content/目录

1.Model/型号..............................................................................................................................................2

2.Cell Specification/电芯规格说明........................................................................................................ 3

3.Battery/Cell performance test Criteria/电池性能标准.................................................................... 4

3.1 Appearance inspection by visual/外观目测............................................................................ 4

3.2 Environmental test condition/外界环境条件.......................................................................... 4

3.3 Electrical characteristics/电气特性..................................................................................... 4

3.4 Mechanical characteristics/机械特性..................................................................................... 5

3.5 Safety performance/安全性能................................................................................................... 6

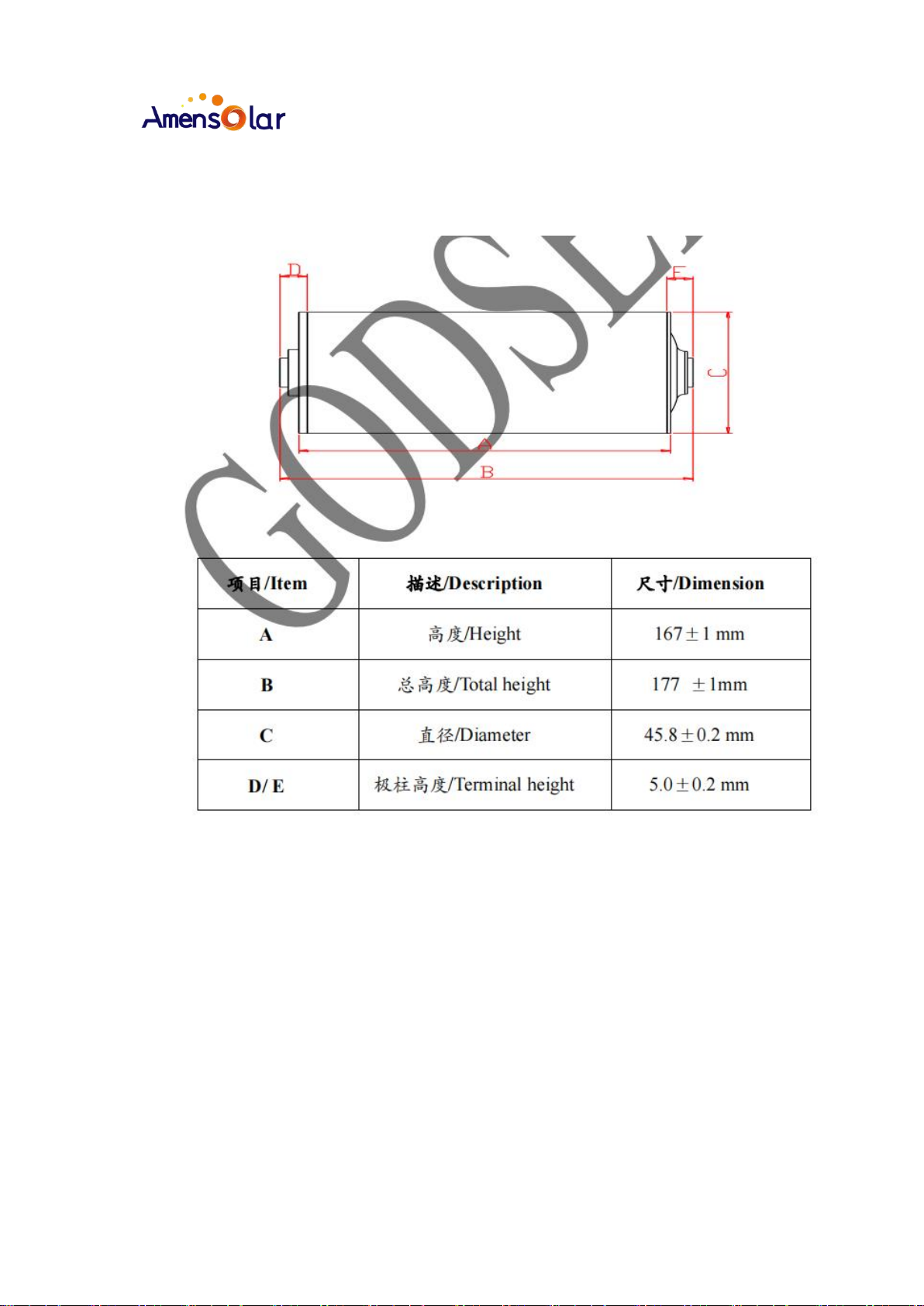

4.Cell initial Dimensions/电芯初始尺寸............................................................................................... 7

5.Battery specifications/产品规格........................................................................................................ 8

6.PCM specification/保护板参数..............................................................................................................9

7.Application Circuit/线路板原理图.................................................................................................... 10

8.Battery Pack Dimensions/电池组尺寸.................................................................................................11

9.Handling of Cells /电池操作注意事项...............................................................................................12

10.Notice for Designing Battery Pack/电池外壳设计注意事项...........................................................12

11.Notice for Assembling Battery Pack 电池装配注意事项................................................................. 13

12.Others/其它........................................................................................................................................ 13

13.Period of Warranty/保质期............................................................................................................... 14

14.Storage of the Batteries/电池的存放............................................................................................. 14

15.Other The Chemical Reaction/其它化学反应.................................................................................... 14

16.Note/注释............................................................................................................................................15