● Never use the autoclave to sterilize any of the following hazardous materials or substances with

alkali content. Sterilization of such objects can cause explosion, corrosion of the working

chamber or chamber piping, and deterioration of gaskets.

List of Hazardous Materials

① Explosive substances

・Nitroglycol, nitroglycerin, nitrocellulose, and other explosive nitric esters.

・Trinitrobenzene, trinitrotoluene, picric acid, and other explosive nitro compounds.

・Peracetic acid, methyl ethyl ketone peroxide, benzoyl peroxide, and other organic peroxides.

② Ignitable substances

・Metallic lithium, potassium, sodium, yellow phosphorous, phosphorus sulfide, and red phosphorus.

・Celluloids, calcium carbide (carbide), lime phosphide, and magnesium powder

・Aluminum powder, magnesium powder, and metallic powders other than aluminum powder

・Sodium dithionite (or sodium hydrosulfite)

③ Oxidizing agents

・Potassium chlorate, sodium chlorate, ammonium chlorate, and other chlorates

・Potassium perchlorate, sodium perchlorate, ammonium perchlorate, and other perchlorates.

・Potassium peroxide, sodium peroxide, barium peroxide, and other inorganic peroxides

・Potassium nitrate, sodium nitrate, ammonium nitrate, and other nitrates

・Sodium chlorite and other chlorites

・Calcium hypochlorite and other hypochlorites

④ Flammable substances

・Ethyl ether, gasoline, acetaldehyde, propylene oxide, carbon disulfide, and other substances

whose flash points range from -30 to 0C.

・Methanol, ethanol, xylene, benzyl acetate (or amyl acetate), and other substances whose flash

points range from 0 to 30C.

・Kerosene, gas oil, turpenine oil, isopentyl alcohol (or isoamyl alcohol), acetic acid, and other

substances whose flash points range from 30 to 65C.

⑤ Flammable gas (hydrogen, acetylene, ethylene, methane, ethane, propane, butane, and other

substances that are gases at a temperature of 15C under 1 atmospheric pressure.)

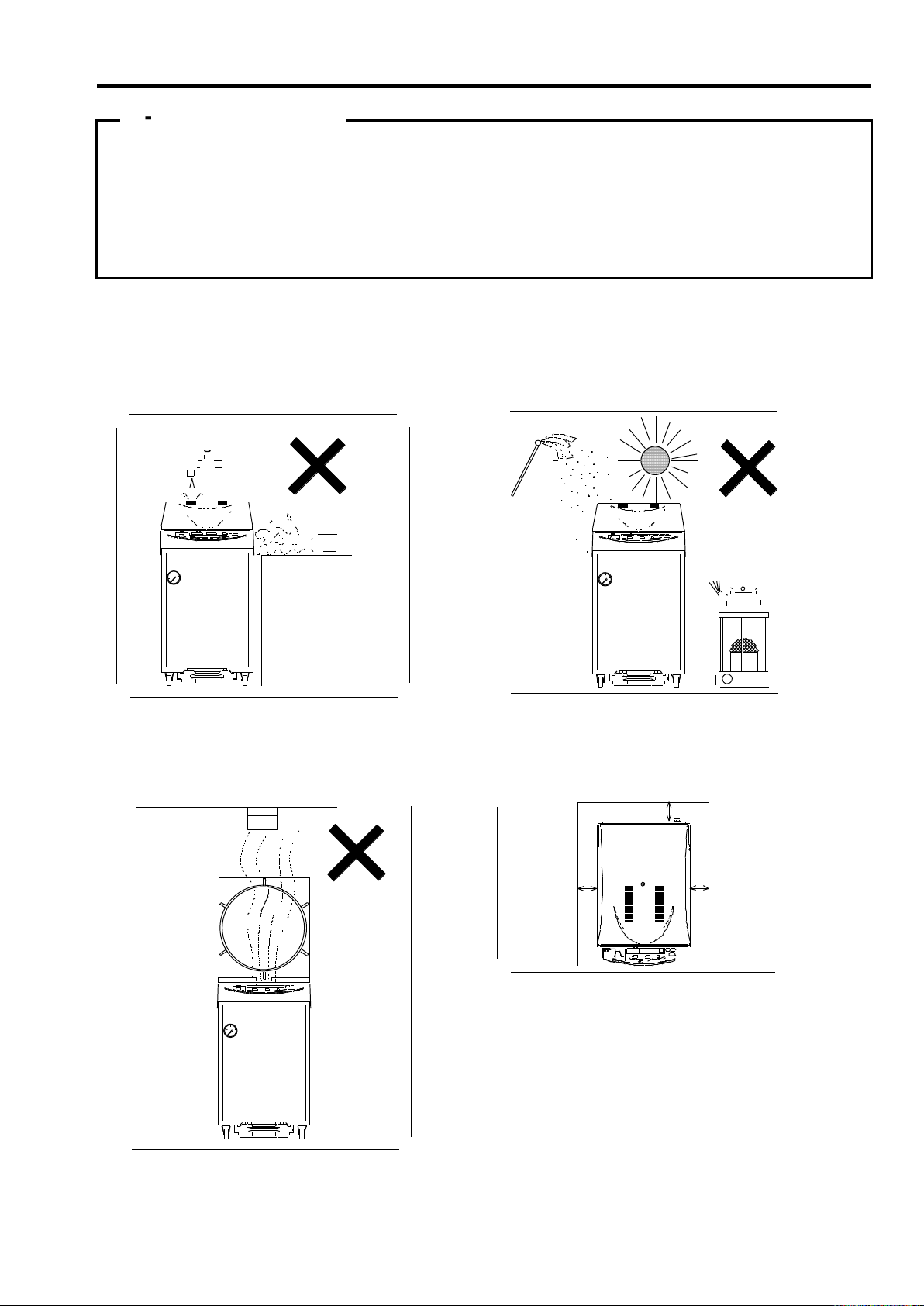

● When liquid with salt water and much salinity of salt agar etc. spills in the chamber, blowing,

discharge water in the chamber and wipe up drop of water around the lid gasket beautifully.

It causes the corrosion of the chamber and the piping when leaving just as it is.

● Check that the pressure is below "0 MPa" before opening the lid.

● Absolutely do not attempt to remodel or alter this product.