1 | P a g e

Contents

1. Assemble the Pedestal Stand if you ordered one. Skip to Step 2 if you did not order a Pedestal

Stand. ............................................................................................................................................................2

2. Mount the Grinder Frame to your bench top, or your Pedestal Stand (whichever is applicable). ......3

3. Test your motor for proper forward rotation without a belt by plugging in the grinder and starting

the motor......................................................................................................................................................4

4. Install and Tension a Belt......................................................................................................................5

5. Shut Down.............................................................................................................................................6

6. Maintenance.........................................................................................................................................6

7. Troubleshooting....................................................................................................................................6

Trips Breaker.............................................................................................................................................6

Bogs Down Easily Under Load...................................................................................................................7

Slows Down and Speeds Up Spontaneously.............................................................................................8

Won’t Start................................................................................................................................................9

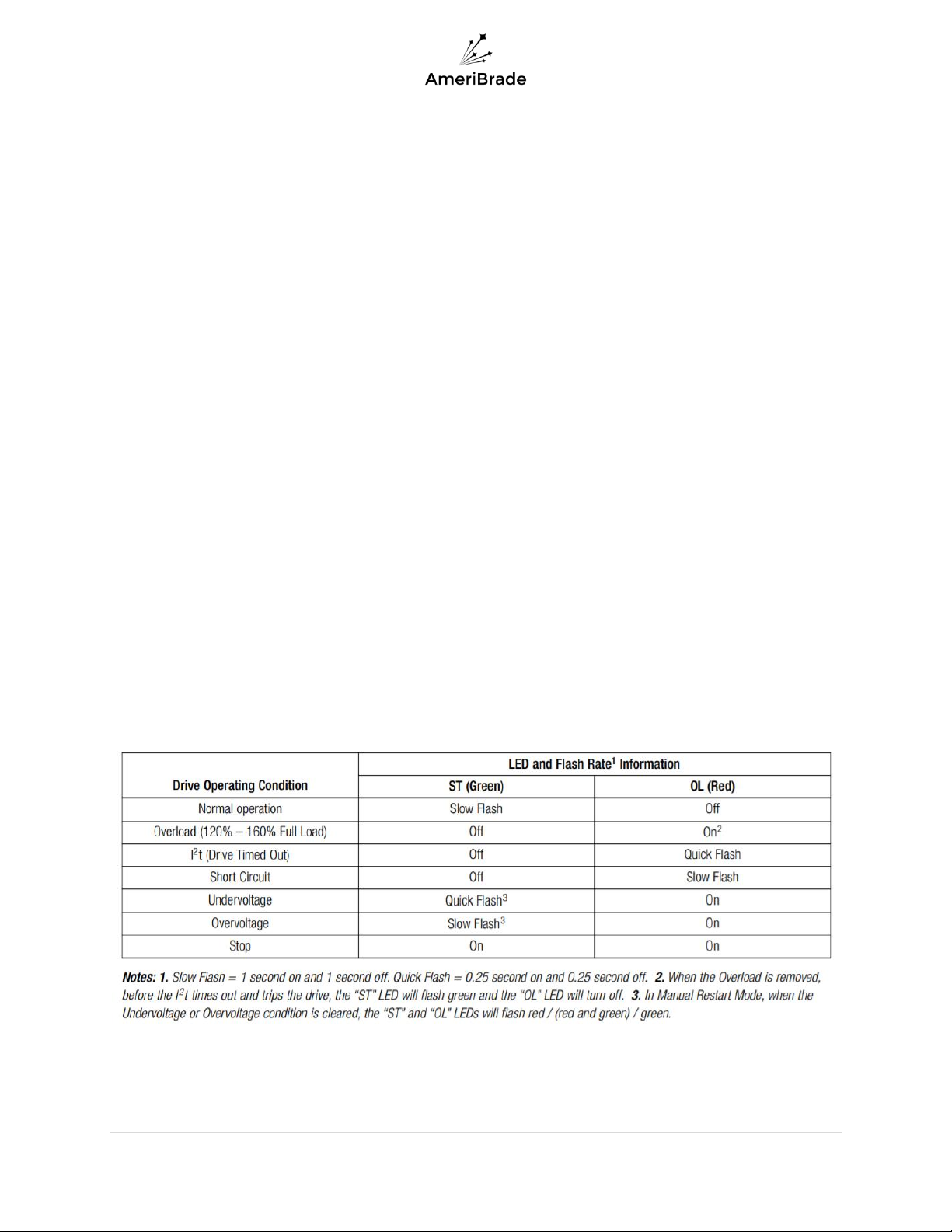

Other VFD Errors.......................................................................................................................................9

Vibration .................................................................................................................................................10

Belt Tracking............................................................................................................................................10

Belt Wobble (Small side to side belt motion) .....................................................................................10

Belt Wander (Large Belt Drifting)........................................................................................................10

Belt Tracks Diagonally Across Platen ..................................................................................................12

Broken Components ...........................................................................................................................12