.

Installation

M528-00-840 Issue A

2 Installation

2.1 Installation safety

2.2 Exhaust temperature transmitter installation

For connection to the control system of the CXS dry pump, follow all steps. If the temperature transmitter is to be

connected to an independent control system, only the mechanical installation steps should be followed and steps 6-

14 should be ignored.

If the pump has previously been run on process, perform the following steps:

1. Allow the pump system to cool to a safe temperature before starting maintenance work.

2. Vent and purge the dry pumping system before starting any installation or maintenance work.

3. Isolate the dry pumping system and other components in the process system from the electrical supply to

prevent accidental operation.

Note: The emergency stop switch on the dry pumping system is not an electrical isolator.

WARNING

The exhaust should only be opened when the pump is switched off, isolated from the electrical

supply and in the absence of explosive atmosphere.

WARNING

The surfaces of the inlet can be very hot when the CXS system is running. Surfaces should be

allowed to cool to a safe temperature before installing the pressure transmitter.

WARNING

Ensure that the pump is purged and isolate the inlet and exhaust before installation or

replacement.

WARNING

Leak test the system after installation and seal leaks to prevent leakage of dangerous substances

out and leakage of air into the system.

WARNING

Use appropriate personal protective equipment.

Personal protective equipment should be checked and used as specified by the supplier. Hazardous

chemicals that have been pumped are located within the pumps and piping. Edwards recommends

the use of suitable protective gloves and clothing along with a respirator if contact with substances

is anticipated. Particular caution should be exercised when working with fluorinated materials

which may have been exposed to temperatures greater than 260°C. Refer to Edwards Material

Safety Data Sheets for detailed information.

M528-00-840 Issue A

Page 4 © Edwards Limited 2013. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Installation

Figure 3 - Exhaust and plug location

4. Remove the plug from the exhaust assembly.

5. Coat the thread of the transmitter with Loctite®577 thread sealant or equivalent suitable for the process. Insert

into the exhaust port pipe and secure with the correct size spanners, ensuring a gas tight seal.

6. Plug the temperature transmitter loom into position 8 (default) or 2 (Refer to Figure 5) depending on which

connection is required (See Section 2.3).

7. Attach the cable gland and its associated lock-nut (Figure 1, items 2 and 3) to the frame as shown in Figure 2.

8. Route the cable as shown in Figure 2 and pass through the gland.

9. Loosely position the cable to the attach points with tie wraps.

10. Ensure the cable glands are fitted but remain loose on the frame and the PT100 temperature transmitter.

11. Continue to route the cable and push through the gland into the PT100 temperature transmitter.

12. Using the minimum bend possible, route the cable into the top of the temperature transmitter as shown in

Figure 4 and secure to terminals 1 (+ve) and 2 (-ve) when plugged into position 8.

Note: If the transmitter is plugged into connection 2 (Figure 5) then the connections to terminals 1 and 2

(Figure 4) must be reversed.

13. Tighten the glands and tie wraps. The tie wraps should be trimmed ensuring no sharp edges protrude.

14. Test the unit according to the instructions in this manual.

1Plug

© Edwards Limited 2013. All rights reserved. Page 5

Edwards and the Edwards logo are trademarks of Edwards Limited.

Installation

M528-00-840 Issue A

Figure 4 - Temperature transmitter electrical connection showing terminals 1 and 2

Figure 5 - Connector bulkhead connections 2 and 8

Note: Front bulkhead removed for clarity.

1Terminals1(+ve)

2 Terminals 2 (-ve)

1 Bulkhead connector 2

2 Bulkhead connector 8

M528-00-840 Issue A

Page 6 © Edwards Limited 2013. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Installation

2.3 Exhaust temperature transmitter set-up

CAUTION

Configuration changes made using the PDT should be performed with the pump not running. It is recommended

that the CXS dry pump is then power-cycled following configuration changes.

The Pump Display Terminal (PDT) must be used to configure the exhaust temperature transmitter. The PDT must be

connected and used in accordance with the instructions in the CXS instruction manual M528-00-880.

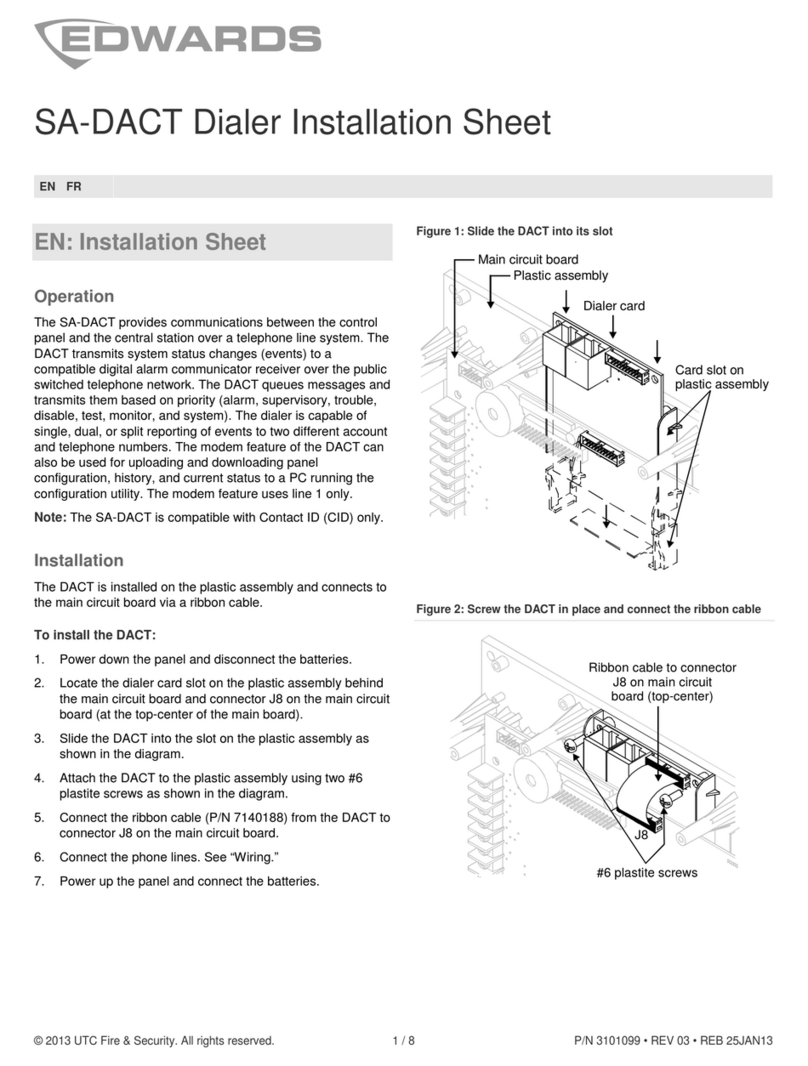

Figure 6 - Pump Display Terminal (PDT)

The PDT should be plugged in and the pump switched on. When the PDT is powered up, select and set the transmitter

accessory options as follows:

1. Press 'setup' - scroll using arrow keys to 'Service'.

2. Scroll to 'fit accessory'.

3. If loom is connected to ' Bulkhead Connector 8' then scroll to transmitter (PT100 1) and select 'fitted' using arrow

keys and press 'enter'.

4. If loom is connected to 'Bulkhead Connector 2' then scroll to transmitter PT100 2 and select 'fitted' using arrow

keys and press 'enter'.

5. To exit the menu press the 'cancel' key three times where the indicator lights will revert to the initial menu.

WARNING

The PDT is a non-Ex device, suitable for use in a hazardous area. It must be connected using a

suitable cable according to EN60079-14 and routed into the safe area.

WARNING

The test/diagnostics port on the Ex d control box door is intended for connection to a PDT for

commissioning, service and diagnostic purposes, only when:

- the CXS dry pump is installed in a safe area, or if safety within the hazardous area can be

guaranteed, for example by the use of a suitable gas detector to ensure the absence of any

explosive atmosphere.

After the PDT socket has been used, the explosion-proof stopping-plug must be refitted. Check the

condition of the threads and O-ring, tighten hand-tight then a further half turn with a wrench.

Incorrect use of the PDT socket and PDT will invalidate the explosion-proof rating of the CXS dry

pump and may result in an explosion in the hazardous area.

© Edwards Limited 2013. All rights reserved. Page 7

Edwards and the Edwards logo are trademarks of Edwards Limited.

Operation

M528-00-840 Issue A

3 Operation

3.1 Exhaust temperature display

Exhaust temperature can be displayed on the PDT (if fitted) after correct installation.

M528-00-840 Issue A

Page 8 © Edwards Limited 2013. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Maintenance

4Maintenance

The wiring should be checked at regular intervals. If damage is found it should be rectified immediately.

Refer to the manufacturer's instruction manual for maintenance of the inlet temperature transmitter.

This page has been intentionally left blank.

This page has been intentionally left blank.

Return the equipment or components for service

Before you send your equipment to us for service or for any other reason, you must send us a

completed Declaration of Contamination of Vacuum Equipment and Components – Form HS2. The

HS2 form tells us if any substances found in the equipment are hazardous, which is important for

the safety of our employees and all other people involved in the service of your equipment. The

hazard information also lets us select the correct procedures to service your equipment.

We provide instructions for completing the form in the Declaration of Contamination of Vacuum

equipment and Components – Procedure HS1.

If you are returning a vacuum pump, note the following:

If a pump is configured to suit the application, make a record of the configuration before

returning the pump. All replacement pumps will be supplied with default factory settings.

Do not return a pump with accessories fitted. Remove all accessories and retain them for

future use.

The instruction in the returns procedure to drain all fluids does not apply to the lubricant in

pump oil reservoirs.

Download the latest documents from www.edwardsvacuum.com/HSForms/, follow the procedure in

HS1, fill in the electronic HS2 form, print it, sign it, and return the signed copy to Edwards.

Note: If we do not receive a completed HS2 form, we will not accept the return of the

equipment.

P80081000, Issue A

P800‐80‐000IssueT

edwardsvacuum.com

Other manuals for CXS

1

This manual suits for next models

1

Table of contents

Other Edwards Transmitter manuals

Popular Transmitter manuals by other brands

NIVELCO

NIVELCO PiloTREK 2-wire Installation and programming manual

Endress+Hauser

Endress+Hauser smartgrad TMD833 Installation and operation manual

Comet

Comet W0810P Quick start manual

Emerson

Emerson PT5N Series Operating instruction

Vega

Vega VEGABAR 82 Quick setup guide

Minebea Intec

Minebea Intec MP 26/10 Installation and Calibration Manual