20 Gear Drive, Plymouth Ind. Park, Terryville, CT 06786

Tel: (860) 585-1254 Fax: (860) 584-1973 http://www.amci.com 3

TABLE OF CONTENTS

General Information

Important User Information ..................... 2

Standard Warranty ................................... 2

Returns Policy .......................................... 2

24 Hour Technical Support Number ........ 2

Waste Electrical and Electronic Equipment

(WEEE) .................................................. 2

About this Manual

Audience .................................................. 5

Trademark Notices ................................... 5

Revision Record ....................................... 5

Revision History ............................ 5

Navigating this Manual ............................ 5

Manual Conventions ................................ 5

Where To Go From Here ......................... 6

Reference: NX2A4E2 Introduction

The NX2A4E2 ......................................... 7

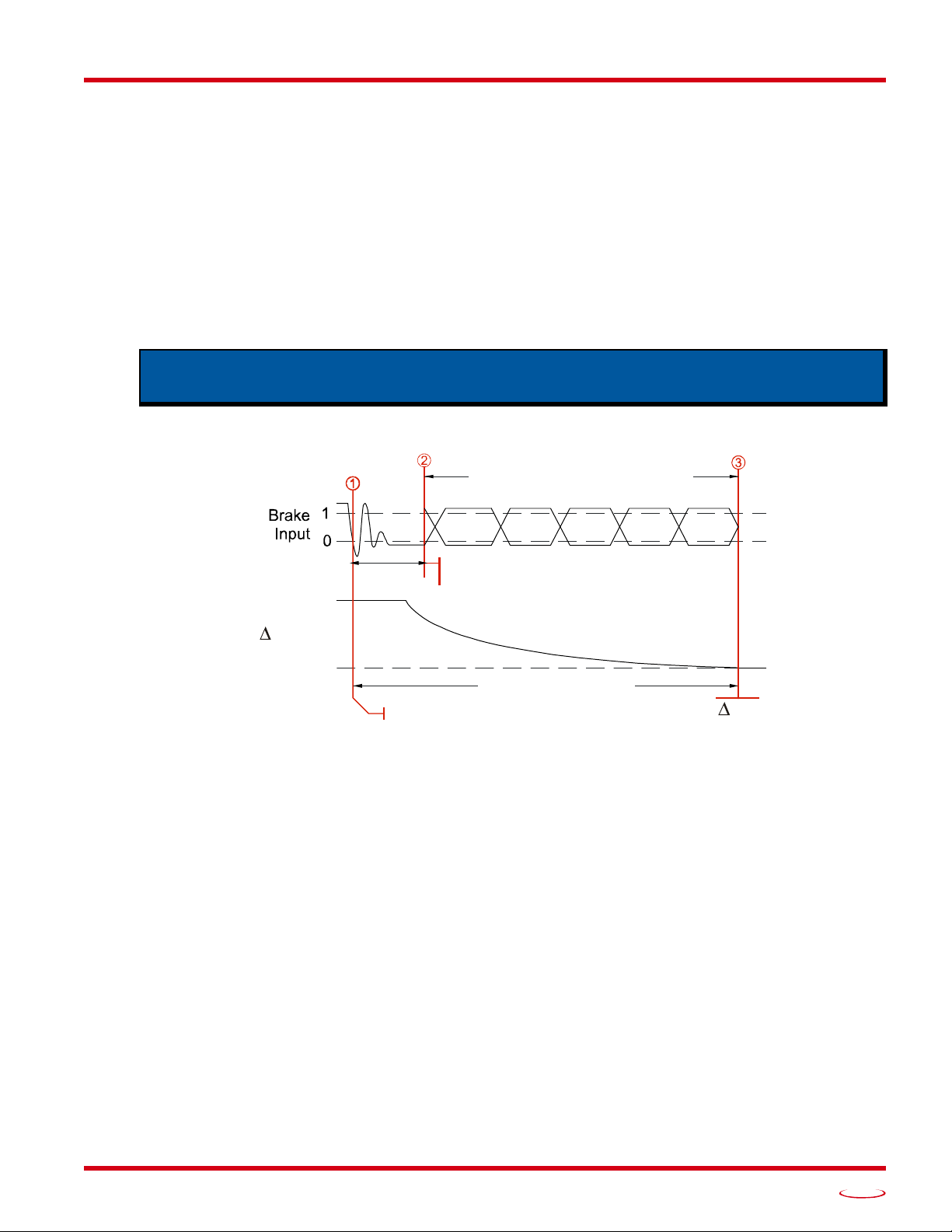

Stop Time Monitoring ............................. 9

NX2A4E2 Programmable Parameters ..... 10

Common Parameters ..................... 10

Single Turn Parameters ................. 10

Multi-turn parameters .................... 11

Front Panel Description ........................... 12

Connector Pinout ........................... 12

Status LEDs ............................................. 13

Resolver Status LEDs .................... 13

Ethernet Status LEDs .................... 13

Input Status LEDs .......................... 14

Specifications ........................................... 15

Reference: Data Formats

Mixed Data Formats ................................ 17

Output Data Formats ................................ 17

Single Resolver Data Format ......... 17

Dual Resolver Data Format ........... 20

Input Data Formats .................................. 24

Data Blocks ................................... 24

Multi-word Data Format ................ 24

Single Resolver Data Format ......... 25

Dual Resolver Data Format ........... 26

Reference: Configuring Network

Interfaces

Firewall Settings ....................................... 29

Disable All Unused Network Interfaces .. 29

Configure Your Network Interface .......... 29

Test Your Network Interface ................... 30

Task: Installing the NX2A4E2

Safe Handling Guidelines ........................ 31

Prevent Electrostatic Damage ....... 31

Prevent Debris From

Entering the Unit ........................ 31

Remove Power Before Servicing .. 31

General Wiring Guidelines ...................... 31

Wiring ........................................... 31

Grounding ..................................... 32

Surge Suppression ......................... 32

Mounting ....................................... 32

DIN Rail Mounting .................................. 32

DIN Rail Installation ..................... 32

Attach the DIN Brackets ............... 32

Dimensions ................................... 33

Panel Mounting ........................................ 34

Attach the Panel Mount

Brackets ...................................... 34

Dimensions ................................... 34

Power Wiring ........................................... 35

Network Connections ............................... 35

EtherNet/IP DLR Applications ..... 35

PROFINET MRP Applications .... 35

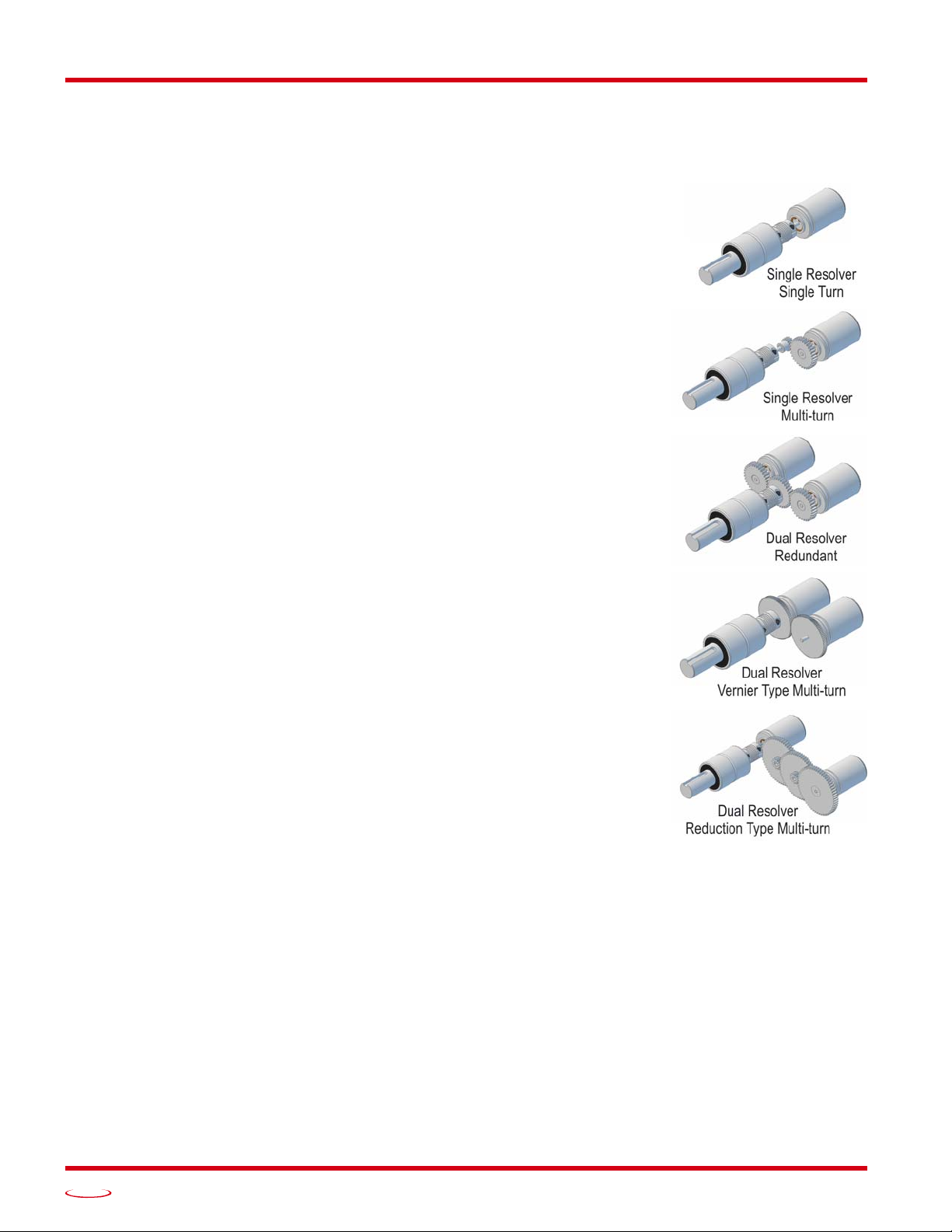

AMCI Transducers ................................... 36

Transducer Outline Drawings ....... 36

Mounting ....................................... 36

Foreign Transducers ................................. 37

Transducer Connector Pinout ................... 37

Transducer Wiring ................................... 38

Single Resolver Transducers ........ 38

Size 11 and Size 15 Resolvers ...... 39

AMCI Dual Resolver

Multi-turn Transducers ............... 40

Foreign Dual Resolver

Transducers ................................. 40

Avoiding Ground Loops and

Ground Shifts .............................. 41

DC Input Wiring ...................................... 42

Cable Shields ................................ 42