page Contents – 2

A-5000 / Nov 98

CONTENTS

Chapter 3 - Stereo Line Inputs

Module Overview...........................................................................3-2

Internal Programming Options ....................................................3-3

Mutes ........................................................................................................................ 3-3

Mix-Minus.................................................................................................................. 3-3

Timer Restart ............................................................................................................ 3-3

Cue Dropout.............................................................................................................. 3-3

Local/Ready .............................................................................................................. 3-4

Remote ON/OFF-Constant vs. Pulse ....................................................................... 3-4

Tallies........................................................................................................................ 3-4

Remote Start/Stop .................................................................................................... 3-4

Hook-ups........................................................................................3-5

AUDIO CONNECTIONS........................................................................................... 3-5

CONTROL CONNECTIONS..................................................................................... 3-5

Remote ON & OFF ................................................................................................... 3-5

On Tally..................................................................................................................... 3-6

External START & STOP ......................................................................................... 3-6

Ready........................................................................................................................ 3-6

Remote Cue.............................................................................................................. 3-6

DB Connector Pinout Drawings...................................................3-7

Chapter 4 - Output Modules

Module Overview...........................................................................4-2

Internal Programming Options ....................................................4-3

Insert Bypass ............................................................................................................ 4-3

Hook-ups........................................................................................4-3

Master Output Module A (PGM and AUX)

Upper DB-25 Connector — Analog Audio ........................................................ 4-3

Lower DB-25 Connector — Analog Outputs..................................................... 4-4

Master Output Module B (AUD and UTL)

Upper DB-25 Connector — Analog Audio ........................................................ 4-4

Lower DB-25 Connector — Analog Outputs...................................................... 4-4

DB Connector Pinout Drawings

Master Output A........................................................................................................ 4-5

Master Output B........................................................................................................ 4-6

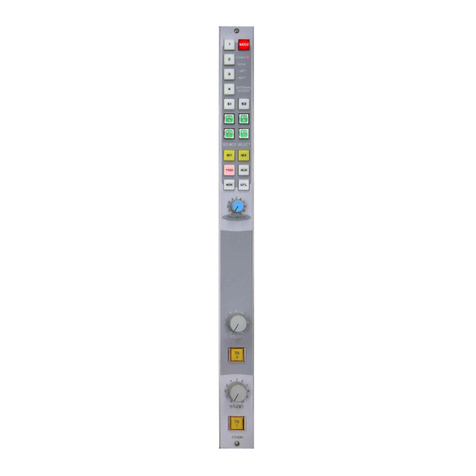

Chapter 5 - Control Room Module

Module Overview...........................................................................5-2

Internal Programming Options ....................................................5-3

Cue Interrupt............................................................................................................. 5-3

Cue Mute .................................................................................................................. 5-3

Mono Cue ................................................................................................................. 5-3