Table of Contents

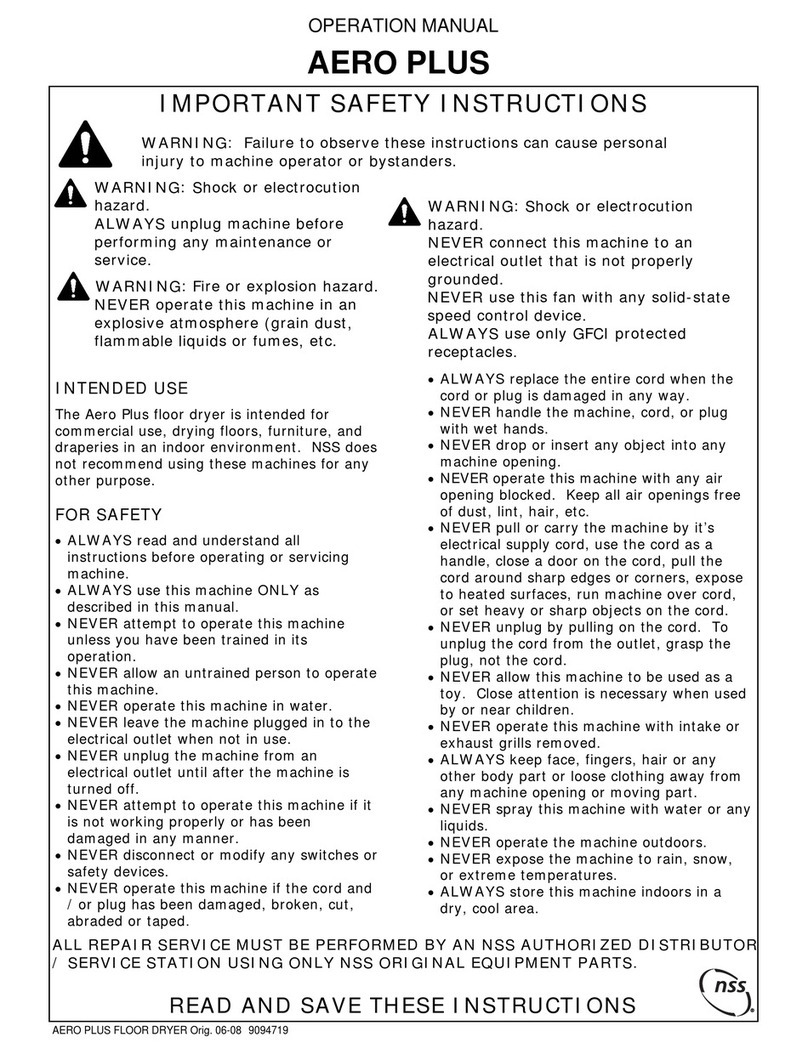

SECTION I

SAFETY PRECAUTIONS ..............................................................................................................................2

SECTION II

SPECIFICATIONS ..........................................................................................................................................4

A. Specifications.......................................................................................................................................... 4

SECTION III

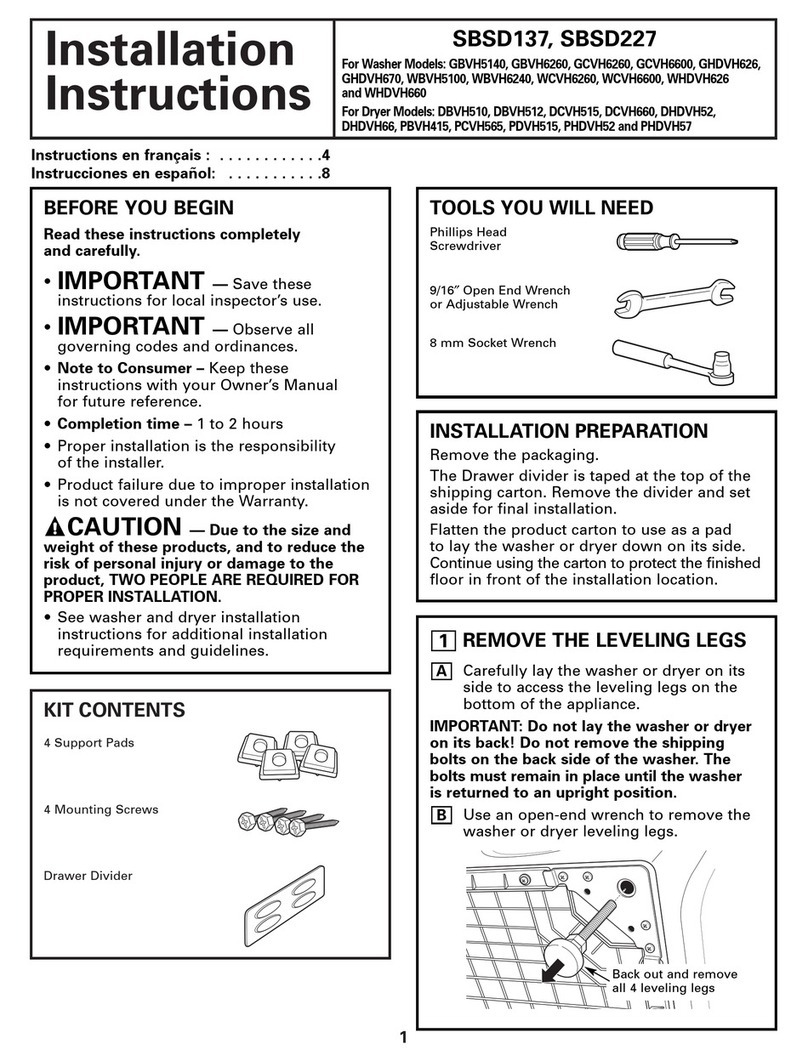

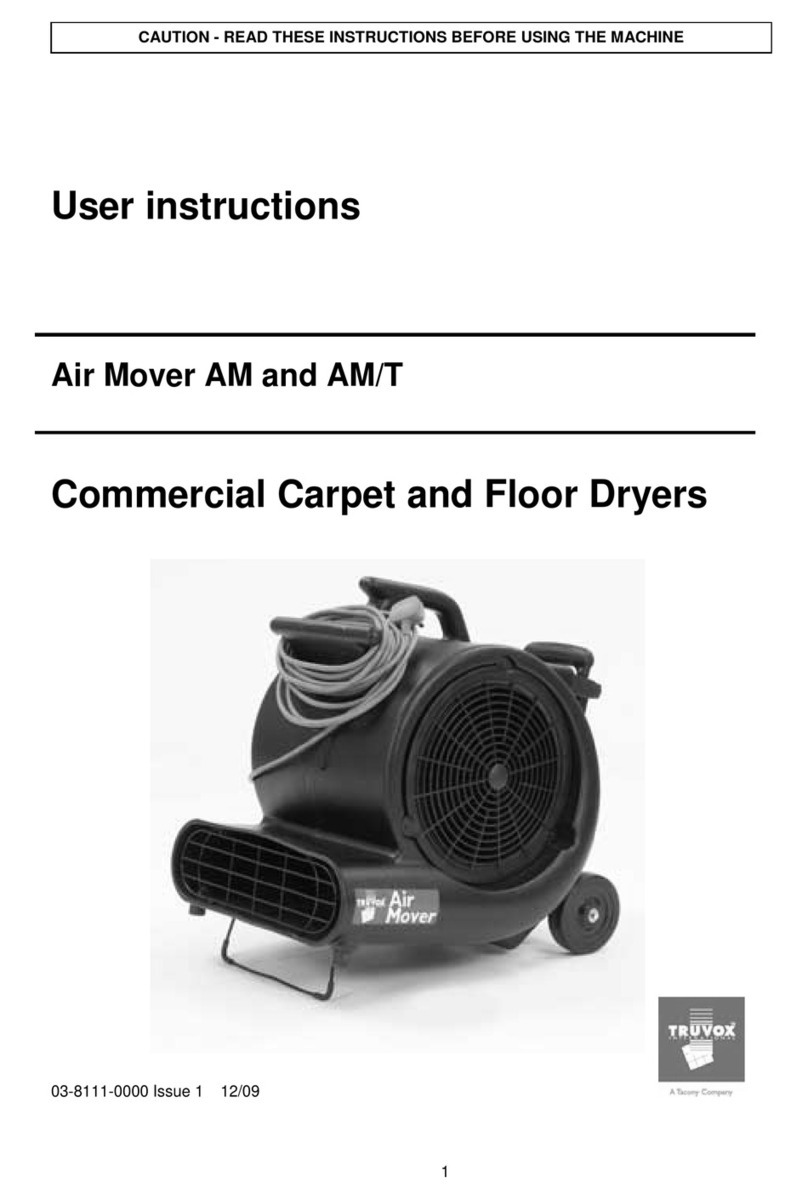

INSTALLATION PROCEDURES ................................................................................................................6

A. Location Requirements........................................................................................................................... 6

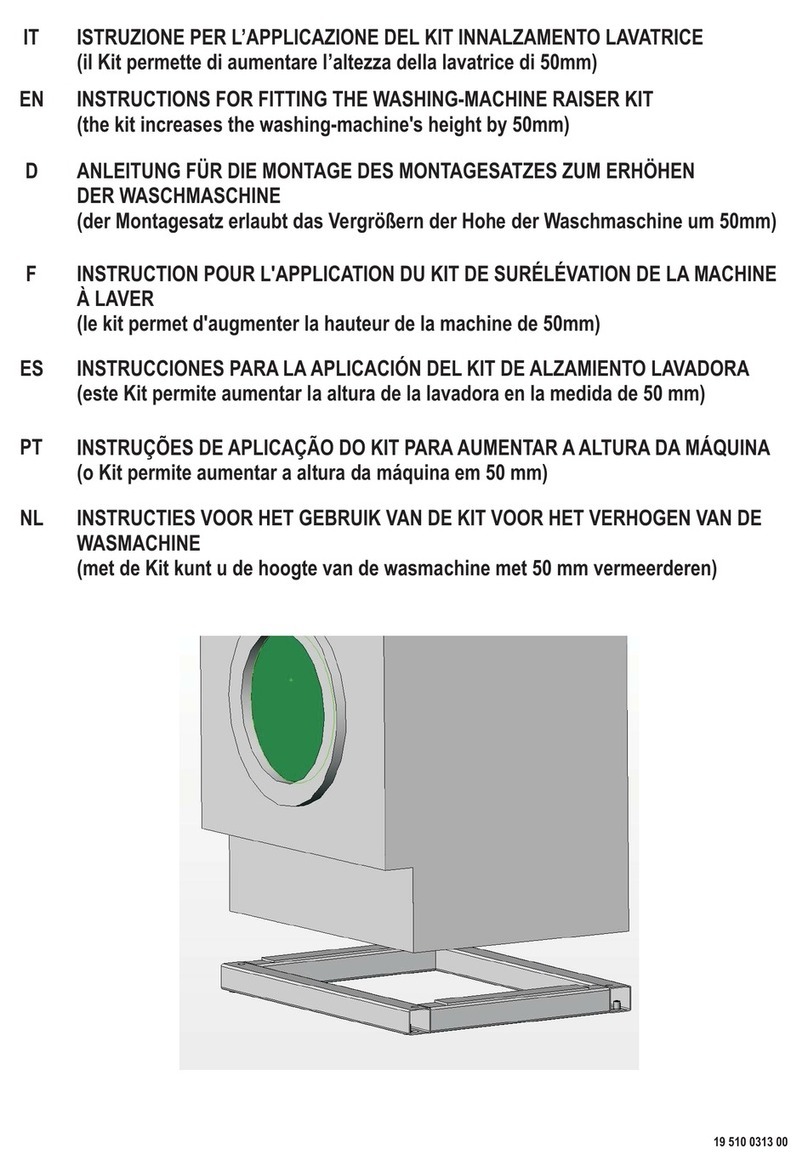

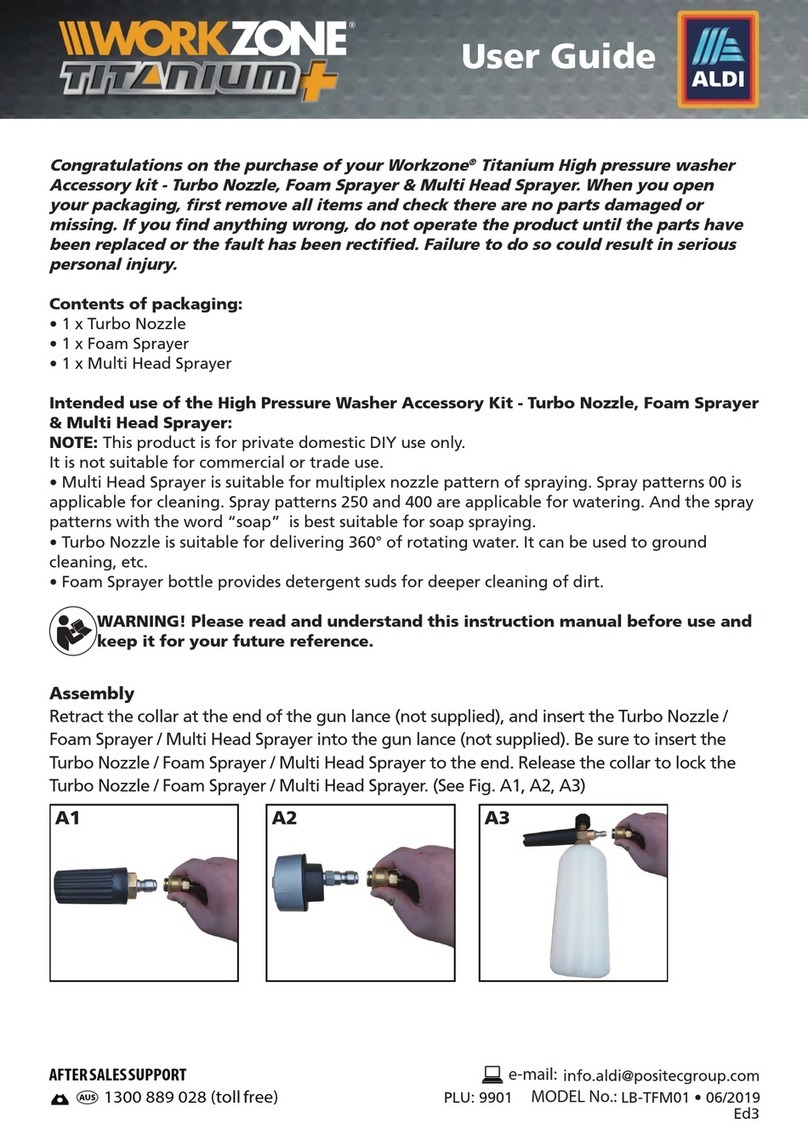

B. Unpacking/Setting Up............................................................................................................................. 7

C. Dryer Enclosure Requirements .............................................................................................................. 9

D. FreshAir Supply Requirements ............................................................................................................ 10

E. Exhaust Requirements.......................................................................................................................... 11

F. Electrical Information ........................................................................................................................... 17

G. Gas Information .................................................................................................................................... 20

H. Steam Information ................................................................................................................................ 24

I. Preparation for Operation/Start-Up...................................................................................................... 28

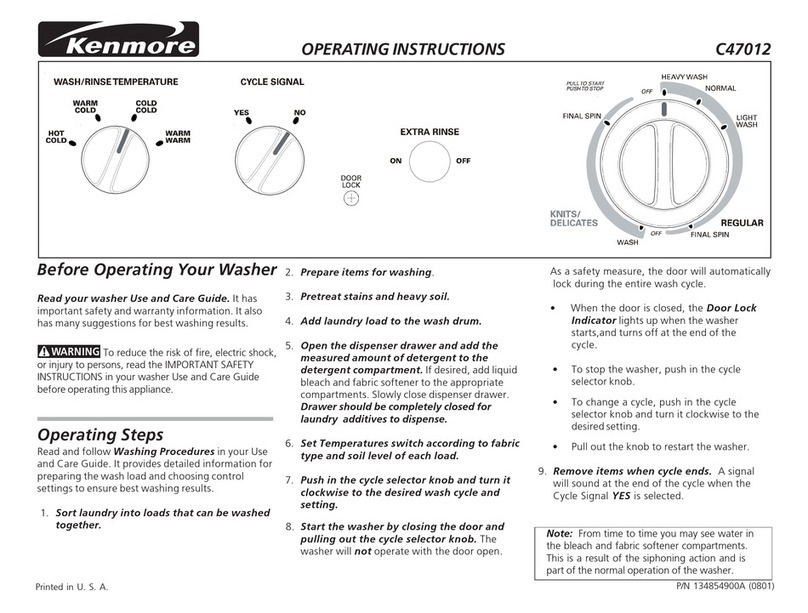

J. Preoperational Tests ............................................................................................................................. 29

K. Compressed Air Requirements............................................................................................................. 31

L. Shutdown Instructions .......................................................................................................................... 32

SECTION IV

SERVICE/PARTS INFORMATION ...........................................................................................................33

A. Service .................................................................................................................................................. 33

B. Parts...................................................................................................................................................... 33

SECTION V

WARRANTY INFORMATION ...................................................................................................................34

A. Returning Warranty Cards ................................................................................................................... 34

B. Warranty ............................................................................................................................................... 34

C. Returning Warranty Parts..................................................................................................................... 34

SECTION VI

ROUTINE MAINTENANCE ......................................................................................................................36

A. Cleaning ................................................................................................................................................ 36

B. Adjustments .......................................................................................................................................... 38

C. Lubrication ............................................................................................................................................ 38

SECTION VII

MANUAL RESET BURNER HI-LIMIT INSTRUCTIONS ..................................................................39

SECTION VIII

DATA LABEL INFORMATION .................................................................................................................40

SECTION IX

PROCEDURE FOR FUNCTIONAL CHECK OF REPLACEMENT COMPONENTS ...................41

SECTION X

FIRE SUPPRESSION SYSTEM ..................................................................................................................43