8

Copyright ADS Installation Manual Model ASQ, Revision 2.0, 6/7/2013

ADS provides three (3) peristaltic pumps to dispense liquid chemicals

Chemical feed lines are color coded “Red” Detergent, “Green” Sanitizer, “Blue” Rinse-aid

Pick-up tubes are provided for chemical product containerers

Sanitizer (chlorine) concentrations shall be set at 50 parts per million

Inspect the transfer tubing for any cuts or holes, keep them protected and secured out of the way

Showing chemical lines and temp gauge in

cabinet Optional Chemical Alarm switch, barb with

adjusting screw *

TYPE OF CHEMICALS — Use only commercial grade low-energy chemicals. For proper operation, use

non-foaming detergents and buffered sanitizer. Do not wash gold, pewter, silver, or silver-plate with

chlorine based sanitizers. High concentrations of chlorine sanitizers and caustic detergents will cause

damage to metals and welds. Do not exceed 50 parts-per-million (PPM) “free” or available chlorine, using

higher than 50 ppm will be dependent on local health requirements, however, the increased chlorine will

result in higher corrosion of metal parts. The resulting damage from overusing chlorine is not

covered under the ADS warranty. Purpose-built ware-washing dispensers are needed to properly meter

chemicals for wash and rinse. These dispensers are included with this model. Manually adding industrial

chemicals to the machine is unsafe and not approved.

CHEMICAL LINES — Place color coded tubes into proper chemical containers. The containers of one

gallon each are placed inside the lower cabinet. On the side of the control box door, there are

chemical prime switches. There is a decal identifying each switch. To prime chemicals, use these

momentary switches, verifying that all three pumps rotate. If a chemical pump squeeze tube has taken a

set (not allowing the pump to turn), manually free the pump by pulling on the discharge side (right-hand)

of the squeeze tube while pushing the prime switch. Squeeze tubes should be replaced at least every six

months.

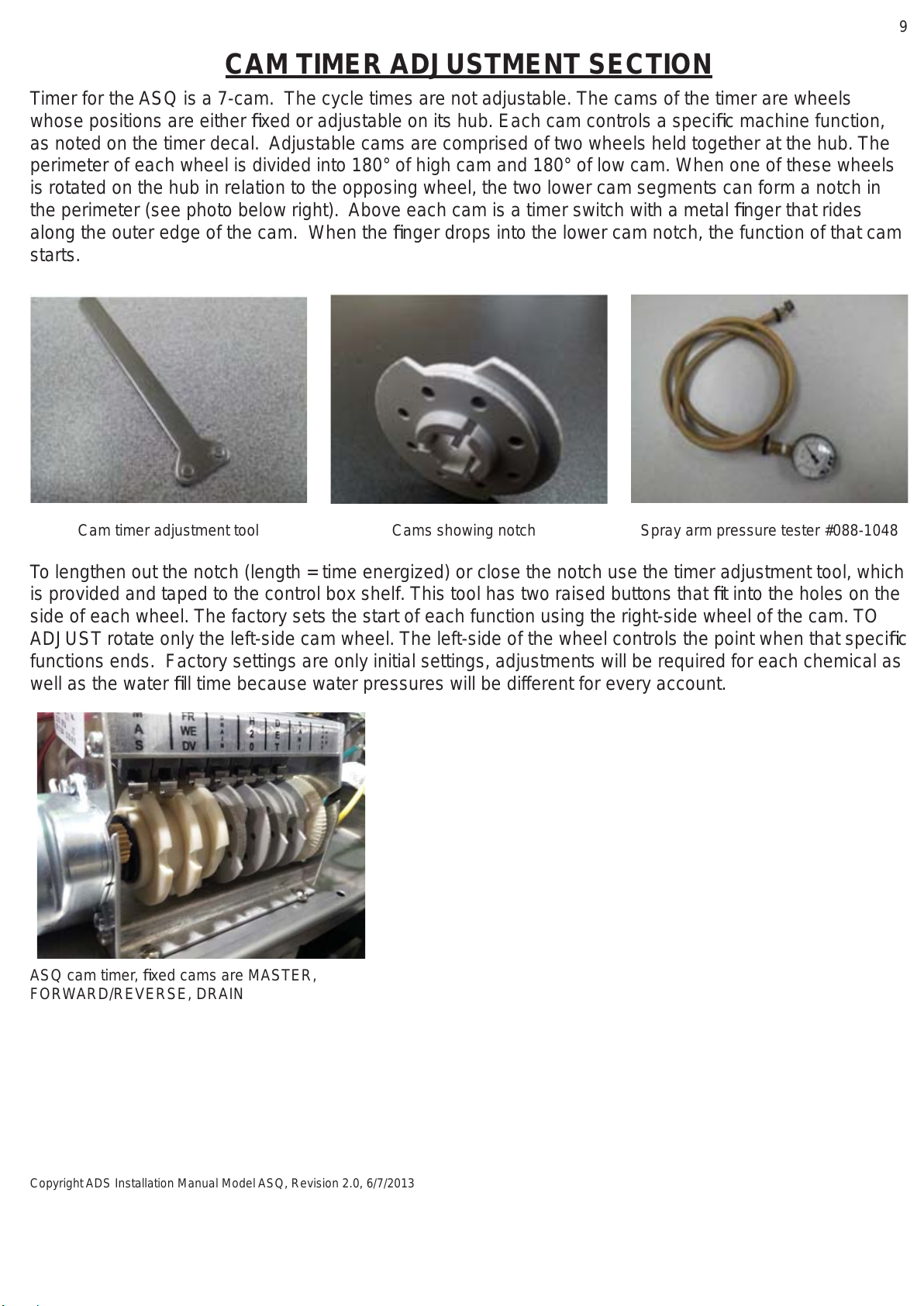

CHEMICALADJUSTMENT— Chemical dispensing is controlled by a mechanical cam timer. All chemical

products must be adjusted for the product’s concentration and local water conditions. It will be necessary

to adjust initial factory settings (See page 9 for Cam Timer Adjustment Section). Water softeners should

be added to correct hard water conditions. Hard water is often treated with more expensive ware-washing

chemicals, but it is more effective and less destructive to the metal to soften the water before it comes to

the machine.

AUDIBLE CHEMICALALARM OPTION —The optional chemical alarm (P/N 031-0326) uses a pressure

switch with a barb fitting that extends from the control box and connects to the chemical line by means of

a “t” fitting. The switch sends voltage to a buzzer located in the control box. Sensitivity is adjusted by an

Allen wrench (5/64” or 2mm) to turn a screw located in the center of the barb (see photo above*).

Remove the tube from the barb; turn the screw to the right for less sensitivity. Chemical must be placed

on the floor of the cabinet for the pressure switch to work