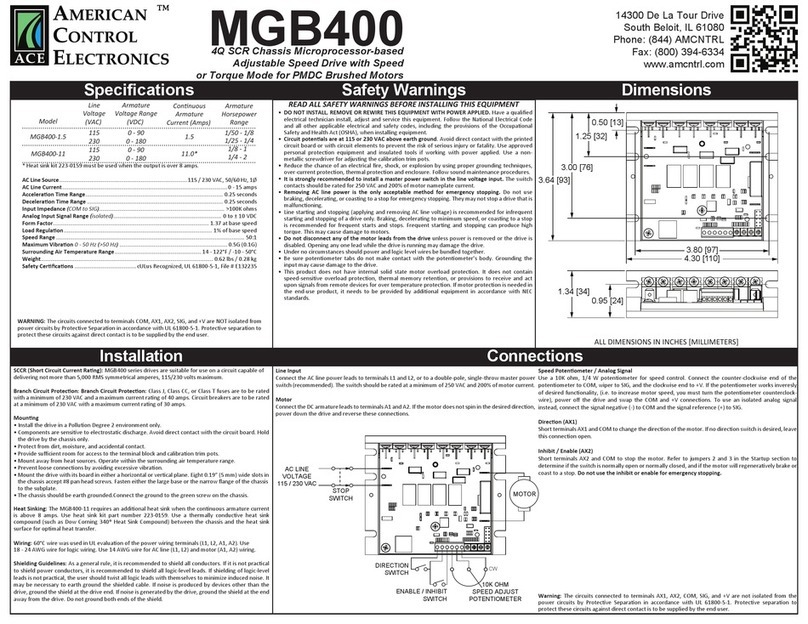

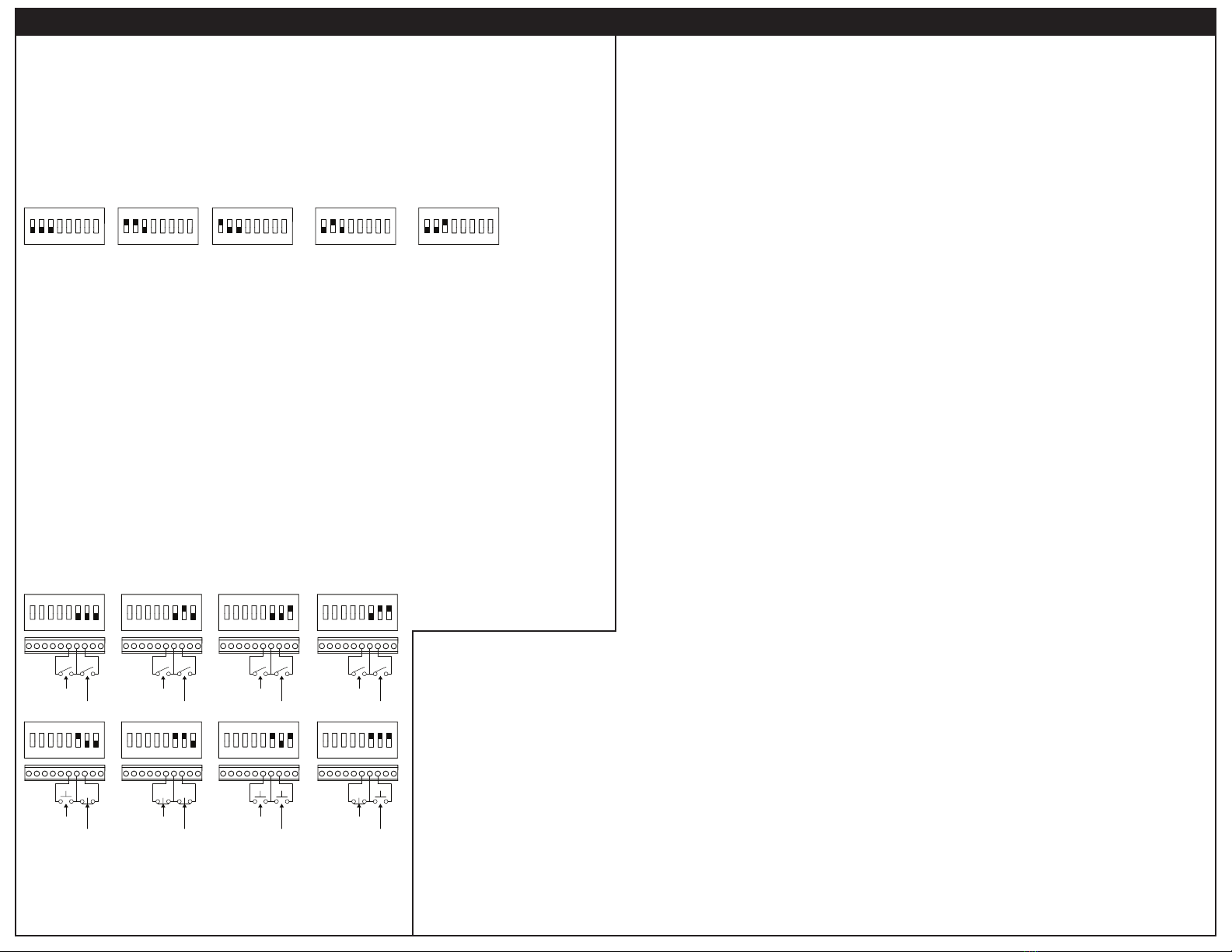

IR/TRACCFACC

MOPRVCLFWCL

MAXOFS2OFS1

10A

5A

2.5A

1.7A

Place the jumper on 10A if using a motor between 5 and 10 amps.

Place the jumper on 5 A if using a motor between 2.5 and 5 amps.

Place the jumper on 2.5A if using a motor between 1.7 and 2.5 amps.

Place the jumper on 1.7A if using a motor smaller than 1.7 amps.

MOTOR CURRENT

SELECT

FEEDBACK

SELECT

A180

A90

TACH

J504

Place the jumper on A180 if using a 180 VDC motor with no tach feedback.

Place the jumper on A90 if using a 90 VDC motor with no tach feedback.

Place the jumer on TACH if using tach feedback.

Feedback Select

If using tachogenerator feedback, set the feedback select jumper for TACH. If no tachogenerator

feedback is used, set the feedback select jumper to A90 if using a 90 VDC motor or to A180 if using a

180 VDC motor.

Motor Current Select

of the motor. This adjusts the scaling of the current limit trim pots to allow for as small a range on the

POWER JUMPERS

Setup

US

10A

5A

2.5A

1.7A

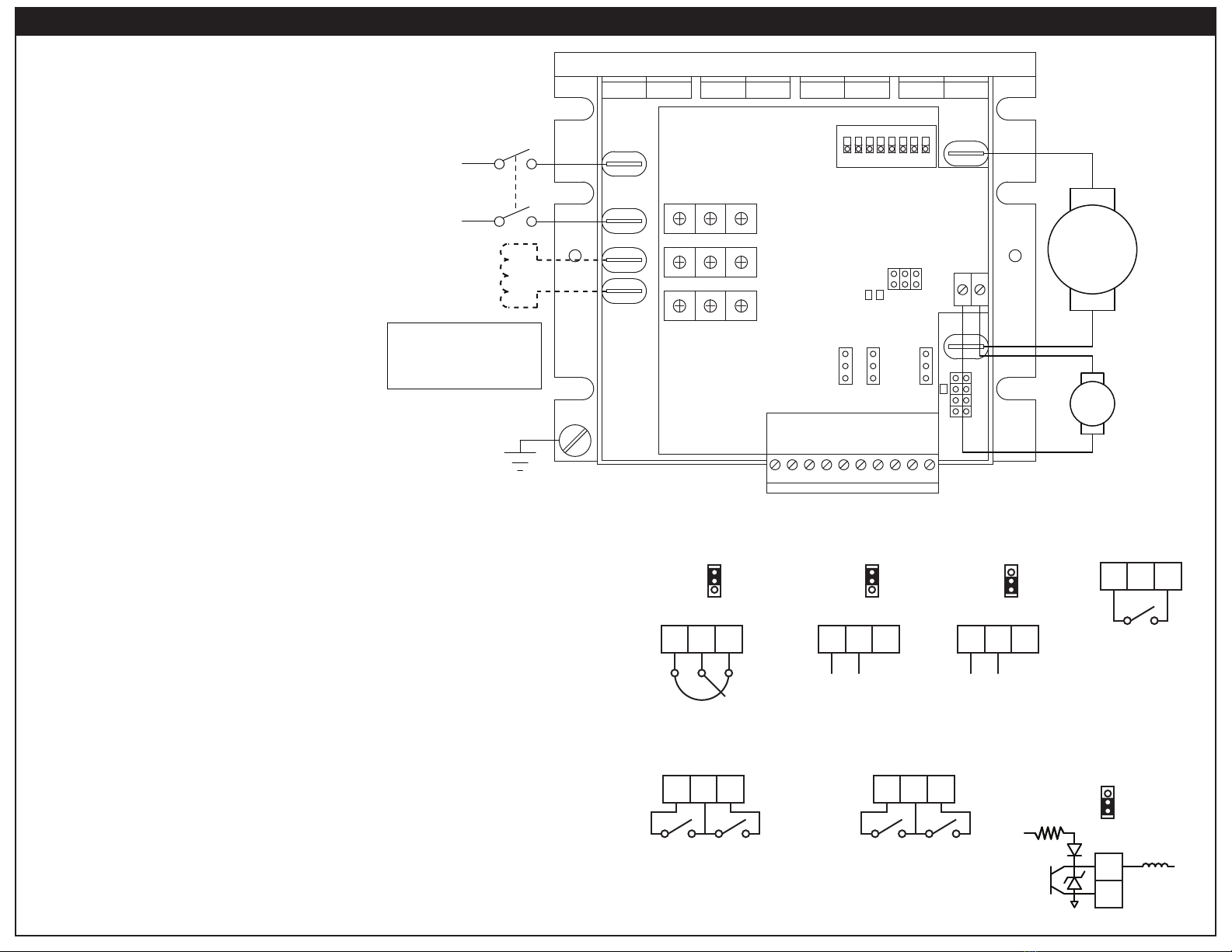

A2 A1

F- F+

L2L1

COM SIG1 10V SIG2 DIR EN COM INH COM AUX

OUT IN

SIG2SIG1

VDC

mA

T1 T2

A180

A90

TACH

J504

STAT

LIMIT

OFFSET1 FACC FWDCL MAXSPD

OFFSET2 RACC REVCL IRCOMP

1 2 3 4 5 6 7 8

ON

STATUS LED

BOTTOM BOARD

LIMIT LED

TOP BOARD

STAT LED

TOP BOARD

Status 1 LED (STAT): Green LED on Top Board

1 FLASH: The drive is disabled. Refer to DIP Switches 6 and 7 and terminal EN.

2 FLASHES: Cycle the AC power, enable, or inhibit.

2 FLASHES: Refer to DIP Switch 4.

5 OR MORE FLASHES: Contact the factory.

Limit LED (LIMIT): Red LED on Top Board

SOLID: The drive is in current limit. The motor is asking for more current than what the drive

SOLID: is set for. Refer to FWDCL and REVCL trim pots.

1 FLASH: The power board is not receiving a run command from the top board.

2 OR MORE FLASHES: Contact the factory.

LEDs

MGC403 series drives are suitable for use on a circuit capable of

•

• board. Hold the drive by the chassis only.

• Protect the drive from dirt, moisture, and accidental contact.

• temperature range.

•

• chassis to the subplate.

• The chassis should be earth grounded. Connect the ground to the green screw on the chassis.

60°

wiring.

to shield power conductors, it is recommended to shield all logic-level leads. If shielding of logic-level

Installation

ALL DIMENSIONS IN INCHES [MILLIMETERS]

US

10A

5A

2.5A

1.7A

A2 A1

F- F+

L2L1

COM SIG1 10V SIG2 DIR EN COM INH COM AUX

OUT IN

SIG2SIG1

VDC

mA

T1 T2

A180

A90

TACH

J504

STAT

LIMIT

1 2 3 4 5 6 7 8

ON

3.64 [93]

3.00 [76]

1.25 [32]

0.50 [13]

3.80 [97]

4.30 [110]

1.34 [34]

0.95 [24]

1.94 [50]

Dimensions

• Have a

•

•Electrical Code and all other applicable electrical and safety codes, including the provisions of the

•

• . Avoid direct contact with the printed

•circuit board or with circuit elements to prevent the risk of serious injury or fatality. Use a non-

•

•equipment and insulated tools if working on this drive with power applied.

•

• The

•switch contacts should be rated for 250 VAC and 200% of motor nameplate current.

• Do not use

•

•

•method for emergency stopping.

•

•

•produce high torque. This may cause damage to motors.

• unless power is removed or the drive is

•disabled. Opening any one lead while the drive is running may destroy the drive.

•using a permanent magnet motor.

• Under no circumstances should power and logic level wires be bundled together.

•input will cause damage to the drive.

•

•

•in accordance with NEC standards.

READ ALL SAFETY WARNINGS BEFORE INSTALLING THIS EQUIPMENT

Safety Warnings

......................................................115/230 VAC ± 10%, 50/60 Hz, single phase

........................................................................................................0 - 15 Amps

..............................................................50 or 100 VDC

............................................................100 or 200 VDC

...................................................................................................0.74 Amps

...................................................................................................1.37 at base speed

..........................................................1% base speed

.............................................0.1% base speed

................................................................................50:1

......................................................................60:1

....................................................................................0.5 - 15 seconds

..................................................................................0.5 - 15 seconds

.........................................................................................................................3 kV

...........0 to ± 10 VDC; 4 - 20 mA

..................................................................>100K ohms

.......................................................................10°C - 50°C

...............................................cULus Listed, UL 61800-5-1, File # E132235

AC Line Voltae

AC Line Current

with 115 VAC line voltage

with 230 VAC line voltage

Maximum Field Current

Form Factor

with Armature Feedback

with Tachogenerator Feedback

with Armature Feedback

with Tachogenerator Feedback

Input Impedance (COM to SIG1 / SIG2)

(0 - 50 Hz)

(>50 Hz)

* Heat sink kit 223-0159 must be used when the output is over 8 amps.

1/50 - 1/8

1/25 - 1/4

1/8 - 1

1/4 - 2

1.5

11.0*

0 - 90

0 - 180

0 - 90

0 - 180

115

230

115

230

MGC403-1.5

MGC403-11

Armature

Horsepower

Range

Connuous

Armature

Current (Amps)

Armature

Voltage Range

(VDC)

Line

Voltage

(VAC)

Model

Specifications

Full manual available online

14300 De La Tour Drive

South Beloit, IL 61080

Phone: (800) AMCNTRL

(800) 262-6875

www.americancontrolelectronics.com

4Q SCR Chassis Microprocessor-based

Adjustable Speed Drive with Isolation

and Speed or Torque Modes

for PMDC or Field Wound Brushed Motors

MGC403

An ISO 9001:2008 Certified Company

TM