Metso neles RCI9H2 User guide

10SM RCI en • 3/2015

RCI9H2

Remote Communication

Interface for VG9000H

Safety Manual

2 RCI9H2, Safety Manual

Table of Contents

1 Introduction ���������������������������������������������������������������������������������������������������������������������������������������������3

1.1 System description ........................................................................................................................................................... 3

1.2 Supplementary documentation ................................................................................................................................. 3

2 Safety function�����������������������������������������������������������������������������������������������������������������������������������������4

2.1 Safety function ................................................................................................................................................................... 4

2.2 Safe State.............................................................................................................................................................................. 4

2.3 Reaction Time ..................................................................................................................................................................... 4

3 Functional safety and product reliability indicators ����������������������������������������������������������������������������4

4 Behavior of device �����������������������������������������������������������������������������������������������������������������������������������5

4.1 Normal vs. loop powered mode .................................................................................................................................. 5

4.2 During power-up............................................................................................................................................................... 5

4.3 During operation .............................................................................................................................................................. 5

5 Restrictions for use in safety-related applications �������������������������������������������������������������������������������5

6 Installation and commissioning �������������������������������������������������������������������������������������������������������������6

6.1 Operation ............................................................................................................................................................................ 6

6.2 Maintenance ...................................................................................................................................................................... 6

7 Proof-testing ��������������������������������������������������������������������������������������������������������������������������������������������6

8 Repair �������������������������������������������������������������������������������������������������������������������������������������������������������6

9 Certicate �������������������������������������������������������������������������������������������������������������������������������������������������6

RCI9H2, Safety Manual 3

1� Introduction

This manual contains information for application of RCI9H2 product in functional safety related loops.

1�1 System description

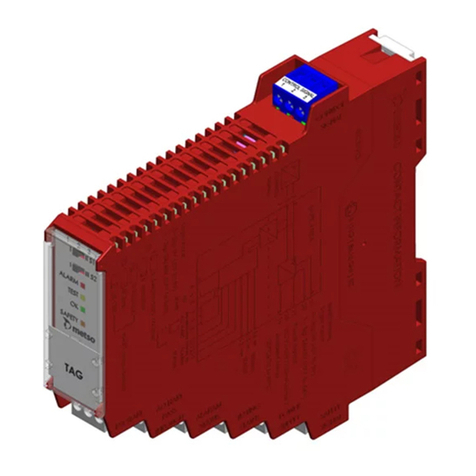

RCI9H2 is meant to be used together with Neles ValvGuard VG9000H safety valve controller. It is needed when

24 VDC output (DO) is used in the safety system. RCI9H2 is connected between the safety system and the eld

device VG9000H as presented in gure 1.

Figure1. RCI9H2 System Level Diagram

The primary function of RCI9H2 is to convert safety binary input from a safety DO (Digital Output) system into

a SIL 3 compatible 4-20mA current signal. RCI9H2 also provides relay outputs for monitoring the test and alarm

status of the VG9000H and a discrete input for commanding VG9000H to start a Partial Stroke Test. Additionally,

RCI9H2 includes an isolated barrier and can be used in intrinsically safe application.

RCI9H2 has local interface with status relays and LED’s, which can be used to indicate the status information of

the VG9000H (Alarm and Test status).

RCI9H2 has two conguration switches. One switch is for conguring Mode A (Secondary master) / Mode B

(Monitor) selection and other switch is to connect RCI9H2 internal HART loop resistor (250 Ohm) to HART loop.

1�2 Supplementary documentation

Table 1� List of references

Document ID Name of document

7RCI9H270EN RCI9H2 Installation, Maintenance and Operation instructions

7VG9H70EN VG9000H Installation, Maintenance and Operation instructions

VG9000H_Safety_Manual VG9000H Safety Manual

Power supply

Safety signal

Safe Area Hazardous Area

VG9000H

DO

Safety system

4/20 mA + HART

HART

RCI9H2

Testing status

Alarm status

PST start

DI

DI

DO

4 RCI9H2, Safety Manual

2� Safety function

2�1 Safety function

The current output (terminal SIGNAL TO VG) is in low condition when the controlling input (terminal SAFETY

SIGNAL) is in the de-energized condition.

2�2 Safe State

The safe state of the RCI9H is dened as the current output is less than 5.6mA.

2�3 Reaction Time

The reaction time (switch o delay) of the safety function is less than 50ms.

3� Functional safety and product reliability indicators

Functional safety and product reliability indicators are presented in table 2.

Table 2� Functional safety data

Item Value Remark

Safety Integrity Level SIL 3

MTTR 8 h

MRT 4 h

PFDav 4,72 x 10-5 Corresponds to <1% of SIL 3; this value is valid for

the stated Proof Test Interval T

Proof Test Interval T 10 years

λSU 5,3 x 10-7 /h

λSD 0

λDU 1,1 x 10-9 /h

λDD 0

Safe Failure Fraction 98,9 %

MTBF 216 years

RCI9H2, Safety Manual 5

4� Behavior of device

In this section the behavior of voltage to current conversion is explained in dierent situations.

Safety signal thresholds are presented in gure 3.

Figure 3. RCI9H2 safety signal thresholds in normal use case.

4�1 Normal vs� loop powered mode

RCI9H2 normal use case is to connect power supply to POWER SUPPLY terminal. RCI9H2 can additionally be

used without power supply, i.e., in loop powered mode. See details in RCI9H2 IMO.

4�2 During power-up

During power-up it may take up to 40 ms for RCI9H2 to power up and to be fully operational. This is valid when

the RCI9H2 receives logic level high (1-Signal) from safety system DO to energize the VG9000H with output

current level 18...22 mA / ≥ 16 mA when loop powered.

4�3 During operation

When the input signal to RCI9H2 from the system DO is in logic state 1, the RCI9H2 output current level is

18…22 mA. When loop powered, RCI9H2 output current level will be ≥ 16 mA, which is sucient to keep the

VG9000H in normal state.

When the input signal to RCI9H2 from the system DO is in logic state 0, the RCI9H2 output current level will

be 3.8...5.6 mA. When loop powered, RCI9H2 output current level will be 0 mA, which de-energizes VG9000H

completely. It may take up to 90 ms for RCI9H to trip the VG9000H.

5� Restrictions for use in safety-related applications

Assembly, installation, commissioning, maintenance and operation of this product may only be carried out by

trained, qualied personnel who have read and understood the instruction manuals.

Please ensure that the RCI9H2 is used correctly for the application described in RCI9H2 IMO and that the ambi-

ent conditions are taken into account. The instructions for installation conditions, as detailed in the IMO shall

be observed. The specications in the IMO shall not be exceeded.

De-activating or bypassing safety functions or failure to follow the advice given in this manual may cause dam-

age to property, environment or persons for which Metso will not be liable.

This product is developed, manufactured and tested according to the relevant safety standards. This product

must be used for the applications described in the instructions and with specied environmental conditions

and only in connection with approved external devices.

6 RCI9H2, Safety Manual

6� Installation and commissioning

The installation of the device needs to be done according to the RCI9H2 IMO.

Installation has to consider all aspects regarding the SIL level of the loop. During installation or replacement of

the device the loop has to shut down. Devices have to be replaced by the same type of devices.

6�1 Operation

See RCI9H2 IMO for the operation instructions of the device.

6�2 Maintenance

During maintenance work on the device, alternative safety function methods shall be taken to ensure process

safety.

See the RCI9H2 IMO for maintenance instructions.

7� Proof-testing

Assuming proof test interval of 10 years, RCI9H2 has average PFD value less than 1 % of the SIL3 budget value.

This means that RCI9H2 practically does not need to be proof tested. It is more likely that other components of

the system need proof testing prior to RCI9H2.

Nevertheless, the proof test procedure of the RCI9H2 is as follows. This procedure can only be done during

service shutdown.

1. Energize RCI9H2 safety system input and the power supply.

2. Now output current shall be within range 18...20 mA. Current measurement can be done using multimeter

or VG9000H Local User Interface. See more information on LUI usage from VG9000H manual (7VG9H70EN),

chapter “Measurement monitoring”.

3. De-energize RCI9H2 safety system input.

4. Now output current shall be within range 3.8...5.6 mA

8� Repair

Any repair to the device shall be carried out by the manufacturer only. Device failures must be reported to the

manufacturer. The user shall provide a detailed report to the manufacturer describing the failure and any pos-

sible eects.

9� Certicate

See the next page.

RCI9H2, Safety Manual 7

Metso Flow Control Inc.

Europe, Vanha Porvoontie 229, P. O. Box 304, FI-01301 Vantaa, Finland. Tel. +358 20 483 150. Fax +358 20 483 151

North America, 44 Bowditch Drive, P. O. Box 8044, Shrewsbury, M A 01545, USA. Tel. +1 508 852 0200. Fax +1 508 852 8172

South America, Av. Independéncia, 2500-Iporanga, 18087-101, Sorocaba-São Paulo, Brazil. Tel. +55 15 2102 9700. Fax +55 15 2102 9748

Asia Pacic, Haw Par Centre #06-01, 180 Clemenceau Avenue, Singapore 239922. Tel. +65 6511 1011. Fax +65 6250 0830

China, 11/F, China Youth Plaza, No.19 North Rd of East 3rd Ring Rd, Chaoyang District, Beijing 100020, China. Tel. +86 10 6566 6600. Fax +86 10 6566 2583.

Middle East, Roundabout 8, Unit AB-07, P. O. Box 17175, Jebel Ali Freezone, Dubai, United Arab Emirates. Tel. +971 4 883 6974. Fax +971 4 883 6836

www.metso.com/valves

8 RCI9H2, Safety Manual

Table of contents

Other Metso Recording Equipment manuals