General Operating Instructions

Panning and Loading

Follow the methods below for faster cooling, freezing and thawing:

• Place the food in shallow pans.

• Do not use food pans deeper than 2 ½” and do not fill the pan with more than 2” of product.

• Separate the food in smaller or thinner portions.

• Do not cover the containers unless danger of overhead contamination.

• Loosely cover the containers if necessary. Allow the cover material (aluminum foil…) to touch

the surface of the food.

• Arrange the pans for optimum air circulation within the cabinet.

• Know the capacity of the unit. Do not overload the unit.

Probing (for Chilling & Freezing Cycles)

Follow the methods below to ensure correct probing of the product:

• Insert the food probe into the thickest part of the product.

• The tip of the food probe will have to be located at the core of the food.

• Always place the available food probe in the hardest to cool product.

• It is a good practice to restart the cycle every time food is added.

• Clean and sanitize the food probe after each use.

5

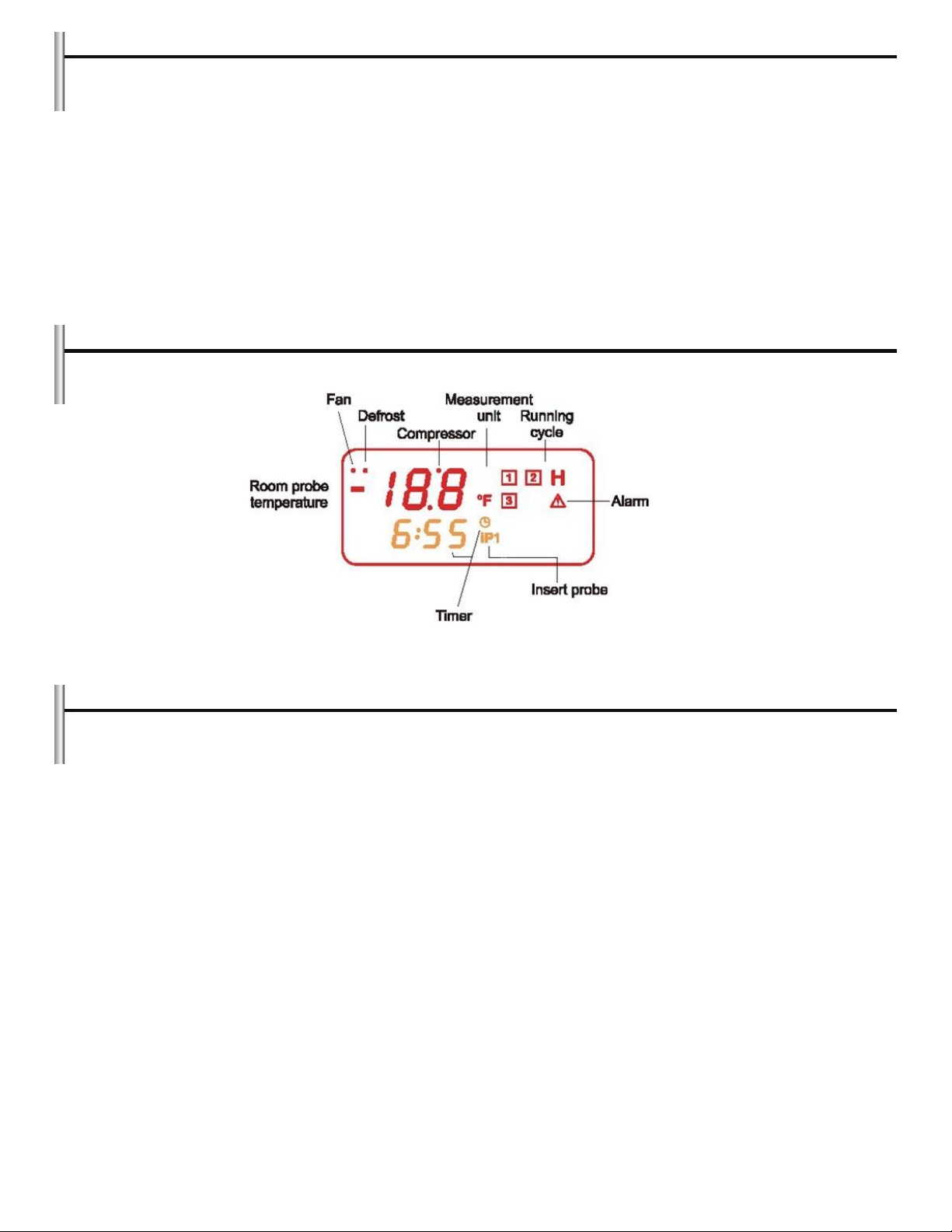

Cycles Explained

There are three different cycles available Soft Chill, Hard Chill, and Shock Freeze.

Cycle 1 - Soft Chill: Used for delicate items and salad items. Items with low fat or moisture content such

as bakery goods should also be chilled using this cycle.

The air temperature will cycle between 28°F and 35°F until the food core temperature will reach 38°F, at

this point the blast chiller will switch into holding mode meaning that the air temperature will cycle

between 35°F and 42°F. until the food is removed from the cabinet and/or the cycle is stopped by the

operator.

The soft chilled cycle is timed, if the temperature of the product does not reach 38°F within the 4 hours

the unit will continue to work except that the display will show “OCF” alarm.

Cycle 2 - Hard Chill: Used for all foods. Some freezing on the food surface may occur, especially with

thicker items; if this is not acceptable use Soft cycle as described above.

In the first part of the cycle the air temperature will cycle between 0°F and 10°F until the food core

temperature will reach 60°F, after that the controller will switch to the second part of the cycle. In the

second part of the cycle the air temperature will cycle between 28°F and 35°F until the food core

temperature will reach 38°F, at this point the blast chiller will switch into holding mode meaning that the

air temperature will cycle between 35°F and 42°F until the food is removed from the cabinet and/or the

cycle is stopped by the operator.

The first part and the second part of the hard cycle are individually timed at 2 hours. If timers for the

first or the second part of the cycle expire before the food temperature reaches the target temperatures

(60°F for first part and 38°F for the second part) the unit will continue to work except that the display

will show “OCF” alarm.

Cycle 3 - Shock Freeze: Used for all freezing needs. When using the Shock Freeze Cycle the ice crystals

that form within the product are very small. The quality and the texture of the product is preserved. For

that reason, the Shock Freeze Cycle is suitable even for delicate products such as sushi meat and prime

meat cuts. Shock Freeze Cycle will give excellent results when used in the process of Ice Cream and

Gelato hardening, it will give a smooth texture to the product.